Eilersen 5024G User manual

Software: StdLim.140630.5v7

Doc. no.: StdLim-140630-5v7-UG-eng

Date: 2020-09-08

Rev.: 5v7

Contact:

Eilersen Electric A/S

Kokkedal Industripark 4

DK-2980 Kokkedal

Denmark

www.eilersen.com

info@eilersen.com

Tel: +45 49 180 100

Fax: +45 49 180 200

5024G User’s guide StdLim

5024G LCD weighing terminal

Basic scale with automatic dosing

2

WWW.EILERSEN.COM

Contents

Contents...................................................................................................................................... 2

Introduction................................................................................................................................ 5

Installation.................................................................................................................................. 5

How to ........................................................................................................................................ 5

–Perform basic operations.................................................................................... 5

–Perform automatic dosing................................................................................... 7

–Change setpoints for automatic dosing .............................................................. 8

Setting Coarse and Fine limits........................................................................... 8

Start/Stop of dosing.......................................................................................... 8

–Change dosing parameters ................................................................................. 9

Change registration period ............................................................................... 9

Change afterflow status.................................................................................... 9

Change afterflow correction............................................................................. 9

–Reading totals.................................................................................................... 10

Reset of totals ................................................................................................. 10

–Operate the menu system................................................................................. 10

–Set date and time.............................................................................................. 10

- Unlock the keyboard.......................................................................................... 11

- Unlock for parameter update ............................................................................ 11

–Enter values....................................................................................................... 12

Entry using selection list ................................................................................. 12

Entry of numbers ............................................................................................ 12

–Check the software version............................................................................... 14

–Activate Intelligent Setup.................................................................................. 15

–Set up the load cell configuration ..................................................................... 15

Load cell communication protocol type ......................................................... 16

Number of load cells....................................................................................... 16

Number of supports........................................................................................ 16

–Detect the load cell configuration..................................................................... 16

–Configure the weighing ranges ......................................................................... 17

–Perform coarse taring ....................................................................................... 17

3

WWW.EILERSEN.COM

–Configure display, filtering and stability requirement ...................................... 18

Interval............................................................................................................ 18

Filters............................................................................................................... 18

Steady/stability detection............................................................................... 18

–Configure zero tracking..................................................................................... 18

–Change reading to high resolution mode.......................................................... 19

–Perform load check ........................................................................................... 19

–Perform corner calibration................................................................................ 19

Corner calibration factor................................................................................. 20

Reset corner calibration factors...................................................................... 20

Corner calibration procedure ......................................................................... 20

–Perform system calibration............................................................................... 22

Calibration factor ............................................................................................ 22

Calibration load............................................................................................... 22

Perform calibration......................................................................................... 23

–Perform linearization ........................................................................................ 23

–Zero with extended range (power-up zeroing)................................................. 24

–Configure Ethernet settings .............................................................................. 25

Address settings.............................................................................................. 25

–Configure Ethernet TCP communication........................................................... 25

Enable TCP protocol........................................................................................ 25

Select TCP port................................................................................................ 25

Select data output........................................................................................... 26

–Check Ethernet communication status............................................................. 26

–Check load cell serial no., exponent and capacity............................................. 27

–Check individual load cell signals ...................................................................... 27

–Check load cell diagnostics................................................................................ 28

Trouble shooting....................................................................................................................... 29

–Error situations.................................................................................................. 29

–Error code display (in NORMAL screen)............................................................ 30

–Error solving (in STATUS screen)....................................................................... 30

Appendices ............................................................................................................................... 31

Appendix A –Installation checklist ...................................................................... 31

4

WWW.EILERSEN.COM

Appendix B –Electrical connections .................................................................... 32

Rear view......................................................................................................... 32

Power Connection........................................................................................... 32

Load cell connection ....................................................................................... 33

Digital I/O connector....................................................................................... 33

RS485 communication .................................................................................... 33

Analog output connector................................................................................ 34

Ethernet connector......................................................................................... 34

Jumper settings............................................................................................... 34

Light Emitting Diodes (LED’s) .......................................................................... 34

Appendix C –Screen overview............................................................................. 35

Appendix D –Filters ............................................................................................. 35

Sampling filter................................................................................................. 35

Display and steady filters................................................................................ 37

Appendix E –Setting of MAC Address.................................................................. 37

Appendix F –Software download ........................................................................ 38

Appendix G –Advanced features......................................................................... 38

Revision History ........................................................................................................................ 39

Contact...................................................................................................................................... 39

5

WWW.EILERSEN.COM

Introduction

This document describes the use of a 5024G LCD display terminal from Eilersen Electric,

when the software version listed on the front page is installed.

With this software, the terminal can perform automatic dosing (coarse/fine) using its digital

outputs and inputs. One digital output is used for coarse dosing and one digital output is

used for fine dosing, while a digital input is used for start of dosing and a digital input is used

for registration of dosed amount.

Installation

The following steps must be performed before the system is used:

•Install the load cells and check mechanical installation

•Optional: Connect digital outputs and digital inputs

•Connect and apply power

•Check software version

•Optional: Activation of Intelligent Setup feature

•Set up load cell configuration

•Power cycle the unit

•Configure weighing ranges

•Perform coarse taring

•Optional: Configure display, filtering, zero tracking range, stability requirement

•Optional: Corner calibration, system calibration, linearization

•Perform load check

Please notice: Perform a load check before the system is used to be sure that all require-

ments regarding accuracy, stability etc. are met before the system is used.

Please notice: If the Intelligent Setup feature is used, this will perform some of the subse-

quent points in the above list.

Details on the steps needed to install the system are explained below.

