EkoStinger Fixed System User manual

Installation Manual | Fixed System

V 1.02

1/28/2021 EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com

Need help? Please call EkoStinger at 855-833-7940

www.ekostinger.com

Installation Manual | Fixed System

Important Safety Instructions

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 1

General Safety Warning

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in serious injury.

SAVE A WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

1) Work Area Safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids,

gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep non needed personnel away while performing the installation. Distractions can cause accidents.

2) Personal Safety

Use personal protective equipment. Always wear eye and ear protection.

3) Unit Servicing

Recheck declared Torque after the rst 1,000 miles.

Recheck declared Torque every 10,000 miles.

4) Manufacturer's suggested Torque values

3/8" Hardware: 23 ft-lb

1/4" Hardware: 6.3 ft-lb

U.S. Recommended Bolt Torque Table

Size

Recommended Torque

Grade 2 Grade 5 Grade 8 18-8 S/S Bronze Brass

Coarse Fine Coarse Fine Coarse Fine Coarse Fine Coarse Fine Coarse Fine

* #4 - - - - - - 5.2 - 4.8 - 4.3 -

* #6 - - - - - - 9.6 - 8.9 - 7.9 -

* #8 - - - - - - 19.8 - 18.4 - 16.2 -

*#10 - - - - - - 22.8 31.7 21.2 29.3 18.6 25.9

1/4 4 4.7 6.3 7.3 9 10 6.3 7.8 5.7 7.3 5.1 6.4

5/16 8 9 13 14 18 20 11 11.8 10.3 10.9 8.9 9.7

3/8 15 17 23 26 33 37 20 22 18 20 16 18

7/16 24 27 37 41 52 58 31 33 29 31 26 27

1/2 37 41 57 64 80 90 43 45 40 42 35 37

9/16 53 59 82 91 115 129 57 63 53 58 47 51

5/8 73 83 112 128 159 180 93 104 86 96 76 85

3/4 125 138 200 223 282 315 128 124 104 102 118 115

7/8 129 144 322 355 454 501 194 193 178 178 159 158

** 1 188 210 483 541 682 764 287 289 265 240 235 212

* Sizes from 4 to 10 are in in.-lbs.

Sizes from 1/4 up are in ft.-lbs.

**Fine thread gures are for 1-14.

Grade 2, 5, and 8 values are for plated bolts.

Installation Manual | Fixed System

Table Of Contents

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 2

Important Safety Instructions

Table of Contents

Parts ist

Shipped Items

Hardware Box (Fixed)

Exploded Diagram - Part Numbers

Assembly

Know Your Stinger Parts

Assembly Tools

Front Brace Assembly

Rear Brace Assembly

Attaching Bottom Support Angle

Attaching Cables

Assembly Finished

Installation

Installation Tools

Airline Cover

Measuring and Prep

Raising Stinger

I-Beam Anchoring via Plates

Wing Gussets

Installation Complete

Notes

1

2

3

4

5

6

7

8-9

10-11

12

13

14

15

16-17

18-22

23-25

26-28

29

30

31

1x - Stinger Shell - M Dxxx-Fx

1x - Bottom Support Angle - 10093F

1x - Hardware Box (Fixed) - HBFX

2x - 24" x 27" Aerodynamic Mud Flaps 14x - Zip Ties

8’ - Wire oom

Installation Manual | Fixed System

Parts List - Shipped Items

What comes with your EkoStinger order?

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 3

Installation Manual | Fixed System

Parts List - Shipped Items

What comes with your EkoStinger order?

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 4

20004 161/4"-20x1" Washer Head w/Patch

Part # Items QTY

Fixed Plate Bolts w/Loctite Patch

FX1001B

20091

20010

16

16

3/8"-16x1.5" Hex Bolt SS

3/8"-16 Nylock Nut

Part # Items QTY

Fixed Faceplate Hardware Bag

FX1002B

20044

20085

20006

EYE-H

10

4

7

1

1/4"x1" SS Fender Washer

1/4"-20x1" SS Hex Bolt

1/4"-20 Nylock Nut

Eyehook 1/4"x1"x7/8"

