ELAP MEM620-Bus User manual

1

MEM-BUS ABSOLUTE ENCODER

Instruction Manual

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 2

References

THE CIP NETWORKS LIBRARY

Volume 1 –Common Industrial Protocol (CIP™), Edition 3.23

Volume 2 –EtherNet/IP Adaptation of CIP, Edition 1.23

For more information regarding ODVA, visit www.odva.org.

Registered Trademarks

RSLinx™ and RSLogix5000™ are registered trademarks of Rockwell Automation.

EtherNet/IP™and CIP™ are registered trademarks of ODVA®.

All other specified products, names and logos, serve exclusively for information purposes and may be

trademarks of their respective owners, without any special marking to indicate this.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 3

Summary

1 EtherNet/IP™...........................................................4

1.1 General information ...........................................4

1.2 CIP™ Protocol .....................................................4

1.3 The “Producer / Consumer” Model....................6

1.4 RPI Parameter.....................................................6

1.5 EtherNet/IP™ topologies ....................................6

1.6 CIP™ Object Model .............................................7

1.7 EDS File ...............................................................8

2 Installation...............................................................9

2.1 Safety .................................................................9

2.2 Transport and storage .......................................9

2.3 Mechanical assembly.........................................9

2.4 Electrical supply.................................................9

2.5 IP Address H/W Setting ...................................10

2.6 IP Address S/W Setting ....................................11

2.7 Preset button...................................................12

2.8 LED Indicators ..................................................12

3 CIP Objects ............................................................13

3.1 Identity Object –01H.......................................14

3.2 Position Sensor Object –23H ..........................15

3.3 Assembly Object –04H....................................20

3.4 TCP/IP Interface Object –F5H......................... 23

3.5 Ethernet Link Object –F6H ............................. 26

4 Configuring the encoder using RSLogix5000 ........ 29

4.1 General tab...................................................... 30

4.2 Connection tab................................................. 32

4.3 Module Info tab ............................................... 33

4.4 Internet Protocol, Port Configuration and

Network tabs ........................................................ 33

4.5 Configuration ................................................... 34

4.6 Preset function................................................. 35

TECHNICAL SPECIFICATIONS..................................... 38

ORDERING INFORMATION........................................ 39

Enclosures: dimensional drawings

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 4

1 EtherNet/IP™

1.1 General information

EtherNet/IP™(Ethernet Industrial Protocol) is a frame-based computer networking technology for local

industrial area networks.

It follows the seven layers of the OSI (Open System Interconnection) model:

Layer

Function

7. Application

It supplies network services to end-user application.

6. Presentation

It handles syntax processing of message data such as format conversions and

encryption / decryption needed to support the application layer above it.

5. Session

It manages the sequence and flow of events that initiate and tear down

network connections. It is built to support multiple types of connections that

can be created dynamically and run over individual networks.

4. Transport

It delivers data across network connections. Different transport protocols

may support a range of optional capabilities including error recovery, flow

control, and support for re-transmission.

3. Network

Logical addressing is translated here into physical addressing.

2. Data Link

It checks for physical transmission errors and packages bits into data

"frames".

1. Physical

It is responsible for ultimate transmission of digital data bits from the

Physical layer of the sending (source) device over network communications

media to the Physical layer of the receiving (destination) device.