How to

–Perform basic operations

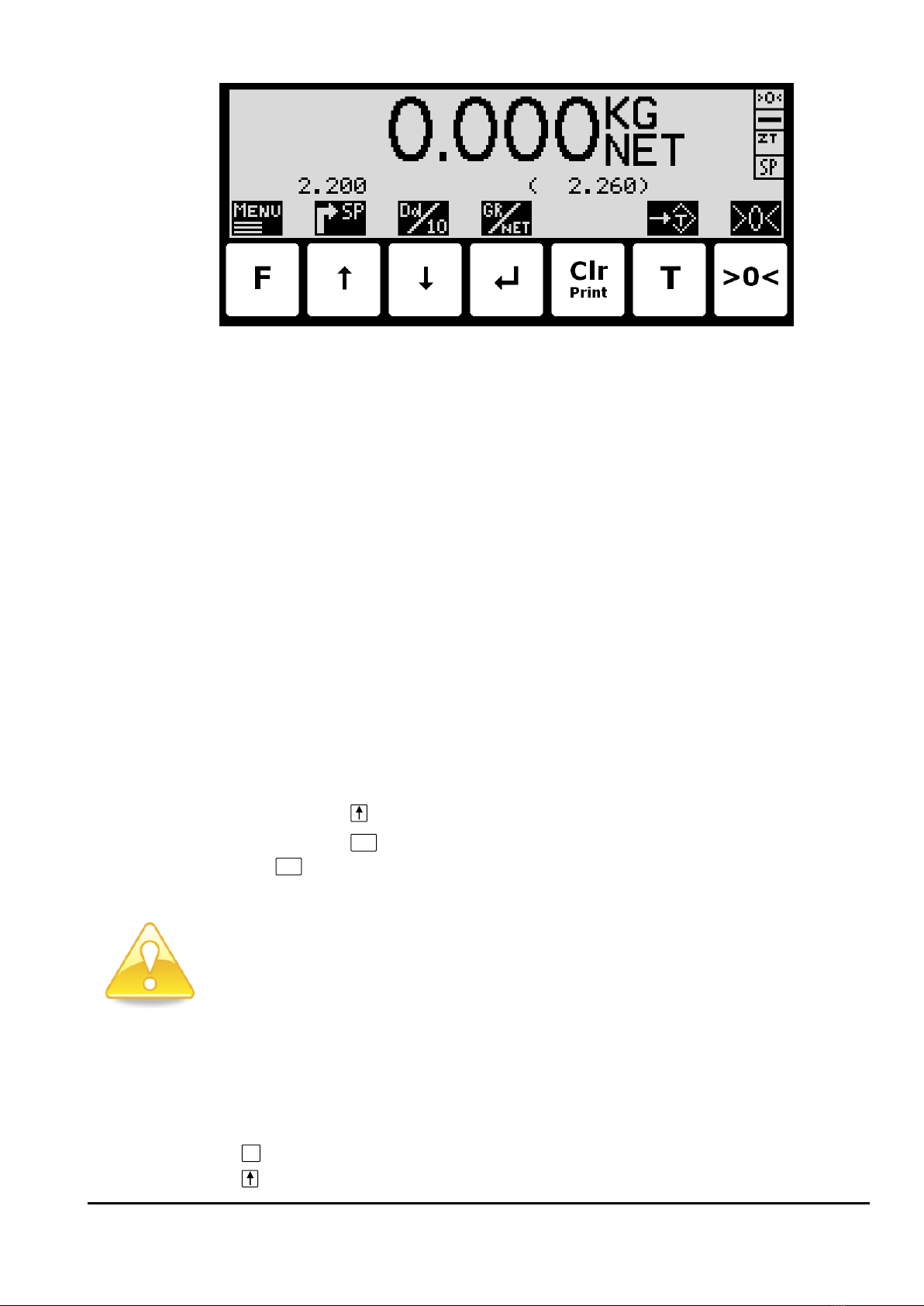

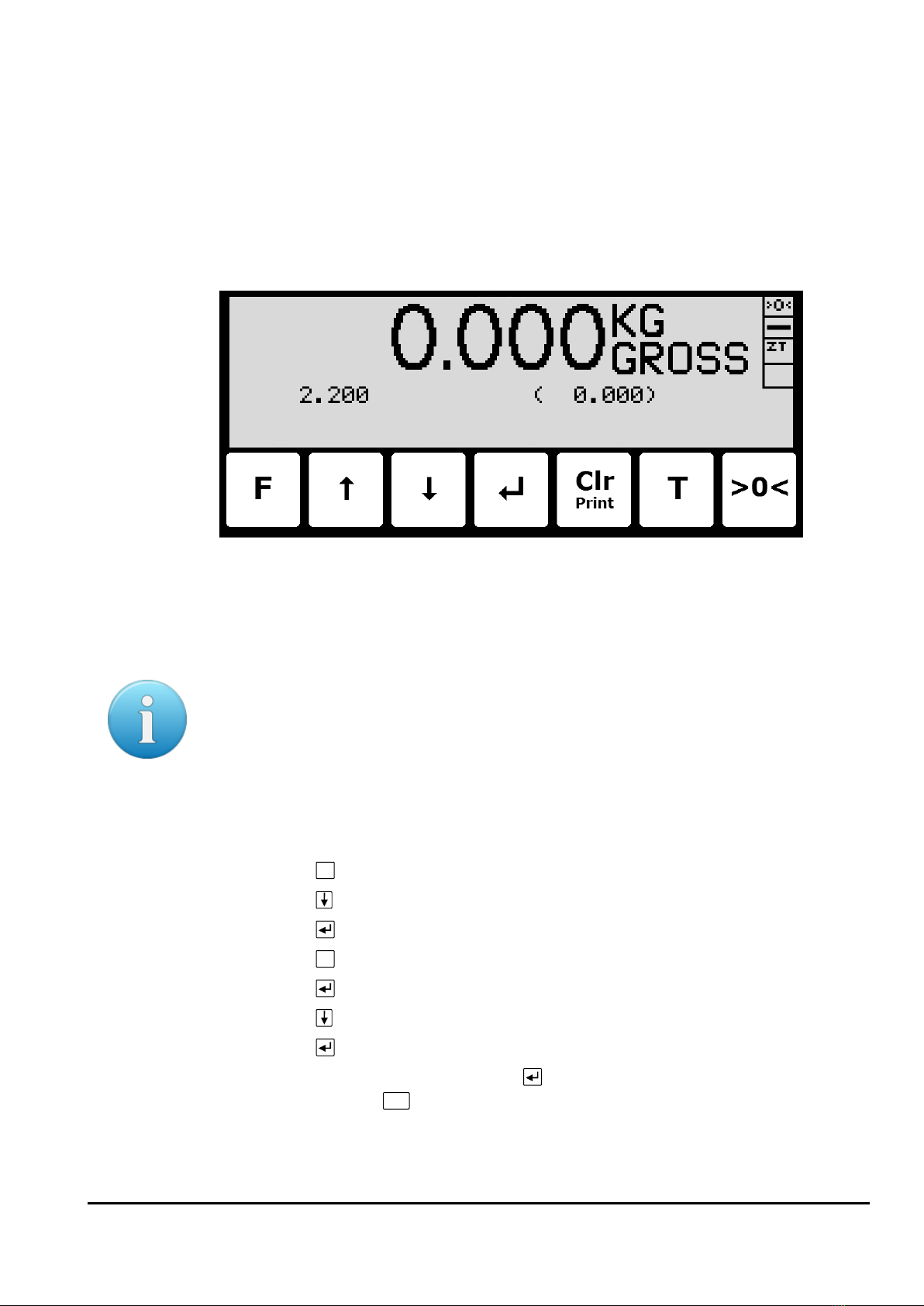

When the system is installed and power-up sequence has ended the display will look like this:

6

WWW.EILERSEN.COM

Weight reading:

•The actual weight reading is displayed in large types.

•To the right of the weight reading, the unit is indicated, like KG, LB etc.

•Below the unit gross/net selection is indicated with GROSS or NET.

•If an error condition is present the weight reading will indicate the error, like UL, OL,

- 0080 –etc. Please see below in section Trouble shooting, page 29 for details on er-

ror codes and how to recover from various error situations.

Status indications:

•‘>0<’ in the upper right corner status field indicates that the actual gross weight is ze-

ro (within ± ¼ division).

•‘--’in the second status field indicates that the weight reading is steady/stable. If the

reading is unstable ‘~’ will be indicated.

•‘ZT’ in the third status field indicates that a zero tracking device is active, holding the

actual gross weight at zero.

•‘SP’ in the fourth status field if automatic dosing is running.

‘R’ in the fourth status field if registration is in progress.

•Above the key the actual setpoint (fine limit) is shown.

•Above the

Print

Clr

key the last registered weight is shown in parenthesis. Also above the

Print

Clr

key an “OK” icon is shown for a short period following every successful registra-

tion.

Please notice: The net weight is used to determine the state of the digital outputs during

dosing even when the gross weight is displayed.

Please see below how automatic dosing and digital outputs are used.

Please notice: If none of the icons directly above the keys are visible as shown in the

screen shot above, the keyboard is locked, since the Keyboard unlock length parameter

in the SETUP SYSTEM screen has been activated. As long as the keyboard is locked, no

keyboard actions will be available. Please see below in section - Unlock the keyboard,

page 11 on how to unlock the keyboard.

Keys/actions:

F

Invoke the MAIN menu.

Select the DOSING screen to enter the setpoints and start/stop of dosing.

7

WWW.EILERSEN.COM

Displays weight with enhanced resolution for 3 seconds. The “Dd/10”symbol

above the key will flash when enhanced resolution is shown.

Switch between Gross and Net reading.

Print

Not used.

T

Sets the net weight to zero and select Net reading.

>0<

Sets the gross weight to zero and select Gross reading.

