Aeroflex SmartStep 8310 User manual

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 1

Manual Rev. G (4-18-11)

Operation & Installation Manual

Model 8310

SmartStep®Programmable Attenuator

Units w/Ethernet

This documentation may not be reproduced in any form, for any

purpose unless authorized in writing by Aeroflex / Weinschel, Inc.

© Aeroflex / Weinschel, Inc.

Frederick, Maryland

2008-2011

IM-4

93

SAFETY SUMMARY

DEFINITIONS.

The following definitions apply to WARNINGS,

CAUTIONS, and NOTES found throughout this manual.

WARNING

An operating or maintenance procedure, practice,

statement, condition, etc., which, if not strictly

observed, could result in injury and/or death of

personnel. Do not proceed beyond a WARNING

symbol until all the indicated conditions have been

fully understood and/or met.

CAUTION

An operating or maintenance procedure, practice,

statement, condition, etc., which, if not strictly

observed, could result in damage or destruction of the

equipment or long-term health hazards to personnel.

Do not proceed beyond a CAUTION symbol until all

the indicated conditions have been fully understood

and/or met.

NOTE

An essential operating or maintenance procedure,

condition, or statement that must be highlighted.

GENERAL PRECAUTIONS.

The following are general precautions that are not related

to any specific procedure and, therefore, do not appear

elsewhere in this publication. These are precautions that

personnel must understand and apply during various phases of

instrument operation or service.

WARNING

•Potentially lethal voltages are present in this

instrument. Serious shock hazards from voltages

above 70 volts may exist in any connector,

chassis, or circuit board. Observe the following

precautions:

•To minimize shock hazard, the instrument chassis

must be connected to an electrical ground. Using

the supplied three-conductor power cable ensures

that the instrument can be firmly connected to the

ac power source and electrical ground at a

grounded power outlet. If using a 3-2 wire

adapter be sure to connect the ground lead to earth

ground.

•Use the buddy system any time work involving

active high voltage components is required. Turn

OFF the power before making/breaking any

electrical connection. Regard any exposed

connector, terminal board, or circuit board as a

possible shock hazard. DO NOT replace any

component or module with power applied.

•If test conditions to live equipment are required,

ground the test equipment before probing the

voltage or signal to be tested.

•Personnel working with or near high voltage

should be familiar with modern methods of

resuscitation.

•DO NOT wear jewelry (rings, bracelets, metal

watches, and/or neck chains) while working on

exposed equipment. Be very cautious about

using hand tools near exposed backplanes, bus

bars, and/or power supply terminals. Use

properly insulated tools. When making test

connections to the power supply terminals and

bus bars, use only insulated probe tips.

•Verify that the instrument is set to match the

available line voltage and the correct fuse is

installed.

•DO NOT install substitute parts or perform any

unauthorized modification to this instrument.

Contact Weinschel Corporation to acquire any

information on replacement parts or returning

the instrument for repair. Unauthorized

modification can cause injury to personnel and/or

destruction of the instrument.

•Operating personnel must not remove instrument

covers. Component replacement or adjustments

MUST BE performed by qualified service

personnel.

•DO NOT operate the instrument near or in the

presence of flammable gases or fumes.

DETAILED PRECAUTIONS.

The following WARNINGS, CAUTIONS and NOTES

appear throughout the text of this manual and are repeated here

for emphasis.

SAFETY SUMMARY

i

CAUTION

•All procedures and/or steps identified as

must be followed exactly as written and

according to industry accepted ESDS device

handling procedures. Failure to comply WILL

RESULT in ESDS damage.

•DO NOT use a nylon bristle brush in the solvent

as the bristles may dissolve and cause damage to

the circuit card or component.

•DO NOT use ultrasonic cleaning on parts or

assemblies containing electrical or electronic

components.

•DO NOT bend pins of electrical connectors

when using fiber-bristle brush.

•Compressed air used for cleaning and/or drying

can create airborne particles that may enter the

eye. Goggles/faceshields should be worn. DO

NOT direct air stream towards self or other

personnel. Pressure should be restricted to a

maximum of 15 psi to avoid personal injury.

•Under no circumstances should a wire brush,steel

wool, or abrasive compound be used on any

surface. Using these items will cause extensive

damage to the instruments surface.

NOTE

DO NOT return any instrument or component to

Weinschel Corporation without receiving prior

factory authorization.

SAFETY SYMBOLS.

The following symbols are used to identify safety hazards

found throughout this publication and/or located on the

instrument.

WARNING

HIGH

VOLTAGE

CAUTION

HIGH VOLTAGE

SAFETY SUMMARY

ii

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 2

TABLE OF CONTENTS

1. GENERAL INFORMATION.........................................................................................................................................5

1-1. PURPOSE.....................................................................................................................................................................5

1-2. SCOPE .........................................................................................................................................................................5

1-3. EQUIPMENT DESCRIPTION........................................................................................................................................5

1-4. USING THE 8310-XXX-X .............................................................................................................................................6

1-5. UNPACKING AND INSPECTION.................................................................................................................................6

1-6. RESHIPMENT INSTRUCTIONS ...................................................................................................................................6

1-7. STORAGE INSTRUCTIONS .........................................................................................................................................6

1-8. RELATED MANUALS....................................................................................................................................................7

1-9. ELECTROSTATIC DISCHARGE SENSITIVE (ESD) ....................................................................................................7

1-10. ABBREVIATIONS & ACRONYMS ..............................................................................................................................7

1-11. SAFETY CONSIDERATIONS .....................................................................................................................................7

1-12. POWER REQUIREMENTS .........................................................................................................................................7

1-13. ENVIRONMENTAL REQUIREMENTS........................................................................................................................7

2. SPECIFICATIONS .......................................................................................................................................................8-10

3. INSTALLATION ..................................................................................................................................................11

3-1. RACKMOUNTING.......................................................................................................................................................11

3-2. INTIAL SETUP ............................................................................................................................................................11

3-3. INPUT/OUTPUT OPTIONS................................................................................................................................... 11-12

3-3.1. POWER ENTRY MODULE ASSEMBLY .........................................................................................................12

3-3.2. CHANNEL PORT CONNECTORS ..................................................................................................................12

3-3.3. MODE SELECT SWITCH................................................................................................................................12

4. FRONT PANEL CONTROLS & INDICATORS..................................................................................................13

5. REMOTE OPERATION ..................................................................................................................................... 14

5-1 COMMUNICATIONS INTERFACE......................................................................................................................... 14-15

5-1.1. OPERATING MODES .....................................................................................................................................15

5-1.2 SERIAL PORT SETUP....................................................................................................................................15

5-1.3 ETHERNET SETUP ........................................................................................................................................15

5-1.3.1 DEVICEINSTALLER .......................................................................................................................15

5-1.3.2 SERIAL PORT LOGIN .....................................................................................................................16

5-1.3.3 ARP AND TELNET .........................................................................................................................17

5-1.3.4 DHCP ..............................................................................................................................................17

5-1.3.5 AUTOIP ..................................................................................................................................... 17-18

5-1.3.6 BOOTP .............................................................................................................................................18

5-1.3.7 DEVICE SERVER SETUP ...............................................................................................................18

5-1.3.8 EXAMPLE SETUP USING THE SERIAL PORT ...................................................................... 18-22

5-2. SERIAL OPERATION ........................................................................................................................................... 22-23

5-2.1. RS-232 OPERATION ....................................................................................................................................23

5-3. STATUS REPORTING .......................................................................................................................................... 24-25

5-4. GENERAL SYNTAX STRUCTURE.............................................................................................................................25

5-4.1. SYNTAX OF QUERIES ...................................................................................................................................25

5-4.2. SYNTAX OF COMMANDS........................................................................................................................ 25-26