Part # Items QTY

Fixed Support Hardware

FX1005B

20044

20085

20006

2

2

2

1/4"x1" SS Fender Washer

1/4"-20x1" SS Hex Bolt

1/4"-20 Nylock Nut

Part # Items QTY

Wing Gusset Hardware Bag

FXG S-HWB

FX-GUS

20018

20004

1

2

2

3" x 3" x 5" Aluminum Bracket

Small Plate

1/4"-20 Bolt

Part # Items QTY

Rear Wing Gusset - Flat Bottom

FX1004F

FXBR-

FXBR-R

2

2

6"x15"90°Plate 4 Holes, 4 Slots, Powder

Coated, Painted, eft (Steel Brace Plate)

6"x15"90°Plate 4 Holes, 4 Slots, Powder

Coated, Painted, Right (Steel Brace Plate)

Part # Items QTY

Fixed Braces

FXSP

FXFP

FX1002B

8

8

1

1/4"x4.25" Aluminum Plate (Mold Brace Spacer)

1/8"x4.25" Aluminum Plate (Fixed Faceplate)

Fixed Faceplate Hardware Bag

Part # Items QTY

Faceplates and Spacers with Bolts and Nuts

FX1002A

FX1001B

PF Bag

1

1

Fixed Plate Bolts w/ octite Patch

arge Plates - Fixed

Part # Items QTY

Fixed Large Plate Bag

FX1001A

FX-CB

FX1005B

2

1

Rear Support Cable

Fixed Support Hardware

Part # Items QTY

Rear Cable Bag with Fixed Support Hardware Bag

FX1005A

20017F

20017RED

4

4

arge Plate

arge Plate - Paint Red

Part # Items QTY

Large Plate Fixed nit Bag

LPF Bag

Hardware Box (Fixed) - HBFX

Installation Manual | Fixed System

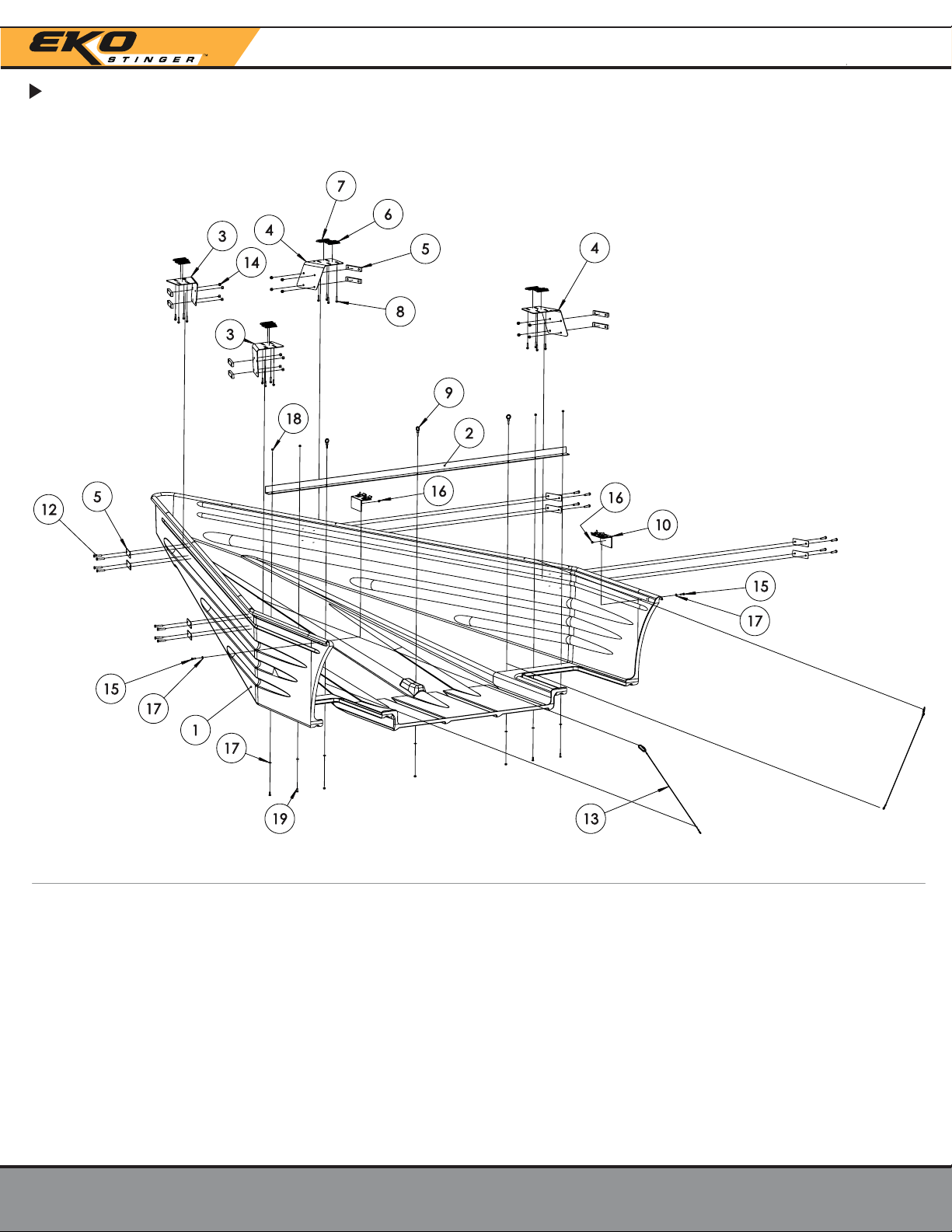

Parts List - Exploded Diagram

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 5

M Dxxx-Fx

10093

FxBR-

FxBR-R

FxFP

20017RED

20017

20004

EYE-H

FX-GUS

20091

FX-CB

20010

20085

20006

20044

20006

20085

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

Stinger Shell

Bottom Support Angle

FX eft Brace

FX Right Brace

FX Faceplate

Red Plate

Plate

Plate Bolts

Eyehook

Wing Gusset

FX Faceplate Bolt

Rear Support Cable

3/8"-16 ocknut

Wing Gusset Shell Bolt

Wing Gusset Shell Nylock

Washer

1/4"-20 ocknut

Bottom Support Angle Bolt

# #Part Name Part NamePart Number Part Number

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 6

Know Your Stinger Parts - Assembled Stinger Unit

Right Brace

FxBR-R

eft Brace

FxBR-

eft Brace

FxBR-

Right Brace

FxBR-R

Plate

20017F

(4x)

Red Plate

20017F

(4x)

Support Cable Hole

(2x)

Stinger

Shell

M Dxxx-Fx

Wing Gusset

FX-GUS

Bottom Support Angle

10093F

Support Cables

FX-CB

9/16 Wrench

Installation Manual | Fixed System

Assembly - Stinger Unit - Required Tools

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 7

Cordless Impact Driver

Socket Adapter

7/16 Wrench

7/16 Socket

9/16 Socket

3/8 Driver

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 8

Torque

23 ft-lb

Refer to

manufacturers

suggested

Torque values

on pg. 2.

Front Brace Assembly

Attach the Left Brace (FxBr-L) by inserting 4x Outside Bolts (20091)

through 2x Faceplates (FxFp), Stinger Shell, and continuing through the

2x Spacers (FxSp), the Left Brace (FxBr-L), and fastening at the end with

4x Lock Nuts (20010). Make sure the Brace is facing outward just like

in the picture. Do the same for the right side.

1

eft Brace

FxBr-

(Right Side: FxBr-R)

3/8 ock Nut

20010

(4x)

Spacer

FxSp

(2x)

Faceplate

FxFp

(2x)

Outside Bolt

3/8-16 x 1.5 Hex Bolt

20091

(4x)

Fixed Faceplate Hardware Bag

Faceplates and Spacers w/ Bolts + Nuts

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 9

Fixed Plate Bolts w/Loctite Patch

Fixed Large Plate Bag

Front Brace Assembly

Attach the Plate (20017F) by inserting 2x Plate Bolts (20004) through

the Brace and into the threaded Plate. Make sure the Plate

is facing toward the center of the Brace, just like in the picture.

Do the same on the other side. Finger tighten for now.

2

Plate

20017F

Plate Bolt

20004

(2x)

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 10

Torque

23 ft-lb

Refer to

manufacturers

suggested

Torque values

on pg. 2.

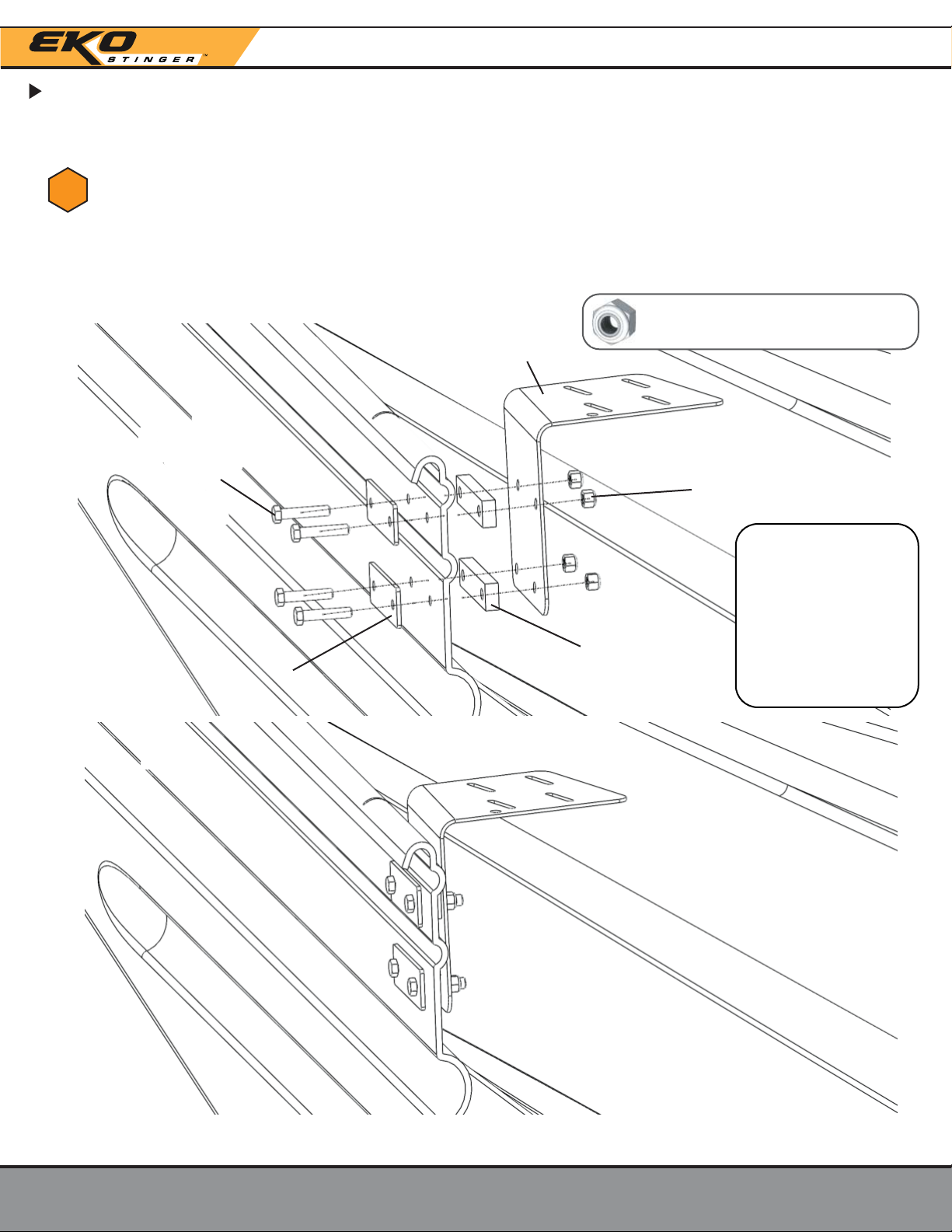

Rear Brace Assembly

Attach the Left Brace (FxBr-L) by inserting 4x Outside Bolts (20091)

through 2x Faceplates (FxFp), Stinger Shell, and continuing through the

2x Spacers (FxSp), the Left Brace (FxBr-L), and fastening at the end with

4x Lock Nuts (20010). Make sure the Brace is facing inward just like in

the picture. Do the same for the right side.

3

eft Brace

FxBr-

3/8 ock Nut

20010

(4x)

Spacer

FxSp

(2x)

Faceplate

FxFp

(2x)

Outside Bolt

3/8-16 x 1.5 Hex Bolt

20091

(4x)

Fixed Faceplate Hardware Bag

Faceplates and Spacers w/ Bolts + Nuts

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 11

Plate

20017

Plate Bolt

20004

(2x)

Fixed Plate Bolts w/Loctite Patch

Fixed Large Plate Bag

Rear Brace Assembly

4Attach the Plate (20017) by inserting 2x Plate Bolts (20004) through

the Brace and into the threaded Plate. Make sure the Plate

is facing toward the center of the Brace, just like in the picture.

Do the same on the other side. Finger tighten for now.

Torque

6.3 ft-lb

Refer to

manufacturers

suggested

Torque values

on pg. 2.

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 12

5

Attaching Bottom Support Angle5

Fixed Support Hardware Bag

Attach the Bottom Support Angle (10093F) by installing 3x Eyehooks (EYE-H)

from the top and 4x Hex bolts (20085) from the bottom. Secure each

Eyehook and Hex bolt using a washer (20044) and a Locknut (20006).

Eyehook

EYE-H

(3x)

Cable

FX-CB

(2x)

No Cable

ocknut

20006

(7x)

Note: Two of the Eye Hooks come with cables pre-

attached. These need to be installed on the sides.

The center EyeHook is not attached to a cable.

Washer

20044

(7x) Hex bolt

20085

(4x)

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 13

Attaching Cables

6

Rear Cable w/ Fixed Support Hardware

Attach the cross cables using the provided carabiners to the rear Braces.

Installation Manual | Fixed System

Assembly - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 14

Assembly Finished

7Your Fixed System Stinger assembly is now nished. Please look over all bolts,

and make sure they are tightened to their specied Torque values (reference

pg.2 ).

Installation Manual | Fixed System

Installation

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com

Installation - Required Tools

Installing the Stinger Unit onto the Trailer

Cordless

Impact

Driver

3/8 Driver

Tape Measure

pg. 15

OPTIONAL LIFT KIT

An optional lift kit can be provided containing ocking Block and Tackle and Nose Cable, which would

allow the system installation to be performed by one installer, but we recommend two installers for ease

of installation.

Without the ift Kit, we recommend the installation to be performed by at least 3 installers.

Installation - Airline Cover

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com

Installation Manual | Fixed System

pg. 16

Locate the Wire Looms (8x) and the Zip Ties (14x).

Starting with the front air line and electrical wires, slip the protective wrap

over the air lines and wires. Position the cover so there is no more than

four (4) inches of exposed lines. Secure with Zip Ties.

8

9

4”MAX

Installation - Airline Cover

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com

Installation Manual | Fixed System

Continue working the Wire Looms over the air lines and electrical harness

until the rst cable restraint and spring tensioner is reached. Secure with

Zip Ties every 12 inches.

Continue installing the Wire Loom until the entire air line, and electrical

wiring is covered from end to end. Secure with Zip Ties every 12 inches.

10

11

pg. 17

Installation Manual | Fixed System

Installation - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 18

Measuring and Prep

Locate the starting I-Beam, determined by the customer’s Suspension

Sub-Frame placement.

12

Starting position will be a minimum of 42” and a maximum of 48” from

the leading edge of the tire from customer's designated maximum

forward position.

42”-48”

Installation Manual | Fixed System

Installation - Stinger Unit

EkoStinger|140 Despatch Dr, East Rochester, NY 14445|855.833.7940|info@ekostinger.com pg. 19

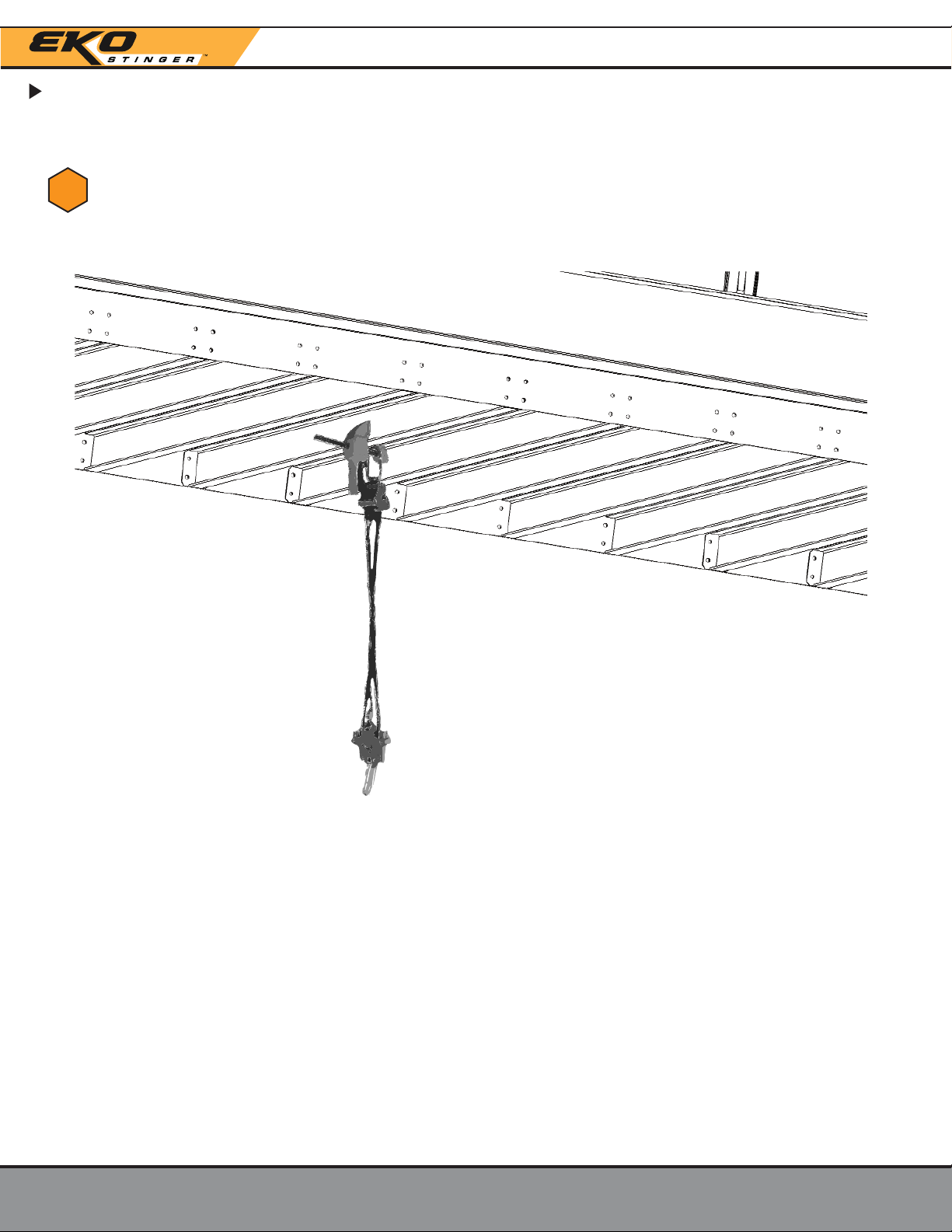

Measuring and Prep

Mark center of the I-Beam and hang Winch with a Quick Clamp.

