D

10

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut

auf, damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen zur Folge haben.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

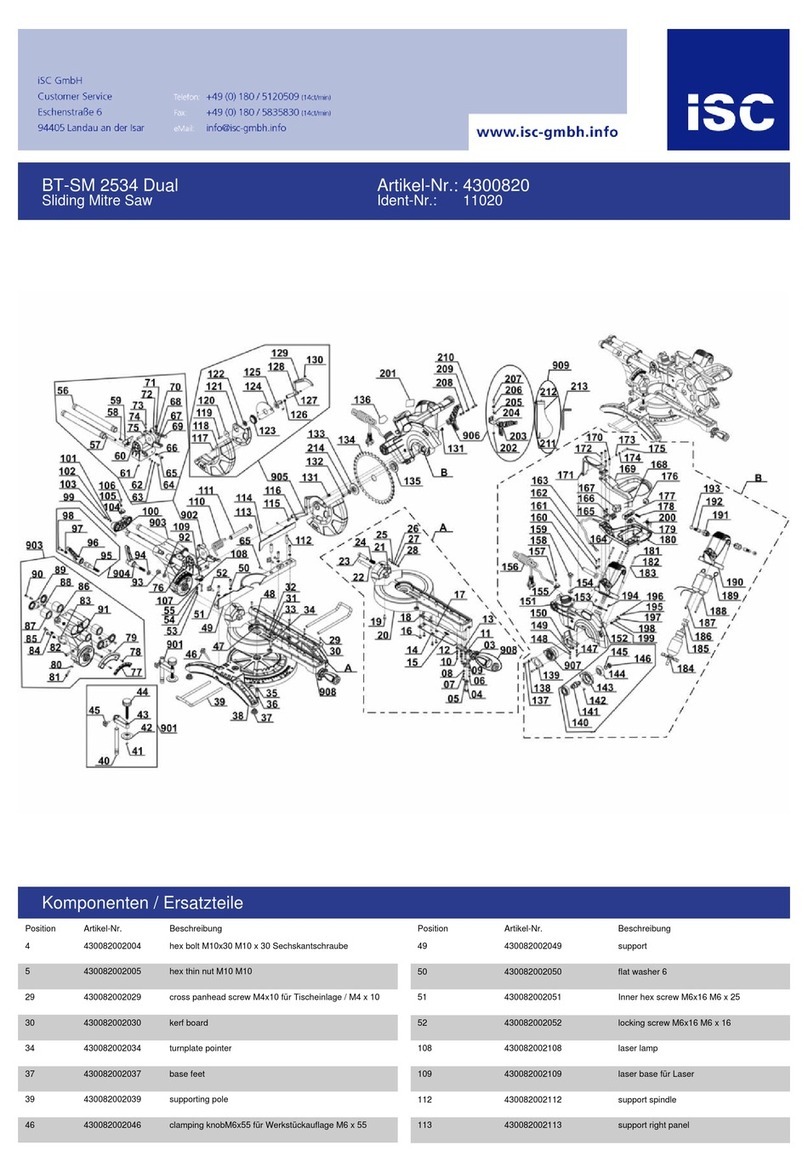

2. Gerätebeschreibung (Abb. 1-3)

1 Sägetisch

2 Sägeblattschutz

3 Schiebestock

4 Sägeblatt

5 Spaltkeil

6 Tischeinlage

7 Universalanschlag

8 Handkurbel

9 Werkzeughaken

10 Zusatztisch

11 Schalter-Stecker-Kombination

12 Klemmschraube

13 Absaugschlauch

14 Absauganschluss Ø 100 mm

15 Fahrgestell

16 Fahrgriffe

17 Spänekasten

18 Standfüsse

19 Standfuß mit Ausstanzung

20 Klemmschiene

21 Halterung für Absaugschlauch

22 Halterung für Räder

23 Führungsschiene füe Queranschlag

24 Streben

25 Gummifüße

26 Motor

27 Flügelschrauben

3. Lieferumfang (Abb. 1-4)

Tischkreissäge

Hartmetallbestücktes Sägeblatt

Universalanschlag

Schiebestock

Zusatztisch

Werkzeug

Fahrgestell

Montagematerial

4. Bestimmungsgemäße Verwendung

Die Tischkreissäge dient zum Längs- und Quer-

schneiden (nur mit Queranschlag) von Hölzern ent-

sprechend der Maschinengröße.

Rundhölzer aller Art dürfen nicht geschnitten

werden.

Die Maschine darf nur nach ihrer Bestimmung

verwendet werden.

Jede weitere darüber hinausgehende Verwendung

ist nicht bestimmungsgemäß. Für daraus hervor-

gehende Schäden oder Verletzungen aller Art haftet

der Benutzer/Bediener und nicht der Hersteller.

Es dürfen nur für die Maschine geeignete Säge-

blätter (HM- oder CV-Sägeblätter) verwendet

werden. Die Verwendung von HSS-Sägeblättern

und Trennscheiben aller Art ist untersagt.

Bestandteil der bestimmungsgemäßen Verwendung

ist auch die Beachtung der Sicherheitshinweise,

sowie der Montageanleitung und Betriebshinweise in

der Bedienungsanleitung.

Personen, die die Maschine bedienen und warten,

müssen mit dieser vertraut und über mögliche

Gefahren unterrichtet sein.

Darüber hinaus sind die geltenden Unfallverhütungs-

vorschriften genauestens einzuhalten.

Sonstige allgemeine Regeln in arbeitsmedizinischen

und sicherheitstechnischen Bereichen sind zu

beachten.

Veränderungen an der Maschine schließen eine

Haftung des Herstellers und daraus entstehende

Schäden gänzlich aus.

Trotz bestimmungsmäßiger Verwendung können

bestimmte Restrisikofaktoren nicht vollständig

ausgeräumt werden. Bedingt durch Konstruktion und

Aufbau der Maschine können folgende Risiken

auftreten: