Eisco CH0814 User manual

Instruction Manual

WATER STILL

CAT NO. CH0814

ASSEMBLY & OPERATING INSTRUCTIONS

MOUNTING & PLACEMENT

This equipment can be wall mounted or bench mounted.

ENVIRONMENTAL CONDITIONS

* For indoor use only statement: Water Still is designed for reliable

continuous operation incorporating a host of features unmatched by

comparable stills. It is Easy to Use, Portable, Safe to Operate and

thoroughly reliable, i.e., the reason it is recommended for indoor use

only.

* Ambient Temperature +5°C to 40°C

* Altitude : Up to 2000 meters

* Relative Humidity : Not exceeding 80%

* Electrical Supply :

* :

:

* Impairment statement :- If the equipment is not used in the manner

may be impaired. Please read the manual carefully before installation

or operating the unit.

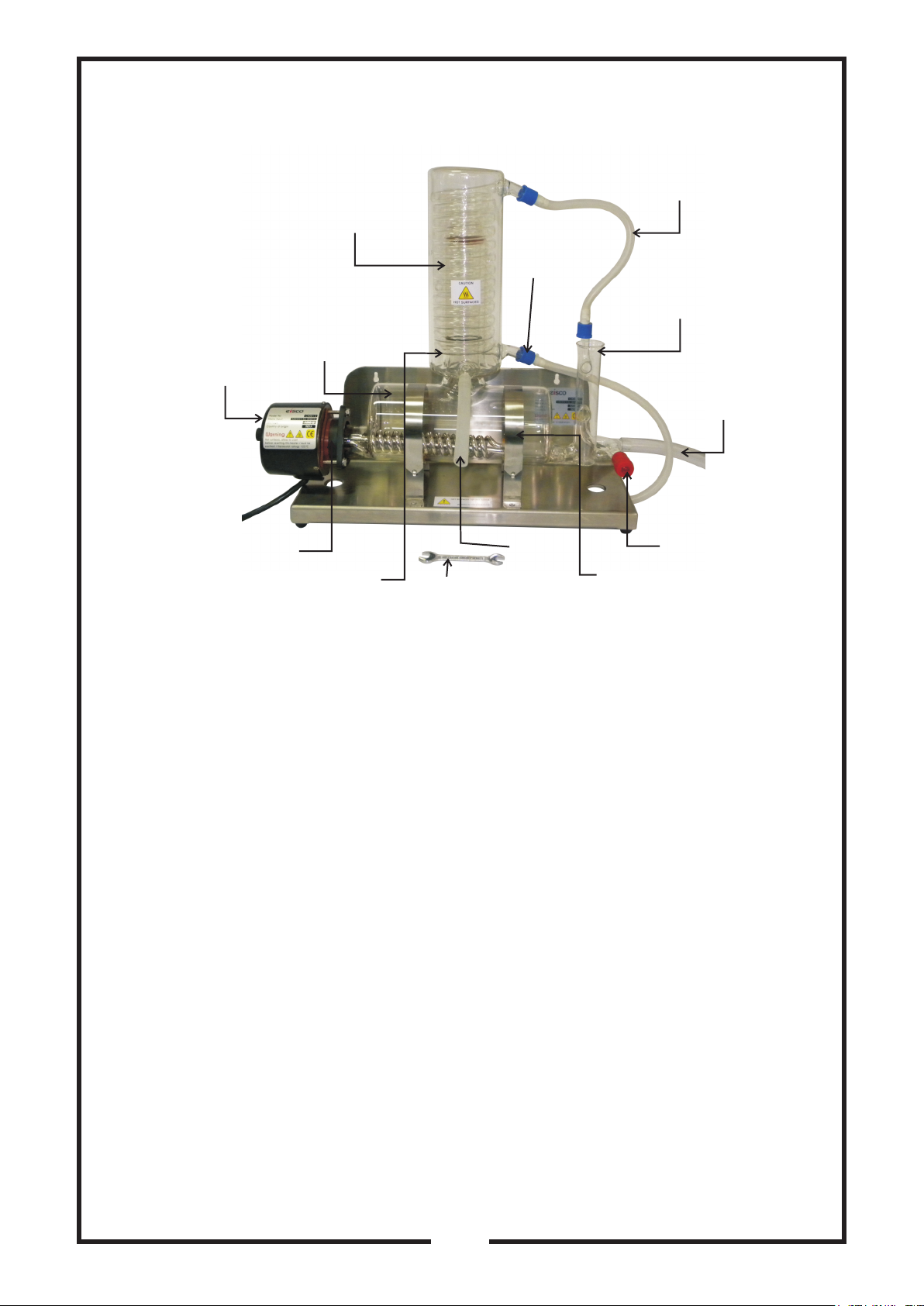

Condenser

Cooling water

Inlet

Boiler

Heater

Gaskets & Clamp

Vent Straps

Drain cock

To Drain

Constant Level

Control

Boiler Inlet

Key

Distillate

Outlet

-1-

© EISCO SCIENTIFIC ●www.eiscolabs.com

:

220-240VAC, 50Hz, Single Phase

Pollution Degree 2 According to IEC 60664

*

Over Voltage Category Category II According to IEC 60664

described in the manual the protection provided by the equipment

IP IP20

:

*

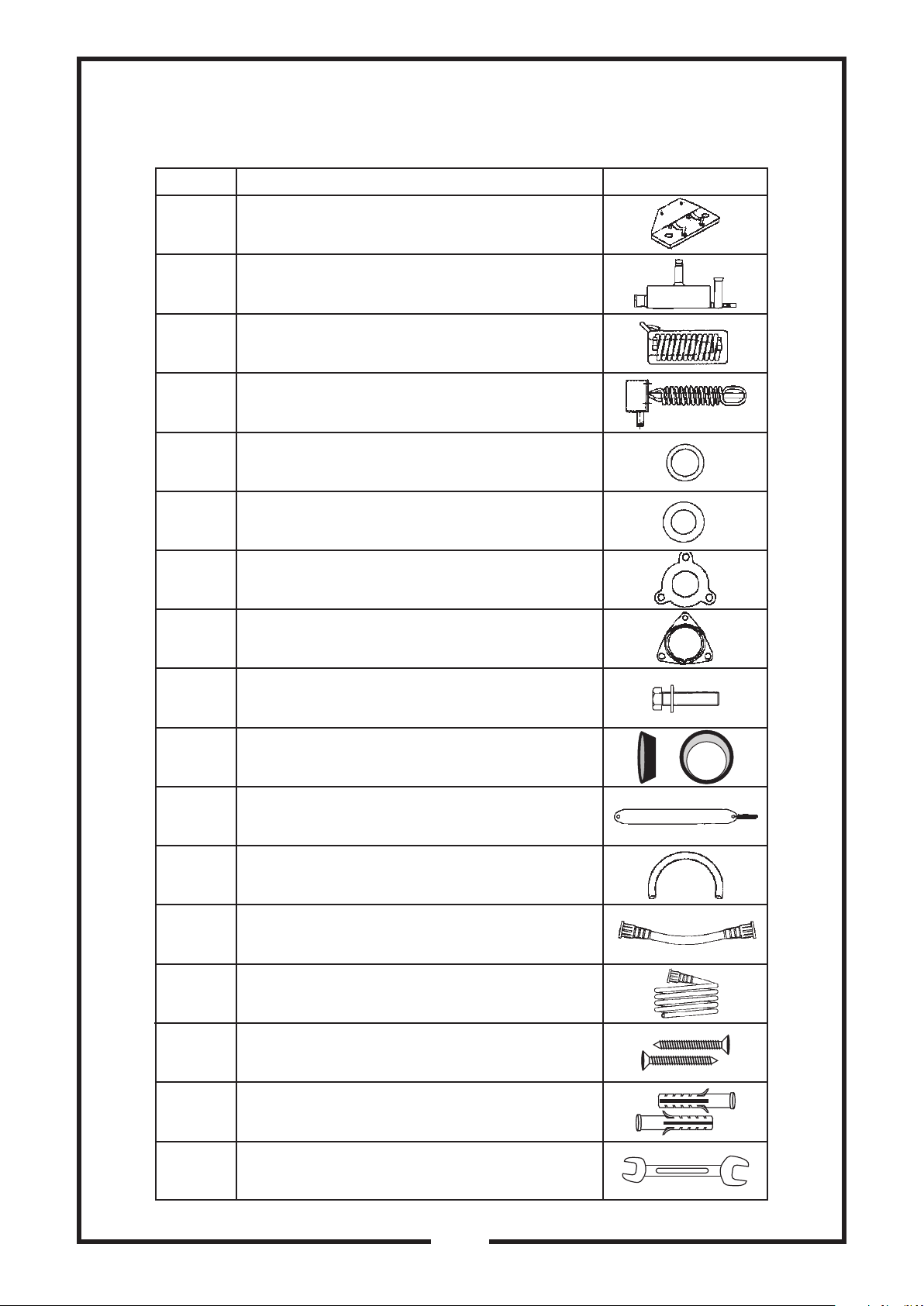

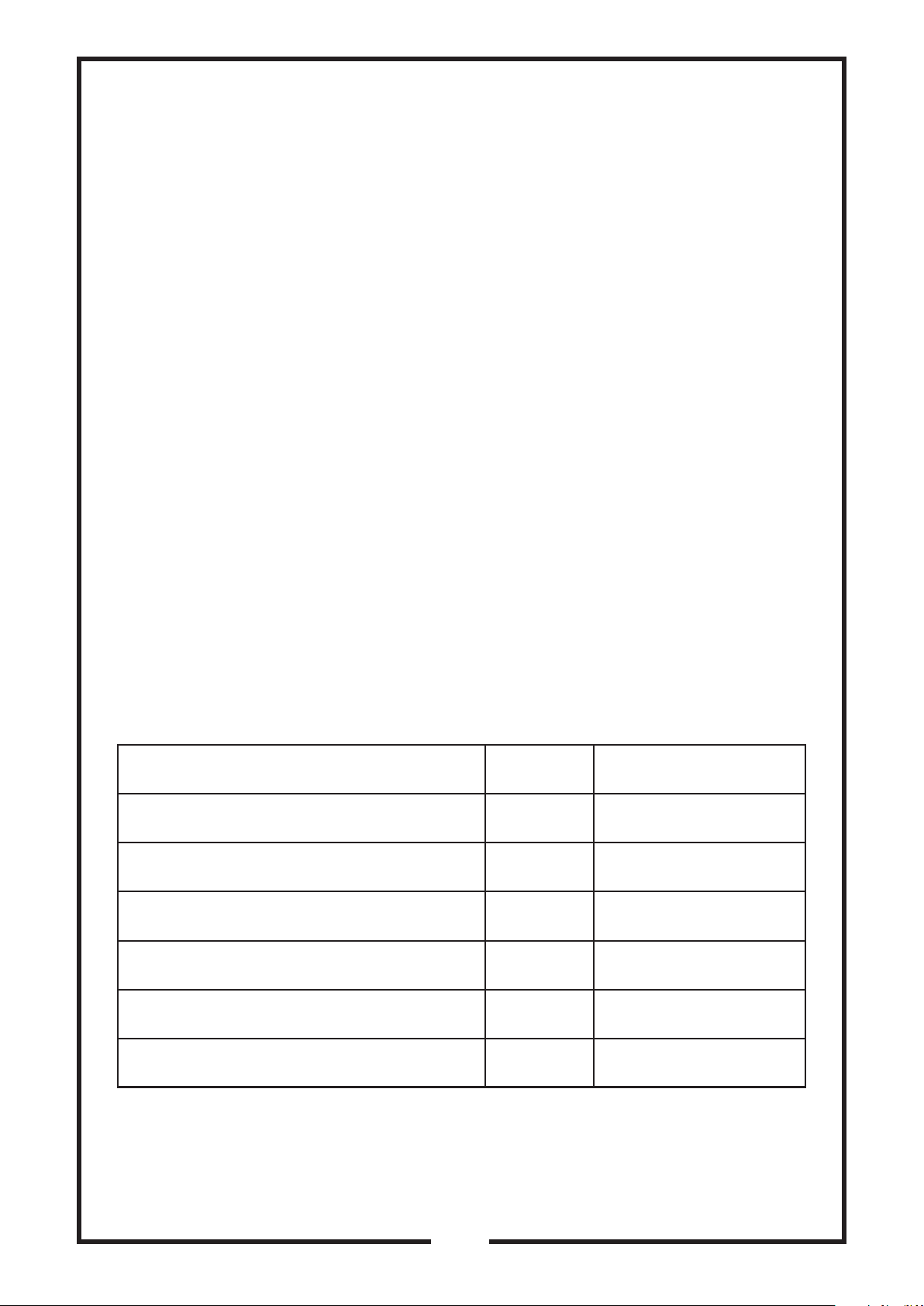

PART LIST OF PURE HILL STILL

Part No. Description Diagram

S.S. Stand

Glass Boiler

Glass Condenser

Metal Heater (with reset able)

Silicon 'O' Ring

Silicon 'O' Ring

Neoprene Rubber Gasket

Metal Flange

Stainless Steel Bolt for Heater

Rubber Collar Insert

Stainless Steel Boiler Straps with

Springs

PVC drain Tube

Silicon Tubing with threaded plastic

connector

Silicon Tubing with plastic connector

16.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

17.

Self Tapping Screw

Plastic Gitti

Spanner

10

11

-2-

© EISCO SCIENTIFIC www.eiscolabs.com

PH/BSSS

PHB/B4

PHC/B4

PH/H/3KW

PH/HK

PH/GK

Order No. for spares

1

1

1

1

1

1

Quantity

Component

S.S. Stand with 2 stainless steel boiler

straps with springs (Part 1 & 11)

Glass Boiler (Part No. 2)

Glass Condenser (Part No. 3)

Metal Heater (Part No. 4)

Hose Kit (Part No. 12, 13, 14)

Gasket Kit (Part No. 5, 6, 7, 8, 9, 10)

CHECK FOR THE FOLLOWING SERVICES

* Single phase electric supply capable of handling a load of 3KW, 230V

± 10%, 50 Cycles and with a fuse carrier of 13 amps. Supplies should

be fitted with a 30mARCD circuit breaker.

* A conventional 13 amps plug and socket, wall mounted is

recommended.

* The equipment must be earthed in all cases. Red - Live, Black-

Neutral and Green - Earth.

* Cooling water supply for Glass Condenser (Part No. 3) capable of

providing minimum flow rate of 60 ltrs/hr. The flow rate has to be

adjusted by the lab technician using a measuring cylinder or using a

flow meter.All water supplies should be earth bonded.

* A drain located below the level of the still so that the PVC Drain pipe

(Part No. 12) from the Glass Boiler (Part No.2) can fall straight without

kinks or bends to allow unimpeded flow of water. Ensure all drainage

systems are earth bonded.

* Reservoir :-Adistillate collection reservoir should be below the output

of still.

INSTALLATION

1. Open the box carefully and identify the following components:

2. Place the S.S. Stand (Part No. 1) at a suitable location, bench top ro

wall mounted using the two key holes provided.

-3-

© EISCO SCIENTIFIC ●www.eiscolabs.com

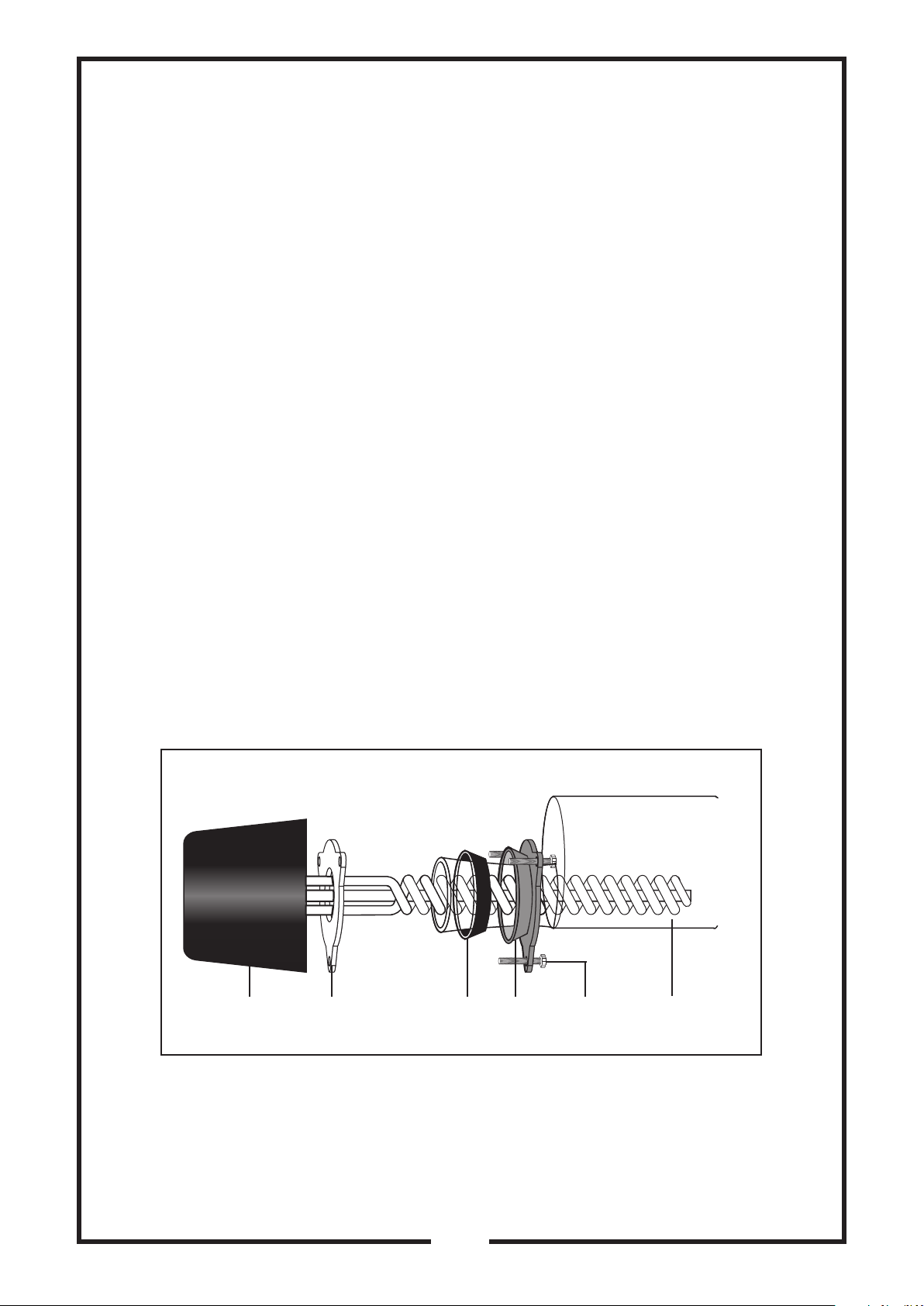

3. Take the Glass Boiler (Part No. 2) ensuring that the two Silicon rubber

'O' rings (Part No. 5) on the vapour tube are in place. The smaller

silicon rubber 'O' ring (Part No. 6) to be seated on the top groove of

the vapour tube of the Glass Boiler (Part No. 2). The bigger silicon

rubber 'O' ring (Part No.6) is to be adjusted to a distance of approx.

35mm from the top surface of the Glass Boiler (Part No. 2) or such

that when the Glass Condenser (Part No.3) is placed over the vapour

tube it does not shake. Take the metal Heater (Part No. 4) the Metal

Flange (Part No.8) the Neoprene Rubber Gasket (Part No.7) and the

Rubber Collar Insert (Part No. 10) and assemble as shown in the Fig.

No. 1.

(a) Place the Metal Flange (Part No. 8) (Flat side facing the Boiler) over

the tapered Glass neck of the Glass Boiler. (Part No. 2).

(b) The Rubber Collar Insert (Part No. 10) is bent around the tapered

Glass neck and into the Metal Flange (Part No. 8). The Metal Flange

(Part no. 8) is pulled and inserted towards the end of the Glass Boiler

(Part No. 2) neck so that when the Metal Flange (Part No. 8) is pulled,

the Rubber Collar Insert (Part No. 10) seals on the neck.

(c) Place the Neoprene Rubber Gasket (Part No. 7) over the metal

heater (Part No.4) and insert the metal heater (Part No. 4) through the

tapered Glass neck and into the Glass boiler (Part No. 2).

(d) Secure the Metal Heater (Part No.4) with the three Stainless Steel

Bolts (Part No. 9) provided. Care should be taken not to over tighten

the bolts. The heater axis should be parallel to the boiler axis.

4. Place the Glass Boiler (Part No. 2) and Heater assembly in the cradle

of the powder coated stand (Part No. 1) It plug not installed connect

the Metal Heater (Part No. 4) cables to the pins of the 13 amps

connector as per circuit diagram page. 9.

-4-

© EISCO SCIENTIFIC ●www.eiscolabs.com

FLANGE ASSEMBLY

Boiler

S.S.

Bolt

Metal

Flange

Rubber

Coller

Insert

Neoprene

Rubber

Gasket

Metal

Heater

Fig. 1

5. Mount the Glass Condenser (Part No. 3) onto the vapour tube of the

Glass Boiler (Part No.2). The distillate outlet tube or vent should face

the front.

11. Connect the distillate outlet on the Glass Condenser (Part No. 3) to a

suitable collection reservoir with the help of Silicon tubing with plastic

connector (Part No. 14)

12. Connect the mains of the Metal Heater (Part No. 4) to a fused 13 amp

electric supply capable of providing a load of 3KW at 230V ± 10% 50

cycles single phase.

IMPORTANT : THE EQUIPMENT MUST BE EARTHED

STARTING THE WATER STILL

1. Turn on the cold water supply and adjust the flow rate to

approximately 60ltr/hr. Allow the water to flow via the Glass

Condenser (Part No. 3) into the Glass Boiler (Part No. 2). When the

water level reaches the correct operating level and excess water

flows to the drain, turn on the heater.

2. When the boiling commences and the distillate emerges from th

Glass condenser (Part No. 3) start collecting in the reservoir.

6. Take the silicon tubing with Screw thread connectors at either end

(Part No. 13). Screw one end of the silicon tubing on to the upper

outlet of the Glass Condenser (Part No. 3) and the other end to the

Glass thread on the Glass Boiler (Part No. 2) inlet.

7. Take the PVC Drain Pipe (Part No. 12) and connect to the drain of the

Glass Boiler (Part No. 2).

8. Lead the free end of the PVC Drain Pipe (Part No. 12) to the drain.

Ensure that there are no kinks or bends in the tube so that water flow

is not impeded.

9. Ensure that the Teflon drain cock on the Glass Boiler (Part No. 2) is

closed.

10. Connect the cooling water inlet of the Glass Condenser (Part No. 3)

to the cold water feed supply through the hose provided. For easy

attachment to the Glass Condenser (Part No. 3) a plastic screw

thread is provided along with the hose.

-5-

© EISCO SCIENTIFIC ●www.eiscolabs.com

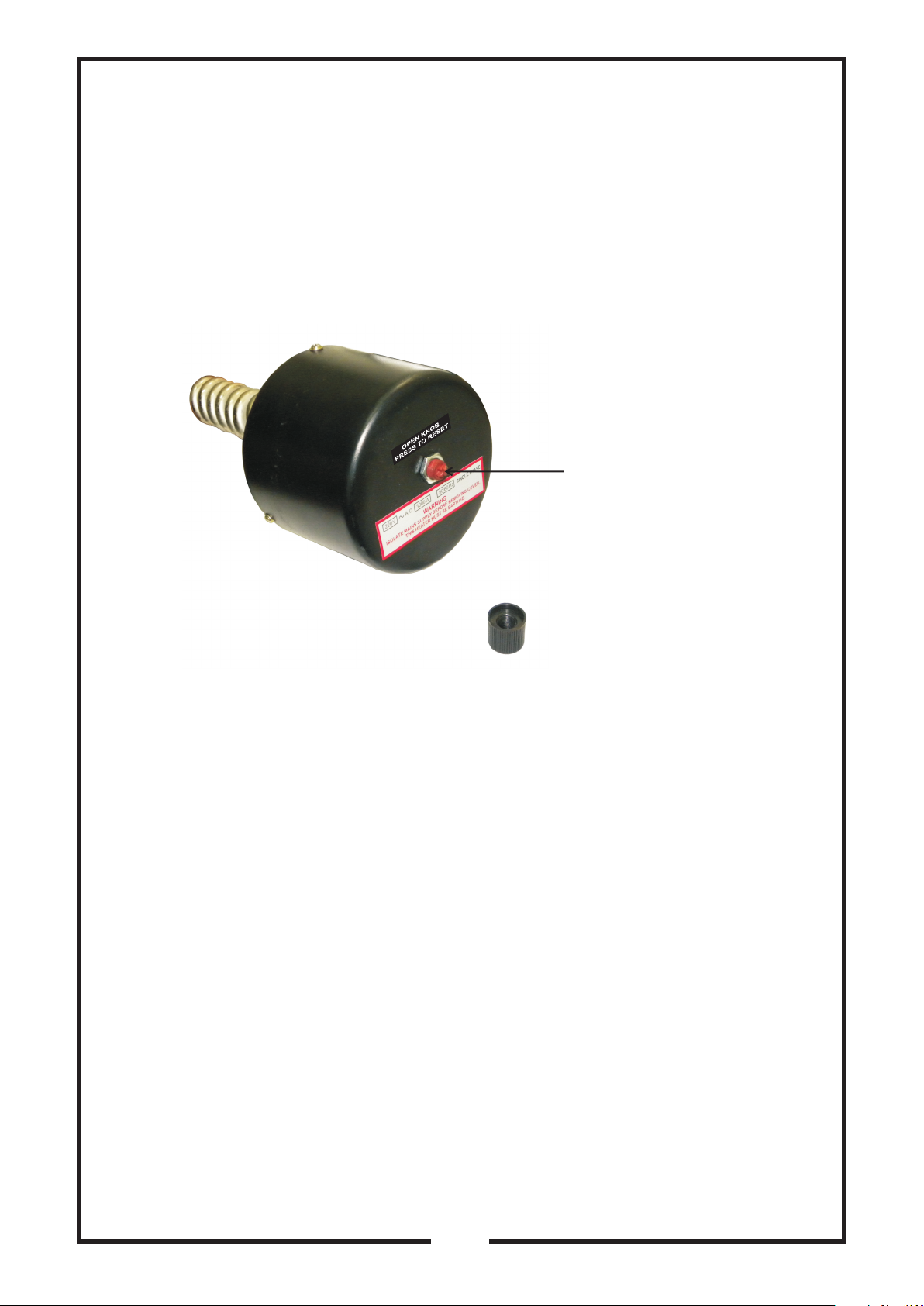

SAFETY CUT OUT

A thermostat is provided with the Metal Heater (Part No. 4) to protect the

still from accidental failure of the water supply. When the Glass Boiler (Part

No. 2) runs dry, the thermostat automatically shuts off the metal heater

(Part No. 4) to reset open the knob on top of cap and push the lever down

as shown in picture the thermostat.

CLEANING

Over a period of operation, scale deposits may develop inside the Glass

Boiler (Part No. 2) For peak performance from you still it is necessary to

clean the Glass Boiler (Part No. 2) regularly.

The number of times the still needs to be cleaned during the course of its

operation depends on the hardness of the water used. In very hard water

areas it might be necessary to clean the still once a week, while in soft

water areas several weeks may elapse before cleaning becomes

necessary. 10% formic acid (mechanic acid or Kettle descale) is used for

removing scale deposits. Do not use strong acids such as hydrochloric

acid, because it can damage the metal heating element.

CARE AND MAINTENANCE

For prolonged life of the still it is necessary that regular care and

maintenance should be taken. Before any maintenance operation, the still

must be isolated from the mains electric supply.

Push to Reset

-6-

© EISCO SCIENTIFIC ●www.eiscolabs.com

PROPER PRECAUTIONS MUST BE TAKEN DURING

HANDLING OF ACIDS.

