Eisco PULLEY KIT User manual

USER MANUAL

PULLEY KIT

EIPUL-KIT

PULLEY KIT

EIPUL-KIT

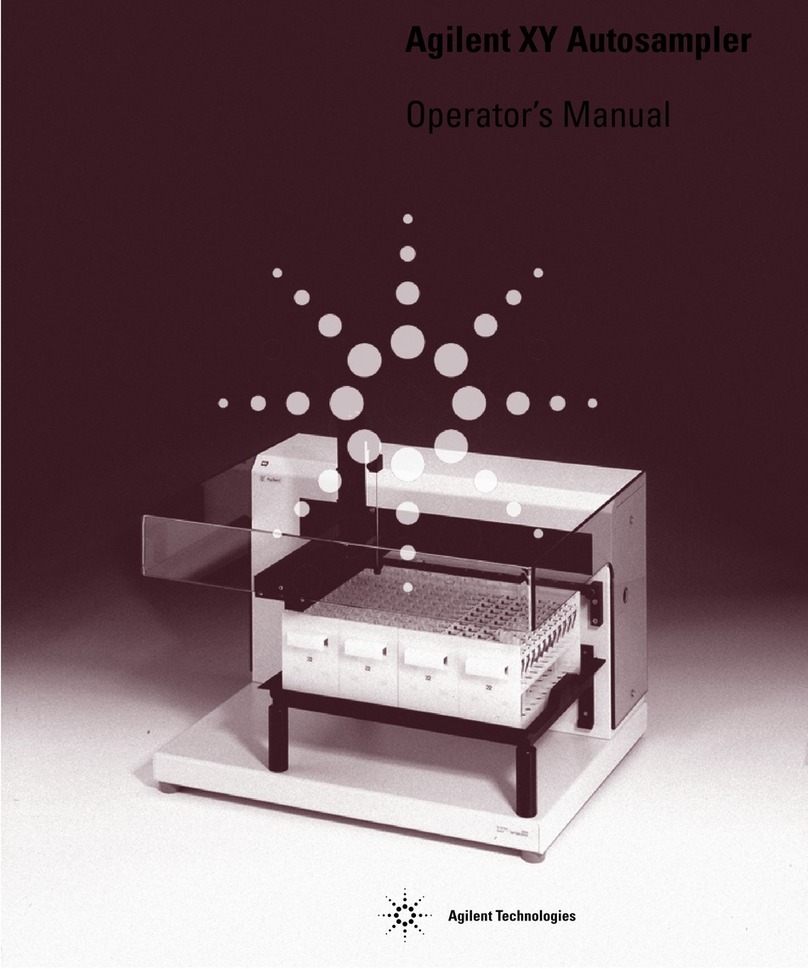

The KIT Included:

▪1 35cm Track

▪2 Track Leg

▪2 20" Rod

▪2 Track Rider

▪2 Boss Head

▪2 100g Slotted Mass

▪3 50g Slotted Mass

▪1 Slotted Mass Hanger

▪1 Rod with Pulley (Perpendicular)

▪1 Pulley with Hook

▪1 Thread

Experimental Contents:

▪Pulley System

Ver 2.15.4 1

EXPERIMENT

PULLEY SYSTEM

Objectives

▪To learn about pulley systems: fixed, movable and compound pulleys.

▪To measure the effort force and the load force.

▪To measure the distance the force sensor has to be pulled in order to move the load

10 cm and calculate the velocity ratio.

▪To calculate the mechanical advantage of each system.

