EKOVENT AB The right to changes is reserved 2022-06

3

Product management

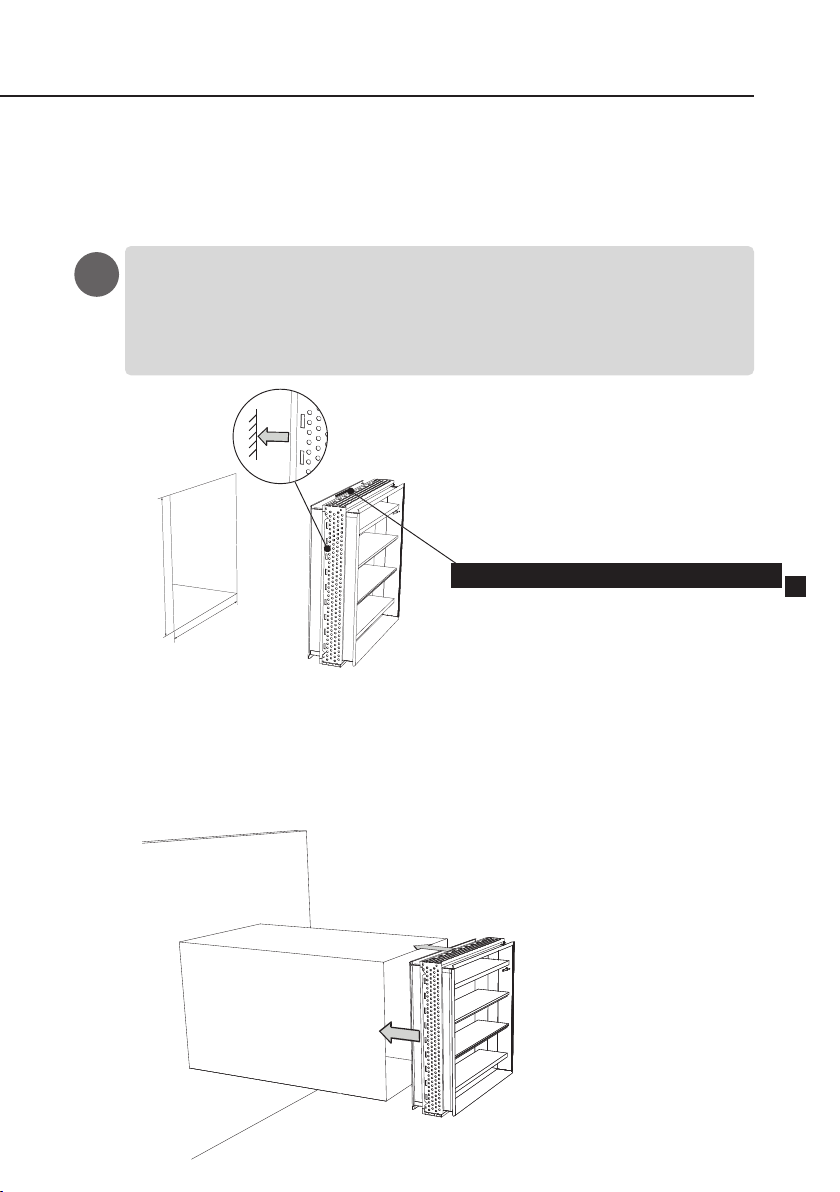

Transport

The re dampers must be transported to the

installation site using a truck or crane

with lifting fork.

Important !

To avoid damage the product must be

lifted, the product must not be pulled or

lowered hard against the surface.

Reception and inspection

of the delivery

Check the delivery for transport damage

and to ensure that it is copmplete as soon

as it arrives to the site. The approved

delivery is acknowledged by the

consignment note. Products with defects

may not be installed. Contact the supplier

immediatel

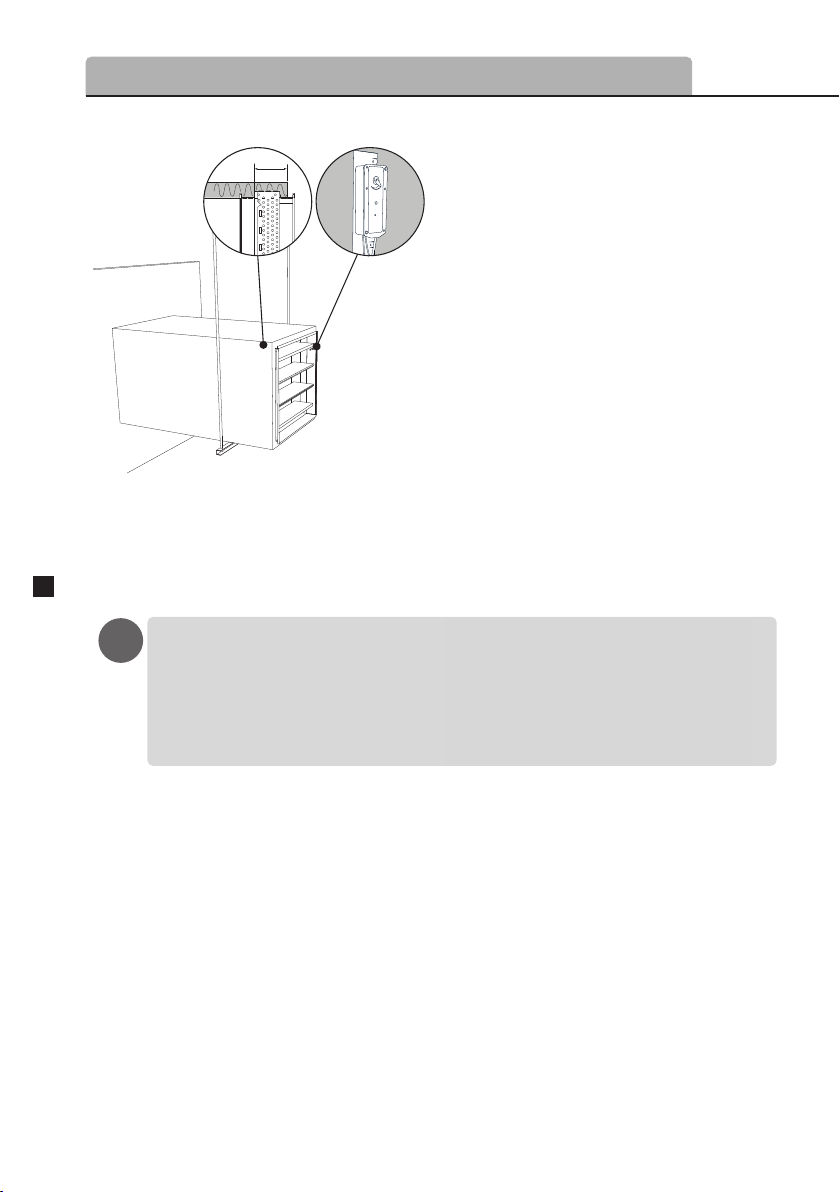

Storage

The storage of materials at the site should

be planned so that you get the minimum

possible internal transport. The re

dampers must protected against water and

always stored in a dry place. Furthermore,

they must be handled so that no

mechanical damage occurs to them.