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 3

5-4.3. OUTPUT DATA FORMAT ...............................................................................................................................26

5-4.4. NOTATIONAL CONVENTION.........................................................................................................................26

5-5. COMMON COMMANDS ..................................................................................................................................... 27-28

5-6. GENERAL COMMANDS ...................................................................................................................................... 29-30

6.. MAINTENCE..................................................................................................................................................... 31

6-1. INSPECTION ..............................................................................................................................................................31

6.2. PREVENTIVE MAINTENANCE...................................................................................................................................31

6.3. SPECIAL CLEANING INSTRUCTIONS ......................................................................................................................31

6-3.1. MICROWAVE COAXIAL CABLE ASSEMBLIES .............................................................................................31

6-3.2. CIRCUIT CARDS AND MODULES .................................................................................................................31

6-3.3. MACHINED SURFACES AND HARDWARE ..................................................................................................32

6-3.4. CHASIS CLEANING........................................................................................................................................32

6-3.5. CONNECTOR CLEANING ..............................................................................................................................32

6.4. LINE VOLTAGE FUSE REPLACEMENT ....................................................................................................................33

7. REPLACABLE PARTS LIST...............................................................................................................................34

7-1. UNDERSTANDING REFERENCE DESIGNATORS ...................................................................................................34

7-2. ORDERING INFORMATION .......................................................................................................................................34

7-3. DRAWING NUMBER...................................................................................................................................................34

7-4. REPLACABLE PARTS LIST .......................................................................................................................................34

7-4.1. REFERENCE DESIGNATOR..........................................................................................................................34

7-4.2. DESCRIPTION................................................................................................................................................34

7-4.3. PART NUMBER ..............................................................................................................................................34

7-4.4. VENDOR PART NUMBER ..............................................................................................................................34

7-5.5. CAGE CODE...................................................................................................................................................34

7-4.6. ASSEMBLY AND COMPONET LOCATION....................................................................................................34

MODEL 8310-1-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7001-4) ..............35

MDEL 8310-1-2-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7002-5) ..............35

MODEL 8310-1-3-TN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7001-6)...................... 36

MODEL 8310-2-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7002-3) ..............37

MODEL 8310-2-2-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7002-4) ...........37

MODEL 8310-35-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-9)...............38

MODEL 8310-35-2-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-10)..........38

MODEL 8310-35-3-TN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-11)...................39

MODEL 8310-35-4-TN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-12)...................39

MODEL 8310-35-F / R-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-13) ............40

MODEL 8310-35-2-F / R -EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-14)........40

MODEL 8310-35-3-T-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-15) ..............41

MODEL 8310-35-4-T-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7035-16) ..............41

MODEL 8310-36-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7036-8)...............42

MODEL 8310-36-2-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7036-9)............42

MODEL 8310-36-3-TN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7036-10)...................43

MODEL 8310-36-F / R-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-11) ............44

MODEL 8310-36-2-F / R -EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7036-12)........44

MODEL 8310-36-3-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7036-13)..................45

MODEL 8310-38-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-9)...............45

MODEL 8310-38-2-FN / -RN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-10)..........46

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 4

MODEL 8310-38-3-TN ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-11)...................47

MODEL 8310-38-4-TN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-12) ..................47

MODEL 8310-38-F / R-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-13) ............48

MODEL 8310-38-2-F / R -EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-14)........48

MODEL 8310-38-3-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-15)..................49

MODEL 8310-38-4-EN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7038-16)..................49

MODEL 8310-138-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7138-5)............50

MODEL 8310-138-2-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7138-6).........51

MODEL 8310-138-3-TN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7138-7)..................52

MODEL 8310-138-4-TN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7138-8)..................53

MODEL 8310-352-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7403-5)............54

MODEL 8310-352-2-FN / -RN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7403-6).........55

MODEL 8310-352-3-TN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7403-7)..................56

MODEL 8310-352-4-TN, ATTENUATOR UNIT ASSEMBLY REPLACEABLE PARTS LIST (P/N 193-7403-8 ...................57

ASSY, BASE UNIT W/ETHERNET (+15V) PARTS LIST (P/N 193-8034-3)........................................................................58

ASSY, BASE UNIT W/ETHERNET (+5V) PARTS LIST (P/N 193-8034-4)..........................................................................59

8. CONTACTING AEROFLEX / WEINSCHEL............................................................................................................60

9. AEROFLEX / WEINSCHEL WARRANTY ............................................................................................................. 60

10. ASSEMBLY/WIRING DIAGRAMS

MODEL 8310-1-X-XN ASSEMBLY DRAWING ............................................................................... 193-7002-4A THRU -6A

MODEL 8310-2-X-XN ASSEMBLY DRAWING ......................................................................................... 193-7002-3A, -4A

MODEL 8310-35-X-XN ASSEMBLY DRAWING ........................................................................... 193-7035-9A THRU -16A

MODEL 8310-36-X-XN ASSEMBLY DRAWING ........................................................................... 193-7036-8A THRU -13A

MODEL 8310-38-X-XN ASSEMBLY DRAWING ........................................................................... 193-7038-9A THRU -16A

MODEL 8310-138-X-XN ASSEMBLY DRAWING ........................................................................... 193-7138-5A THRU -8A

MODEL 8310-352-X-XN ASSEMBLY DRAWING ........................................................................... 193-7403-5A THRU -8A

BASE UNIT W/ETHERNET (+15 V) ASSEMBLY DRAWING.............................................................................193-8034-3A

MODEL 8310 W/ETHERNET (+15 V) WIRING DIAGRAM ................................................................................ 193-8135A

BASE UNIT W/ETHERNET (+5 V) ASSEMBLY DRAWING...............................................................................193-8034-4A

MODEL 8310 W/ETHERNET (+5 V) WIRING DIAGRAM .................................................................................... 193-8136A

MODEL 8310 W/ETHERNET, 8310-X-X-XN SPECIFICATION, ICD DRAWING .................................................. 089-4051A

MODEL 8310 (75 OHM) W/ETHERNET, 8310-1-X-XN SPECIFICATION, ICD DRAWING .................................. 089-4052A

MODEL 8310-138-X-XN SPECIFICATION, ICD DRAWING ................................................................................. 089-4066A

MODEL 8310-352-X-XN SPECIFICATION, ICD DRAWING ................................................................................. 089-4065A

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 5

9. GENERAL INFORMATION:

1-1 PURPOSE: This manual contains setup and operation information for the Aeroflex / Weinschel’s 8310-XXX-XN

Series of Programmable Attenuator Units with Ethernet Control. The manual also provides component location,

reference designators, part numbers, and nomenclature to identify all the assemblies and sub-assemblies of the

Attenuator Unit.

1-2 SCOPE: This manual is to be used in conjunction with the operation and maintenance of an 8310-XXX-XN Series

of Programmable Attenuator Units with Ethernet Control. The manual also provides a description of each assembly;

assembly parts list; block diagrams: and general maintenance procedures to maintain the instrument.

1-3 EQUIPMENT DESCRIPTION: Aeroflex / Weinschel’s 8310-XXX-XN Series of

Programmable Attenuator Units with Ethernet Control represents a new concept in

programmable attenuation for bench test and subsystem applications. Standard Model

8310-XXX-XN designs house and control various Aeroflex / Weinschel Programmable

Attenuator Models (3200T, 3400T, 150T, and 4200 Series) via front panel controls or

standard communications interfaces including Ethernet, GPIB (IEEE-488) and RS-

232/RS-422/RS485. Special configurations also exist where the RF section is designed

to specific customer requirements which can contain to multiple programmable

attenuations used in-conjunction with other coaxial devices such as switches, power

combiners, directional couplers, and filters creating single or multi-channel subsystems.