–Perform automatic dosing

To perform an automatic dosing, follow this procedure:

1. The desired Coarse and Fine setpoints must be entered. Use the key in the NORMAL

screen to select the DOSING screen. Then use the DOSING screen to enter the desired

setpoints.

2. To start a new dosing select the “Action: START DOSING” using the or key in the

DOSING screen and then press the key. Alternately start a new dosing by activating

the digital START input.

3. This will zero the net weight (automatic tare) and activate the digital COARSE and FINE

dosing outputs.

4. During dosing the COARSE output is active as long as the net weight does not exceed the

COARSE limit. An active COARSE output indicates dosing should be done at high speed

for the first part of the dosing, followed by slow speed for the final part of the dosing

where the COARSE output is deactivated.

5. When the net weight (positive or negative) reaches the FINE setpoint (possibly adjusted

by the afterflow correction) the FINE output will be deactivated and dosing is stopped.

6. Hereafter the COARSE and FINE outputs will remain deactivated until a new dosing is

started.

7. The dosed amount is automatically registered after the entered registration period, if

the registration period is different from 0 ms. In this case a registration can be made by

activating the REGISTRATION input. The result of the last registration can be read in the

NORMAL screen.

8. Following a registration the totals are updated and a possible new afterflow correction

may be calculated.

9. An ongoing dosing can be stopped prior to reaching the setpoint, by selecting the “Ac-

tion: STOP DOSING” using the or key in the DOSING screen and then pressing the

key. An ongoing dosing is also aborted if the weighing range is exceeded or if a load

cell error occurs.

10. The weighing terminal is ready for start of a new dosing.

8

WWW.EILERSEN.COM

–Change setpoints for automatic dosing

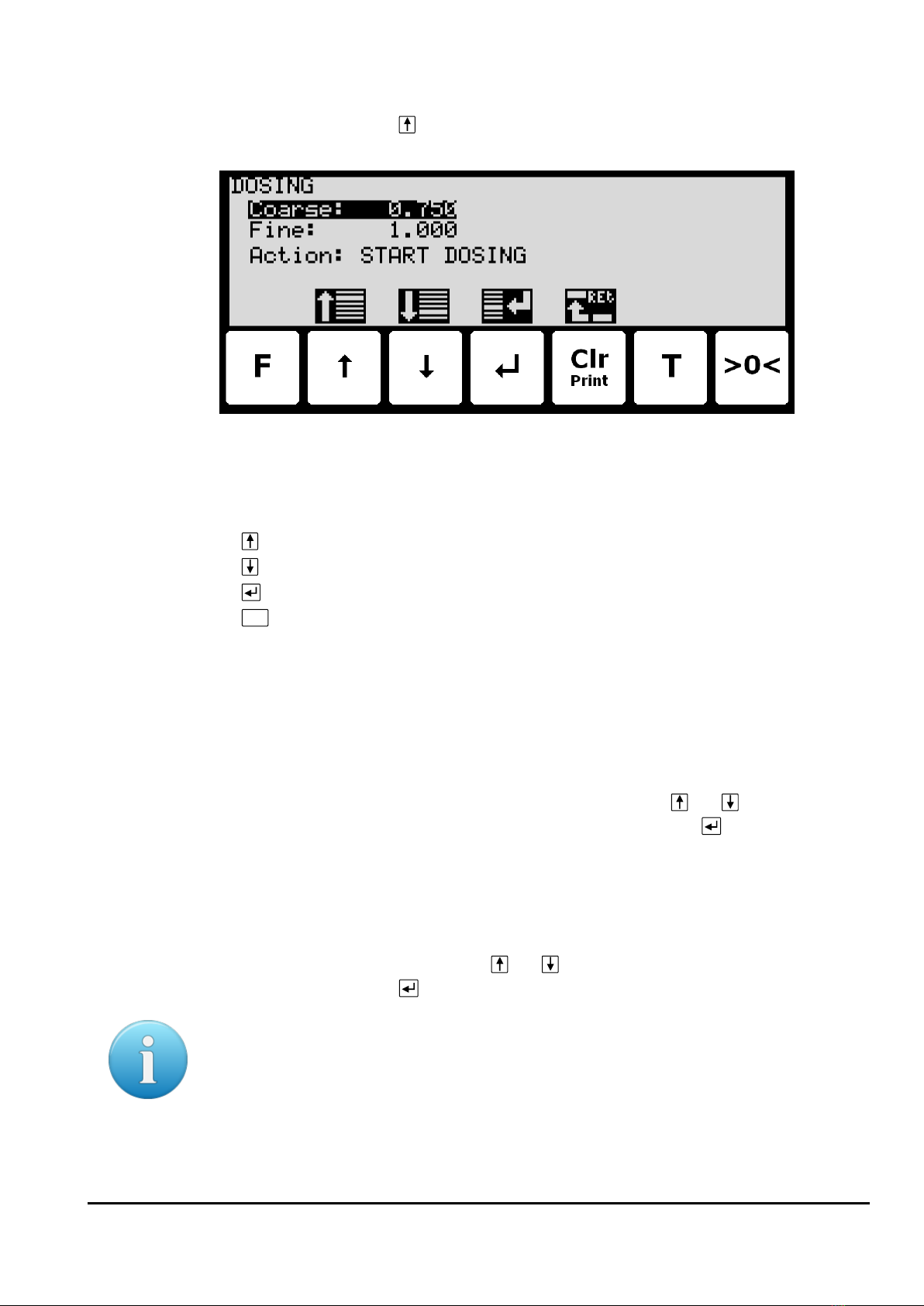

In the MAIN screen press to select the DOSING screen, looking like this:

In this screen setpoints for dosing are shown and can be changed. It is also possible to

start/stop a dosing.

Keys/actions:

Select the previous setpoint/parameter.

Select the next setpoint/parameter.

Start entry of the selected setpoint or chooses the marked action.

Print

Clr

Return to the MAIN previous screen.

Setting Coarse and Fine limits

The COARSE and FINE setpoints used for automatic dosing must be specified in the DOSING

screen.

The COARSE limit is used to control the COARSE output indicating high speed dosing until the

COARSE setpoint is reached. The FINE limit is used to control the FINE output indicating the

desired amount to be dosed. The setpoints are changed by using and to select the de-

sired setpoint (“Coarse” or “Fine”) with the cursor, and then pressing to request change

of the setpoint.

Start/Stop of dosing

In addition to starting a dosing using the digital START input, a dosing can be started (or

stopped if a dosing is already in progress) using the keyboard in the DOSING screen.

A dosing is started or stopped by using and to select the “Action” parameter with the

cursor, and then pressing to request the indicated action (“START DOSING” or “STOP DOS-

ING”).

Please notice: Some other dosing parameters (such as registration period and afterflow cor-

rection) are configured in the DOSING PAR. screen.

9

WWW.EILERSEN.COM

–Change dosing parameters

From the menu system the DOSING PARAMETERS screen is selected:

In this screen dosing parameters such as registration period and afterflow correction are

shown and can be changed.

Change registration period

The registration period is the time from a dosing has finished to the actual amount dosed is

registered automatically. The registration period is entered in milliseconds (0 - 30000 ms).

The value should be set large enough to ensure no vibrations and a stable weight indication is

achieved before the automatic registration is performed. A value of 0 ms indicates that NO

automatic registration is performed, and that a registration must be made using the REGIS-

TRATION input (or the keyboard).

Change afterflow status

The afterflow status indicates whether afterflow correction is disabled (OFF), enabled using a

fixed correction (ON) or enabled using an automatically adjusted correction (AUTO).

Change afterflow correction

The actual afterflow correction used during dosing if enabled using the “Afterflow status” pa-

rameter (ON or AUTO), is the amount prior to the net weight reaching the FINE limit, where

the dosing is assumed to be completed and the FINE and COARSE outputs are deactivated.

