BST CLS Pro 600 User manual

Web Guiding System

Installation and

Operating Manual

CLS Pro 600

Line and Contrast Sensor

MD.323.EN.08

Translation of the Original Manual

BST eltromat International GmbH

Heidsieker Heide 53

D-33739 Bielefeld

Tel.: +49 (0) 5206 999 0

Fax: +49 (0) 5206 999 999

E-Mail: [email protected]

Internet: www.bst-eltromat.com

This documentation is protected by copyright. The translation as well as reproduction and distribution in any form is forbidden without the approval

of the rights holder and will be pursued under civil and criminal law. Technical modifications reserved.

Table of contents

CLS Pro 600 – Line and Contrast Sensor iii

Table of contents

1 About This Document........................................................................................ 6

1.1 What You Need to Know............................................................................................... 6

1.2 Target Group................................................................................................................. 6

1.3 Storage and Distribution............................................................................................... 6

1.4 Meanings of the Safety Instructions and Symbols........................................................ 6

1.4.1 Safety Instructions ........................................................................................................ 6

1.4.2 Symbols......................................................................................................................... 7

1.4.3 Operation Using Keys.................................................................................................... 7

1.5 More Detailed Information........................................................................................... 7

2 Description ....................................................................................................... 8

2.1 General Information ..................................................................................................... 8

2.2 Intended Use................................................................................................................. 8

2.3 System Description ....................................................................................................... 9

2.3.1 System Design............................................................................................................... 9

2.3.2 Functional Principle..................................................................................................... 10

2.4 Terms Used in this Manual ......................................................................................... 12

2.4.1 General Information ................................................................................................... 12

2.4.2 Set Position ................................................................................................................. 13

2.4.3 Measuring Range ........................................................................................................ 14

2.4.4 Search Area................................................................................................................. 14

2.4.5 Status Bar.................................................................................................................... 15

2.4.6 Footer.......................................................................................................................... 15

2.4.7 First Edge / Second Edge............................................................................................. 15

2.5 Control Panel .............................................................................................................. 16

2.5.1 Graphic Display ........................................................................................................... 16

2.5.2 Control Panel .............................................................................................................. 16

2.6 Safety Information ...................................................................................................... 17

2.7 Laser............................................................................................................................ 19

2.8 Emissions..................................................................................................................... 19

3 Assembly .........................................................................................................20

3.1 Installation Site Requirements.................................................................................... 20

3.2 Sensor Installation ...................................................................................................... 20

3.2.1 General Information ................................................................................................... 20

3.2.2 Sensor with supplied holder ....................................................................................... 20

3.2.3 Installing the Sensor Using a Holder Supplied by the Customer................................. 21

3.2.4 Setting the Gap Between the Sensor and the Sensing Roller ..................................... 22

3.2.5 Turning the Control Panel........................................................................................... 22

3.2.6 Rotating the Control Panel.......................................................................................... 24

3.3 Installing the Control Panel......................................................................................... 25

3.3.1 General Information ................................................................................................... 25

3.3.2 Dismantling the Holder............................................................................................... 25

3.3.3 Wall Mounting ............................................................................................................ 27

3.3.4 Console Installation..................................................................................................... 31

4 Installation.......................................................................................................35

4.1 Fitting the Cable Connections..................................................................................... 35

4.2 Sensor ......................................................................................................................... 35

4.2.1 Enclosure Sockets ....................................................................................................... 35

4.3 Service Indicator Displays ........................................................................................... 36

4.3.1 Bus Status LEDs ........................................................................................................... 36

4.3.2 Unit Status LED............................................................................................................ 37

4.4 Setting the DIL Switches.............................................................................................. 37

5 Commissioning.................................................................................................38

5.1 Menus ......................................................................................................................... 39

Table of contents

iv CLS Pro 600 – Line and Contrast Sensor

5.1.1 General Information ................................................................................................... 39

5.1.2 Input Options .............................................................................................................. 39

5.1.3 Main Menu.................................................................................................................. 41