1-4 USING THE 8310-XXX-XN: The 8310-XXX-XN Series provides front-panel and computer control for up to four

channels of attenuation, RF switching, or other functions. The 8310-XXX-XN combines the features of the Aeroflex /

Weinschel 8210A Device Controller with a front panel user interface to form a flexible, easy to use solution. Most

8310-XXX-XN Series are single channel configurations where RF signal is routed through either the front or rear

mounted Ports A & B connector (Ports A-A if the RF is routed front to rear) to a single or multiple Aeroflex / Weinschel

programmable attenuators thus creating CH1 (Channel 1). Note that when a Port is in use the Port indicator will be

illuminated. Dual channel units typically use Ports A and B for CH1 and Ports C and D for CH2 (Ports A-A if the RF is

routed front to rear for CH1 and Ports B-B for CH2). Multi-channel (3-4) units are generally routed front to rear and

configured as follows:

CH1 Port A (Front) to Port A (Rear)

CH2 Port B (Front) to Port B (Rear)

CH3 Port C (Front) to Port C (Rear)

CH4 Port D (Front) to Port D (Rear)

For specialized configurations refer to supplemental

information in the front of this manual for details.

Typically Aeroflex / Weinschel digital attenuators are bi-directional and the RF signal can be applied to either Port

connector. Channels can be selected by toggling the front panel CHAN button until the desired CH1-CH4 indicator is

illuminated. Repeated depressions of the CHAN key will select the next available channel. The main display will show

the current attenuation setting of the channel. A new attenuation setting in dB may be entered using the INCR/DECR

or ENTRY keys. The front panel STEP key allows the user to define the attenuation step size used by the INCR and

DECR keys. Remember that the attenuation step size (resolution) is limited to the physical size of the internal

attenuator cells. For example a 0-70 unit with 10 dB steps can only be adjusted in 10 dB increments but larger

increments such as 20, 30, 40 dB can be set using this key.

The REL key allows the user to set relative mode for attenuators. When turned on, the currently displayed attenuation

value is used as a reference value from which the attenuation may be set. In this mode, attenuation values may be

positive or negative from the reference setting. When REL is

turned off, the display returns to the actual attenuation setting for

the channel. Refer to Section 5 for more detailed information

about the front panel keys and indicators. All 8310-XXX-XN

Series functions can also be controlled via standard

communications interfaces including Ethernet, GPIB (IEEE-488)

and RS-232/RS-422 /RS485. Refer to Section 6 for bus setup

and operating instructions when using the 8310-XXX-XN Series

in the remote mode.

Model Number Index:

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 6

1-5. UNPACKING AND INSPECTION: Upon unpacking the equipment, retain the shipping container and packing

material for future shipment for recalibration. Perform the following initial inspection:

a. Carefully look at the outside of the shipping container for discoloration, stains, charring, or other signs of

exposure to excessive heat, moisture, or liquid chemicals. Check for any physical damage to the shipping

container such as dents, snags, rips, crushed sections or areas, or similar signs of excessive shock or

careless handling.

b. With the equipment and any accessory package removed from the shipping container, check each item

against the packing list or Items Supplied List. If any items are missing, contact the Weinschel Corporation

Customer Service Department.

c. Carefully inspect the equipment looking for dents, deep scratches, damaged or loose connector, or any other

d. signs of physical abuse or careless handling. If damage is found, forward an immediate request to the

delivering carrier to perform an inspection and prepare a concealed-damage report. DO NOT destroy any

packing material until it has been examined by an agent of the carrier. Concurrently, report the nature and

extent of damage to Weinschel Corporation, giving equipment model and serial numbers, so that necessary

action can be taken. Under U.S. shipping regulations, damage claims must be collected by the consignee;

DO NOT return the equipment to Aeroflex / Weinschel until a claim for damages has been established.

1-6. RESHIPMENT: Use the best packaging materials available to protect the unit during storage or reshipment.

When possible, use the original packing container and cushioning material. If the original packing materials are not

available, use the following procedure:

a. Wrap the storage cases in sturdy paper or plastic;

b. Place the wrapped storage cases in a strong shipping container and place a layer of shock-absorbing material

(3/4 inch minimum thickness) around all sides of the unit to provide a firm cushion and to prevent movement

inside the container.

c. If shipping the unit for service, attach a tag to indicate:

1. model and serial numbers

2. service required

3. description of malfunction

4. return address

5. authorization to conduct repairs

6. return authorization number

d. Thoroughly seal the shipping container and mark it FRAGILE. Ship to:

Aeroflex / Weinschel, Inc.

Attn: Customer Service Department

5305 Spectrum Drive

Frederick, MD 21703-7362

or to an authorized sales representative.

1-7. STORAGE: Storage of the Model 8310-XXX-XN SmartStep® Attenuator Unit is possible for extended periods

without incurring damage to internal circuitry if the 8310-XXX-XN Series is packaged according to the instructions

above. The safe limits for storage environment are as follows:

Temperature: 4° to +167 °F (-20° to +75 °C)

Humidity: less than 95% without condensation

Altitude: Up to 40,000 feet

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 7

1-8. RELATED MANUALS: The following manuals contain information that may be used in conjunction with this

manual to operate, service, or calibrate this instrument.

Manual Title

H4-1 and H4-2 Federal Supply Code for Manufacturers Cataloging Handbook

1-9. ELECTROSTATIC DISCHARGE SENSITIVE: The equipment documented in this manual contains certain

Electrostatic Discharge Sensitive (ESDS) components or parts. Therefore, certain procedures/steps are identified by

the use of the symbol . . This symbol is used in two ways:

CAUTION

All procedures and/or steps identified as must be followed exactly as written and according to

accepted ESDS device handling procedures. Failure to comply WILL RESULT in ESDS damage.

a. When the ESDS symbol is placed between a paragraph number and title , all of that

paragraph, including all subparagraphs, is considered ESDS device handling procedure.

b. When the ESDS symbol is placed between a procedure/step number and the text , all of

that procedure is considered an ESDS device handling procedure.

1-10. ABBREVIATIONS AND ACRONYMS: The following list contains abbreviations used throughout this manual.

Abbreviations and acronyms that are not listed conform to MIL-STD-12D.

DUT Device Under Test

ESDS Electrostatic Discharge Sensitive

DIB Device Interface Bus

TBD To Be Determined

1-11. SAFETY CONSIDERATIONS: The Model 8310-XXX-XN Attenuator Unit and all related documentation must be

reviewed for familiarization with safety markings and procedures before any operation and/or service. Refer to the

SAFETY SUMMARY located at the beginning of this manual for a summary of safety information and procedures.

Following these simple safety precautions will ensure safe operation and service of the Attenuator Unit.

1-12. POWER REQUIREMENTS: Aeroflex / Weinschel supplies a detachable power cable (P/N 068-21) to connect

a 115 to 230 Vac power source with a frequency between 50 to 60 HZ to the Attenuator Unit. To minimize shock

hazard, the instrument chassis must be connected to an electrical ground. Using the supplied three-conductor power

cable ensures that the instrument can be firmly connected to the ac power source and electrical ground (safety

ground) at a grounded power outlet. Refer to paragraph 3-2 (Initial Setup) before applying any power to the

instrument.

