2.2 Applications

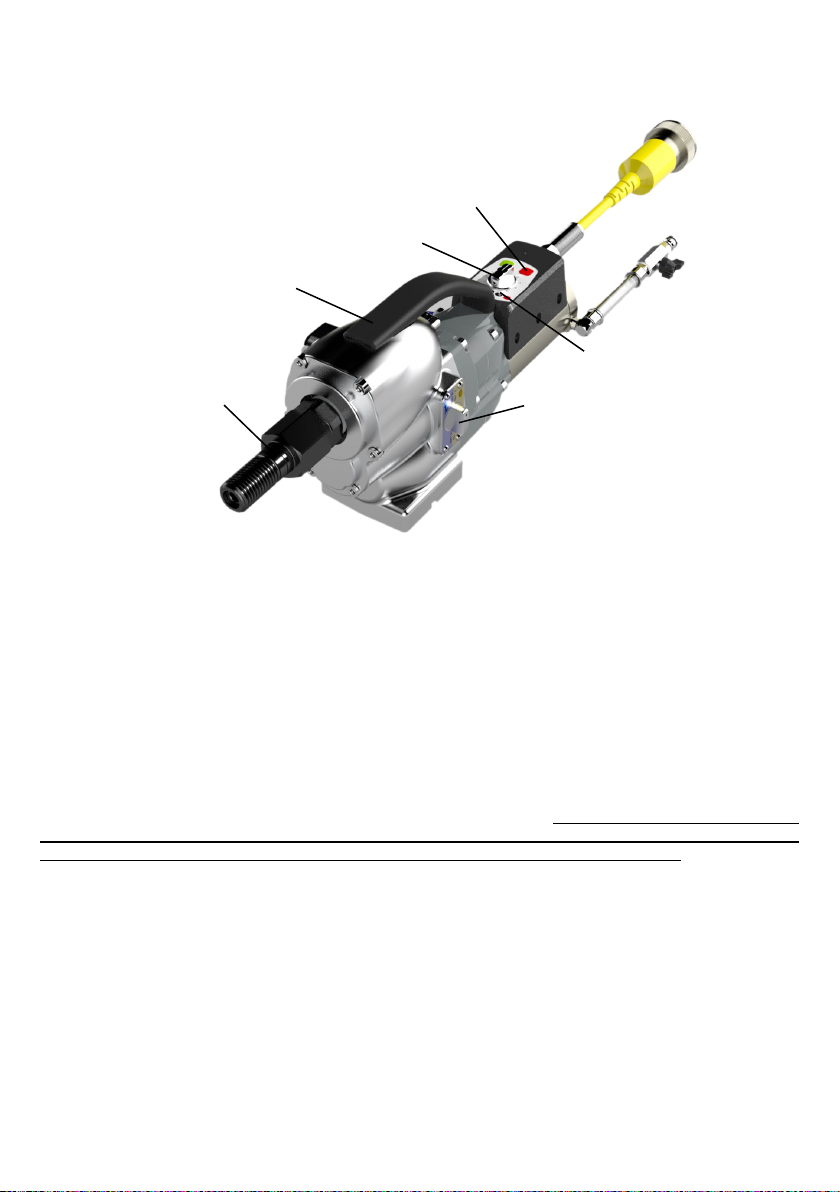

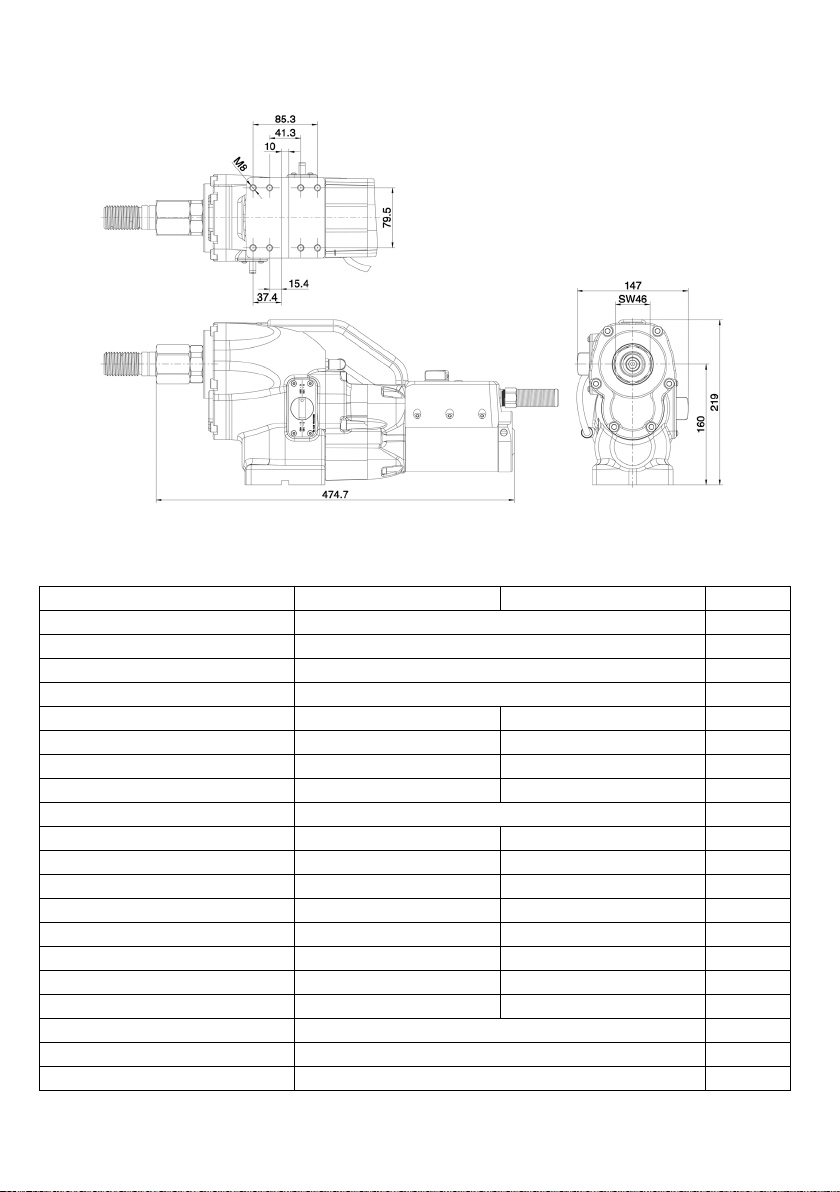

The drive units BELUGA and the related Powerboxes can be used according to the data attached to the

information plate. When you are using custom-built machines, the details on the quotation and the order

confirmation also apply.

The drive units and the Powerboxes are essentially Class I appliances, only this guarantees the full high-

quality protection of the residual current circuit breaker.

When suitable saw blades and drill bits are used, a wide range of materials can be cut:

- Concrete (even with strong reinforcement)

- Sandstone and limestone

- All building materials for solid walls

- Asphalt road surfacing

The machines must be connected to the Powerbox RX/SX 12.

2.3 Safety

Warning

Before commissioning, check that the mains voltage and frequency match the

data given on the information plate. ± 5 % voltage and/or ± 2 % frequency

deviation are permitted. Repairs may only be performed by suitably qualified

staff based on their training and experience.

Pay particular attention to:

- the technical data and information on the permitted use (commissioning, standard operating

conditions), which are included e.g. in the catalogue, the operating manual, the information plate

details, and other product information.

- the relevant accident prevention regulations

- the correct use of tools

- the use of personal protective equipment

3.0 Transport and storage

3.1 Transport

Warning

The drive units must be inspected for transport damage after receipt.

Any damage present must be recorded in writing.

3.2 Storage

The storage location should be dry, clean, and at a constant temperature wherever possible. In order that

the lubrication film in the bearings and the seal systems does not separate, the drive shaft should be turned

several times manually after a lengthy storage period, e.g. at monthly intervals. The roller bearings of the

devices should be replaced (or re-lubricated) if the period between delivery and commissioning is more

than 4 years. This period will be significantly reduced if the storage conditions are unsuitable.