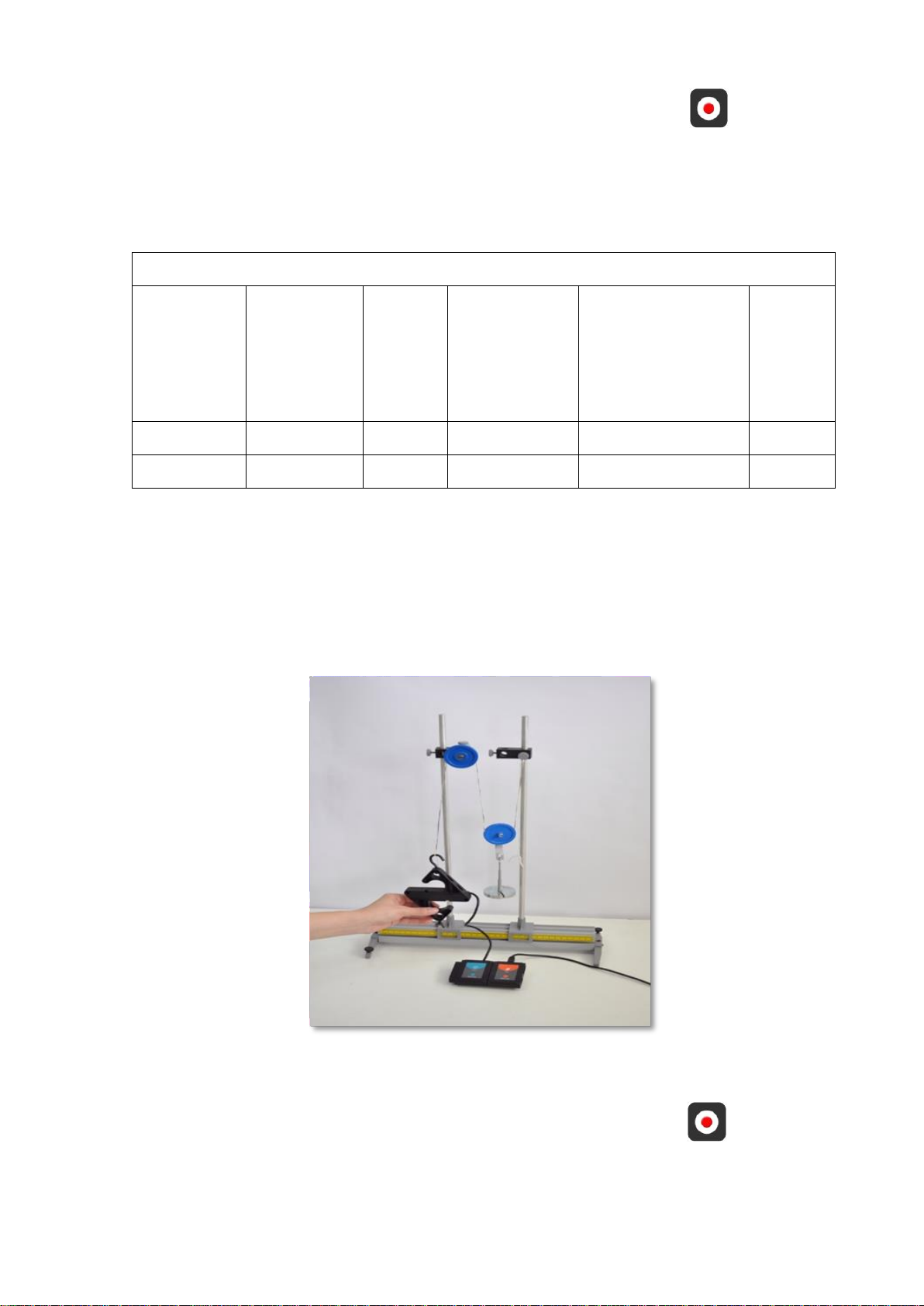

▪To find the relationship between the mechanical advantage and the velocity ratio.

1.1. Introduction

A pulley is a grooved wheel firmly attached to an axle. A rope or a cable fits into the

groove and passes over the wheel. A fixed pulley is fastened to one spot. The fixed

pulley has no gains in force or distance, but it changes the direction of the force. A

movable pulley moves along a rope. It decreases the force, but the rope must be

pulled for a longer distance. A compound pulley is the combination of fixed and

movable pulleys. The fixed pulley changes the direction of the force and the movable

pulley decreases the applied force.

In this experiment, you will study these three types of pulley systems. You will use a

force sensor to measure the effect of each type of pulley on the force that must be

applied to perform work. You will also find the velocity ratio of each system.

1.2. Prepare equipment and experiment materials

* Equipment and Sensor

▪PC + NeuLog application

▪EIUSB-200 module

▪EINUL-211 Force sensor

* Tools and experiment materials

▪35 cm track

1

▪Slotted mass hanger

1

▪Track leg

2

▪Rod with pulley (perpendicular)

1

▪20" rod

2

▪Pulley with hook

1

▪Track rider

2

▪Thread (~1m)