5.2 Commissioning With a Controller ............................................................................... 43

5.2.1 ekrPro Com60 ............................................................................................................. 43

5.2.2 ekr 500 Plus / ekr 500 digital ...................................................................................... 44

5.2.3 EKR 1500 / CCD Line Guider and C2M Coupler........................................................... 44

6 Operation ........................................................................................................45

6.1 General Information ................................................................................................... 45

6.2 Operating Display........................................................................................................ 45

6.2.1 Setup Mode Display Window...................................................................................... 45

6.2.2 Scanning Mode Display Window................................................................................. 47

6.2.3 Status Bar.................................................................................................................... 48

6.3 Remote Control of ekrPro Com60 / ekr 500 Plus / ekr 500 digital Controllers........... 48

6.3.1 Manual Mode.............................................................................................................. 49

6.3.2 Automatic ................................................................................................................... 49

6.3.3 Servo Center Position.................................................................................................. 49

6.3.4 Moving the Set Point Position (W-value).................................................................... 50

6.3.5 Moving the Guiding Device......................................................................................... 50

6.3.6 Setting the Controller Gain ......................................................................................... 50

6.4 Operation.................................................................................................................... 51

6.4.1 General Information ................................................................................................... 51

6.4.2 Activating Line Setup / Edge Setup ............................................................................. 51

6.5 Standard Operation .................................................................................................... 51

6.5.1 Selecting a Job............................................................................................................. 51

6.5.2 Edge Setup Mode........................................................................................................ 52

6.5.3 Line Setup Mode......................................................................................................... 54

6.6 Extended Operation.................................................................................................... 56

6.6.1 Change User................................................................................................................ 56

6.6.2 Job Administration...................................................................................................... 57

6.6.3 Assigning User Levels to the Parameters.................................................................... 58

6.6.4 Setting up Quick Menus.............................................................................................. 59

6.6.5 Setup Administration .................................................................................................. 60

6.7 Main Menu Parameter Meanings............................................................................... 61

6.7.1 Configuration .............................................................................................................. 61

6.7.2 Parameter ................................................................................................................... 68

6.7.3 Remote Control EKR.................................................................................................... 75

6.7.4 Display......................................................................................................................... 76

6.7.5 System Info ................................................................................................................. 77

7 Factory Default Settings ...................................................................................78

7.1 Device Addresses ........................................................................................................ 78

7.1.1 Sensor Device Address................................................................................................ 78

7.1.2 Control Panel Device Address..................................................................................... 79

7.2 Terminator Resistors................................................................................................... 80

7.2.1 Sensor Terminator Resistors....................................................................................... 80

7.2.2 Control Panel Terminator Resistor.............................................................................. 81

7.3 Restoring Factory Default Settings.............................................................................. 82

8 Troubleshooting / FAQ.....................................................................................83

9 Technical Data .................................................................................................84

9.1 Sensor ......................................................................................................................... 84

9.1.1 Environmental Conditions .......................................................................................... 84

9.1.2 Power Supply .............................................................................................................. 84

9.1.3 Digital Inputs............................................................................................................... 84

9.1.4 Digital Outputs............................................................................................................ 84

9.1.5 Analogue Output......................................................................................................... 84

9.1.6 Measuring Window Cover .......................................................................................... 85

Table of contents

CLS Pro 600 – Line and Contrast Sensor v

9.1.7 Control Panel Interface............................................................................................... 85

9.1.8 Weight / Dimensions .................................................................................................. 85

9.2 Control Panel .............................................................................................................. 85

9.2.1 Environmental Conditions .......................................................................................... 85

9.2.2 Power Supply .............................................................................................................. 85

9.2.3 Display......................................................................................................................... 85

9.2.4 Weight / Dimensions .................................................................................................. 85

9.2.5 Space Requirement (Details in mm) ........................................................................... 86

9.2.6 Plug Assignment.......................................................................................................... 88

10 Maintenance....................................................................................................90

10.1 General Information ................................................................................................... 90

10.2 Sensor ......................................................................................................................... 90

10.3 Control Panel .............................................................................................................. 90