The “Afterflow” parameter indicates the actual correction.

Please notice: The “Afterflow” parameter is not used if afterflow correction is disabled by

setting the “Afterflow status” parameter to OFF.

Please notice: The “Afterflow” parameter can be changed automatically after each dosing if

afterflow correction is performed automatically by setting the “Afterflow status” parameter

to AUTO.

10

WWW.EILERSEN.COM

–Reading totals

In the MAIN screen

F

is pressed to select the TOTALS screen from the menu:

In this screen the totals are shown. Whenever a registration is performed the total weight is

updated with the registered amount and the total count is incremented.

Reset of totals

Totals are reset by pressing

F

to show the TOTALS menu, where the ”RESET TOTALS” item is

selected with the cursor using the and keys and then pressing the key.

Please notice: Reset of totals can NOT be undone.

–Operate the menu system

The installation and service of the system is operated by a series of menus and screens.

Please see below in section Appendix C –Screen overview, page 35, for an overview on all

screens. When using setup and maintenance screens these keys are used:

F

Select a menu depending on the actual screen.

Increase a value, select previous parameter or move cursor up in a menu.

Decrease a value, select next parameter or move cursor down in a menu.

Select entry or accept of a value, or select an action from a menu.

Print

Clr

Return to previous screen. Exit menu without action.

Please notice: Parameters cannot be changed and actions not performed when the system is

powered on. Before such operations are possible the parameters must be unlocked as ex-

plain below in section - Unlock for parameter update, page 11.

–Set date and time

It is possible to set the date and/or time of the internal clock by use of the SETUP menu. To

set date and/or time from the SETUP screen perform the following:

F

Press once to select the SETUP menu.

Press several times to select the “SET DATE” or “SET TIME” entry from the SET-

UP menu.

Press once to start entry of the selected parameter (date or time).

11

WWW.EILERSEN.COM

- Unlock the keyboard

The terminal is equipped with a keyboard lock feature, which can be enabled or disabled us-

ing the Keyboard unlock length parameter in the SYSTEM screen as described below. If the

keyboard lock is disabled, then the keyboard functions will always be active. If the keyboard

lock is enabled, and the terminal is in the NORMAL screen without any key activation for 10

minutes (or directly after power-on), the keyboard will automatically lock. When the key-

board is locked, the NORMAL screen will appear as follows without any icons above the keys:

To unlock the keyboard:

•Press any key to start the keyboard unlock sequence.

•Press the indicated keys one at a time until the required sequence (specified by the

Keyboard unlock length parameter) is completed without error.

Please notice: This feature is disabled by setting the Keyboard unlock length parameter in

the SYSTEM screen to 0. Any other value specifies the length of the key sequence that must

be pressed correctly to unlock a locked keyboard.

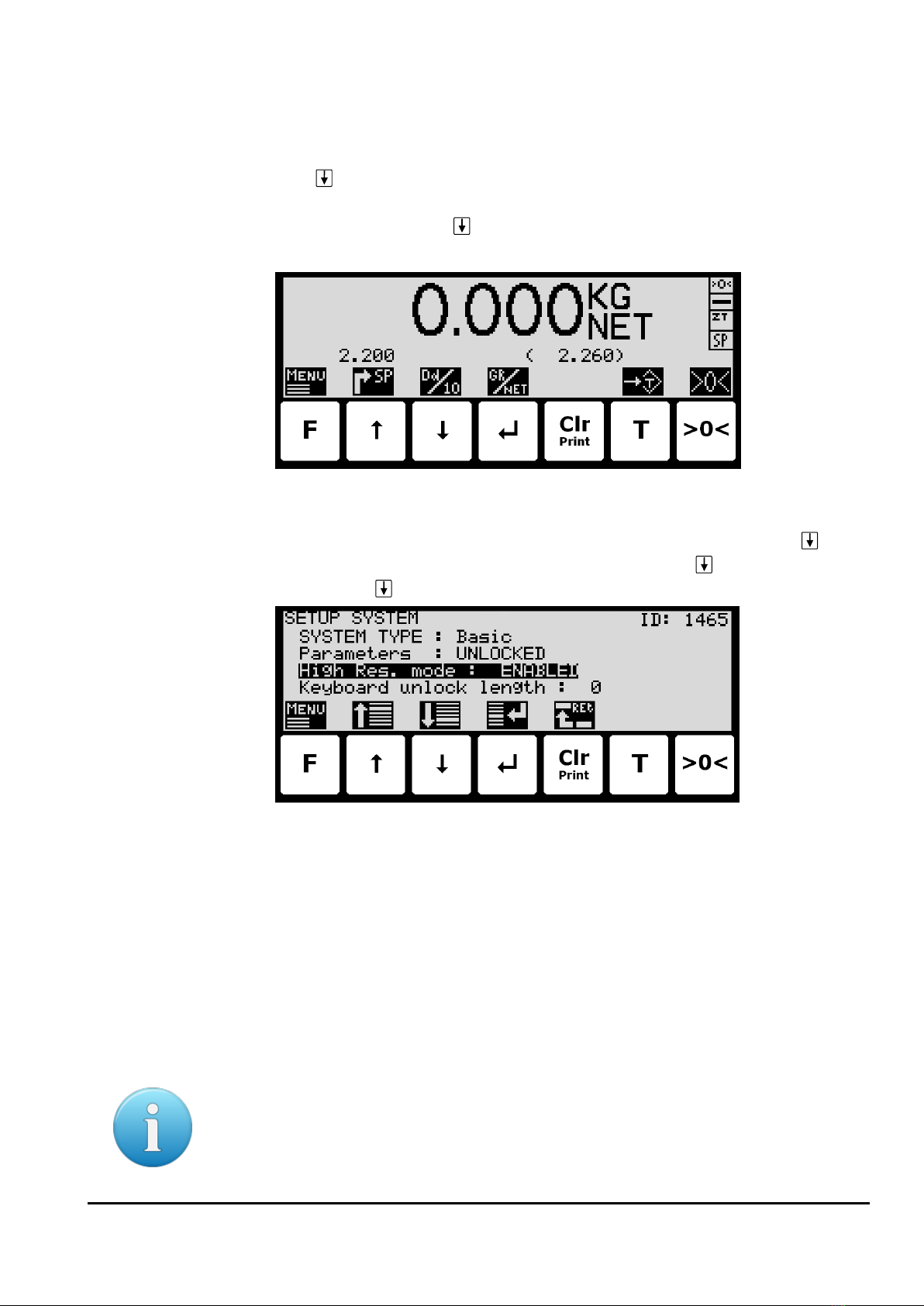

- Unlock for parameter update

Parameters cannot be changed and actions not performed when the system is powered on.

Before such operations are possible the parameters must be unlocked:

•Press

F

to invoke the menu system.

•Press to highlight the SERVICE MODE menu item.

•Press to select the SETUP screen.

•Press

F

to invoke the menu where the SYSTEM menu item is highlighted.

•Press to select the SYSTEM screen.

•Press to highlight the Parameters entry.

•Press to select the ENTER UNLOCK PARAM parameter entry.

•Enter the password 1357 and press . Parameters are now unlocked and can be

changed. Press

Print

Clr

once to return to the SETUP screen or twice to return to the

NORMAL screen. Please see below in section –Enter values, page 12, for details on

how to enter values (like the password).

12

WWW.EILERSEN.COM

The status automatically returns to LOCKED after 5 minutes without keyboard activity in

NORMAL screen or when the terminal is power-cycled.

–Enter values

Perform these steps to enter a new parameter value:

•Unlock parameters as described in the above section.

•Use the menus to select the screen where the value is displayed.