13

Table of contents

Popular Industrial Equipment manuals by other brands

Greenlee

Greenlee Gator Intelli-PUNCH instruction manual

Siemens

Siemens SINUMERIK MPP 1500D Equipment manual

schmersal

schmersal AZM300B-I2-ST-SD2P-A-T-DU Operation instructions

Titan

Titan VS-32-L Operating and maintenance instructions

Siemens

Siemens SIMATIC NET SCALANCE M-800 Getting started

Premier

Premier 470 Installation, Inspection, Operation & Maintenance Guide

TigerStop

TigerStop TigerSPC user manual

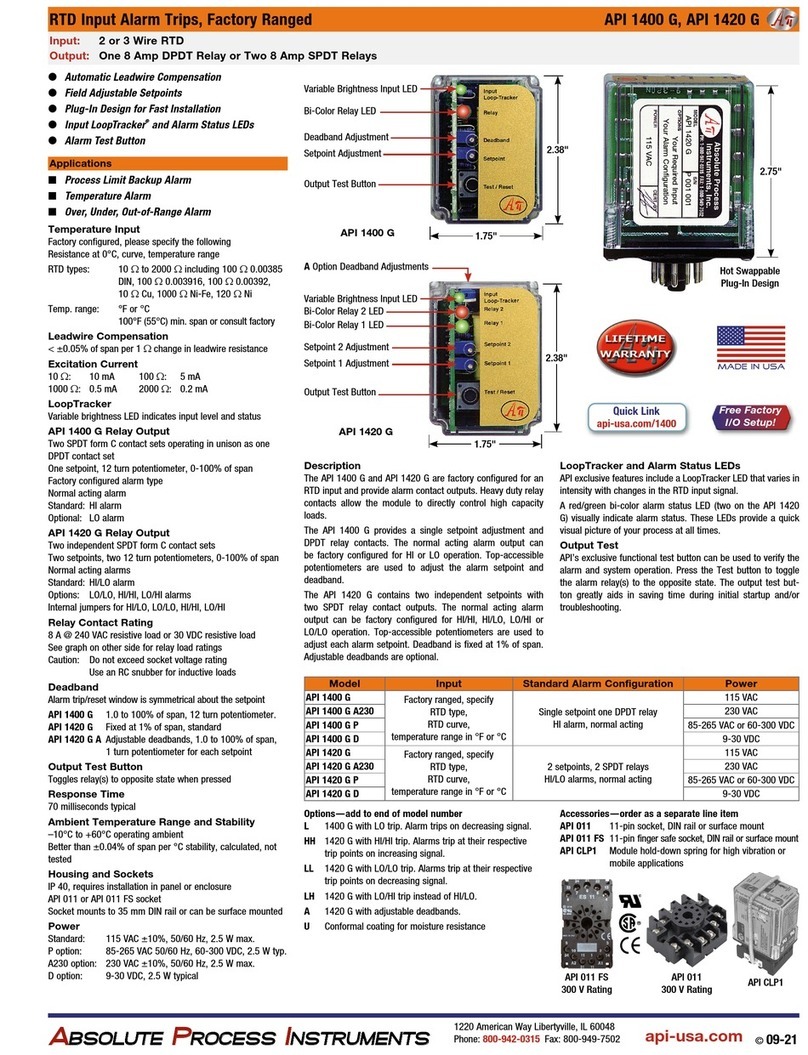

Absolute Process Instruments

Absolute Process Instruments API 1400 G quick start guide

Goudsmit

Goudsmit Easy Clean Cleanflow SECE Series user manual

GRUNDFOS ALLDOS

GRUNDFOS ALLDOS Oxiperm C 164 Series Operation and service manual

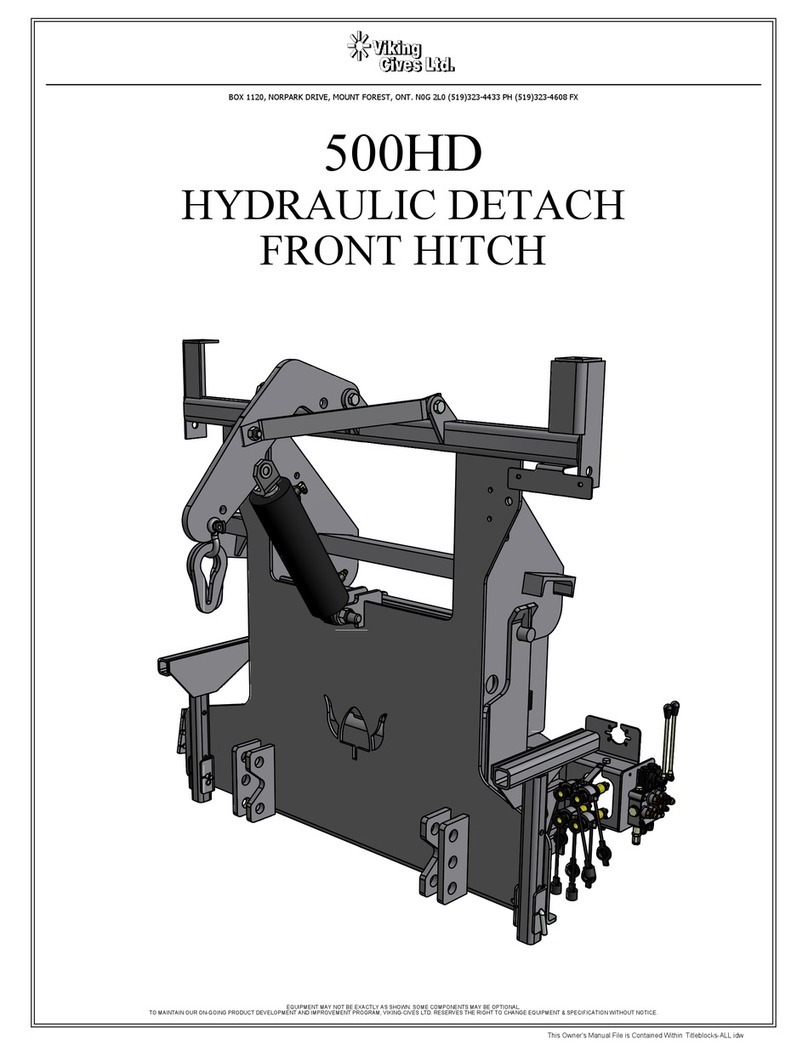

Viking-Cives

Viking-Cives 500HD manual

CKD

CKD M4G Series instruction manual