11 Transport / Storage..........................................................................................91

11.1 Transport..................................................................................................................... 91

11.2 Storage........................................................................................................................ 91

12 Decommissioning.............................................................................................92

Index................................................................................................................93

A Appendix 1 - Commissioning as a Stand-Alone System .....................................95

A1 Blockage...................................................................................................................... 95

A2 Control Signal.............................................................................................................. 95

A3 Commissioning............................................................................................................ 95

A4 Configuring the Guiding Block Output ........................................................................ 96

A5 Defining the Mounting Position.................................................................................. 97

B Appendix 2 - Saving Parameters and Loading Firmware....................................98

B1 Save Parameters ......................................................................................................... 98

B2 Loading Firmware ....................................................................................................... 98

B2.1 Loading Sensor Firmware............................................................................................ 99

B2.2 Loading Panel Firmware.............................................................................................. 99

C Appendix 3 - Factory Default Settings.............................................................100

D Appendix 4 - BST eltromat STB 1 Connections ................................................104

D1 Installation Instructions For EMC-Wiring.................................................................. 105

E Appendix 5 - Teach-in Template .....................................................................107

E1 Aligning the Teach-In Template in Front of the CLS Pro 600 .................................... 108

1About This Document

6/108 CLS Pro 600 – Line and Contrast Sensor

1 About This Document

1.1 What You Need to Know

These instructions help you to work with the system in a safe,

simple and successful manner.

The following instructions must be observed in order to avoid haz-

ards and incorrect operation:

■Every user must have read these instructions in full before

working with or on the system.

■Every user must follow the safety information in these instruc-

tions.

1.2 Target Group

These instructions are directed to all persons that work with or on

the system. The operating company of the entire system and su-

pervising personnel must also be familiar with these instructions.

1.3 Storage and Distribution

These instructions must be stored at the workplace in such a man-

ner that the user has access to them at all times.

These instructions and all other applicable documents are a com-

ponent of the product and must be handed over to the operating

company of the system.

1.4 Meanings of the Safety Instructions and Symbols

1.4.1 Safety Instructions

DANGER

Danger that will lead to death or severe injuries!

►Here you can find how to avoid the danger.

WARNING

Danger that may lead to death or severe injuries!

►Here you can find how to avoid the danger.

CAUTION

Danger that may lead to medium or minor injuries!

►Here you can find how to avoid the danger.

NOTICE

Danger that may lead to damage to assets!

There is no risk of injury.

►Here you can find how to avoid the danger.

About This Document 1

CLS Pro 600 – Line and Contrast Sensor 7/108

1.4.2 Symbols

Information that is essential for successful operation.

Information that makes operation easier.

Action requirements may include the following symbols:

›› Requirements that must be fulfilled for the action steps.

1. Requirement for you to take actions. And ...

2. …in the sequence specified.

►Requirement for you to take actions - without any certain se-

quence.

1.4.3 Operation Using Keys

Operations using the keys are indicated by the following symbols:

►Press key ①.

►Press key ① or key ②.

►Press key ① and key ② at the same time.

1.5 More Detailed Information

►Observe the accompanying documents (e.g. order confirma-

tion) for this system and the operating instructions of the en-

tire system.

The latest version of these instructions can be obtained in all

available languages at:

www.bst-eltromat.com

2Description

8/108 CLS Pro 600 – Line and Contrast Sensor

2 Description

2.1 General Information

WARNING

Please note:

The start-up, maintenance and installation instructions described

in this operating manual must be strictly adhered to!

You are only permitted to install and commission theCLS Pro

600line and contrast sensor after you have read the accompany-

ing operating manual. This will help to avoid hazards and prevent

the sensors from being damage due to improper installation or

operation.

Everyone working on or with theCLS Pro 600sensor must abide by

this operating manual and the safety instructions in particular.

You must read, without fail, the safety instructions given in

Chapter 2.6 of this operating manual prior to starting the installa-

tion and commissioning work!