1-13. ENVIRONMENTAL REQUIREMENTS: This instrument performs best within its specifications when operated

within a controlled environment having an ambient temperature of 0°± 50°C, Relative Humidity of up to 95% non

condensing, and a altitude of less than 40,000 feet. Operating beyond these limits can affect the accuracy and

performance of the instrument and damage internal circuitry.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 8

2. SPECIFICATIONS:

2-1. GENERAL SPECIFICATIONS:

Input Power Requirements ac 115 to 230 Vac, 1.6 A, 50/60 Hz, 50 Watts

Environmental Operating Temperature 0 to +50°C

Storage Temperature: 4° to +167 °F (-20° to +75 °C)

RS-232 (Serial) Bus(1) Connector: 9-pin male D

Signals: TXD, RXD, RTS, CTS, DTR, GND

Baud Rates: 2400, 9600, 19200, and 38400

Data Bits: 8

Handshaking: None, RTS/CTS, XON/XOFF

Parity: None, Odd, Even

Indicators: Tx (Transmit) and Rx (Receive)

Ethernet TC/IP 10/100 Base T Connector: Standard RJ45

RF Characteristics(3) See Model Configuration Tables (pg 8)

NOTES:

1. RS-232 can be used with standard PC serial port for short and medium distances (up to approximately 50 ft).

2. Refer to Individual data sheet (Appendix C) for detailed specifications on internal programmable attenuators.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 9

2-2. CONFIGURATIONS\RF SPECIFICATIONS:

Table 1. 3200T & 150T Series-Mechanical Relay:

Model No Attenuator

Value

Frequency

Range (GHz) Insertion Loss SWR No of

Channels Attenuator Type Connector

Type Connector Location Drawing No

8310-1-FN 63/1 dc-1.0 (75 )6.0 dB max 1.6 max 1 3250T-63 BNC/F Front 193-7001-4

8310-1-RN 63/1 dc-1.0 (75 )6.0 dB max 1.6 max 1 3250T-63 BNC/F Rear 193-7001-4

8310-1-2-FN 63/1 dc-1.0 (75 )6.0 dB max 1.6 max 2 3250T-63 BNC/F Front 193-7001-5

8310-1-2-RN 63/1 dc-1.0 (75 )6.0 dB max 1.6 max 2 3250T-63 BNC/F Rear 193-7001-5

8310-1-3-TN 63/1 dc-1.0 (75 )6.0 dB max 1.6 max 2 3250T-63 BNC/F Front to Rear 193-7001-6

8310-2-FN 63/1 dc-1.0 (75 )6.75 dB max 2.0 max 1 3250T-63 F/F Front 193-7002-3

8310-2-RN 63/1 dc-1.0 (75 )6.75 dB max 2.0 max 1 3250T-63 F/F Rear 193-7002-3

8310-2-2-FN 63/1 dc-1.0 (75 )6.75 dB max 2.0 max 2 3250T-63 F/F Front 193-7002-4

8310-2-2-RN 63/1 dc-1.0 (75 )6.75 dB max 2.0 max 2 3250T-63 F/F Rear 193-7002-4

8310-35-FN 127/1 dc-2 6.0 dB max 1.4 max 1 3200T-1 N/F Front 193-7035-9

8310-35-RN 127/1 dc-2 6.0 dB max 1.4 max 1 3200T-1 N/F Rear 193-7035-9

8310-35-2-FN 127/1 dc-2 6.0 dB max 1.4 max 2 3200T-1 N/F Front 193-7035-10

8310-35-2-RN 127/1 dc-2 6.0 dB max 1.4 max 2 3200T-1 N/F Rear 193-7035-10

8310-35-3-TN 127/1 dc-2 6.0 dB max 1.4 max 3 3200T-1 N/F Front to Rear 193-7035-11

8310-35-4-TN 127/1 dc-2 6.0 dB max 1.4 max 4 3200T-1 N/F Front to Rear 193-7035-12

8310-35-F-EN 127/1 dc-3 6.0 dB max 1.4 max 1 3200T-1E N/F Front 193-7035-13

8310-35-R-EN 127/1 dc-3 6.0 dB max 1.4 max 1 3200T-1E N/F Rear 193-7035-13

8310-35-F-EN 127/1 dc-3 6.0 dB max 1.4 max 2 3200T-1E N/F Front 193-7035-14

8310-35-R-EN 127/1 dc-3 6.0 dB max 1.4 max 2 3200T-1E N/F Rear 193-7035-14

8310-35-3-T-EN 127/1 dc-3 6.0 dB max 1.4 max 3 3200T-1E N/F Front to Rear 193-7035-15

8310-35-4-T-EN 127/1 dc-3 6.0 dB max 1.4 max 4 3200T-1E N/F Front to Rear 193-7035-16

8310-36-FN 64.5/0.1 dc-2 8.0 dB max 1.4 max 1 3209T-64.5 N/F Front 193-7036-8

8310-36-RN 64.5/0.1 dc-2 8.0 dB max 1.4 max 1 3209T-64.5 N/F Rear 193-7036-8

8310-36-2-FN 64.5/0.1 dc-2 8.0 dB max 1.4 max 2 3209T-64.5 N/F Front 193-7036-9

8310-36-2-RN 64.5/0.1 dc-2 8.0 dB max 1.4 max 2 3209T-64.5 N/F Rear 193-7036-9

8310-36-3-TN 64.5/0.1 dc-2 8.0 dB max 1.4 max 3 3209T-64.5 N/F Front to Rear 193-7036-10

8310-36-F-EN 64.5/0.1 dc-2 8.0 dB max 1.4 max 1 3209T-64.5 N/F Front 193-7036-11

8310-36-R-EN 64.5/0.1 dc-2 8.0 dB max 1.4 max 1 3209T-64.5 N/F Rear 193-7036-11

8310-36-2-F-EN 64.5/0.1 dc-2 8.0 dB max 1.4 max 2 3209T-64.5 N/F Front 193-7036-12

8310-36-2-R-EN 64.5/0.1 dc-2 8.0 dB max 1.4 max 2 3209T-64.5 N/F Rear 193-7036-12

8310-36-3-T-EN 64.5/0.1 dc-2 8.0 dB max 1.4 max 3 3209T-64.5 N/F Front to Rear 193-7036-13

8310-37-FN 63.75/0.25 dc-2 6.0 dB max 1.4 max 1 3200T-2 N/F Front

8310-37-RN 63.75/0.25 dc-2 6.0 dB max 1.4 max 1 3200T-2 N/F Rear

8310-37-2-FN 63.75/0.25 dc-2 6.0 dB max 1.4 max 2 3200T-2 N/F Front

8310-37-2-RN 63.75/0.25 dc-2 6.0 dB max 1.4 max 2 3200T-2 N/F Rear

8310-37-3-TN 63.75/0.25 dc-2 6.0 dB max 1.4 max 3 3200T-2 N/F Front to Rear

8310-37-4-TN 63.75/0.25 dc-2 6.0 dB max 1.4 max 4 3200T-2 N/F Front to Rear

8310-38-FN 63/1 dc-2 5.25 dB max 1.4 max 1 3206T-1 N/F Front 193-7038-9

8310-38-RN 63/1 dc-2 5.25 dB max 1.4 max 1 3206T-1 N/F Rear 193-7038-9

8310-38-2-FN 63/1 dc-2 5.25 dB max 1.4 max 2 3206T-1 N/F Front 193-7038-10

8310-38-2-RN 63/1 dc-2 5.25 dB max 1.4 max 2 3206T-1 N/F Rear 193-7038-10

8310-38-3-TN 63/1 dc-2 5.25 dB max 1.4 max 3 3206T-1 N/F Front to Rear 193-7038-11

8310-38-4-TN 63/1 dc-3 5.25 dB max 1.4 max 4 3206T-1E N/F Front to Rear 193-7038-12