•Use and/or to highlight the parameter.

•Press to start entering a new value.

Entry using selection list

Some parameters (such as resolution and decimal point position) are entered using a selec-

tion list. When change of this type of parameter is requested, a special pull-down menu will

appear with a list of possible values as shown:

The keys can be used as follows:

F

Move the cursor down in this selection list.

Move the cursor up in this selection list.

Move the cursor down in this selection list.

Accept the selected/marked value as the new desired value.

Print

Clr

Abort the entry without change of parameter. This can also be done by selecting

the “CANCEL” entry form the selection list.

Example - Changing resolution from 0.050 to 0.010:

The screen shown above appears once change of resolution is requested from the SETUP

WEIGHING screen by moving the cursor using and so the Resolution parameter is se-

lected and then pressing . In order to change the “Resolution” parameter to 0.010 perform

the following:

•Press and/or repeatedly until 0.010 is selected in the list.

•Press to accept the selection.

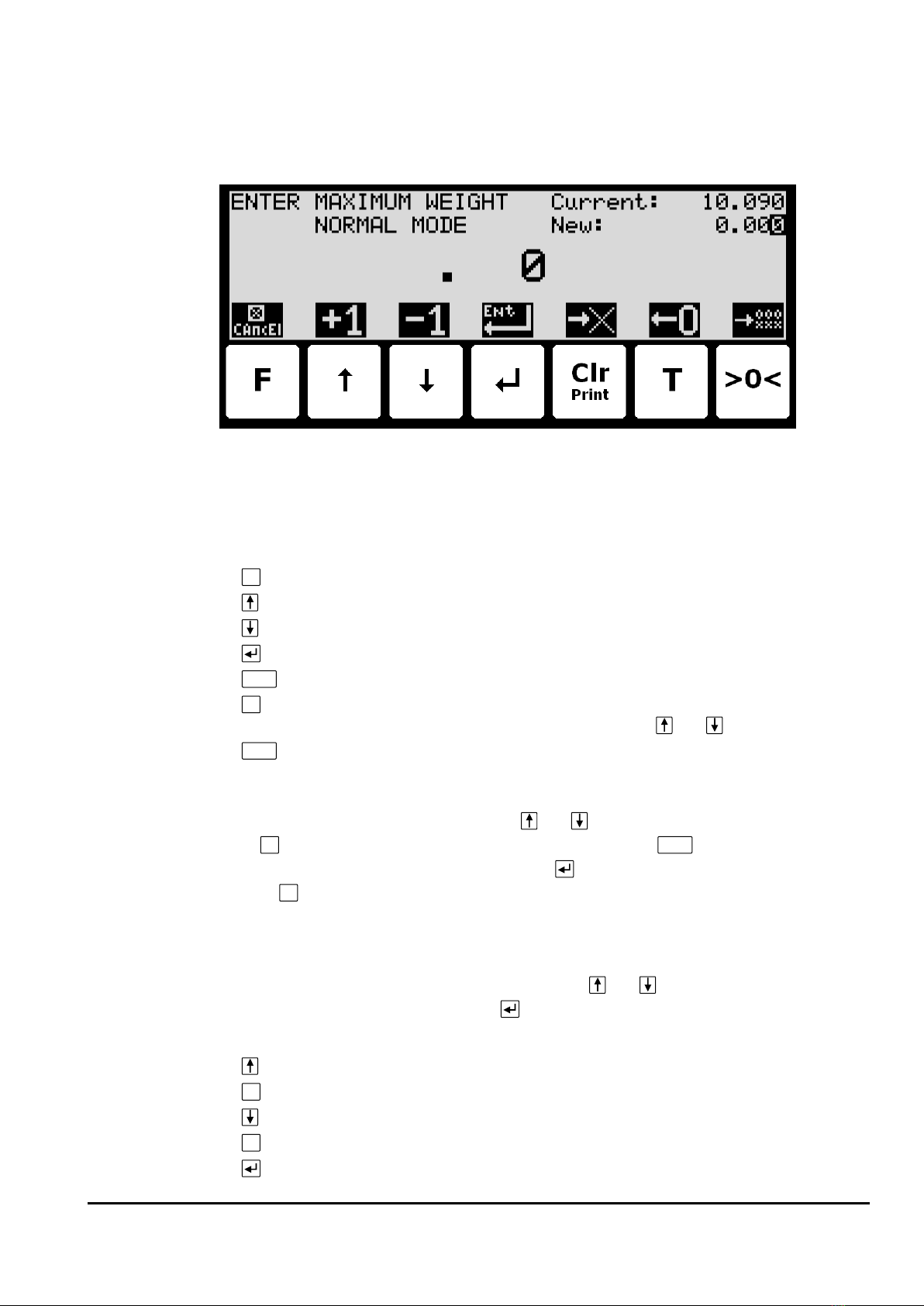

Entry of numbers

Some parameters (such as minimum and maximum weight of the weighing range) are en-

tered using a data entry screen. When change of this type of parameter is requested, a data

13

WWW.EILERSEN.COM

entry screen will appear. Please note the layout of the data entry screen may vary slightly

depending on the actual parameter to be changed. The data entry screen could look as

shown:

The actual parameter changed is indicated in the upper left part of the display. The current

parameter value and the currently entered value is shown in the upper right part of the dis-

play. The currently entered value is also shown in the middle of the display in large font.

The keys can be used as follows:

F

Abort the entry without change of parameter.

Increase the value of the digit currently being entered (digit to the right).

Decrease the value of the digit currently being entered (digit to the right).

Accept the entered value as the new desired value.

Clr

Delete rightmost digit and moves all remaining digits one position to the right.

T

Move digits one position to the left and inserts a zero on the rightmost position.

This new digit can subsequently be changed using and .

>0<

Clears all entered digits setting them to zero as if the data entry screen has just

been entered.

When entering a value the digits are entered left to right. This means that leftmost digit is

entered first. The active digit is changed by and . When the correct value is entered

press

T

to advance to the next digit. If an error is made, press

Clr

to return to the previous

digit. When the complete value is entered press to accept it. To abort without any chang-

es press

F

.

Example - Changing maximum weight from 10.000 to 10.090:

The screen shown above appears once change of maximum weight is requested from the

SETUP WEIGHING screen by moving the cursor using and so the “Maximum” weight

parameter is selected and then pressing .

In order to change the “Maximum” weight parameter to 10.090 perform the following:

Press once until ” . 1” is shown in the display.

T

Press three times until ” 1.000” is shown in the display.

Press once until ” 1.009” is shown in the display.

T

Press once until ” 10.090” is shown in the display.

Press to accept ” 10.090” as the new desired value.

14

WWW.EILERSEN.COM

Example - Changing minimum weight from -1.000 to -0.090:

A similar screen to the screen shown above appears once change of minimum weight is re-

quested from the SETUP WEIGHING screen by moving the cursor using and so the

“Minimum” weight parameter is selected and then pressing .

In order to change the “Minimum” weight parameter to -0.090 perform these steps:

Press once until ”-. 9” is shown in the display.

T

Press once until ”-. 90” is shown in the display.

Press to accept ”-0.090”as the new desired value.