Solely BST-eltromat staff or other persons specifically authorized

by BST-eltromat are permitted to modify or add to the firmware

of this sensor. Ignoring this warning might result in the warranty

rights being invalidated.

The settings and details shown in this operating manual (e.g. in

the display screens) are given as examples only, unless the text ex-

plicitly states otherwise.

The latest version of the operating manual for the CLS Pro 600line

and contrast sensor can be obtained via the Internet in all avail-

able languages under the following address:

http://www.bst-eltromat.com

2.2 Intended Use

The CLS Pro 600 is a microprocessor controlled line and contrast

sensor with a removable control panel. It must only be used for:

■Guiding on continuous or interrupted printed lines

■Guiding over continuous or interrupted printed edges

■Web edges

The CLS Pro 600 line and contrast sensor has been designed to be

fitted in another machine or to be combined with other machines

to form a complete machine in the sense of the Directive

2006/42/EC (machine directive). Start-up of the system is forbid-

den until the user / operator has determined that the machine, in

which the system is installed, conforms to the conditions of this

directive.

Description 2

CLS Pro 600 – Line and Contrast Sensor 9/108

The CLS Pro 600line and contrast sensor is an integral part of our

BST-eltromat web guiding systems. You are only allowed to use

BST-eltromat web guiding systems to correct the position of web-

shaped materials (e.g. those made from paper, film, cardboard,

rubber, etc.). The sensor and the control panel must never in be

installed and used in potentially explosive areas.

BST-eltromat web guiding systems have been designed and built

in accordance with state-of-the-art standards and the recognized

safety regulations.

Nevertheless, its use may constitute a risk to life and limb of the

user or of third parties or damage the BST-eltromat web guiding

systems and other equipment. Therefore BST-eltromat web guid-

ing systems are only to be used if they are working correctly and

in a technically safe condition. Any part found to be working incor-

rectly must be replaced immediately. Only original spare parts are

to be used for this. Spare parts obtained from third parties cannot

be guaranteed to comply with the design and manufacturing con-

ditions and safety regulations. In this case any guarantee claims

made against the BST-eltromat web guiding system will be invalid-

ated. Only qualified personnel who have been trained on the sys-

tem are allowed to undertake any work required on the BST-eltro-

mat web guiding system (i.e. installation, commissioning, opera-

tion, maintenance, etc.). Intended use also includes adhering to

the instructions given in this operating manual. Use for any pur-

pose other than those mentioned above is considered as contrary

to the intended use. BST eltromat International GmbH does not

accept liability for any damage resulting from this type of use.

2.3 System Description

2.3.1 System Design

General Information

The CLS Pro 600 consists of the sensor and the removable control

panel.

The sensor enclosure holds the entire electronics and the control

panel and controller connections.

Sensor with Fitted Control Panel

The sensor is operated via the control panel, which is fitted to the

sensor in the factory. The control panel is pivotable.

2Description

10/108 CLS Pro 600 – Line and Contrast Sensor

Fig.1: Sensor with fitted control panel

Sensor with Removable Control Panel

If necessary (i.e. if the sensor is installed in a difficult to access po-

sition on the machine) the control panel can be removed and in-

stalled in a central control console or a customer-supplied control

station. In this case the connection between the sensor and con-

trol panel is completed using a cable extension that is available as

an optional extra.

Sensor

Control Panel

Cable Extension

(2 m, 5 m, 10 m)

Fig.2: Sensor with control panel removed

NOTICE

Please note:

The length of the connection cable between the sensor and the

control panel must never exceed 20 m (maximum).

2.3.2 Functional Principle

The sensor records the actual position of a line or a contrast trans-

ition point on the material web in automatic mode and then trans-

mits the relevant information to the interconnected controller.

The controller compares the actual recorded position against the

default set point position. A relevant correction signal will be sent

to the guiding device’s actuator if a deviation is found to exists

between the two values. The actuator will drive the guiding device

(rotating frame or swivelling roller guide) until the material web

returns to its set point position.