Table 1.1 –OSI model layers

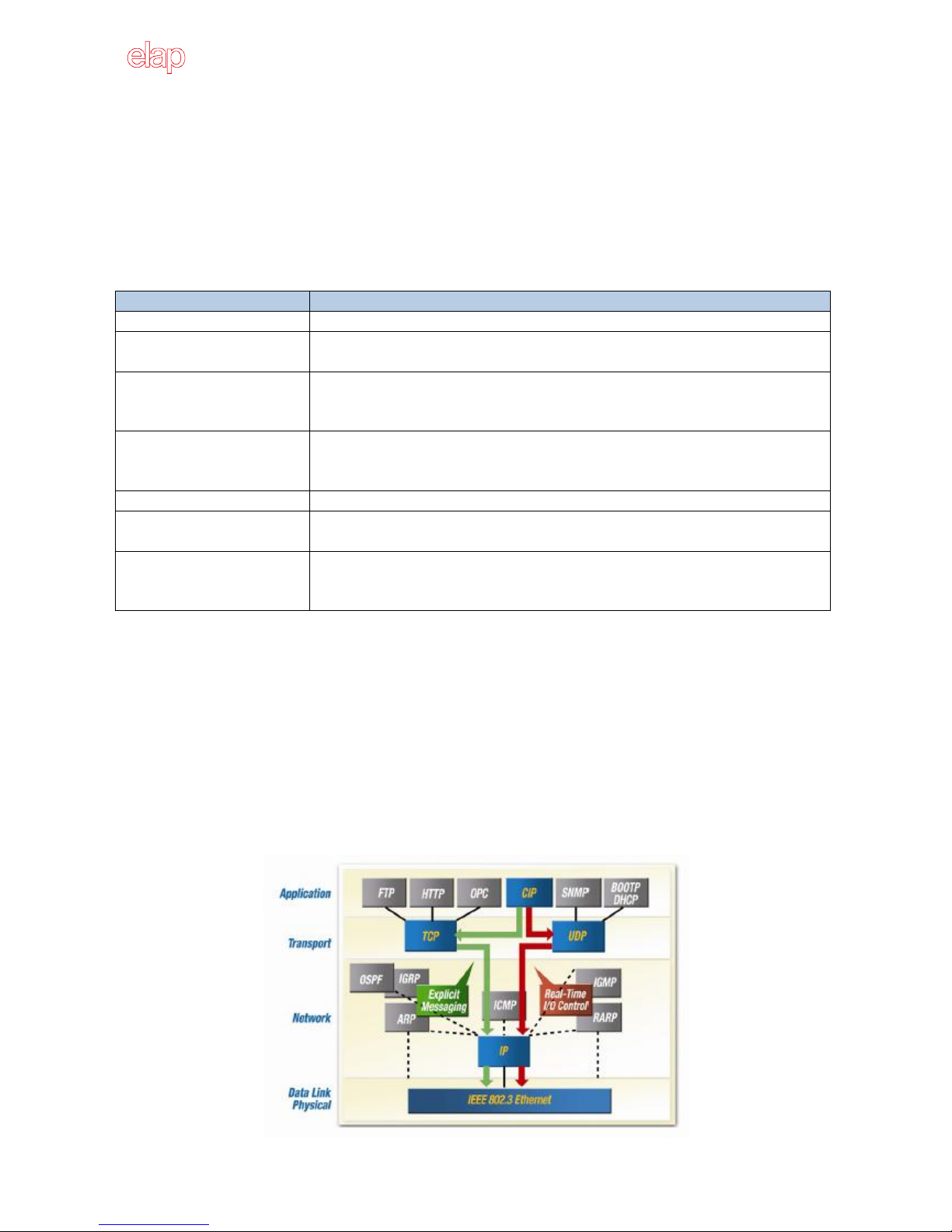

1.2 CIP™ Protocol

As an application layer (number 7 in the OSI model), EtherNet/IP uses the Common Industrial Protocol

(CIP™) for process control. ELAP MEM-BUS encoder meets all the requirements of the EtherNet/IP protocol

according to IEC61784-1 and those of the encoder profile.

The encoder is an I/O adapter in the EtherNet/IP. It receives and sends explicit and implicit messages either

cyclic or on request (polled).

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 5

EtherNetIP uses TCP/IP (Transmission Control Protocol) and UDP/IP (User Datagram Protocol) for

communication.

Implicit messaging is used for real-time communication between a programmable logic controller (PLC) and

the encoder in EtherNet/IP. With implicit messaging a connection is established between exactly two

devices within the CIP™protocol to transfer, for example, I/O data such as position and velocity from the

encoder to the PLC. Implicit messaging uses UDP/IP via port 2222. As a result, a fast data rate is used.

Explicit messaging is used in EtherNet/IP for communication that does not need to take place in real time; it

is used, for example, to transfer parameters from the PLC to the encoder. Explicit messaging uses TCP/IP.

Devices that originate or use data on the network have factory-assigned media access control (MAC)

addresses for unique identification. The MAC address (MAC ID) consists of 6 bytes. The first three bytes

identify the manufacturer. The last three bytes are unique to the device.

The MAC address of ELAP MEM-BUS encoders is 60-D7-E3-1x-xx-xx.

EtherNet/IP is based on the standard Ethernet frame, which consists of the Ethernet header, the Ethernet

data, and the Ethernet trailer. The MAC IDs of the receiver (destination address) and of the source (source

address) are contained in the Ethernet header.

The Ethernet data field consists of several nested protocols:

The IP datagram is transported in the user data of the Ethernet data field.

The TCP segment or the UDP datagram is transported in the user data of the IP datagram.

The CIP™protocol is transported in the user data of the TCP segment or the UDP datagram.

CIP™is a message-based protocol that implements a relative path to send a message from the “producing”

device to the “consuming”devices. The producing device contains the path information that steers the

message along the proper route to reach its consumers. Because the producing device holds this

information, the other devices along the path simply pass it, without any need to store it.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 6

The Producer/Consumer model has two significant benefits:

You do not need to configure routing table in the bridging modules, which greatly simplifies

maintenance and module replacement.

You maintain full control over the route taken by each message, which enables you to select

alternative paths for the same end device.

1.3 The “Producer / Consumer”Model

The CIP Producer/Consumer networking model replaces the old source/destination model (Known as

master/slave). The Producer/Consumer model reduces network traffic and increases speed of transmission.

In traditional I/O systems, controllers poll input modules to obtain their input status. In the CIP system

input modules are not polled any more. Instead, they produce their data either upon a change of state or

periodically. The frequency of update depends upon the options that are chosen during configuration and

the topology of the network. Each input module, therefore, is a producer of input data, while the controller

is a consumer of data.

The controller can also produce data for other controllers to consume. The produced and consumed data is

accessible by multiple controllers and other devices over the EtherNet/IP network. This data exchange

conforms to the Producer/Consumer model.

1.4 RPI Parameter

The requested packet interval (RPI) is the update rate that is specified for a particular piece of data in the

network. This value specifies how often to produce the data for that device. For example, if RPI = 50 ms, it

means that every 50 ms the device sends its data to the controller or the controller sends its data to the

device.

RPIs are only used for devices that exchange data. For example, a ControlLogix® EtherNet/IP bridge in the

same chassis as the controller does not require an RPI because it is not a data-producing member of the

system; it is used only as a bridge to remote modules.

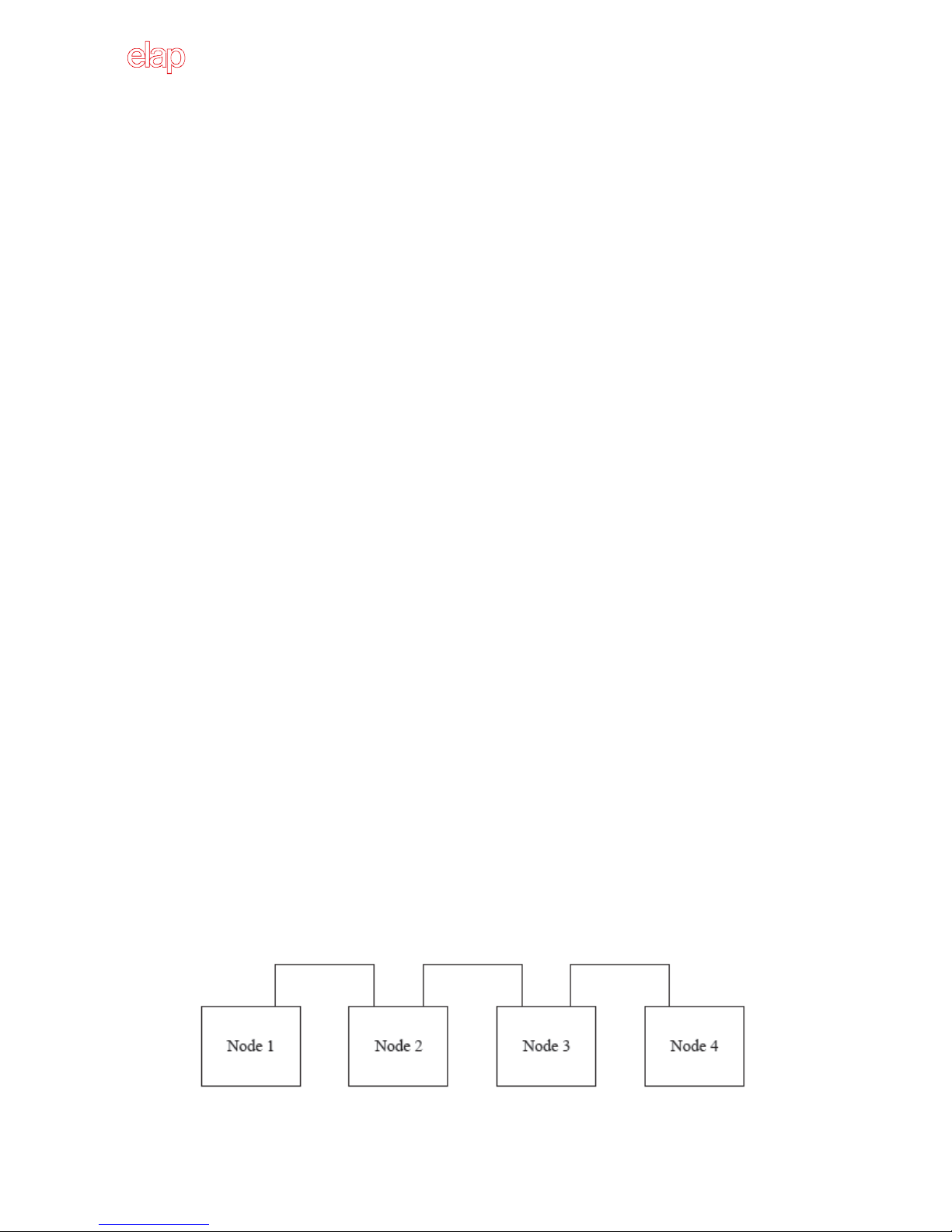

1.5 EtherNet/IP™topologies

ELAP MEM-BUS encoders can be connected in any of three network topologies: star, linear, or Device Level

Ring (DLR).

The linear topology uses the embedded switching capability to form a daisy chain style network that has a

beginning and an end.

Linear topology simplifies installation and reduces wiring and installation costs, but a break in the network

disconnects all devices downstream from the break.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 7

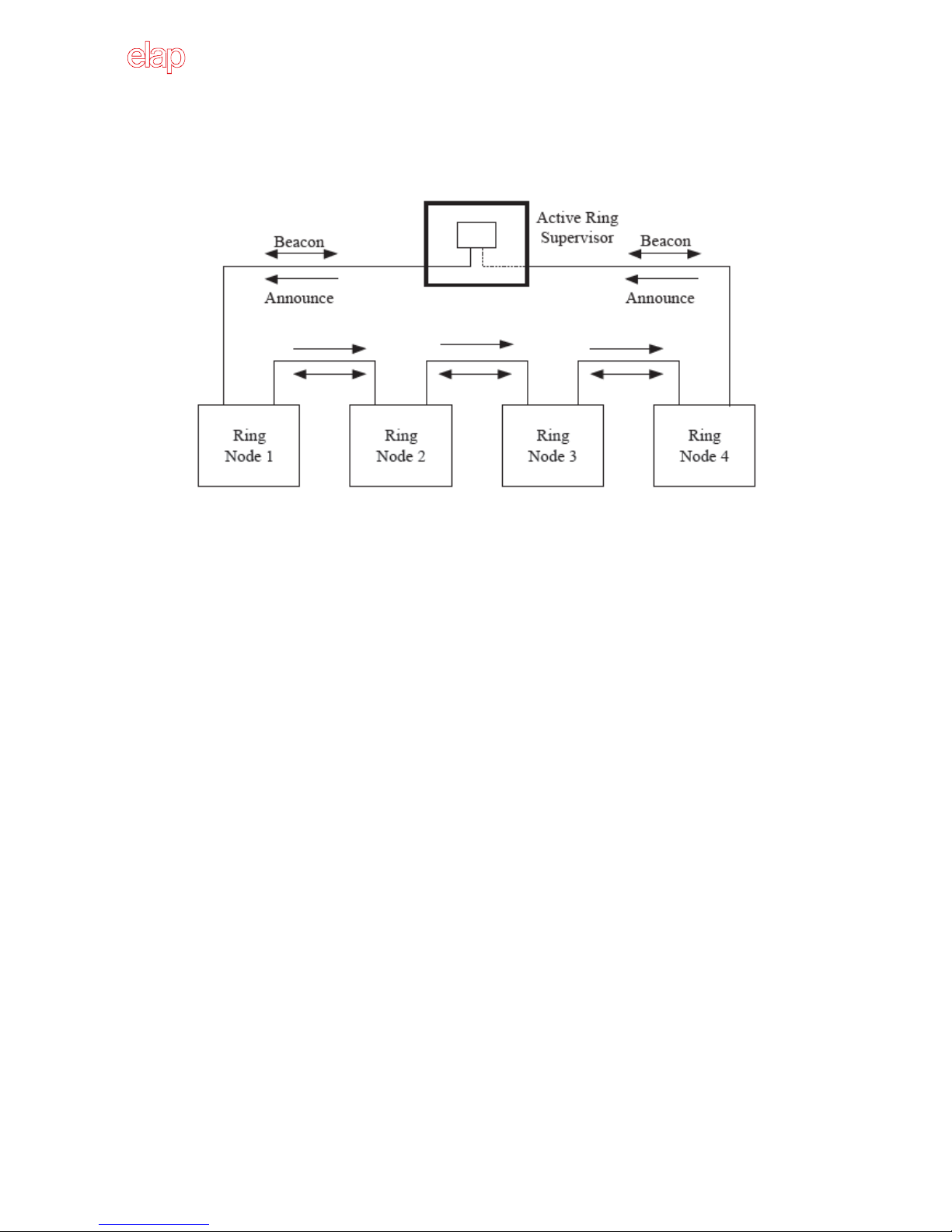

A DLR network is a single-fault-tolerant ring network that is intended for the interconnection of automation

devices. DLR topology is advantageous as it can tolerate a break in the network. If a break is detected, the

signals are sent out in both directions.

The EtherNet/IP™specification include the Device Level Ring (DLR) protocol, allowing multi-port devices to

be connected in a ring topology. DLR provides for fast network fault detection and recognition in order to

support the most demanding control applications. For example, a ring of 50 nodes implementing the DLR

protocol has a worst case fault recovery time of less than 3 ms.

The DLR protocol operates at layer 2, in the OSI model. The presence of the ring topology and the operation

of the DLR protocol are transparent to higher layers protocols, such as TCP/IP and CIP, with the exception

of a DLR object that provides a DLR configuration and diagnostic interface via CIP.

1.6 CIP™ Object Model

EtherNet/IP uses an object model for network communication wherein all functions and data of a device

are defined. CIP objects are organized in Classes, Instances and Attributes.

Class

It contains related objects of a device, which is organized in instances.

Instance

It consists of different attributes that describe the properties of the instance. Different instances of

a class have the same services, the same behavior, and the same attributes. They can, however,

have different values.

Attributes

They represent the data that a device provides over EtherNet/IP. The attributes include the current

values of a configuration or an input. Typical attributes are configuration and status information.

Services

They are used to access the classes or the attributes of a class or to generate specific events. These

services execute defined actions such as reading/writing the attributes.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 8

1.7 EDS File

The EDS (Electronic Data Sheet) file, provided by ELAP, contains all information that is related to the

measuring-system-specific parameters and the operating modes of the MEM-BUS EtherNet/IP encoders.

The EDS file is integrated using the EtherNet/IP network configuration tool to configure and place in

operation the MEM-BUS EtherNet/IP encoder.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 9

2 Installation

The encoder must be installed by qualified experts only, with net voltage off and standstill shaft. The

operating instructions of the machine manufacturer must be always observed.

2.1 Safety

Always observe prevention and safety norms during the installation and operation of the device.

Use the encoder exclusively for its intended purpose.

High voltage, current and rotating parts may cause serious or fatal injuries.

Encoders must not be operated outside the specified limited values (see detailed product

documentation).

2.2 Transport and storage

Always transport or store encoders in their original packaging.

Never drop encoders or expose them to major vibrations.

2.3 Mechanical assembly

Do not open the device.

Do not carry out mechanical changes on the device.

Avoid impacts or shocks on the housing and shaft.

Operate the device within its environmental specifications.

2.4 Electrical supply

Carry out the wiring operations exclusively with unplugged voltage supply

Do not operate on the electrical plant while the encoder is on.

Ensure that the entire plant complies with EMC requirements. The installation environment and

wiring affect the electromagnetic compatibility of the encoder. In particular:

obefore handling and installing the encoder, eliminate any electrostatic charge from your

body and from any tool that will get in contact with the device;

osupply the encoder with steady voltage free from electrical noise; if necessary, install

EMC filters for the supply input;

oalways use shielded and, if possible, twisted cables;

odo not use longer cables than necessary;

othe device cable path should be away from power cables;

oinstall the device away from possible interference sources, or shield it effectively;

oconnect the cable shield and the connector case to a protective earth and make sure that

the protective earth is free from electrical noise; the connection to earth can be carried

out at the encoder side and/or at the user side; it is up to the user to evaluate which is

the best solution to keep the electrical interference as low as possible.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 18/09/2018 10

In order to achieve the highest possible noise immunity, the Ethernet cable screen must be connected to

ground on both ends.

In certain cases current might flow over the screen, therefore it is recommended to use equipotential

connections.

2.5 IP Address H/W Setting

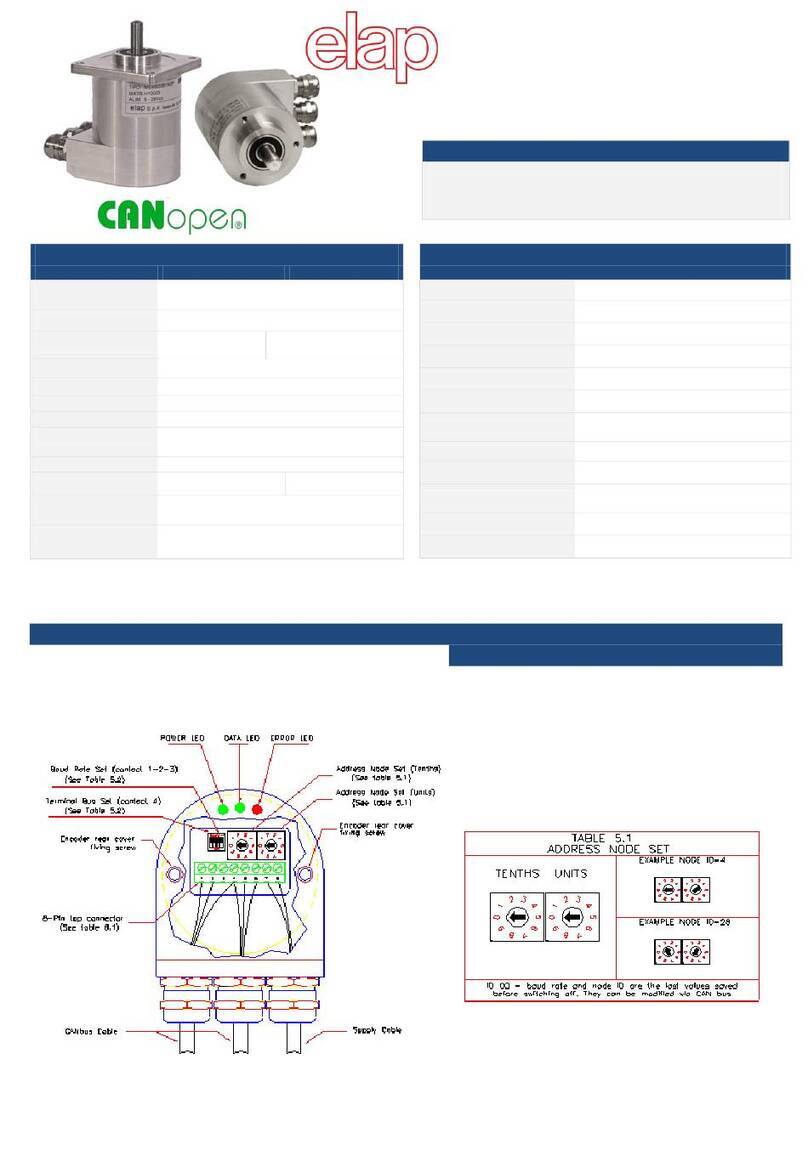

The MEM-BUS encoder is provided with three rotary switches, for hardware setting of the IP address. The

IP address can be assigned using one of the two methods described below:

1. Use of the rotary switches to set the last byte value for the IP address (192.168.1.xxx).

Set the three switches to a valid address, in the range of 001 –254, and take a cycle power to the

encoder. The MEM-BUS encoder will power up with the IP address set to 192.168.1.xxx, where xxx

is given by the position of the three network address switches. In the picture below, it is xxx = 123.

2. Use the BOOTP/DHCP protocol to assign a dynamic IP address.

Set the three rotary switches to 777 (for BOOTP) or 999 (for DHCP) and then take a cycle power to

the encoder. At power up, the MEM-BUS encoder will request an IP address from a BOOTP/DHCP

server, which must be in the same network. This IP address, just assigned, can be statically

allocated by disabling the BOOTP/DHCP mode via software and setting the rotary switches to 000.

At next cycle power, no further request is sent to the BOOTP/DHCP server and the last assigned IP

is used.

Set the rotary switches to 888 to reset the encoder to factory settings. The default IP is 192.168.1.123.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 11

2.6IP Address S/W Setting

1. Set the rotary switches to 888 and take a cycle power in order to load the default factory settings.

2. Set the rotary switches to 000 and take a cycle power in order to enable S/W configuration.

3. Run RXLinx Classic Lite for Rockwell Automation networks.

ELAP MEM-BUS encoder appears in the main window, with its default IP address (192.168.1.123).

Click the right mouse button and select Module Configuration command.

In the “Port Configuration” table, it is possible to configure the TCP/IP interface (see attributes 3 e 5 of

object F5, section 3.4).

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 12

2.7 Preset button

The preset button allows the user to reset the position value of the encoder. Remove the screw cover from

the back of the encoder and briefly press the button inside (see also par. 4.6, Preset Function). This button

is active only when the encoder is powered.

Note: Pressing the preset button result in a change of position reading. This can cause unexpected motion

which could result in personal injury or damage to the product or equipment.

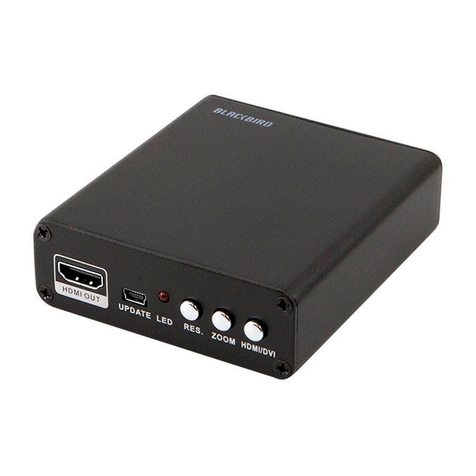

2.8 LED Indicators

Four LEDs show the working conditions of the EtherNet/IP interface.

The Link1 and Link2 LEDs, display the status of the physical connection on the Ethernet interface.

Link1 / Link2

OFF

Power off or no Ethernet connection.

Steady Green

Ethernet connection established.

Yellow

Data transmission TxD/RxD.

Table 2.1 –Ethernet link indicators

The Mod LED shows the device status.

Mod

OFF

Power off.

Steady Green

Device in operation.

Flashing Green

Standby device, not configured, no IP address assigned.

Flashing Red

Major recoverable fault

(for example, inconsistent configuration).

Steady Red

Major unrecoverable fault, device not operational.

Flashing Green/Red

Self-test at power on.

Table 2.2 –Module status indicator

The Net LED show the status of the CIP connection.

Net

OFF

Power off or no IP address configured.

Flashing Green

Device not connected: an IP address is configured, but no CIP

connections are established.

Steady Green

Device connected: an IP address is configured, at least one CIP

connection is established.

Flashing Red

Connection timeout: a reset or a new CIP connection are

requested.

Steady Red

Error: the device has detected that its IP address is already in

use.

Flashing Green/Red

Self-test at power on.

Table 2.3 –Network status indicator

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 13

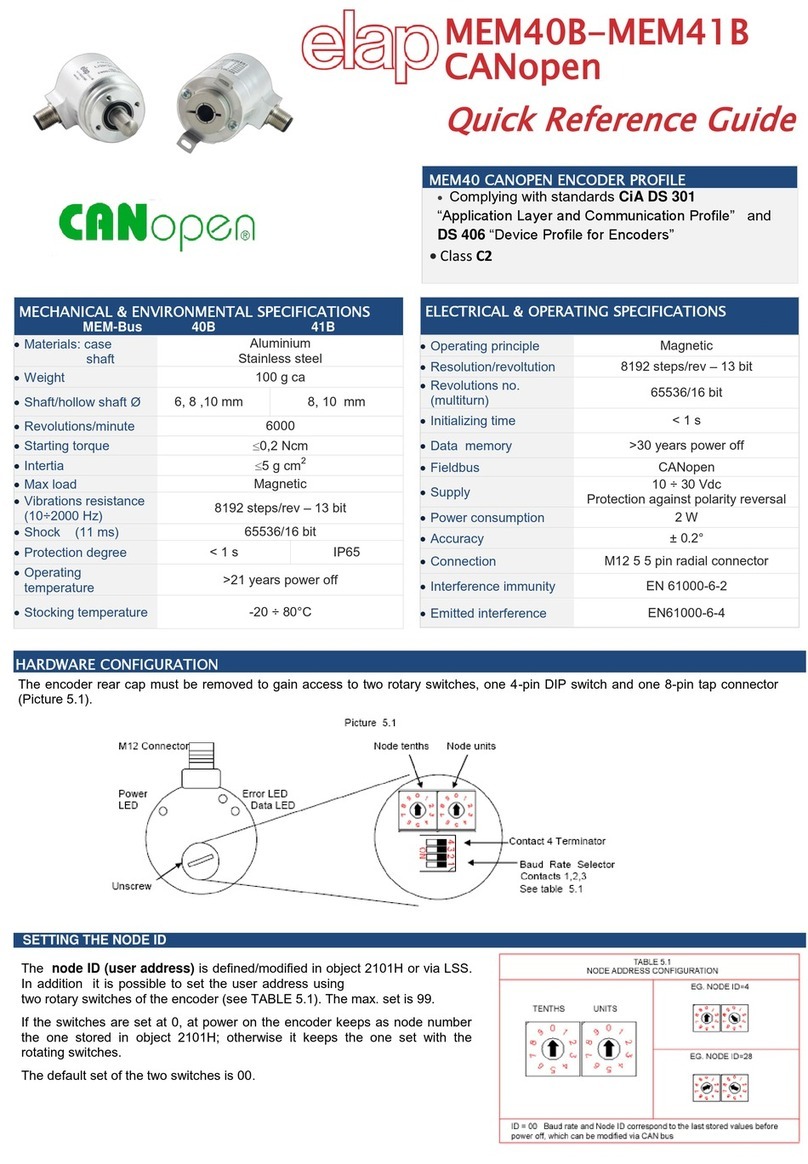

3 CIP Objects

The ELAP MEM-BUS encoder, with EtherNet/IP interface, is an absolute multiturn encoder. The encoder

profile 22H is supported, according to the CIP™ protocol specifications.