1

▪Boss head

2

▪3 m measuring tape

1

▪100 g slotted mass

2

The items above are included in the Pulley kit, EIPUL-KIT

Ver 2.15.4 2

1.3. Experimental procedure

* Experiment setup

1. Set up the experiment as shown in the picture below.

2. Attach the track legs to the track.

3. Slide the track rider to the middle of the track.

4. Insert the 20" rod in the track rider.

5. Attach the boss head to the top of the 20'' rod.

6. Attach the rod with the pulley to the boss head.

7. Place the 100 g slotted mass on the slotted mass hanger.

8. Make sure you have a ~1 m long thread.

* Sensor setup

9. Connect the USB module to the PC.

10. Connect the Force sensor to the EIUSB-200 module.

11. Run the NeuLog application and check that the force sensor is identified.

* Experimental parameter setup

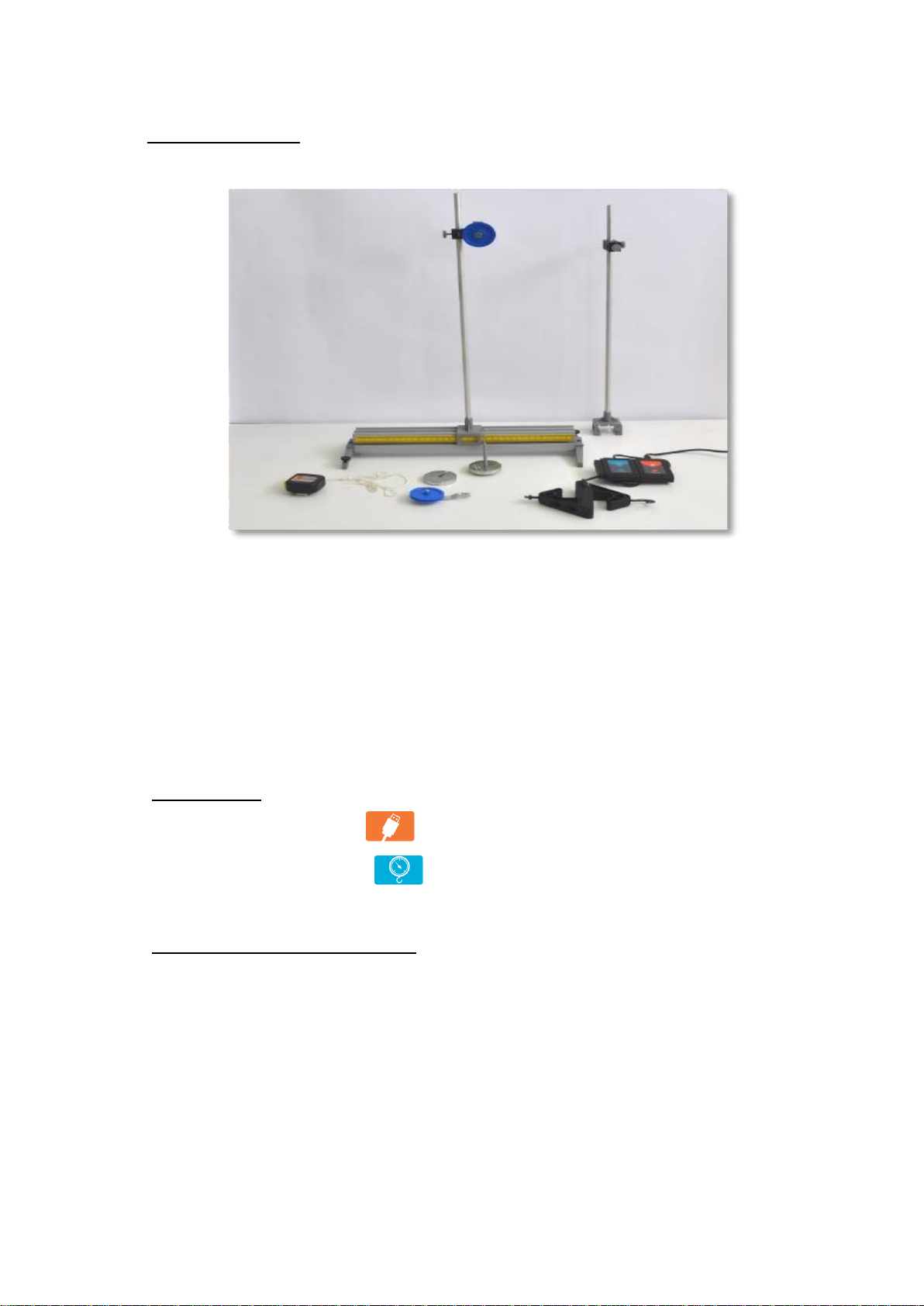

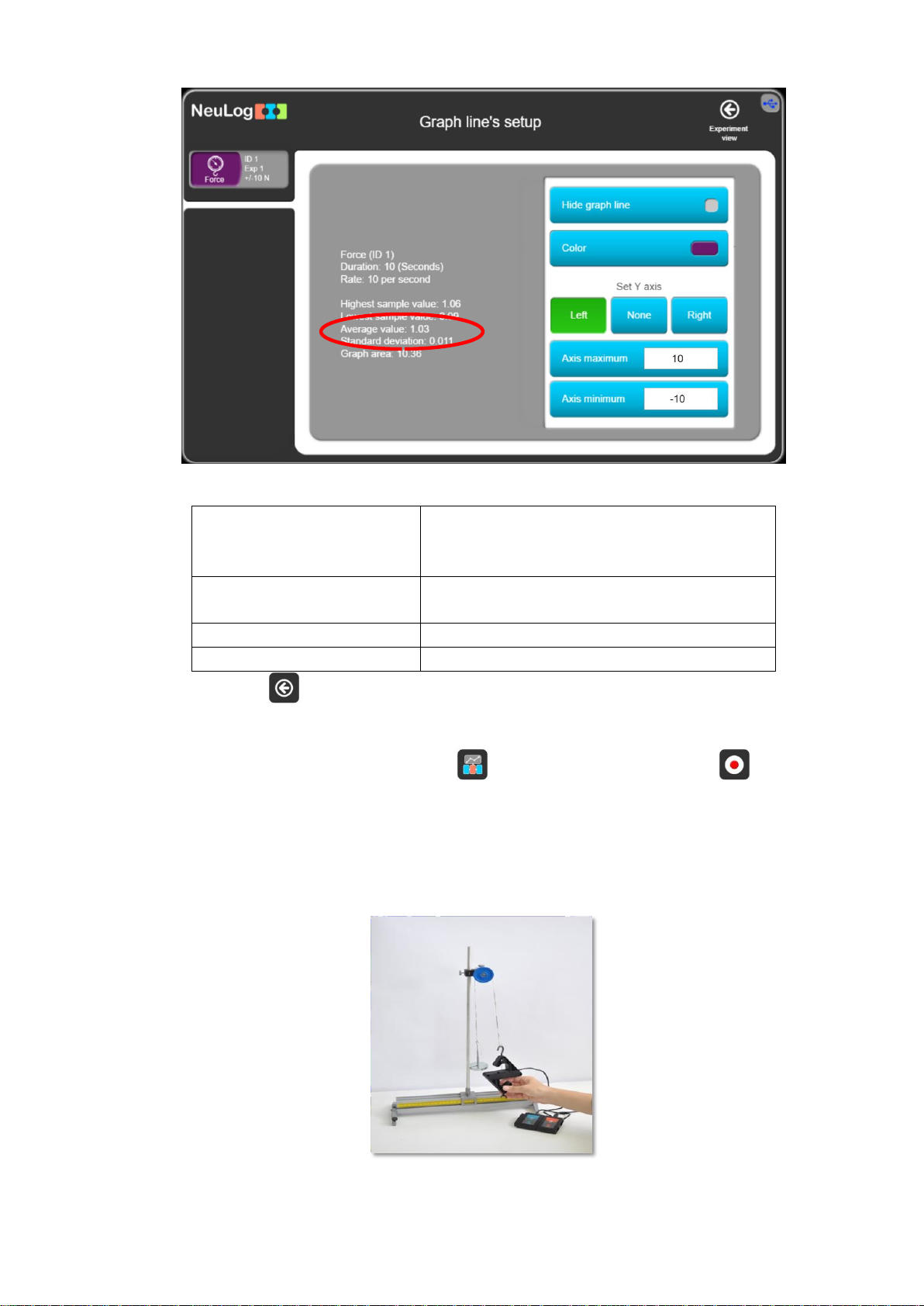

12. Click on the force sensor's module box.

13. Select the 10 N button to set the sensor's mode.

Ver 2.15.4 3

14. Click on the Extra command button and then on the Push=Negative button to get

positive values when hanging the cart from the force sensor's hook.

15. Click on the icon to go back to the graph.

16. Click on the Run Experiment icon and setup:

Experiment duration to 10 seconds

Sampling rate to 10 per second

Ver 2.15.4 4

* Testing and measurements

Note:

The orientation of the sensor is very important. Before each measurement, hold the

sensor in the same orientation you will use for the specific experiment and zero it.

17. Sensor Zeroing: hold the sensor in the proper orientation (the hook should be

facing downwards for the first measurements) and press the button in the sensor’s box

for about 3 seconds.

Alternatively, you can click on the Extra command button in the Module Setup box

menu and then on Reset.

18. When using a pulley, the rope is 'pulled' on the effort side; the weight lifted on the

other side is called the 'load'.