The CLS Pro 600 sensor can be used in the following configura-

tions:

Description 2

CLS Pro 600 – Line and Contrast Sensor 11/108

Stand-Alone Mode:

Customer's machine

controller

Sensor CLS Pro 600

with control panel

BST eltromat Signal

Terminal Box1

Fig.3: Stand-Alone Mode

Application with ekrPro Com60 controller:

Customer's

machine

controller

Sensor CLS Pro 600

with control panel

BST eltromat Signal

Terminal Box1 (optional)

CAN bus connection

(optional)

Fig.4: Application with ekrPro Com60 controller

Application with ekr 500 digital controller:

Customer's

machine

controller

Sensor CLS Pro 600

with control panel

BST eltromat Signal

Terminal Box1 (optional)

CAN bus connection

(optional)

Fig.5: Application with ekr 500 digital controller

2Description

12/108 CLS Pro 600 – Line and Contrast Sensor

Application with EKR 1500 / CCD line guider as CCD 2004 replacement:

Sensor CLS Pro 600

with control panel

(from software version 1.8.1)

CAN – Module bus coupler

EKR 1500

CCD Line Guider

Fig.6: Application with EKR 1500 / CCD line guider as CCD 2004 replacement

2.4 Terms Used in this Manual

2.4.1 General Information

In principle, the windows displayed on the keyboard’s graphics

display are laid out as follows:

Fig.7: Display Layout

①Status Bar

②Footer

Description 2

CLS Pro 600 – Line and Contrast Sensor 13/108

③Display Area

The content shown in this area depends on the mode set-

ting. Detailed descriptions can be found in Section 6.2.1 for

the setup mode and in Section 6.2.2 for the scanning mode.

2.4.2 Set Position

The set position is the required line / contrast transfer point posi-

tion in the sensor scanning area. It can be set up in Automatic

mode using the control panel’s arrow keys (see Chapter 6.3.2).

The set point position will be indicated by a white triangledis-

played on the control panel’s screen.

Fig.8: SET POINT Position without deviation

①Center of Measuring Range

②Contrast Quality (graphical)

③Standard SET Position

The deviation will be faded in as plaintext during displacement of

the set position. The deviation can take positive values and negat-

ive values as well.

2Description

14/108 CLS Pro 600 – Line and Contrast Sensor

Fig.9: Deviation of the SET POINT Position

④Standard SET Position

⑤Numeric Indication of the Deviation

⑥Center of Measuring Range

The contrast quality will be graphically displayed in the bottom

section of the window.

2.4.3 Measuring Range

The sensor’s measuring range is 25 x 3 mm (W x H).

Fig.10: Measuring Range

2.4.4 Search Area

The search area is a section within the measuring area. The line /

edge that has to be evaluated and controlled afterwards is located

in this section.

Description 2

CLS Pro 600 – Line and Contrast Sensor 15/108

2.4.5 Status Bar

The actual sensor status and the controller’s actual operating

status are both displayed in the status bar. See Section 6.2.3 as

well regarding this.

The controller details are not displayed in the stand-alone version.

2.4.6 Footer

Operating help is integrated in the footer. This tells you when op-

timisations can be implemented in the displayed window or what

the actual setting of the selected parameter is and how it can be

configured.

2.4.7 First Edge / Second Edge

The edge that will be controlled afterwards can be defined for the

line scanning process. First Edge and Second Edge are both avail-

able for use as options.

The edge position on the left of the display must be used for set-

ting up the First Edge.

Fig.11: First Edge / Second Edge

①First Edge

②Second Edge

The second edge is used for setting up the Second Edge

2Description

16/108 CLS Pro 600 – Line and Contrast Sensor

2.5 Control Panel

Fig.12: Control Panel

The control panel contains all of the display and operating con-

trols needed to operate the CLS Pro 600.

2.5.1 Graphic Display

Different parameters as well as main and quick menus (depending

on the mode selected) are displayed on the control panel’s screen

during operation.

The meaning of the individual symbols is described in chapter 6.2.