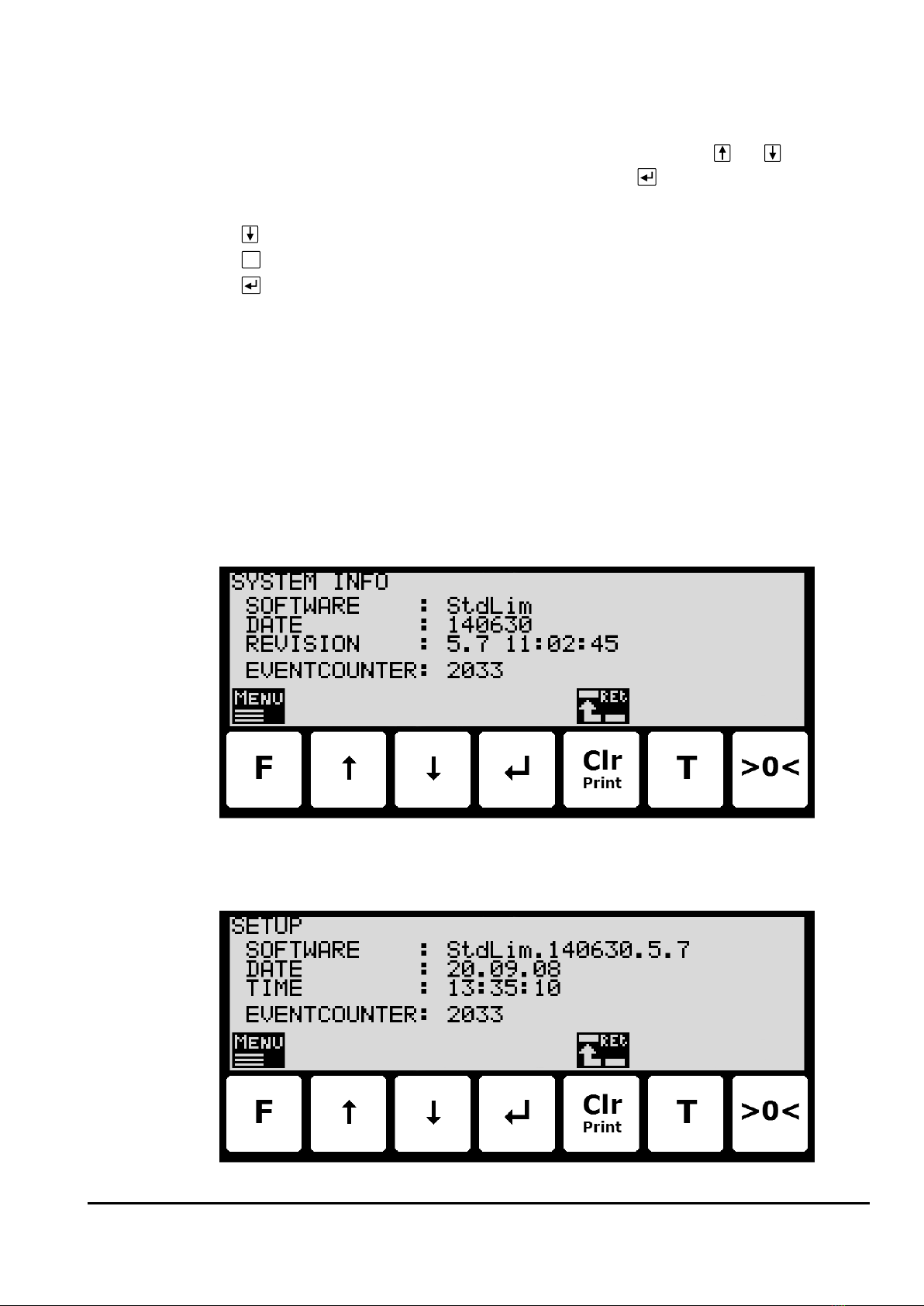

–Check the software version

The software version can be checked during the power-on sequence or in the SYSTEM INFO

or SETUP screen. When power is applied to the system, the following will happen:

•The display will show the logo for 5 seconds.

•The display will show the software version (software name, date and revision).

•The weighing terminal is ready and enters the NORMAL screen.

Select the SYSTEM INFO screen to read the software version (software name, date and revi-

sion):

The SETUP screen also shows the software version (software name, date and revision):

15

WWW.EILERSEN.COM

–Activate Intelligent Setup

With reference to installation of the weighing system, the weighing terminal has a build-in in-

telligent setup feature, that automatically comes with suggestions to configuration of the

weighing technical parameters. If this feature is to be used, it can be activated/started by

performing the following:

•From the NORMAL screen press

F

to activate the menu system, and select SERVICE

MODE menu item to enter the SETUP screen.

•From the SETUP screen press

F

to activate the menu system, and select SYSTEM

menu item to enter the SETUP SYSTEM screen.

•Unlock the parameters for change by entering the password as described earlier.

•Press

F

to activate the menu system, and select INTELLIGENT SETUP menu item to

enter the INTELLIGENT SETUP screen.

•NOTE: Refer to the separate ’Intelligent Setup’manual for further information re-

garding this feature.

–Set up the load cell configuration

To set up the load cell communication protocol type, number of load cells and supports

please follow these steps:

•From the NORMAL screen select the SERVICE MODE menu item to reach the SETUP

screen.

•From the SETUP screen select the WEIGHING menu item to reach the SETUP WEIGH-

ING screen.

•From the SETUP WEIGHING screen select the LOAD CELLS menu item to reach the

Load cell parameters screen.

•Enter the correct values for load cell communication protocol type, number of load

cells and supports, or detect this automatically from the menu.

•Please notice: The terminal must be power-cycled and the load cells must be con-

nected before changes take effect!

16

WWW.EILERSEN.COM

Load cell communication protocol type

The weighing terminal can be connected to and communicate with different kinds of load

cells from Eilersen Electric. Depending on load cells and how they are connected, the weigh-

ing terminal can communicate with the load cells using the following load cell protocols:

•2010: Load cells connected using MCE2010 (StdBB protocol).

•401x: Load cells connected using 4015 connection module.

•4x40-StdBB: Load cells connected using 4x40 unit (StdBB protocol).

•4x40-StdLC: Load cells connected using 4x40 unit (StdLC protocol).

Please notice: Therefore, selection of protocol type must also take into consideration, the

software version in the used load cell modules (MCE2010/4x40).

Number of load cells

The weighing terminal can be connected to a maximum of 16 load cells.

Number of supports

The actual number of supporting points must be in the range 1-16. Note that it is the total

number of supporting points including corners supported by load cells. As an example, the

Supports parameter should be 3 in a system consisting of a three legged tank.

–Detect the load cell configuration

To detect load cell protocol, number of load cells and number of supports the following is

performed:

•Use the screens and menu system to select the LOAD CELLS screen.

•Press

F

to invoke the LOAD CELL PAR. menu.

•Press to select the DETECT LOAD CELL PROTOCOL or DETECT NUMBER OF LOAD

CELLS menu item.

•Press to perform the selected action, and follow the instructions in the following

screens.

Please notice:The load cells must be connected for the above detection to work correctly.