This is a fixed pulley:

Measure the Load force: Put a 100 g on the mass holder and then hang these on the

force sensor.

Ver 2.15.4 5

19. Click on the Record icon to start the measurement.

20. Your graph should be similar to the following:

21. Click on the Export Icon and then on the Save value table (.CSV) button to

save your graph.

22. Click on the icon to go back to the graph.

23. Click on the Experiment module box on the left of the screen.

24. Insert the average value you see in the menu on the following table.

Ver 2.15.4 6

Slotted mass

Measured force

(with mass holder and No pulley)

[N]

100 g

(sample experiment)

1.03

100 g

200 g

25. Click on the icon to go back to the graph.

26. Add another 100 g slotted mass (you will now have 200 g).

27. Click on the Run Experiment icon and the on the Record icon .

28. Insert the new data to the table above.

29. Set up the experiment as shown in the following picture.

30. Remember to zero the sensor in this new orientation, with the hook facing

upwards before putting on any load.

31. This is a fixed pulley. Hang a 100 g slotted mass on it. The length of the thread is

not important.

Ver 2.15.4 7

32. In order to measure the effort force, click on the Record icon to start the

measurement.

33. Your graph should be similar to the following:

34. Repeat the measurement with a 200 g slotted mass (without erasing the first

graph).

35. Click on the Export Icon and then on the Save value table (.CSV) button to

save your graph.

36. Click on the icon to go back to the graph.

Ver 2.15.4 8

37. Write the average force values in the following data table.

Fixed pulley

Slotted

mass

Load force

(without a

movable pulley)

[N]

Effort

force

[N]

Mechanical

advantage

(Load/Effort)

Distance

moved by

the effort

(distance moved

by load is 10cm)

Velocity

Ratio

100 g

(sample

experiment)

1.03

1.004

~1

100 g

200 g

The ratio of the Load to the Effort (Load/Effort) is called the Mechanical Advantage

(MA) of a pulley system. A system with MA>1 decreases the effort (Effort<Load)

while a pulley system with MA<1 increases the effort (Effort>Load).

38. Calculate the Mechanical Advantage (MA) for each mass and write it in the

previous table.

39. Lift the load 10 cm up. What distance did you have to move the force sensor in

order to lift the load? Insert the distance value in the table above.

The velocity ratio is equal to the distance moved by the effort divided by the distance

moved by the load. Calculate the velocity ratio and insert the data in the previous

table.

40. Assemble a second system as shown in the following picture.

41. This is a movable pulley. Put the sensor in place with the right orientation (without

the slotted mass) and zero it again.

Ver 2.15.4 9

42. Hang a 100 g slotted mass and click on the Record icon to start the

measurement.

43. Repeat the measurement with two 100 g slotted masses without erasing the first

measurement.

44. Write the results in the following data table.

Movable pulley

Slotted

mass

Load force

(with a

movable

pulley) [N]

Effort

force

[N]

Mechanical

advantage

(Load/ Effort)

Distance moved

by the effort

(distance moved

by load is 10 cm)

[cm]

Velocity

Ratio

100 g

200 g

45. Calculate the MA and insert the value into the table above.

46. Lift the load 10 cm up. What distance did you have to move the force sensor in

order to lift the load? Insert the distance value in the table above.

47. Calculate the velocity ratio and insert the data in the previous table.

48. Assemble a third system as shown in the following picture:

49. This is a compound pulley system. Put the sensor in place with the right

orientation and zero it again (without the slotted mass).

50. Hang a 100g slotted mass and click on the Record icon to start the

measurement.

Ver 2.15.4 10

51. Repeat the measurement with two 100 g slotted masses without erasing the first

measurement.

52. Write the results in the following data table.

Compound pulley

Slotted

mass

Load force

(with a

movable

pulley) [N]

Effort

force [N]

Mechanical

advantage

(Load/

Effort)

Distance moved by

the effort

(distance moved by

load is 10 cm) [cm]

Velocity

Ratio

100 g

200 g

53. Calculate the MA and insert the value into the table above.

54. Lift the load 10 cm up. What distance did you have to move the force sensor in

order to lift the load? Insert the distance value in the table above.

55. Calculate the velocity ratio and insert the data in the previous table.

ELECTRONIC INSTRUMENTATION

Add.: 12, Mahesh Nagar, Ambala Cantt,

Haryana, India

Tel: +91-171-2663087, 2662797

This manual suits for next models

1

Table of contents

Other Eisco Laboratory Equipment manuals