2.5.2 Control Panel

Three different groups of keys are integrated in the control panel

and they have the following functions:

SETUP Keys Used to select setup mode

Blue Keys:

Used to access the menu; import the

parameters or exit the parameter enter-

ing process

Arrow Keys: Used to enter settings as shown in the

operating help page

You will find the separate key meanings listed in the table on the

following page.

Description 2

CLS Pro 600 – Line and Contrast Sensor 17/108

Function Key Designation Description

Setup

Mode

Edge SETUP

Calls up the edge guid-

ing setup mode (only

possible in MAN

mode)

Line SETUP

Calls up the line guid-

ing set-up mode (only

possible in MAN

mode)

Arrow Keys

Used to enter settings

as shown in the oper-

ating help page

ENTER

■Imports the mode /

parameter settings

■Exit the Setup mode

ESC Aborts the parameter

entering process

Menu

MENU

Calls up or exits the

quick menus (the key

must be held down for

at least 3 seconds to

call up the menu)

Right Arrow

Key

Used to enters a sub-

menu or parameter

Left Arrow

Key

Pages back by one

menu level (does not

exit the menu)

ENTER

Used to open a sub-

menu or select a para-

meter

ESC

Pages back by one

menu level and might

also close the menu

2.6 Safety Information

The safety relevant information in accordance with DIN EN ISO

13857, DIN EN 349 and the industry specific accident prevention

regulations must always be taken into consideration when in-

stalling the BST-eltromat equipment in the production machine,

these include:

■There must always be a safe distance between the BST-eltro-

mat equipment and the machinery already installed on-site,

such as machine panels, building structures, etc.

2Description

18/108 CLS Pro 600 – Line and Contrast Sensor

■Connection lines between the individual system components

must be laid so that nobody can trip over them, not pulled tight

and well anchored down.

■Ensure that there is sufficient free headroom. If the free pas-

sage is restricted, the relevant building components causing

the restrictions must be padded and a danger warning signs

must be affixed to them (yellow / black).

■In principle, if the cable connections are (e.g. between the

sensor and sensors) disengaged then the sensor is no longer

connected to the power supply. Any infringements will result in

the warranty claim being invalidated.

■The sensor has not been ATEX certified, i.e. it is not approved

for use in potentially explosive areas and must never be used in

them!

■Any transport safety devices that were attached to the guiding

device must be removed prior to commissioning.

NOTICE

Please note:

Only trained specialist personnel are permitted to undertake the

assembly, installation and commissioning!

DANGER

Danger of cuts!

Never touch the edges of running material webs.

DANGER

Danger of crushing!

Never reach into the area in between the fixed lower frame and

the guiding device’s moving upper frame (rotating frame or swivel-

ling roller guide). Never reach into the area in between moving

rollers!

DANGER

Caution!

Ensure the equipment is electrically isolated before starting work.

To this end always carry out the following activities:

►Switch off.

►Prevent the device from being restarted.

►Determine that the unit is ‘voltage-free’

►Earth the unit.

►Cover or fence off any adjacent parts that are still live.

ðOnly then can the relevant work be undertaken!

WARNING

Caution!

Do not use the chassis or machine frame as a climbing aid or a ste-

pladder. Do not remove any of the safety devices.

Description 2

CLS Pro 600 – Line and Contrast Sensor 19/108

WARNING

Caution!

Actuator movements will be run by the drive even during function

checks away from the production machine and/or during commis-

sioning. The relevant safety arrangements must implemented dur-

ing performance checks! Monitor the overall safety concept of the

production machine during commissioning!

2.7 Laser

CAUTION

Please note:

A laser is used as a positioning aid when positioning the sensor.

This laser unit has been classified by the manufacturer as a Class 2

laser in compliance with DIN EN 60825-1:2001-11.

This laser will not cause eye damage, even after long radiation

periods and even if other optical tools (lenses, etc.) are used in

the beam’s path.

2.8 Emissions

The A-rated equivalent continuous sound level of the equipment

is less than 70 dB(A).