17

WWW.EILERSEN.COM

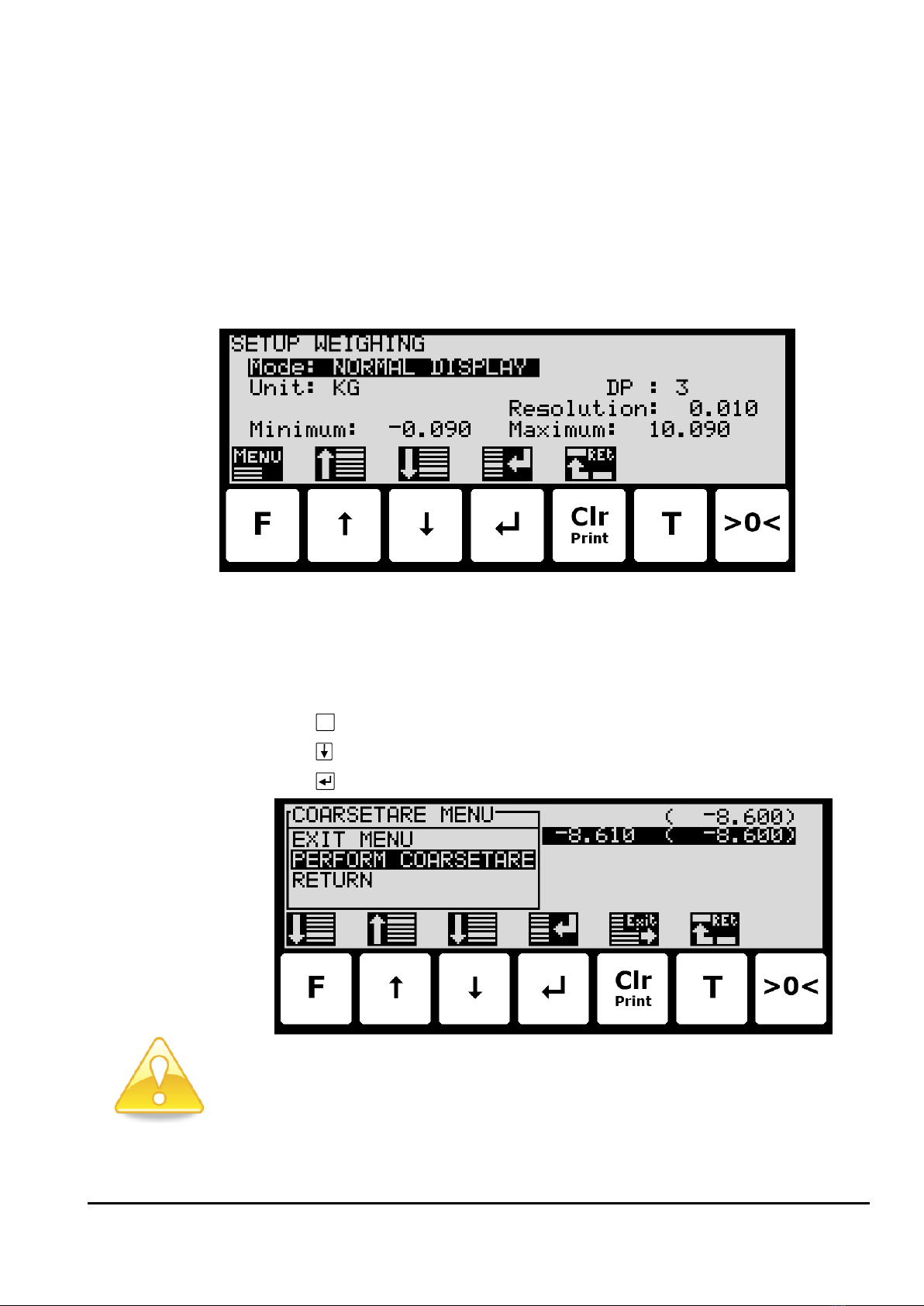

–Configure the weighing ranges

The weighing terminal is equipped with three different weighing range modes that specify

the weighing range used for:

NORMAL: Weight readings during normal display reading.

CALIBRATION: Weight readings during calibration and enhanced/high resolution weight

display.

PROTOCOL: Weight readings transferred using communication protocols.

Using the screens and menu system as described above in section Operate the menu system,

page 10 select the WEIGHING screen to configure the three weighing ranges:

–Perform coarse taring

To coarse tare the system follow these steps:

•Use the screens and menu system to select the COARSETARE screen.

•Press

F

to invoke the COARSETARE menu.

•Press to select the PERFORM COARSETARE menu item.

•Press to perform a coarse tare.

Please notice: Coarse taring should only be done when the system is empty!

18

WWW.EILERSEN.COM

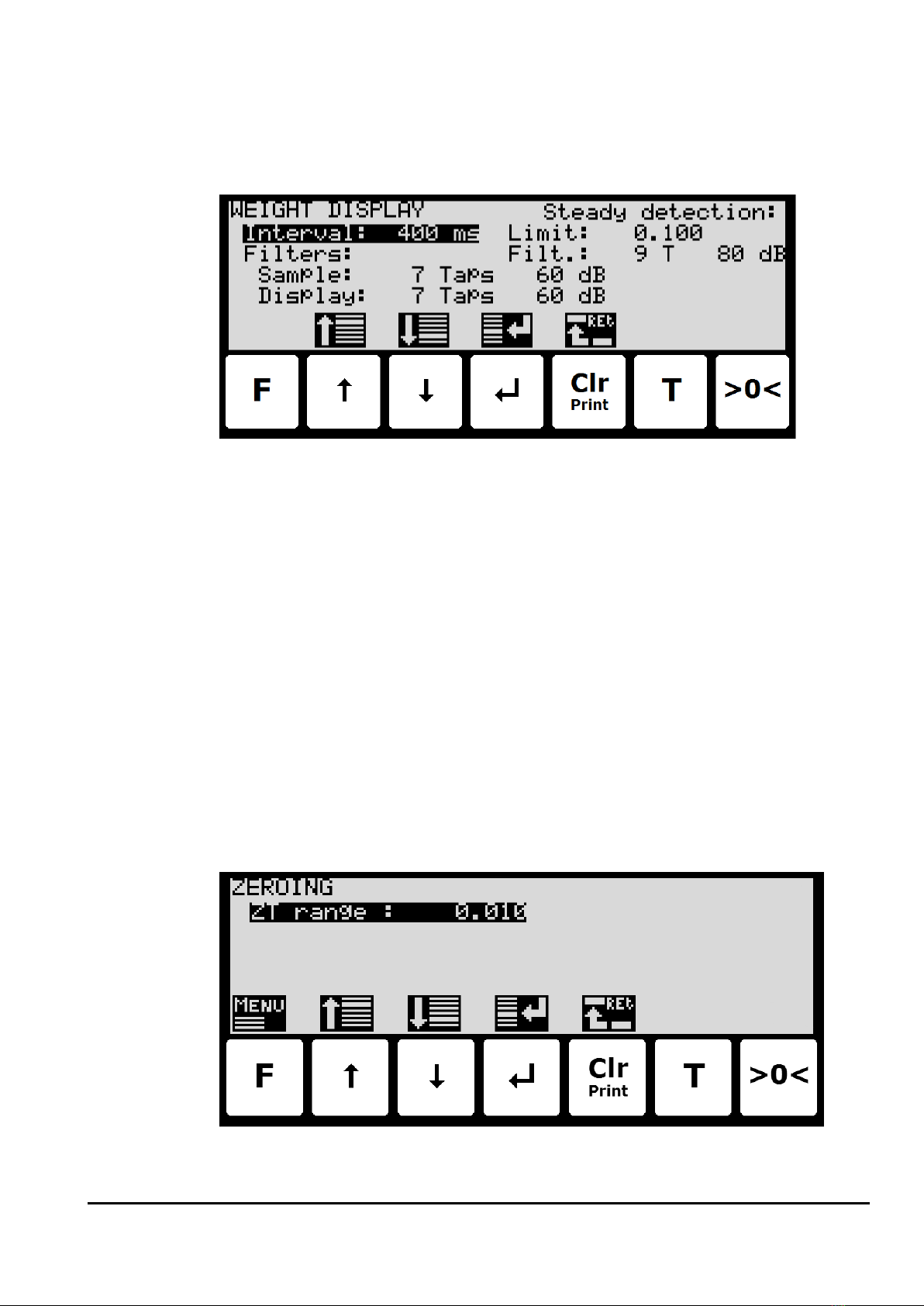

–Configure display, filtering and stability requirement

To configure display update rate, filtering and stability requirement, select the WEIGHT DIS-

PLAY screen:

Interval

The interval between each update of the weight indication is entered in milliseconds (ms). A

small value results in fast update of the display reading, while a larger value results in a more

steady display reading. A good starting/default value is 400 ms.