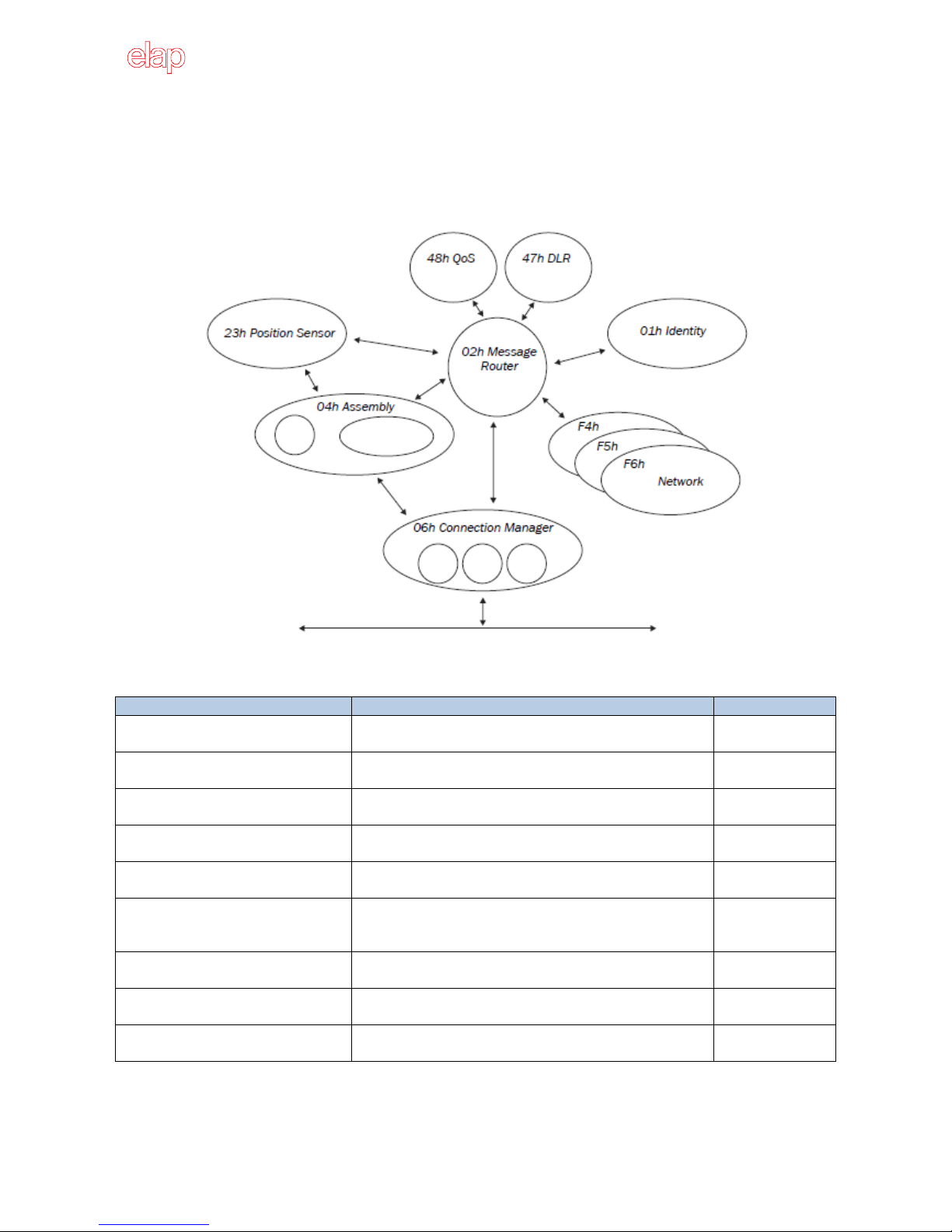

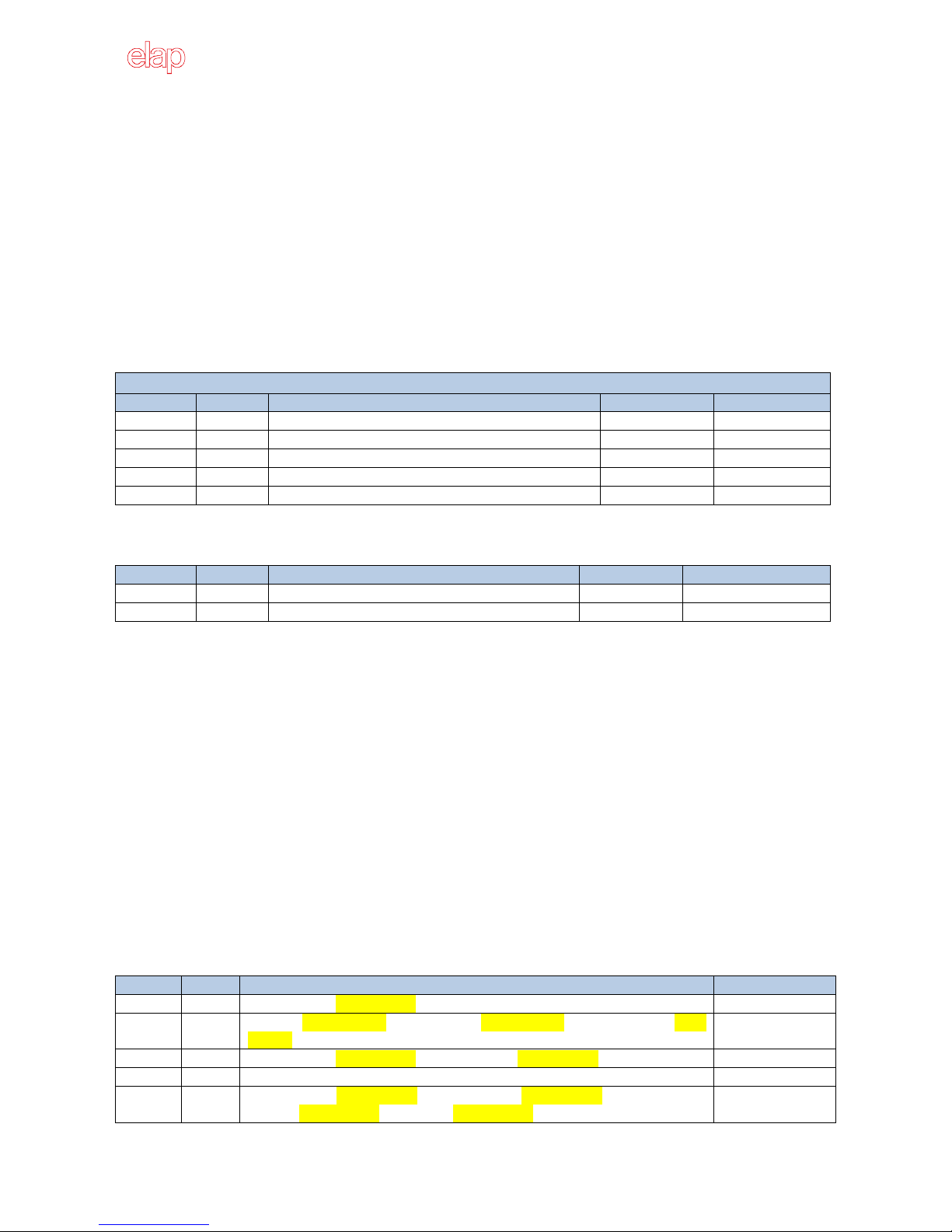

The objects implemented and their interactions are shown in the picture below.

The following table shows the implemented objects and the number of instances available for each class.

Class

Description

Instances

01H: Identity Object

It includes all device specific data (manufacturer, device

type, device status, etc.).

1

02H: Message Router Object

It includes all supported class codes of the encoder and

the maximum number of connections.

1

04H: Assembly Object

It assembles the data of several objects to one single

object (for example, position and velocity values).

4

06H: Connection Manager Object

It includes connection specific attributes for triggering,

transport, connection type, etc.

1

23H: Position Sensor Object

It includes the attributes for programming the encoder

parameters, such as scaling, counting direction, etc.

1

F5H: TCP/IP Interface Object

It includes the attributes for TCP/IP interface, such as IP

address, subnet mask, gateway and acquisition of the IP

address via BOOTP/DHCP or hardware switches, etc.

1

F6H: Ethernet Link Object

It includes connection specific attributes such as

transmission speed, interface status, MAC address, etc.

2

47H: Device Level Ring (DLR) Object

It includes status attributes and configuration attributes

for the DLR protocol.

1

48H: Quality of Service (QoS) Object