3Assembly

20/108 CLS Pro 600 – Line and Contrast Sensor

3 Assembly

3.1 Installation Site Requirements

The following points must be taken into consideration when

choosing the sensor and control panels locations:

■The sensor and the control panel must be installed in a dry,

non-vibrating area and be positioned ergonomically. The oper-

ator must be able to access the control panel easily. Ensure

that sunlight or other external light sources do not cause un-

wanted reflections on the screen.

■Strong electro-magnetic fields in the immediate vicinity of the

sensor, the control panel or the sensors can result in malfunc-

tions.

■Take note of the permitted ambient conditions.

Temperature: 0 to max. 45 °C

Humidity: 5 - 90%, no condensation

WARNING

Sensor is not ATEX certified

• The sensor and the control panel have not been ATEX certified,

i.e. they are not approved for use in potentially explosive areas and

must never be used in them!

3.2 Sensor Installation

3.2.1 General Information

This chapter describes the procedure for installing the sensors us-

ing the holders supplied in the package or the connection options

available if using a holder supplied by the customer.

3.2.2 Sensor with supplied holder

A square holder bar has to be used with the holder supplied in the

package for the CLS Pro 600 sensor. Two sizes can be used, 25x25

mm and 35x35 mm. The holder consists of a special holding device

that enables both sizes to be used.

Fit the holding device onto the square holder bar and slide it into

the required position together with the sensor.

Now tighten up the securing bolt to clamp the holding device into

place on the square bar.

See drawing on the next page.