Filters

Two types of filters can be applied: A filter on each sampling from the load cell and/or a filter

on each display weight reading update. The sampling frequency depends on the load cell

communication formats and number of load cells and the weight display reading update rate,

as described below in section Appendix D –Filters, page 35.

Steady/stability detection

The weight is considered stable when the readings are within the limit entered here. The

weight ready used for steady detection is filtered with the filter entered here. The steady de-

tection filter works like the display filter.

–Configure zero tracking

To configure the zero tracking range, select the ZEROING screen:

19

WWW.EILERSEN.COM

–Change reading to high resolution mode

High resolution mode changes the display reading to the enhanced resolution entered as the

CALI weighing range. This can be done in two ways:

•Press in the NORMAL screen. This will select high resolution mode for 3 seconds

(assuming the High res. mode parameter in the SETUP SYSTEM screen is set to DISA-

BLED). The symbol above will flash while high resolution is active.

•In the SETUP SYSTEM screen, change the High res. mode parameter to ENABLED

(this can only be done when parameters are unlocked). Now when pressing in the

NORMAL screen high resolution mode will be selected until is pressed again. The

symbol above will flash while high resolution is active.

–Perform load check

When checking the weight reading please observe these points:

•Use different loads; small and near the maximum load.

•Do not place the full load on the corners.

•Use approx. 1/3 of full load to check the corners.

•Use High resolution mode for a more accurate reading.

–Perform corner calibration

Please notice: Corner calibration is only necessary in system with more than one load cell.

Corner calibration is not possible when there are more supports than load cells and should

only be used in weighing systems where system mechanics shows non ideal behavior regard-

ing load in the corners.

20

WWW.EILERSEN.COM

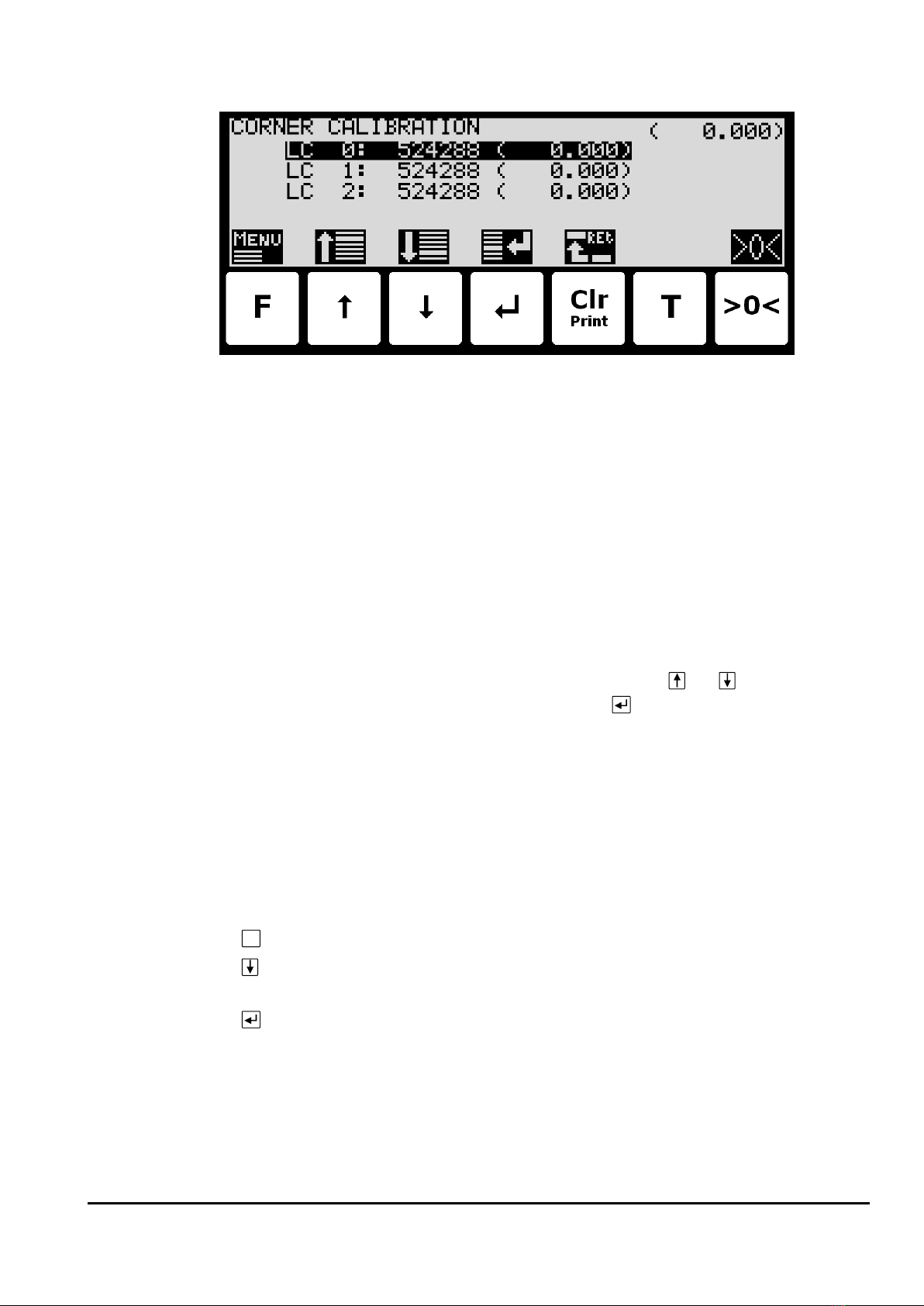

Use the CORNER CALIBRATION screen to perform a corner calibration if necessary.

In this screen corner calibration parameters such as corner calibration factor, and actual load

on corresponding load cell is shown on one line for each load cell. The actual gross weight is

shown in the upper right corner. This makes it possible to manually enter the corner calibra-

tion factor for each load cell. From the CORNER CAL. menu it is possible to select the COR-

NER CAL. PROC. screen for corner calibration of the system. It is also possible to reset the

corner calibration factors to default values from the menu. A cursor (inverted text) indicates

the currently selected parameter.

Corner calibration factor

The corner calibration factors can be changed/specified in the CORNER CALIBRATION screen

by performing a calibration of the corners by switching to the CORNER CAL. PROC. screen as

described below or by manually entering a new factor.

The corner calibration factors can be manually changed by using and to select the de-

sired load cell/corner with the cursor, and then pressing to request change of the selected

corner calibration FACTOR parameter. This is useful when a previous calibration must be re-

established. Note that this is only possible, if the calibration factor for this previous calibra-

tion is known. The standard calibration factor is 524288. If this value is changed 1% (up or

down), the signal from that load cell/corner will also change 1% (up or down).

Reset corner calibration factors

It is possible to reset the corner calibration factors to default values (524288) by using the

CORNER CAL. menu. To perform a reset of corner calibration factors from the CORNER CALI-

BRATION screen use these steps:

F

Press once to select the CORNER CAL. menu.

Press once to select the “RESET CORNER CAL. FACTORS” entry from the CORNER

CAL. menu.

Press once to perform the reset of the corner calibration factors.

Corner calibration procedure

It is possible to perform an automatic corner calibration of the system by selecting the COR-

NER CALIBRATION PROCEDURE screen from the CORNER CAL. menu.

Other manuals for 5024G

3

Table of contents

Popular Accessories manuals by other brands

NATURE & DECOUVERTES

NATURE & DECOUVERTES 60158450 manual

A-oneTech

A-oneTech AIR HALO user manual

Omnicom

Omnicom LLS-Ex 5 manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS HT640B71 Installation and operating manual

Xylem

Xylem WTW NiCaVis 705 IQ TS operating manual

Renishaw

Renishaw RMP60 installation guide