EK-Team VE 600 User manual

©

Page 1 of 25

Operating Instructions

Release: June 13, 2013

EK Vario Engraver VE 600

full size (A3) / half size (A4)

Page 2 of 25

1. Introduction...................................................................................................3

2. Scope of Supply ...........................................................................................4

3. Product Overview .........................................................................................6

4. Taking into Operation....................................................................................7

5. Operation ....................................................................................................11

6. Cleaning and Care .....................................................................................16

7. Accessories ................................................................................................17

8. Fault Rectification .......................................................................................19

9. Technical Data ...........................................................................................20

10. Packing Instructions for the VE 600 ........................................................21

11. Safety Instructions ...................................................................................22

12. Contact Information ..................................................................................25

Operating Instructions

Content

EK Vario Engraver VE 600

full size (A3) / half size (A4)

Page 3 of 25

1. Introduction:

By buying the VE 600 you have acquired a flexible engraving device which will enable

you to engrave materials made from plastics, aluminum, brass and special steel,

easily and rapidly.

●Tough device structure made of aluminum profiles

●Action area dimensions 220 mm x 305 mm

●Easy exchange of fixing plates for different engraving materials

●Engraving materials in thickness of up to 2.5 mm can be worked.

Special solutions up to a height of 10 mm are also possible

●Universal voltage supply of 100-240V AC

●PC interfaces: USB connection 2.0

●Command language: HPGL

●Material fixing by means of vacuum fixing plate or adhesive mat (option)

●Firmware update for VE 600 possible by means of PC connection, and therefore via

the Internet

●Vacuum cleaner connection for suction removal of engraving chips

●Engraving depth indicator

Page 4 of 25

2. Scope of Supply for the VE 600 Engraver

When you take delivery of the engraver, please check that the consignment is

complete. Please keep the outer packing, so that the device can be transported safely

when it comes to servicing.

The scope of supply consists of the following components:

1. Vario Engraver VE 600

2. Mains power cable 3. USB data cable

4. Operating Instructions 5. Engraving spindle with

engraving needle, .5 mm, 15°

Page 5 of 25

Scope of Supply for the VE 600 engraver

6. Connection cable for engraving spindle 7. Suction hose for engraving unit

8. Connection cable for vacuum cleaner 9. Stand tube

10. Clamp for hose and engraving

spindle cable

Page 6 of 25

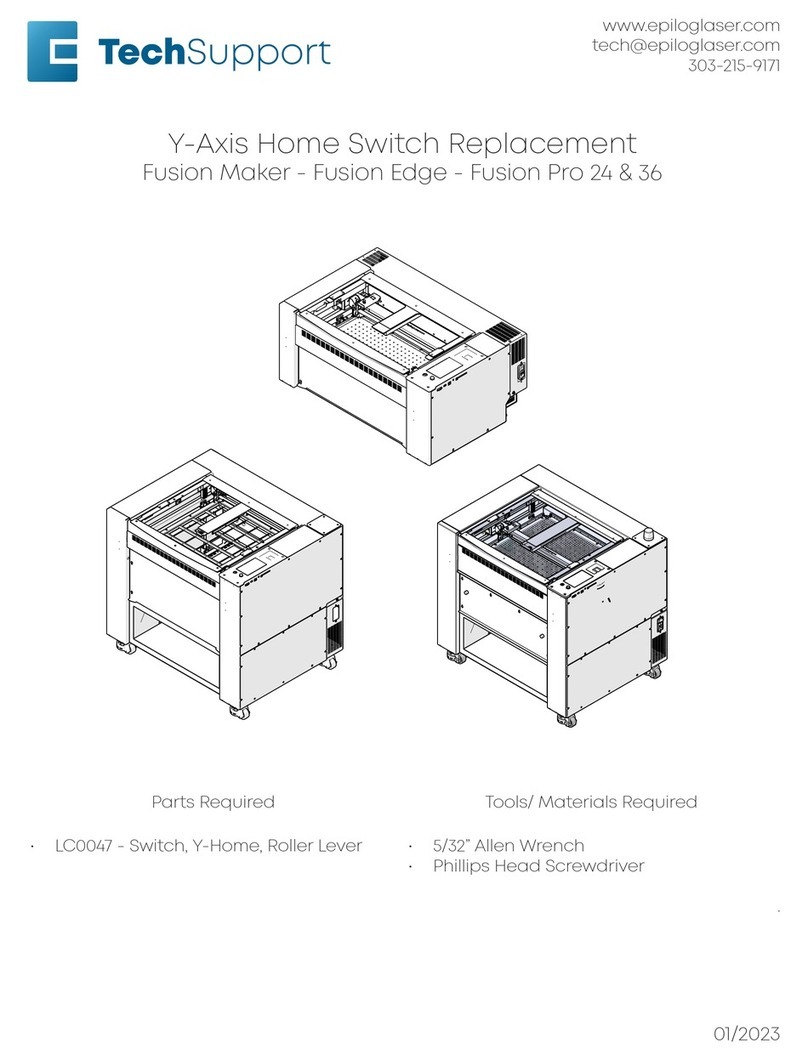

3. Product Overview

1) Engraving surface

2) Connection for engraving spindle

3) Connection for vacuum cleaner

4) On/Off switch

5) Fuse

6) Mains connection

7) USB connection

8) Operating panel/keypad

9) Engraving arm

10) Contact surface for zero setting of the engraving needle

11) Retaining pins for support plates

12) Engraving head

13) Engraving depth indicator

14) Mounting for cable and hose stand

2

45 6

11

Segment 1 Segment 2

11

98

12

7

1

3

10

14

13

Page 7 of 25

4. Taking the Vario Engraver VE 600 into operation

4.1 Setting up the engraver

The engraver is best set up a dry area, as free of dust as possible. Do not expose the

device to direct sunlight. Make sure that the connections are accessible at all times.

Set the VE 600 up in such a way that it stands securely and firmly on the surface

used.

Ensure that the engraving arm can move freely and is not blocked by any objects.

4.2 Connection

Connect the device by means of the mains power cable provided to a socket which

has been installed in the regulation manner. The VE 600 has a variable input AC

voltage of 100-240V~ 50-60Hz. The mains cable is exchangeable and can be adapted

to various different countries with different mains plugs.

The mains power connection is located on the

top left-hand side of the VE 600, which is where

you insert the mains cable provided.

Next to are the connections for the

vacuum cleaner and the engraving spindle.

Located at the connection point, as well as the On/Off switch, is

also the miniature fuse (4A).

Next, connect the device by means of the

USB data cable provided.

The connection point is located on the top

right-hand side of the VE 600.

Page 8 of 25

4.3 Insert the engraving spindle into the engraving head

As shown in the illustration, place the engraving spindle into the

engraving head and clamp the spindle tight with the quick-action

tightener. The engraving spindle is already fitted with an

engraving needle.

Note: Make sure the connection of the engraving spindle is

pointing towards the lever.

Caution:

Please read and take note of the safety instructions

for operation

4.4 Fitting the cable and hose stand

Insert the aluminum tube into the mounting.

Insert the clamping element for the engraving cable and the suction

hose into the aluminum tube.

4.5 Connections at the engraving head

Place the engraving head by hand (the engraver must be switched off)

into the bottom right-hand corner.

Connect the engraving spindle cable to the spindle and

tighten the screw connection of the plug to hand tightness. Now, as

shown in the illustration, lay the cable in a loose loop and clamp it

into the clamping element of the stand. Connect the other end of

the cable to the VE 600 and likewise tighten the screw connection

to hand tightness. Now plug the suction hose onto the engraving

head and lay the hose, like the cable, in a loose loop, then clamp

the hose into the clamping element of the stand.

4.6 Vacuum cleaner connection

You have the option of using the VC 500 vacuum cleaner, which is part of the product

range, or a conventional commercial vacuum cleaner for the suction clearance of the

engraving chips.

Caution:

Under no circumstances should you work without vacuum cleaning, since

otherwise the chips will cause serious dirt contamination of the engraver

Page 9 of 25

The EK-TEAM VC 500 vacuum cleaner is characterized by its

low noise development, and can be used in sustained

operation.

Note: If you use a conventional commercial vacuum

cleaner, take care to ensure that it is not overloaded by

excessively long operation.

4.7 Connection of the VC 500 vacuum cleaners

If possible, place the vacuum cleaner on the left

next to the engraver.

Now connect the vacuum cleaner connection

cable provided with the engraver to the

vacuum cleaner and the engraver, and tighten the screw

connections to hand tightness.

Next, remove the stopper on the vacuum cleaner and insert

the vacuum cleaner hose into the vacuum cleaner.

Note: During the engraving process the vacuum cleaner

switches on automatically and switches off again when the

process has ended.

4.8 Changing the vacuum cleaner filter

Conventional commercial vacuum cleaner bags are used for the

vacuum cleaner. Replacement bags can be obtained from us or via

a retail outlet.

To change the vacuum cleaner bag, actuate the catch on the

vacuum cleaner. The cover with the suction hose and vacuum

cleaner bag will open.

Before taking the bag out of its mounting, you must take off the

suction hose. To do this, rotate the hose and draw it outwards at

the same time. Re-installation takes place in the reverse order.

4.9 Replacing or cleaning the motor filter

Once you have opened the cover as described above, you can

remove the motor protection filter. To do this, you must reach

into the chamber for the vacuum cleaner bag and take out the

motor filter. It is sufficient to clean this filter from time to time.

Replacement filters can be obtained from EK-TEAM.

Page 10 of 25

4.10 Connecting a conventional commercial vacuum cleaner

If you want to use a conventional commercial vacuum cleaner, you need appropriate

adaptations, a switchbox for adapting the electrical arrangement

and a suction hose adapter. These can be optionally obtained

from us.

Plug the switch box provided into a socket installed in the

regulation manner.

Now connect the vacuum cleaner connection

cable supplied with the engraver to the switch

box and to the VE 600 and tighten the screw

connections to hand tightness.

Connect the suction hose fitted to

the VE 600 to the adapter

provided, and plug the hand

piece of the vacuum cleaner into

the rubber sleeve.

Plug the mains cable of the vacuum cleaner into the socket of

the switch box and turn the vacuum cleaner on.

Note: During the engraving process the vacuum cleaner

switches on automatically and switches off again when the process has ended.

Page 11 of 25

5. Operation

Once you have set up the VE 600, and the power supply and the data cable are

connected, you can switch the device on.

Caution:

Before the device is switched on, please make sure that there are no obstructive

objects on the working surface of the engraver which could interfere with the free

movement of the engraving arm.

Operating panel

Switching the vacuum

cleaner on and off

Changing the rotational

speed of the engraving

spindle

Failure with the

engraving spindle

Delete transferred

data from the PC Interruption or

breaking off the

engraving activity

5.1 Switching the VE 600 on and off

Turn the device on or off using the mains switch. When the device is switched on, the

engraving arm moves into the upper right-hand corner of the processing area, and

carries out auto-calibration. The green display lights up when the device is switched

on. The device is now ready for operation and can receive data from the PC.

All settings and actions are carried out via the operating panel.

VE 600 ready for

operation

Standardising the

engraving needle

zero setting

Changing the engraving

speed

Engraving spindle in

operation

Vacuum cleaner in

operation

Changing the penetration

speed

Page 12 of 25

5.2 Stop button

If the Stop button is actuated during a current job, the job will immediately be

interrupted and the engraving head will move into the upper right-hand corner of the

device. The red display indicates the interruption. When the button is actuated again,

the engraving arm will be calibrated and the job continued. The red display will go out.

5.3 Delete data memory with Clear Buffer button

If there are data present in the VE 600, this will be indicated by the yellow display

lighting up. You can delete these data by using the Clear buffer button. To do this, the

device must be in Stop mode (red display illuminated).

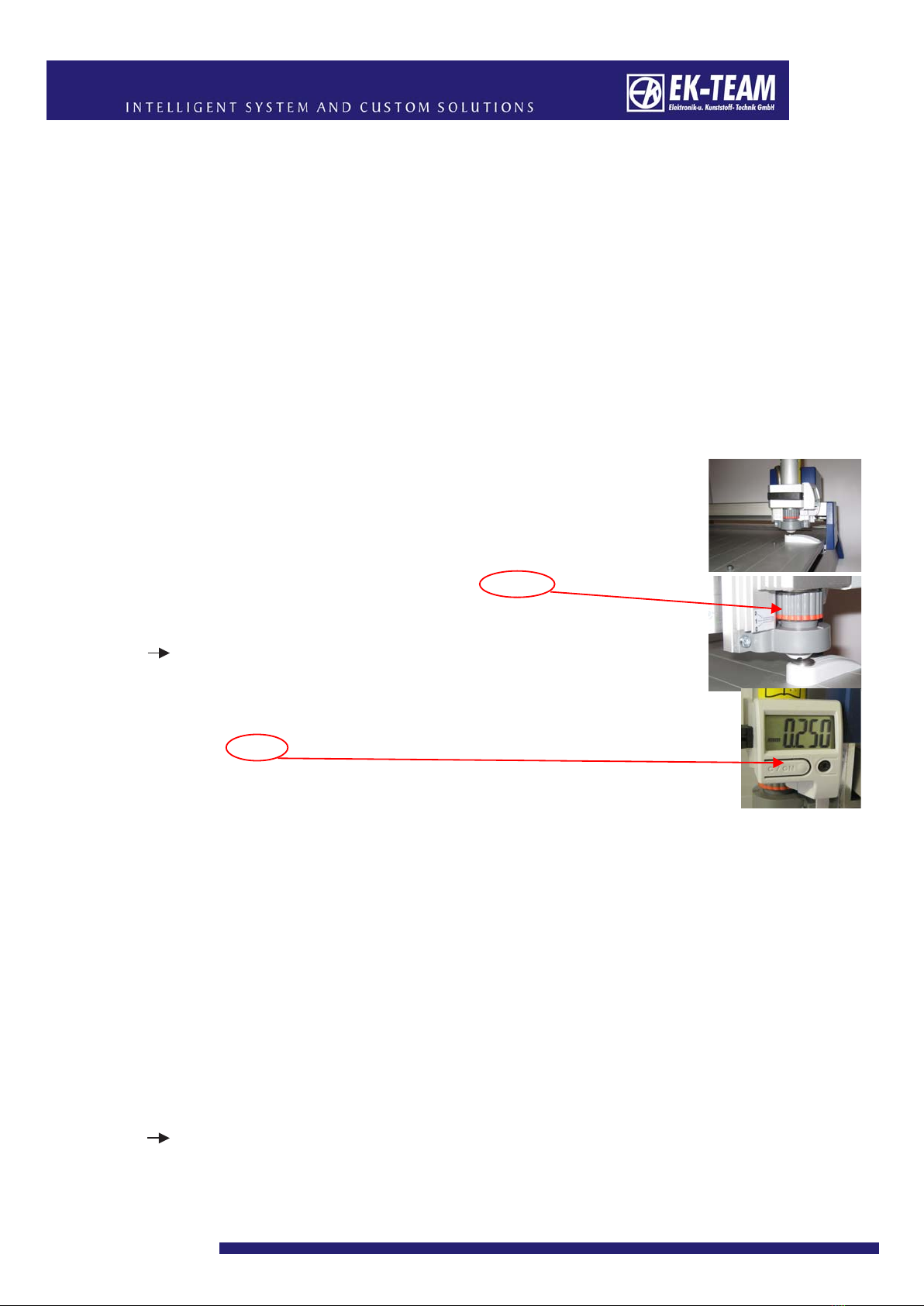

5.4 Norm button (standardisation of the engraving needle, zero setting)

If the Norm button is actuated, the engraving head will move to the

position (bottom right of the device) beneath which a contact

surface is located, and the engraving head will be lowered slowly.

As soon as the engraving needle reaches the contact surface, the

lowering of the engraving head will stop and an audible

signal will be issued. Now turn the depth adjuster to the left until the

audible signal stops.

This sets the engraving needle to the “zero position.”

Note: If there is no audible signal when the engraving head is

lowered, turn the depth adjuster to the right until the signal does

sound. Then turn it by one latch engagement position to the left.

The signal will go out and the “zero position” is set.

Press the button in order to zero the nos. of the indicator.

5.5 HIGH / LOW rotational speed of engraving spindle

When engraving data are transferred from the PC to the engraver, the

rotational speed of the engraving spindle will also be automatically transferred. If you

want to change these data during the engraving process, you can change the speed

by means of the appropriate buttons.

Actuation of the HIGH button will increase the engraving spindle speed 5000 rpm

(revolutions per minute), and actuation of the LOW button will reduce it by 5000 rpm.

5.6 HIGH / LOW engraving speed

When engraving data are transferred from the PC to the engraver, the engraving

speed will also be automatically transferred. If you want to change these data during

the engraving process, you can change the speed by means of the appropriate

buttons.

By actuating the HIGH button, the engraving speed will be increased by

2 mm/sec., and by actuating the LOW button it is reduced by 2 mm/sec.

Note: The adoption of the speed change takes place with a slight delay.

Page 13 of 25

5.7 HIGH / LOW penetration speed

When engraving data are transferred from the PC to the engraver, the penetration

speed will also be automatically transferred. If you want to change these data during

the engraving process, you can change the speed by means of the appropriate

buttons.

By actuating the HIGH button, the penetration speed will be increased by 2 mm/sec.,

and by actuating the LOW button it is reduced by 2 mm/sec.

Note: The adoption of the speed change takes place with a slight delay.

5.8 Placing support plates for fixing the engraving materials

There are a number of different support plates optionally available for fixing the

engraving material. Place the support plate being used over the retaining pins on the

engraving unit.

1) Universal support plate DIN A4/A3 (adhesion mat)

The universal support plate is suitable for materials up to

dimensions of 400x300 mm. The thickness of the material must not

exceed 2.5 mm.

The adhesion mat secures the engraving material against sliding.

2) Universal support plate DIN A4 with vacuum connection

The universal support plate is suitable for materials up to

dimensions of 200x300 mm. The thickness of the material must not

exceed 2.5 mm. The support plate has a vacuum connection

to which you can connect an in-house vacuum line.

As an option, we can offer a vacuum pump or a converter

which produces a vacuum out of compressed air

(see Accessories).

3) 3-fold Universal support plate

You can process three engraving plates on this support plate, up to

dimensions of 90x100 mm. Material thickness up to 2.5 mm.

4) 4-fold Universal support plate

You can process four engraving plates on this support plate, up to

dimensions of 60x100 mm. Material thickness up to 2.5 mm.

5) 9-fold Universal support plate

You can process nine engraving plates on this support plate, up to

dimensions of 30x100 mm. Material thickness up to 2.5 mm.

Page 14 of 25

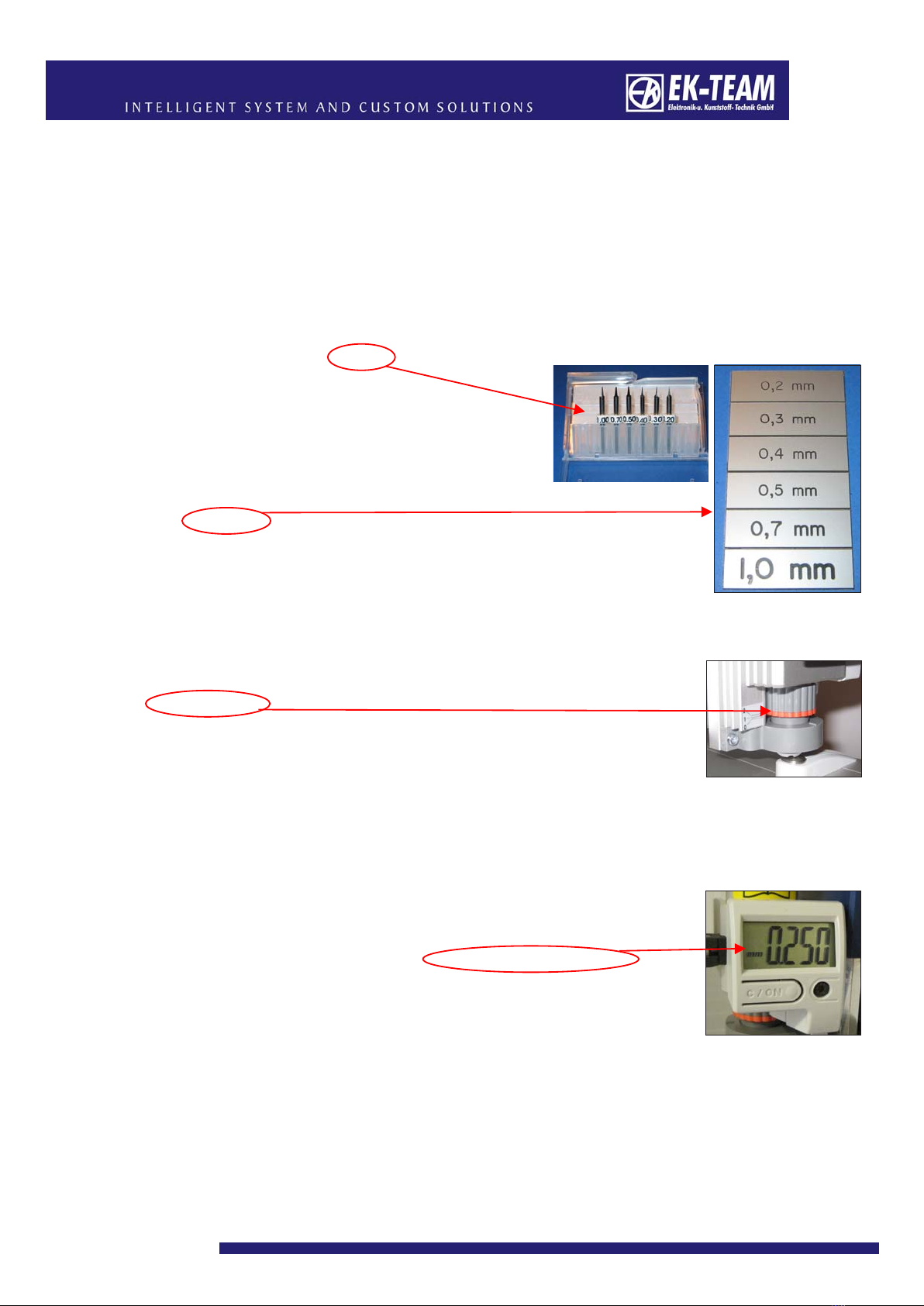

5.9 Adjusting the engraving depth

The engraving depth is determined by means of the depth adjuster on the engraving

spindle. Different script widths for the engraving are attained as a function of the width

and grinding angle of the engraving needle used, as well as the penetration depth into

the material.

For normal use we recommend the use of engraving needles with a grinding angle

of 15°.

These are available in widths of 0.2; 0.3; 0.4;

0.5; 0.7; 1.0 mm.

Special shapes are available on request.

The examples shown will give you an idea of

the different results of the engravings.

5.9.1 Engraving depth indicator

The setting of the engraving depth is carried out by rotating the

depth adjuster. By turning it to the right, the depth of the engraving

is increased, and by turning it to the left it is reduced.

When you actuate the depth adjuster, you will feel

a latching engagement.

With each engagement, the engraving needle is set higher or lower by 0.05 mm. Once

you have turned the adjuster by one revolution to the right, you will have

reached an engraving depth of 1 mm

(20 latch engagements of 0.05 mm each).

You can read off the depth on the engraving depth indicator on the

left next to the engraving spindle.

Caution: The tips of the engraving needle are highly sensitive and must be

treated very carefully. Avoid damaging the tips. If they are damaged, the quality

of the lettering will be severely impaired.

Page 15 of 25

5.10 Changing the engraving needle

To change the engraving needle, proceed as follows: Release the securing

arrangement on the engraving

head and take out the

engraving spindle.

The connection cable does not

need to be detached. Now

rotate the depth adjuster away from the engraving spindle.

Caution: The engraving needle and the spindle may have

become hot due to operation.

Next, you must release the clamping jaws by using

the rotary knob at the end of the spindle. To do this,

push the knob in and turn it to

the left.

The jaws will now be open and

you can remove the

engraving needle.

Caution: Only release the clamping jaws just enough to allow the engraving

needle to be removed. The clamping jaws should only be opened completely for

cleaning purposes.

In order to ensure the correct length of the engraving needle, only use

engraving needles supplied exclusively by EK-TEAM with the identification ring.

We cannot undertake any guarantee for script quality or damage to the units if

other makes are used.

Caution: The tips of the engraving needles are highly sensitive and must be

treated very carefully. Avoid damaging the tips. If they are

damaged, the quality of the lettering will be severely impaired.

Slide the engraving needle into the clamping jaws as far as the

identification ring, and then tighten it up again.

Now rotate the depth adjuster onto the engraving spindle again,

until the tip of the engraving needle is still not quite projecting

(finger or material test).

Now put the engraving spindle back into the engraving head and tighten the clamping

block again with the quick-action clamping device.

For the zero setting of the engraving needle, now actuate the Norm switch and

proceed as described under 5.4.