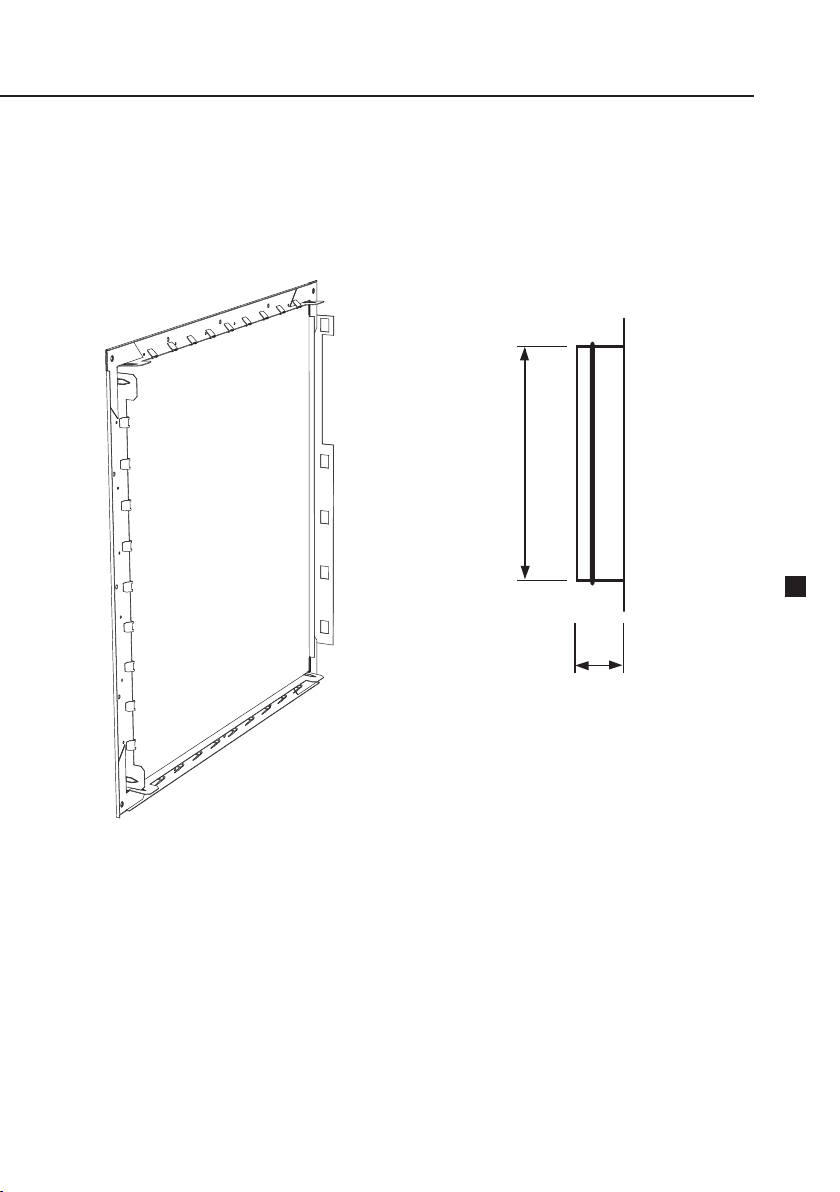

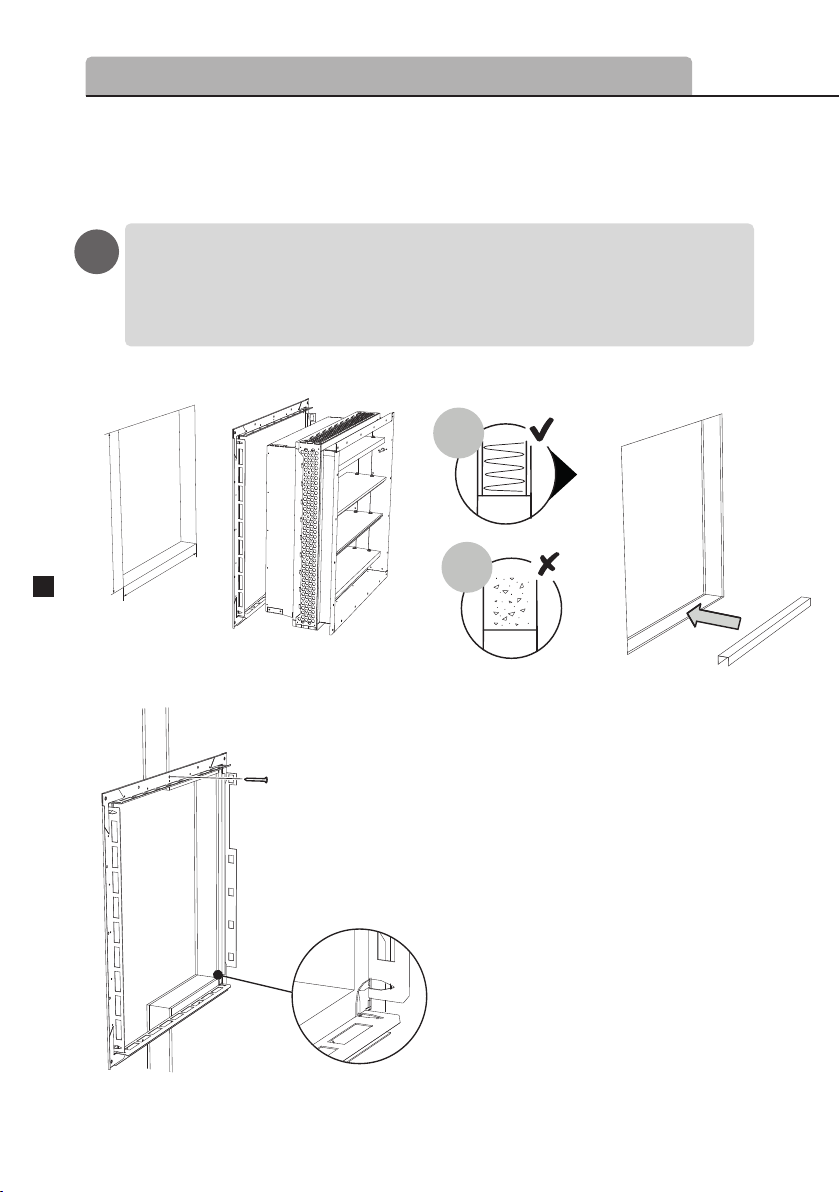

Mounting

Should not be installed outdoors or in

damp area spaces.

Commissioning

The re dampers must not be put into

operation until the complete installation

is in operational condition.

Responsibility and training

Assembly must be carried out by personnel

with training and experience in installation

of re damper products. Electrical

installation requires authorization.

Personnel must read through and

understand this instruction manual before

assembly. For questions, contact the

manufacturer or nearest dealer.

– Damage due to incorrect transport,

handling or storage.

– That the user has failed to inspect,

maintain and to a reasonable extent

take care of the equipment.

EKOVENT AB hereby disclaims all responsibility for:

– Personal injury or property damage as a

result of the product has been used in viola-

tion of instructions and specications in this

manual.

EKOVENT’s liability shall be limited to repair

or replacement of faulty equipment part.

Certication by: RISE Certifiering 0402

Product type description: EKO-RBG1, -R, -C

Approval number : C900166

Fire resistance class: EI 60 (ve i< >o, ho i< >o) S