Table of contents

Other BST Accessories manuals

Popular Accessories manuals by other brands

Preco

Preco Wireless PreView WorkSight WWS7220 operating manual

Liebert

Liebert Liqui-tect 300 installation manual

grabner

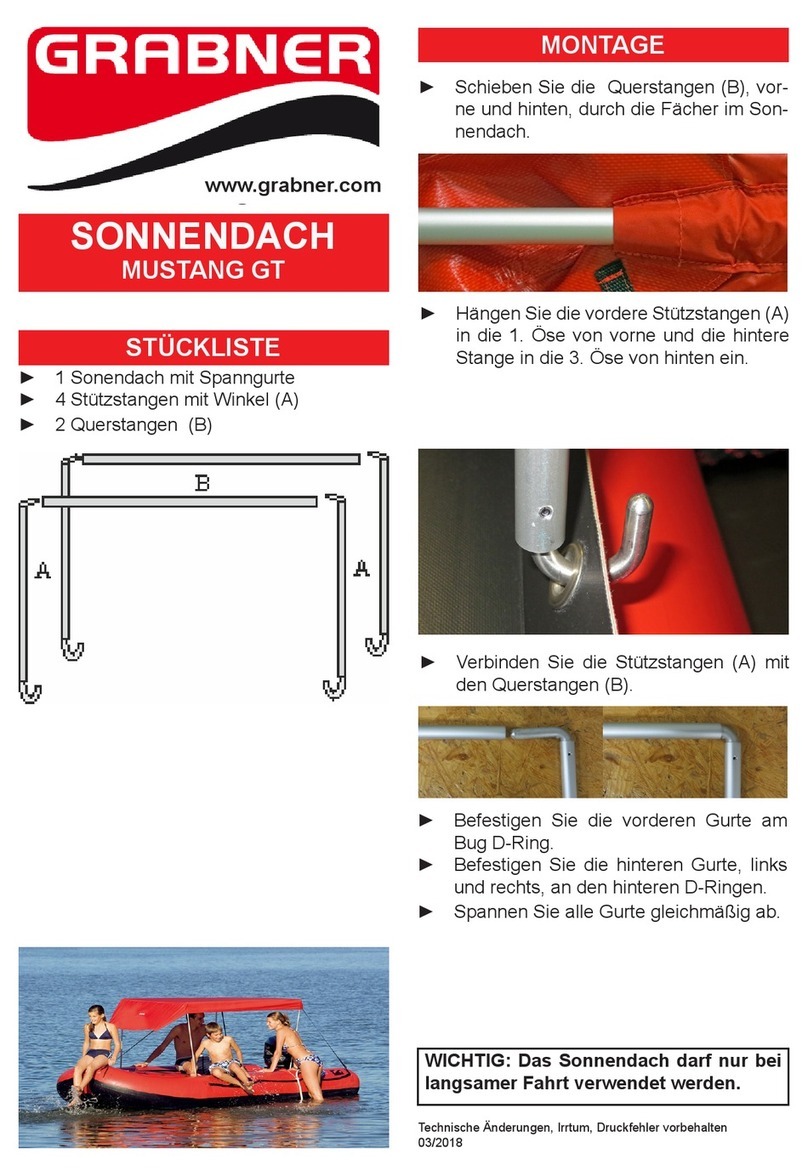

grabner SUN AWNING MUSTANG GT manual

Deuba

Deuba DBHD03 user manual

Sound Performance Lab

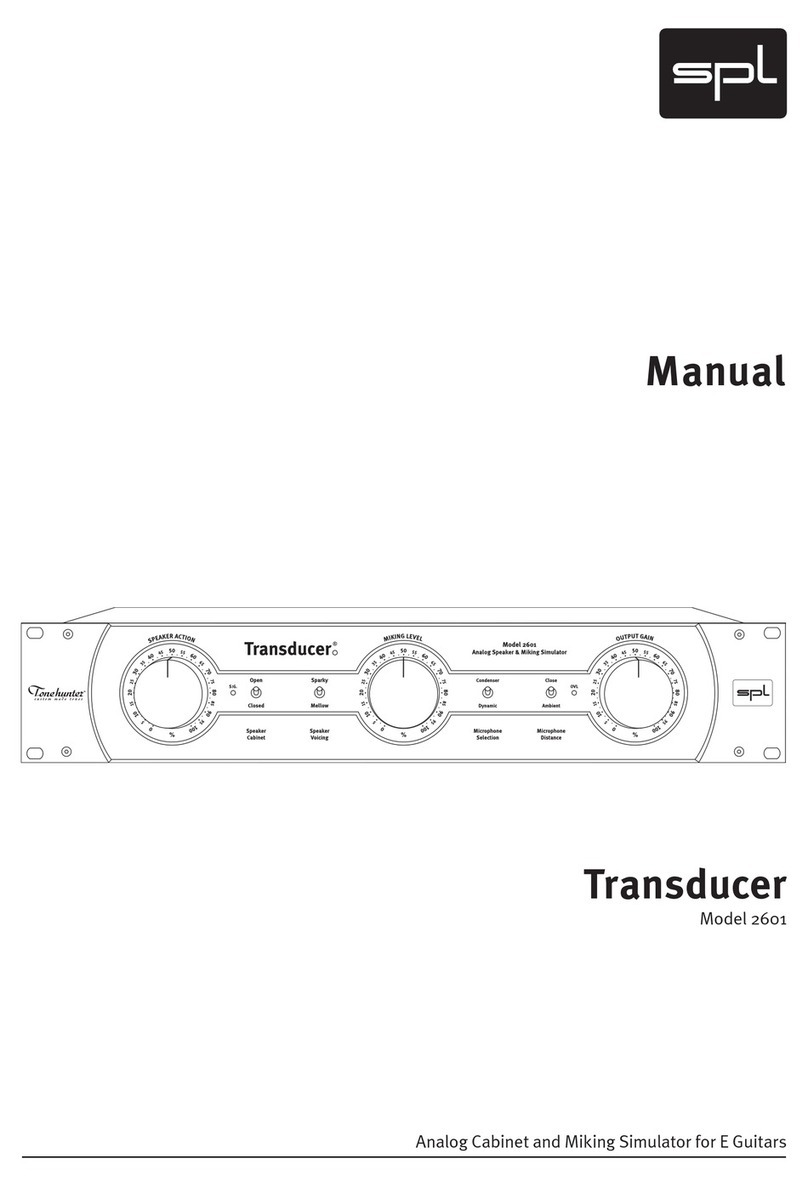

Sound Performance Lab Model 2601 manual

IFM Electronic

IFM Electronic Efector 500 PN3 operating instructions