STEPS ON CLEANING

1. The electric supply to the still is switched off and the water in the

Glass Boiler (Part No. 2) is allowed to cool.

2. The cooling water supply is turned off.

3. The Teflon drain cock is the Glass Boiler (Part No. 2) is opened and

the water in the Glass Boiler (Part No. 2) is completely drained off.

The drain cock is the closed.

4. Through the funnel of the Glass Boiler (Part No. 2) inlet tube fill dilute

10% formic acid solution till the operating level is reached. Excess

acid should be avoided.

5. The acid is allowed to react and break down the scale deposits. The

time taken depends on the severity of scale build up.

Important : Safety precautions have to be observed since the liquid

flowing to the drain may be acidic as it may not be completely

neutralized.

6. The drain cock in the Glass Boiler (Part No. 2) is closed and the Glass

Boiler (Part No.2) is filled with cold water and allowed to drain out.

This procedure is repeated two or three times.

7. The still can be restarted when the Glass Boiler (Part No. 2) is filled

with water. The still should be allowed to run for around 10 minutes

before collecting the distillate.

REGULAR CLEANING WILL KEEP YOUR STILL RUNNING AT

OPTIMUM CONDITION.

-7-

© EISCO SCIENTIFIC ●www.eiscolabs.com

TROUBLE SHOOTING

Incase of any operating difficulties with the still the following tips may help.

Warning :- Please ensure that electrical connections are

disconnected before opening the Heater cup.

-8-

© EISCO SCIENTIFIC ●www.eiscolabs.com

S. No. SYMPTOM CAUSE REMEDY

1Distillate rate less

than 4ltr/hr.

2

3

4a

4b

4c

5a

5b

6a

6b

7a

7b

7c

8a

8b

Distillate

temperature high

Distillate quality poor

Water in Glass Boiler

(Part No. 2 is pumped

out of Glass Boiler of

drain.

Water level in the

Glass Boiler is too

high e.g.,boiling water

surging into Glass

condenser (Part No.3)

Water level in Glass

Boiler (Part No.2) is

too low e.g., Metal

Heater (Part No. 4)

exposed

Metal Heater

(Part No.4) Not

working

Metal Heater

(Part No.4)repeatedly

cycles On & Off

Mains electric supply

below 230V±10%

Flow of cooling water in Glass

Condenser (Part No. 3) not adequate

Glass Boiler (Part No. 2) heavily

scaled

Vent on Glass Condenser

(Part No. 3) distillate outlet is blocked

Silicon tubing with plastic connector

(Part No. 14) from Glass Condenser

(Part No. 3) distillate outlet to

reservoir is constricted.