8310-38-F-EN 63/1 dc-2 5.25 dB max 1.4 max 1 3206T-1 N/F Front 193-7038-13

8310-38-R-EN 63/1 dc-2 5.25 dB max 1.4 max 1 3206T-1 N/F Rear 193-7038-13

8310-38-2-F-EN 63/1 dc-2 5.25 dB max 1.4 max 2 3206T-1 N/F Front 193-7038-14

8310-38-2-R-EN 63/1 dc-2 5.25 dB max 1.4 max 2 3206T-1 N/F Rear 193-7038-14

8310-38-3-T-EN 63/1 dc-2 5.25 dB max 1.4 max 3 3206T-1 N/F Front to Rear 193-7038-15

8310-38-4-T-EN 63/1 dc-3 5.25 dB max 1.4 max 4 3206T-1E N/F Front to Rear 193-7038-16

Table 1, Continued on next page

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 10

Table 1. 3200T & 150T Series-Mechanical Relay (Continued):

Model No Attenuator Value Frequency

Range (GHz) Insertion Loss SWR No. of

Channels Attenuator Type Connector

Type

Connector

Location

Drawing

Number

8310-201-FN 70/10 dc-18 3.25 dB max 1.75 1 150T-70 Sma/F Front

8310-201-RN 70/10 dc-18 3.25 dB max 1.75 1 150T-70 Sma/F Rear

8310-201-2-FN 70/10 dc-18 3.25 dB max 1.75 2 150T-70 Sma/F Front

8310-201-2-RN 70/10 dc-18 3.25 dB max 1.75 2 150T-70 Sma/F Rear

8310-202-FN 121/1 dc-18 5.25 dB max 1.95 1 150T-11+ 150T-110 Sma/F Front

8310-202-RN 121/1 dc-18 5.25 dB max 1.95 1 150T-11+ 150T-110 Sma/F Rear

8310-203-FN 105/1 dc-18 6.75 dB max 1.85 1 152T-15+ 152T-90 Sma/F Front

8310-203-RN 105/1 dc-26.5 6.75 dB max 1.85 1 152T-15+ 152T-90 Sma/F Rear

8310-204-FN 62/2 dc-18 3.25 dB max 1.95 1 150T-62 Sma/F Front

8310-204-RN 62/2 dc-18 3.25 dB max 1.95 1 150T-62 Sma/F Rear

8310-204-2-FN 62/2 dc-18 3.25 dB max 1.95 2 150T-62 Sma/F Front

8310-204-2-RN 62/2 dc-18 3.25 dB max 1.95 2 150T-62 Sma/F Rear

8310-352-FN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 1 3408T-103 N/F Front 193-7403-5

8310-352-RN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 1 3408T-103 N/F Rear 193-7403-5

8310-352-2-FN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 2 3408T-103 N/F Front 193-7403-6

8310-352-2-RN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 2 3408T-103 N/F Rear 193-7403-6

8310-352-3-TN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 3 3408T-103 N/F Front-Rear 193-7403-7

8310-352-4-TN 0-103/1 dB dc-6.0 GHz 6.0 dB max 1.55 4 3408T-103 N/F Front-Rear 193-7403-8

Table 2. 4200 Series-Solid-State, Pin Switched

Model No Attenuator Value Frequency

Range (GHz) Insertion Loss SWR No. of

Channels Attenuator Type Connector

Type

Connector

Location

Drawing

Number

8310-136-FN 63.75/0.25 0.8-2.5 6.0 dB max 1.6 max 1 4226T-63.75 N/F Front

8310-136-RN 63.75/0.25 0.8-2.5 6.0 dB max 1.6 max 1 4226T-63.75 N/F Rear

8310-136-2-FN 63.75/0.25 0.8-2.5 6.0 dB max 1.6 max 2 4226T-63.75 N/F Front

8310-136-2-RN 63.75/0.25 0.8-2.5 6.0 dB max 1.6 max 2 4226T-63.75 N/F Rear

8310-137-FN 63/1 0.8-3.0 4.7 dB max 1.6 max 1 4226T-63 N/F Front

8310-137-RN 63/1 0.8-3.0 4.7 dB max 1.6 max 1 4226T-63 N/F Rear

8310-137-2-FN 63/1 0.8-3.0 4.7 dB max 1.6 max 2 4226T-63 N/F Front

8310-137-2-RN 63/1 0.8-3.0 4.7 dB max 1.6 max 2 4226T-63 N/F Rear

8310-138-FN 103/1 0.8-3.0 6.0 dB max 1.6 max 1 4228T-103 N/F Front 193-7138-5

8310-138-RN 103/1 0.8-3.0 6.0 dB max 1.6 max 1 4228T-103 N/F Rear 193-7138-5

8310-138-2-FN 103/1 0.8-3.0 6.0 dB max 1.6 max 2 4228T-103 N/F Front 193-7138-6

8310-138-2-RN 103/1 0.8-3.0 6.0 dB max 1.6 max 2 4228T-103 N/F Rear 193-7138-6

8310-138-3-TN 103/1 0.8-3.0 6.0 dB max 1.6 max 3 4228T-103 N/F Front-Rear 193-7138-7

8310-138-4-TN 103/1 0.8-3.0 6.0 dB max 1.6 max 4 4228T-103 N/F Front-Rear 193-7138-8

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 11

3. INSTALLATION:

3-1. RACKMOUNTING: Standard 8310 Attenuator Units are shipped with four plastic feet mounted to the bottom

cover, this allows the user to place the instrument on any bench or to stack the with other Weinschel instruments. The

Model 8310 can also be rack mounted as a single unit using Rack Mounting Kit (P/N 193-8033-1) or two Model 8310’s

can be mounted together using Rack Mounting Kit (P/N 193-8033-2). Using these kits will allow the Model 8310 to be

mounted in any rack or cabinet that is designed according to EIA RS-310 or MIL-STD-189.

3-2. INITIAL SETUP: The following initial setup procedures should be performed prior to operating the 8310-XXX-XN

Attenuator Unit.

a. Perform inspection paragraph 1-4 prior to connecting the 8310-XXX-XN to any power source.

b. Check that the external power source outputs to the 8310-XXX-XN Series are in accordance with

Section 2, Specifications.

c. Install the 8310-XXX-XN Series into a cabinet or rack, if desired.

d. Using the supplied power cord connect the 8310-XXX-XN to the external power source.

e. Setup the IEEE-488 bus address or other Communications options for your application using 5. If

using the Ethernet configure the selectable Bus Select switch to Ethernet and refer to section 5 for

operating instructions.

3-3 INPUT/OUTPUT OPTIONS: The following paragraphs provide a description of the connections that can be made

to the 8310-XXX-XN Attenuator Unit. Figure 2 shows the location of these connectors and switches.

WARNING

Sufficient power levels are present at the Power Input Assembly to cause personal injury.

Ensure that the instrument power cord is DISCONNECTED before attempting to change

fuses.

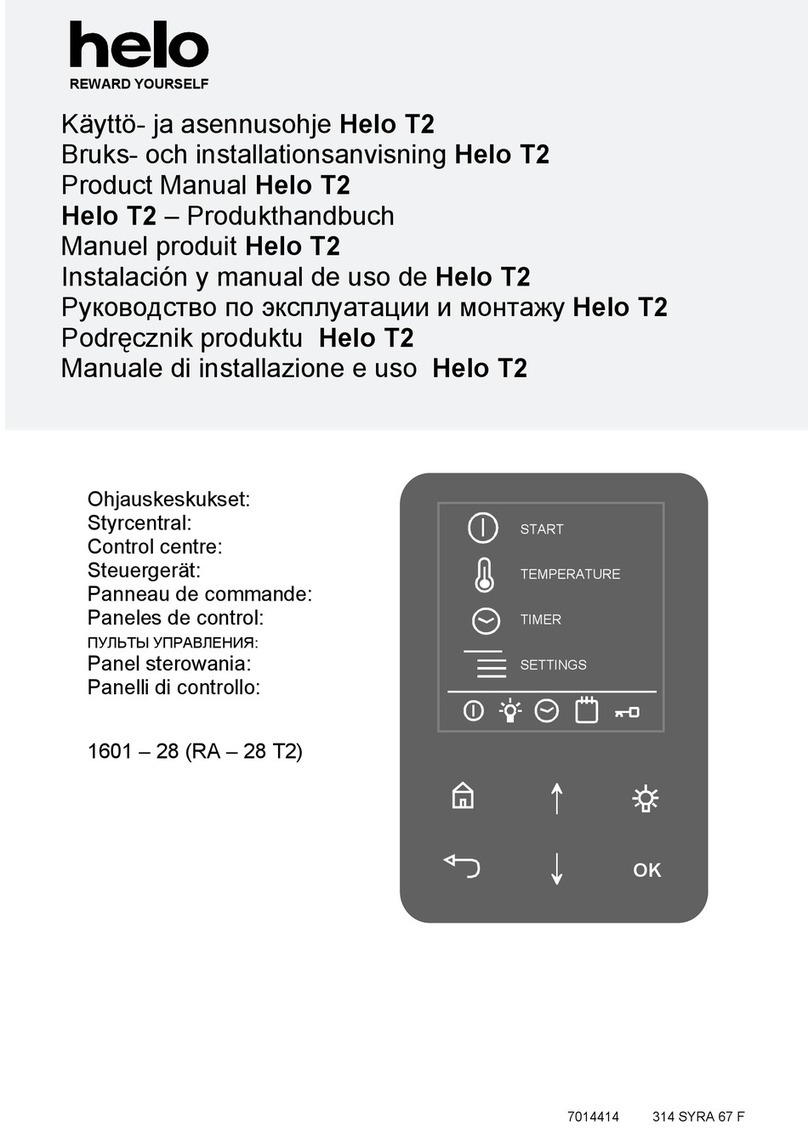

Figure 2. Rear Panel Controls & Connectors

3-3.1 POWER ENTRY MODULE ASSEMBLY: The Power Entry Module Assembly located on the rear panel contains

a three-prong ac power input connector and a fuse drawer assembly (Figure 1). The Fuse Drawer Assembly

contains the line voltage fuse (Weinschel P/N 052-1-1.5). The Model 8310-XXX-XN uses a T 1.5A, 250 Vac fuse

which is 5 x 20 mm in size. Refer to paragraph 6-4 for replacement of the fuse.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 12

The AC Power Connector, located on the left side of XF1 (Figure 2), is a plug-type, prong insert connector with three

conductors for connection of the power cord (P/N 068-21) to the Power Supply Assembly located within the Hot-

Switching High Power Attenuator Unit. This connector also grounds the chassis of the Hot-Switching High Power

Attenuator Unit when the ac power cord is connected to a grounded wall outlet. If necessary, use a three prong to two

prong adapter and connect the adapter’s ground lead to the outlet plate retaining screw.

The Power ON/OFF Switch is located on the rear panel and in part of the Power Entry Module Assembly. Placing the

POWER ON/OFF switch in the ON position applies power to the instrument.

CAUTION

When applying an RF signal to the RF INPUT connector, DO NOT exceed the maximum allowable

power level specifications of the Model 8310-XX-X-XN.

3-3.2. CHANNEL PORT CONNECTORS: A typical Model 8311-XX-X-XN Series Attenuator Unit contains 12 standard

D holes on the front and rear panel allowing for single or multichannel configurations. Standard Model 8311-XX-X-

XN’s are supplied with two PLANAR CROWN®Type N connectors that can be mounted on the front or rear panel.

These connectors provide a input and output port where various types of RF signals can be applied to the devices

internally mounted in the Model 8311-XX-X-XN (Connector location specified by customer when ordering). Some

special configurations could contain Aeroflex / Weinschel’s Model 1568 SMA Panel Adapters or other types of crowns

(see accessories for other types).

NOTE

The use of the PLANAR CROWN®connectors provide the user with easy exchange of connector

types, which eliminates the need for adapters and other devices that would create additional insertion

loss. This type of connector also provides quick removal and replacement of defective connectors.

For more information about the PLANAR CROWN®connectors contact the Sales Department at

Aeroflex / Weinschel, Inc.

3-3.3. MODE SELECT SWITCH: This 3 position slide switch located on the rear panel, allows the user to select

between Serial, Ethernet or Console Mode operation. Refer to paragraph 5-1 for more information about the different

operational modes of the Model 8310-XXX-XN communication interface

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 13

4. FRONT PANEL CONTROLS & INDICATORS:

The following paragraphs provide setup and general guidelines for operating the Model 8310-XXX-XN

Programmable Attenuator Unit and its different bus configurations.

Figure 3. 8310-XXX-XN Series Front Panel

ENTRY keys: The numeric entry keys allow the user to directly enter numeric values. When using

the keypad, values are not updated until the ENT (enter) key is pressed. The Minus (-) and CE (clear

entry) functions may be accessed via first depressing the SHIFT key.

INCR & DECR: The INCR and DECR keys allow settings to be scrolled from their current value.

Unlike the ENTRY keys, the new setting is updated immediately without the use of the ENT key.

CHAN: Allows the selection of the current channel, as indicated by the CH1-CH4 indicators.

Repeated depressions of the CHAN key will select the next available channel. The main display will

show the current setting of the channel.

REL: This key control allows the use of a relative mode for attenuators, as indicated by the REL

mode indicator. When turned on, the currently displayed attenuation value is used as a reference

value from which the attenuation may be set. In this mode, attenuation values may be positive or

negative from the reference setting. When REL is turned off, the display returns to the actual

attenuation setting for the channel.

STEP: This key allows the user to change the attenuation step size used by the INCR and DECR

keys. When turned on, as, indicated by the STEP indicator, the current step size is displayed in the

main display, and a new value may be entered using the INCR/DECR or ENTRY keys. The step size

may be set to any multiple of the intrinsic step size for the currently selected channel.

MENU: Invokes the menu functions. Menu selections may be made via the INCR and DECR keys.

(NOTE: menu functions are currently not implemented as of 3/8/99)

AUX1/AUX2: The function of these keys is user-programmable via remote operation. They invoke

any currently defined AUX1 and AUX2 macros. Refer to the macro programming section for

information on creating macro definitions.

LOCAL: This key places the 8310-XXX-XN in local operation mode, unless the key function has

been overridden via an IEEE-488.2 local lockout or execution of the LOCKOUT command.

ADDR: This key displays the current IEEE-488.2 address. The address may be changed from the

front-panel, however, the initial setting at power on is derived from the rear-panel address switch.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 14

5. REMOTE OPERATION:

The following paragraphs provide setup and general guidelines for operating the Model 8310 using an

external controller.

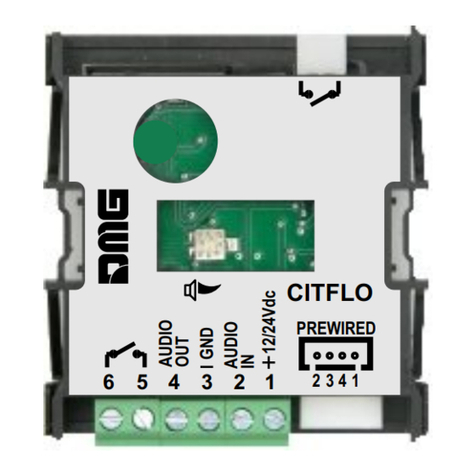

5-1. COMMUNICATIONS INTERFACE: The unit provides for control via a number of interface methods, including

IEEE 488.2, RS232 serial, and 10/100 baseT Ethernet. Interface functions are split between two assemblies:

1). The main controller (generically referred to as the 8210A),

2). The exadeci control interface.