Page 16 of 25

6. Cleaning and Care

Protect the VE 600 from dust and other dirt contamination.

Cover it over when it is not in use.

Wipe the device with a duster occasionally after use, either dry or moistened with a

mild cleaning agent.

Caution:

Never use aggressive cleaning agents to clean the Vario Engraver VE 600.

Never oil the mechanical parts of your engraver.

6.1 Handling the engraving spindle

The engraving spindle is a sensitive unit and should be treated extremely carefully.

Please use the spindle in dust-free areas only. An excessive dust burden will lead to

the sensitive bearings becoming clogged with dust, and then wearing out rapidly.

Never use compressed air to clean the spindles, because that will remove the

lubricant from the ball bearings. Do not use any lubricants when engraving. Never

clean the engraving spindle with water.

If, despite this, dust particles do appear in the clamping jaws, this may be indicated,

for example, by unclean engraving. In this case, remove the

engraving needle and rotate the jaws out with the aid of the rotary

knob. Wipe out the front part of the jaw seat with a

clean cotton swab (Q-tip), (see illustration).

Page 17 of 25

7. Accessories

Description Part no. Illustration

Engraving needle 15° - .2 mm 3501 0003

Engraving needle 15° - .3 mm

Engraving needle 15° - .4 mm

3501 0002

3501 0001

Engraving needle 15° - .5 mm

Engraving needle 15° - .7 mm

Engraving needle 15° - 1.0 mm

Engraving needle 15° - Set of .2; .3; .4; .5; .7; 1.0

3501 0000

3501 0004

3501 0005

3501 0006

Engraving needle 36° - .2 mm

Engraving needle 36° - .3 mm

Engraving needle 36° - .4 mm

Engraving needle 36° - .5 mm

3501 0015

3501 0016

3501 0017

3501 0018

Engraving needle 36° - .7 mm

Engraving needle 36° - 1.0 mm

Engraving needle 36° - Set of .2; .3; .4; .5; .7; 1.0

Engraving needle 60° - .2 mm

3501 0019

3501 0020

3501 0021

Engraving needle 60° - .3 mm

Engraving needle 60° - .4 mm

Engraving needle 60° - .5 mm

Engraving needle 60° - .7 mm

3501 0022

3501 0023

3501 0024

3501 0025

Engraving needle 60° - 1.0 mm

Engraving needle 60° - Set of .2; .3; .4; .5; .7; 1.0

Engraving needle 90° - .2 mm

Engraving needle 90° - .3 mm

3501 0026

3501 0027

3501 0028

Engraving needle 90° - .4 mm

Engraving needle 90° - .5 mm

Engraving needle 90° - .7 mm

Engraving needle 90° - 1.0 mm

3501 0029

3501 0010

3501 0011

3501 0012

Engraving needle 90° - Set of .2; .3; .4; .5; .7; 1.0

Engraving needle 35° - .2 mm

Engraving needle 35° - .4 mm

3501 0013

3501 0014

Double tooth cutter fishtail .50 mm

Double tooth cutter fishtail .60 mm

Double tooth cutter fishtail .80 mm

3501 0030

3501 0031

3501 0032

Double tooth cutter fishtail 1.00 mm

Double tooth cutter fishtail 1.20 mm

Double tooth cutter fishtail 1.40 mm

Double tooth cutter fishtail 1.60 mm

3501 0033

3501 0034

3501 0035

3501 0036

Double tooth cutter fishtail 2.00 mm

Double tooth cutter fishtail 2.40 mm

Double tooth cutter fishtail 3.00 mm

Double tooth cutter fishtail - Set of .50; .60;

3501 0037

3501 0038

3501 0039

.80; 1.00; 1.20; 1.40; 1.60; 2.00; 2.40; 3.00

Page 18 of 25

Description Part no. Illustration

Universal support plate

for Engraving and Plotting 3490 2106

half size

(

DIN A4

)

Engraving material please call for details

full size DIN A3/ half size DIN A4

blank sheet or pre-sized tags

Universal support plate 3490 2156

for Engraving and Plotting

half size

(

DIN A4

)

Vacuum

Vacuum cleaner bags (5 bags) 3502 0000

Adapter set to connect with 3400 0057

standard vacuum cleaners

Converter compressed air to vacuum 3491 0012

Vacuum pump for vacuum support plates 3491 0011

Universal support plate 3490 2117

90x100 mm

Universal support plate 3490 2116

60x100 mm

Universal support plate 3490 2115

30x100 mm

Optical measurement tool 3400 0058

Engraving for VE 600

VC 500 Vacuum cleaner 3400 0056

Page 19 of 25

8. Fault Rectification

VE 600 engraver cannot be

switched on.