Supply of feed/cooling water is

insufficient

Flow of drainage water is constricted

Supply of feed/cooling water is

excessive

Drain cock on Glass Boiler

(Part No. 2) inadvertently left open

Supply of feed/cooling water is

insufficient

Burnt out Metal Heater (Part No. 4)

Mains electric fuse blown

Faulty thermostat

Faulty thermostat

Thermostat not operating

Ensure sufficient power

supply

Increase flow rate of

water to approx. 60ltr/hr

Clean Glass Boiler

(Part No. 2)

Ensure that Silicon tubing

with plastic connector

(Part No. 14) falls freely

without any kinks or

bends

Increase flow rate to

approx. 60ltr /hr.

Ensure PVC Drain pipe

(Part No. 12) falls freely

without any kinks or

bends

Remove Blockage

Reduce flow rate of water

Approx. 60ltr/hr.

Close drain cock in the

Glass Boiler (Part No. 2)

Increase flow rate to

Approx. 60ltr/hr.

Replace Metal Heater

(Part No. 4)

Replace fuse

Replace thermostat

Replace thermostat

Reset

REPLACEMENT OF FAULTY PARTS/COMPONENTS

Metal Heater (Part No. 4) Replacement:

1. The Metal Heater (Part No. 4) is turned off and the still is

disconnected from the mains electric supply.

2. The Glass Boiler (Part No. 2) is cleaned if heavy scaling is present by

the following cleaning procedures detailed in this manual.

3. It is easier to replace the heater by working with the Glass Boiler on

the bench

* Remove the Glass Condenser (Part No. 3)

* Drain the Glass Boiler (Part No. 2) via drain cock

* Remove the Glass Boiler (Part No. 2) complete with Metal Heater

(Part No. 4) from the S.S. stand (Part No. 1)

* Unscrew the three stainless steel bolts (Part No. 9) securing the

Metal Heater (Part No. 4) to the Glass Boiler (Part No. 2)

* The new Metal Heater is fitted to the Glass Boiler by following the

installation instructions - 3

4. The still is reassembled by following the installation instructions 4 -

12.

CIRCUIT DIAGRAM

-9-

© EISCO SCIENTIFIC ●www.eiscolabs.com

GREEN

BLACK

RED

THERMOSTAT REPLACEMENT

The thermostat is located within the Metal Heater (Part No.4) and may

easily by replaced by following these instructions.

1. The metal heater (Part No. 4) is turned off

and the still is isolated from the mains

electric supply.

2. The three small retaining screws holding

the plastic cup is place is removed (Not

the three bolts securing the Heater to the

Boiler).

3. Referring to the wiring diagram, the two

wires to the thermostat are disconnected.

4. The thermostat is removed from the

Heater pocket.

5. The new thermostat is placed in position and the electrical

connections are made.

6. Check whether the thermostat is set of 125°C.

7. Replace the Metal cover of the Heater.

-10-

© EISCO SCIENTIFIC ●www.eiscolabs.com

RED

BLACK

RED

GREEN

BLACK

RED

Wiring Detail

Green : Earth

Black : Neutral

Red : Live

Thermostat

ENVIRONMENTAL CONDITIONS

1. Pollution Degree: 2

2. Installation Category: 2

3. Altitude: 2000 meters Max.

4. Electrical Supply: 220V - 240V AC, 50Hz

5. Equipment is meant for Indoor use only

6. Ambient Temperature: 40°C Max.

U.S. Distributor:

Eisco Scientific

788 Old Dutch Road, Victor, NY 14564

Website: www.eiscolabs.com

EISCO SCIENTIFIC instrucons, content and design is intellectual property of EISCO

Manufactured by :

www.eiscolabs.com

Table of contents

Other Eisco Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Heathrow Scientific

Heathrow Scientific Vortexer HS120209 instruction manual

Okolab

Okolab H301-KEYENCE-BZX user manual

BioLAB

BioLAB BIFL-205 Operation manual

NSW

NSW Caltan NSW-227 Maintenance manual

World Precision Instruments

World Precision Instruments PUL-1000 instruction manual

Heidolph

Heidolph REAX 2 instruction manual

Amerex

Amerex Hirayama HG-50 Operation manual

HACH LANGE

HACH LANGE AMTAX inter2 Basic user manual

IKA

IKA ULTRA -TURRAX Tube Drive P control operating instructions

Minebea Intec

Minebea Intec PR 57 installation manual

Wyatt Technology

Wyatt Technology Optilab rEX user guide

Primerdesign

Primerdesign genesig q16 instruction manual