The 8210A is responsible for control of the RF devices, and handles GPIB and RS232 communications. The

Ethernet control interface utilizes a Lantronix Xport™ Ethernet to serial device server which allows the 10/100baseT

Ethernet network to communicate to the 8210A via the RS232 port.

A block diagram of the communications subsystem is shown below.

A copy of the Xport Users Guide and the Lantronix DeviceInstaller program is included on the provided CD.

For detailed information regarding the setup and operation of the XPort™ Device Server, consult the Lantronix

documentation available at the Lantronix website www.lantronix.com

5-1.1 Operating Modes: The rear-panel RS232 port serves several functions, which are controlled via the 3-position

Mode Select Switch.

Serial Mode: This position allows the RS232 port to be directly connected to the serial port of the

8210A, effectively bypassing the XPort’s ability to control the unit via the Ethernet port. In this mode,

the serial port settings are controlled via the internal DIP switch of the 8210A.

8210A Attenuator/Switch

Controller Assy

Lantronix

XPort™ 10/100 Ethernet

Port (RJ45)

RS232 Serial

Port (DB9)

Internal

Device

Control

Bus

RS232

Mode

Selector

Mode Select Switch

Console

Etherne

t

Serial

RS232

RS232

Ethernet

Control

Assembly

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 15

Ethernet Mode: This position internally connects the serial port of the device server to the serial

port of the 8210A, allowing for network control of the unit. In this mode, the external serial port is

non-functional. The serial communication settings of the device server must be set to match that of

the 8210A for proper operation.

Console Mode: This position connects the RS232 port directly to the XPort device server. This

mode allows the setup/configuration of the device server to be performed via the RS232 port. In this

mode, serial communications are fixed at 9600 N81. For detailed information regarding operation,

refer to the Xport Users Guide Chapters 5-8 (Setup Mode) and Chapter 11 (Monitor Mode).

5-1.2 Serial Port Setup: By default, the unit is shipped configured for 9600 baud, no parity, and 1 stop bit, with no

handshaking required (9600N81). The rear-panel male DE-9 connector is configured as a DTE port (the same as a

typical PC) with the following pinout:

Pin Name Dir Description

2 RXD Receive Data (in)

3 TXD Transmit Data (out)

5 GND -- System Ground

Connection to another DTE device (ie a PC) requires the use of a null-modem cable to swap pins 2 and 3.

Communication settings for the 8210A are controlled via the internal Serial/GPIB Settings DIP switch located on the

board (refer to the 8210A Manual IM-288), while the XPort serial configuration is set independently and can be done

using a variety of methods. Refer to the Xport Users Guide for a detailed description of the available setup mode

methods and options.

NOTE

If you wish to change the serial port operation, keep in mind that the settings must match in both

places in order for the XPort to communicate successfully with the 8210A when used in the

Ethernet control mode.

5-1.3 Ethernet Setup: The network address of the XPort must be configured prior to use. There are several ways to

assign an IP address to the Xport. A general overview is provided here. For more detailed information and links to

video tutorials on performing many of these steps, refer to the information provided on the CD.

5-1.3.1 DeviceInstaller: The Lantronix DeviceInstaller is a Windows-based program that can be used to setup the

Xport. Of the methods presented here, this is the simplest. However, the DeviceInstaller relies on the Xport being set

for DHCP. If a static IP has been previously assigned to the Xport, there is a high probability that the DeviceInstaller

will not be able to see the Xport, especially if the IP or Gateway network settings do not match that of the PC currently

being used. If that is the case, you will have to use one of the other methods outlined below.

To use the DeviceInstaller utility, first install it from the product CD or click on the link below to download the latest

version of DeviceInstaller.

http://ltxfaq.custhelp.com/app/answers/detail/a_id/644

a. Insert the product CD into your CD-ROM drive.

b. View Readme.txt located in the Lantronix Xport CD files Rev2 folder.

c. Select the desired DeviceInstaller and run the associated setup program within the folder.

d. Respond to the installation wizard prompts. (When prompted to select an installation type, select Typical.)

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 16

Assigning an IP Address in DeviceInstaller

a. Click Start->Programs->Lantronix->DeviceInstaller->DeviceInstaller. If your PC has more than one network

adapter, a message displays. Select an adapter and click OK.

b. Click the Search icon and select the unit from the list of Lantronix device servers on the local network.

c. Click the Assign IP icon.

d. If prompted, enter the hardware address (on the product label) and click Next.

e. Select Assign a specific IP address and click Next.

f. Enter the IP address. The Subnet mask displays automatically based on the IP address; if desired, you may

change it. On a local network, you can leave the Default gateway blank (all zeros). Click Next.

g. Click the Assign button and wait several seconds until a confirmation message displays. Click Finish.

h. Select the device from the main window list and select Ping from the Tools menu. The Ping Device dialog box

shows the IP address of the selected unit.

i. From the Tools menu, click the Ping button. The results display in the Status window. Click the Clear Status

button to clear the window so you can ping the device again.

Note: If you do not receive “Reply” messages, make sure the unit is attached to the network properly and

the IP address assigned is valid for the particular network segment you are working with. If you are not

sure, check with your systems administrator.

j. Click the Close button to close the dialog box and return to the main window.

5-1.3.2 Serial Port Login: To assign the IP address and other network settings using a serial connection:

a. Connect a console terminal or a PC running a terminal emulation program to the rear-panel RS232 connector.

The default serial port settings are 9600 baud, 8 bits, no parity, 1 stop bit, no flow control. Set the rear-panel

Mode Select switch to the Console position.

b. To enter Setup Mode, cycle the unit's power (power off and back on). After power-up, the self-test begins and

the red Diagnostic LED starts blinking. You have one second to enter three lowercase ‘x’ characters.

Note: The easiest way to enter Setup Mode is to hold down the ‘x’ key at the terminal (or emulation) while

powering up the unit.

c. The display should be similar to:

MAC address 00204AC530DB

Software version V6.6.0.2 (080926) XPTEXE

Press Enter for Setup Mode

d. The Xport has a built-in timeout function, and you must press the ‘Enter’ key within three seconds to enter the

Setup Mode. If you do not, the Xport will timeout and display “?!?”, after which it will continue with the boot

process and you will have to repeat Step 2.

e. Select 0 (Server Configuration) and follow the prompts until you get to IP address.

f. Enter the new IP address, subnet mask, and gateway (if applicable).

g. Select 9 to save and exit Setup Mode. The unit performs a power reset.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 17

5-1.3.3 ARP and Telnet: If a serial port is unavailable, you can use the Address Resolution Protocol (ARP) method

from UNIX and Windows-based systems to assign a temporary IP address.

To assign a temporary IP address:

a. On a UNIX or Windows-based host, create an entry in the host's ARP table using the intended IP address and

the hardware MAC address of the Xport, which should be available on the rear-panel of the unit. Make sure

that the intended IP is reachable with the current network settings of the host. The following example uses an

IP of 192.12.3.77. Substitute the desired address in it’s place, and the MAC address of the Xport in place of

the 00:20:4a:xx:xx:xx

arp -s 191.12.3.77 00:20:4a:xx:xx:xx (Unix)

arp -s 191.12.3.77 00-20-4a-xx-xx-xx (Windows)

b. Open a Telnet connection to port 1. The connection fails quickly, but the unit temporarily changes its IP

address to the one designated in this step.

telnet 191.12.3.77 1

c. Open a Telnet connection to port 9999, and press Enter within three seconds to go into Setup Mode. If you

wait longer than three seconds, the unit reboots and you will have to repeat Step 2.

telnet 191.12.3.77 9999

d. Select 0 (Server Configuration) and follow the prompts until you get to IP address.

e. Enter the new IP address, subnet mask, and gateway (if applicable).

f. Select 9 to save and exit Setup Mode. The unit performs a power reset.

5-1.3.4 DHCP: The unit ships with a default IP address of 0.0.0.0, which automatically enables DHCP. If a DHCP

server exists on the network, it provides the unit with an IP address, gateway address, and subnet mask when the unit

boots up.

The DeviceInstaller software can be used to search the network for the DHCP assigned IP address and add it to the

list of devices retrieved.

NOTE

This DHCP address does not appear in the unit’s Setup Mode or in Web Manager. You can

determine your unit’s DHCP-assigned IP address in Monitor Mode. When you enter Monitor Mode

from the serial port with network connection enabled and issue the NC (Network Communication)

command, you see the unit’s IP configuration.

5-1.3.5 AutoIP: The unit ships with a default IP address of 0.0.0.0, which automatically enables Auto IP within the

unit. AutoIP is an alternative to DHCP that allows hosts to obtain an IP address automatically in smaller networks that

may not have a DHCP server. A range of IP addresses (from 169.254.0.1 to 169.254.255.1) has been explicitly

reserved for AutoIP-enabled devices. Do not use this range of Auto IP addresses over the Internet.

If your unit cannot find a DHCP server, and you have not manually assigned an IP address to it, the unit

automatically selects an address from the AutoIP reserved range. Then, your unit sends out a (ARP) request

to other nodes on the same network to see whether the selected address is being used.

If the selected address is not in use, then the unit uses it for local subnet communication..

If another device is using the selected IP address, the unit selects another address from the AutoIP range and

reboots. After reboot, the unit sends out another ARP request to see if the selected address is in use, and so

on.

Model 8310-XX-X-XN IM-493

Aeroflex / Weinschel 18

AutoIP does not replace DHCP. The unit continues to look for a DHCP server on the network. If it finds a DHCP

server, the unit switches to the DHCP server-provided address and reboots.

NOTE

If a DHCP server is found, but it denies the request for an IP address, the unit does not attach to

the network, but waits and retries.

AutoIP can be disabled by setting the unit’s IP address to 0.0.1.0. This setting enables DHCP but disables AutoIP.

5-1.3.6 BOOTP: Similar to DHCP, but for smaller networks. Automatically assigns the IP address for a specific

duration of time.

5-1.3.7 Device Server Setup: The Channel Configuration section of the Setup Mode is used to define how the serial

port responds to network and serial communications when operating as a device server. See the Xport Users Guide

Chapter 7 (Setup Mode: Channel Configuration) section for more details on each of these entries. Some of the

important settings in this section are:

Baudrate: This is the baudrate used by the Xport to communicate to the 8210A when in device server

mode. This setting must match the rate used by the 8210A, and is typically 9600.

I/F (Interface) Mode: The Interface (I/F) Mode is a bit-coded byte entered in hexadecimal notation.

This setting controls the serial port settings of the device server, such as number of bits, parity, stop

bits, etc. The default value for this parameter is 4C, which specifies RS-232C, 8-bit, No Parity, 1 stop

bit.

Flow: Flow control sets the local handshaking method for stopping serial input/output. The default

setting for this parameter is 00 (no flow control)

Port Number: The setting represents the source port number in TCP connections. It is the number

that is used to establish a connection via the network interface. The default setting for this parameter is

10001. This number may have to be changed to match the user’s software. Certain ports are reserved

and should not be used. Refer to the section in the Xport Users Guide for a detailed list.

Compatibility note: units previously mfg’d using the Lantronix MSS-LITE were set to communicate via

port 3001

Connect Mode: Connect Mode defines how the unit makes a connection, and how it reacts to

incoming connections over the network. Enter Connect Mode options in hexadecimal notation. The

default setting is C0, which sets the following options:

Incoming Connection - Always Accept

Response - Nothing (quiet)

Active Startup - No active startup

5-1.3.8 Example Setup Using The Serial Port:

a. Set the rear-panel MODE SELECT switch to CONSOLE position.

b. Open a terminal emulator. Set the PC serial port for 9600N81, no flow control. Serial port cable connections

to a PC will require the use of a null-modem cable (DTE to DTE device).

c. To access the Xport SETUP mode, you must enter three lowercase 'x' characters within one second after

powering on the unit. The easiest way to enter Setup mode is to hold down the 'x' key, and power up the unit.

d. Response should be::

MAC address 00204AC530DB

Software version V6.6.0.2 (080926) XPTEXE

Press Enter for Setup Mode

Table of contents

Other Aeroflex Control Unit manuals

Popular Control Unit manuals by other brands

Texas Instruments

Texas Instruments TPS7A8300EVM-209 user guide

Nordson

Nordson Vantage Customer product manual

Artel

Artel DigiLink DLC910 Installation and operation manual

Simplex

Simplex Foundation Series Operation guide

National Instruments

National Instruments 9225 CALIBRATION PROCEDURE

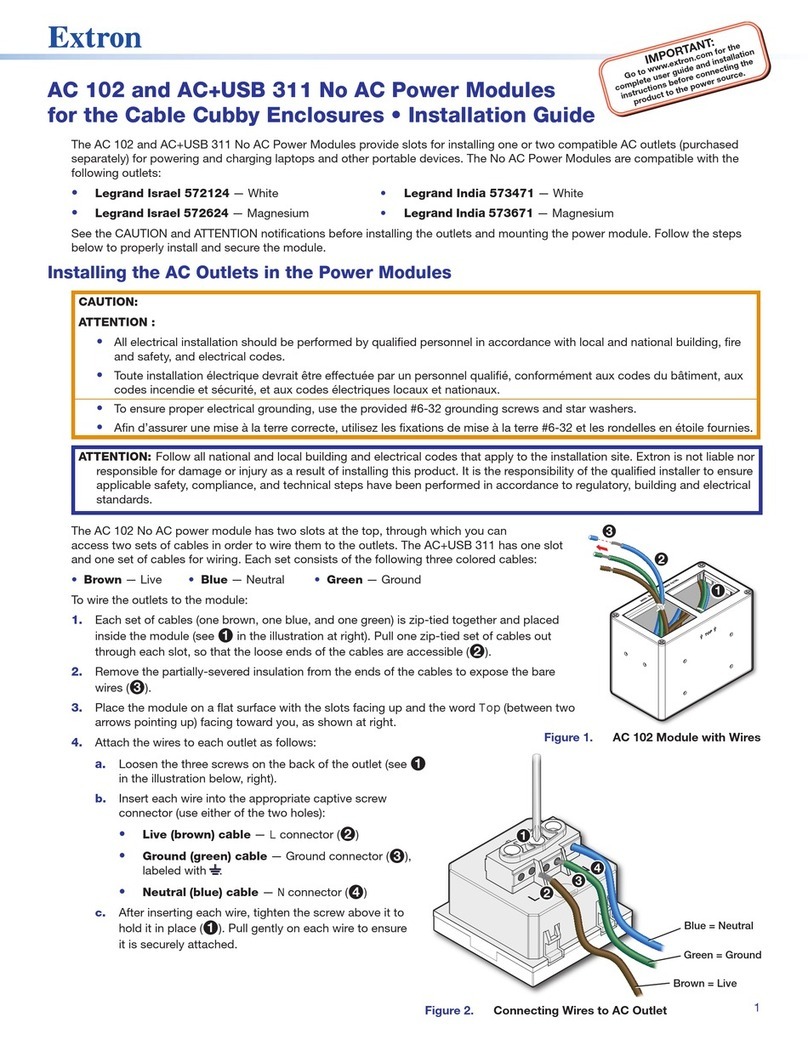

Extron electronics

Extron electronics AC 102 installation guide