The green “Power” LED

is not lighting

up.

The red LED is illuminated on

the VE 600,

“Spindle fault“.

Caution:

Engraving unit interrupts the

en

g

ravin

g p

rocess.

Check whether the mains power connection cable is connected.

Check whether the socket being used is in good order.

Check whether the mains infeed fuse on the VE 600 is in good order.

To do this, pull out the mains cable at the infeed module and the fuse

element next to the mains switch.

See Handbook page 7

High-frequency spindle is defective or there is an overload.

To check this, actuate the buttons HIGH and LOW together on the

VE 600. This allows you to increase or reduce the rotational speed of

the spindle with the buttons. If the red fault LED lights up again, the

spindle is defective and must be replaced.

Engraving operation not

possible

Check whether the connection cable between the VE 600 and the

spindle is connected. Refer to the instructions in the script

creation software VarioSign. Has the correct output device been

selected?

Check the interface cable.

Engraving is not being carried

out cleanly. Poor script image

and/or burr formation on the

engraved characters.

Check the engraving needle. If the tip is broken off or damaged the

engraving needle must be replaced.

Check whether there are any engraving chips in the spindle head or in

the spindle clamping jaws. To do this, unscrew the depth adjuster and

take the jaws out of the spindle. Clean the depth

adjuster and the spindle clamping jaws as described in the

Cleaning and Care section, “Handling the engraving spindle”,

see page 16.

Caution: Do not use compressed air to carry out cleaning.

The desired engraving depth is

not being reached.

Next, check whether there is a sufficient distance between the depth

adjuster and the engraving material, min .5 mm to about

1 mm.

To do this, move the engraving head, with the VE 600 switched off, by

hand over the engraving material and check the distance in this way.

RemedyFault description

Page 20 of 25

9. Technical Data

Vario Engraver VE 600

x-y unit: Flatbed engraver

Maximum engraving surface: A3: 440 mm x 305 mm/17.32 inch x 12.01 inch,

A4: 220 mm x 305 mm/8.66 inch x 12.01 inch

Engraving speed: max. 20 mm/s / .79 inch/s

Interfaces: USB Level 2.0

Command language: based on HP-GL 7475A

Data buffer: 16 MB

Drive: Two-phase stepper motor

Addressable resolution: .01 mm / .0004 inch

Repetition precision: .05 mm / .002 inch

Voltage supply: 100-240V AC 50-60Hz

Input current: .7 A max.

Ambient conditions: Operation: 10°C - 35°C / 50°F - 95°F

35% - 75% rel. air humidity

Storage: -10°C - 50°C / 14°F - 122°F

10% - 90% rel. air humidity

Safety certificates: EN 60950-1

Operational reliability: EN 55022 B

EN 61000-4-2 bis 6

EN 61000-4-11

Dimensions: A3: 660 mm (A4: 440 mm)x 440 mm x 125 mm/

25.98 inch(A4: 17.32 inch)x 17.32 x 4.92 inch

Weight: A3: approx. 8,85 kg / 17.64 inch,

A4: approx. 7 kg / 15.43 inch

Engraving spindle

Rotational speed: min. 5000 RPM, max. 50.000 RPM

Torque: 6 Ncm

Frequency: 83-830 Hz

Power consumption: max. 60 W

Clamping jaws: Shaft diameter 3 mm / .12 inch;

Clamping mechanism: Head gripping

Concentricity with clamping jaws: .03 mm / .001 inch

Motor design: Three-phase AC asynchronous, brushless

Housing: Aluminum

Clamping diameter: 25 mm / .98 inch

Ball bearing type: Steel, permanent lubrication, two-fold

Cooling: Self-ventilating with integrated fan

Weight: approx. 280 g / .62 lbs

Overall length: approx. 175 mm /6.89 inch

Scope of use: Exclusively for engraving

Guaranteed bearing service life: min. 1000 hours with appropriate use

Table of contents