It contains mechanism for processing data streams with

different priorities.

1

Table 3.1 –Implemented CIP objects and instances

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 14

3.1 Identity Object –01H

This object provides general information about the device.

Instance 0 includes the attributes of the class itself, while instance 1 includes the device identification data.

The following services are supported:

01H –Get_attribute_All (for both instances 0 and 1)

0EH –Get_Attribute_Single

05H –Reset

0 The device is re-initialized (power on).

1 The device is re-initialized (power on) and reset to the factory settings.

4BH –Flash_LEDs

9 The device executes 6 flashing sequences of its LEDS.

0 Stops the flashing.

Table 3.2 shows the supported attributes for instance 0.

INSTANCE 0, CLASS 01H

Attribute

Access

Name –Description

Data type

Value

1

Get

Revision

UINT

0001H

2

Get

Max instance

UINT

0001H

6

Get

Number ID of the last class attribute

UINT

0007H

7

Get

Number ID of the last instance attribute

UINT

0009H

Table 3.2 –Class attributes of the object 01H

Table 3.3 shows the supported attributes for instance 1.

INSTANCE 1, CLASS 01H

Attribute

Access

Name –Description

Data type

Value

1

Get

Manufacturer identification

UINT

0580H (ELAP)

2

Get

Device type

UINT

0022H (Encoder)

3

Get

Product code

UINT

000AH

4

Get

Revision

Major code

Minor code

STRUCT

USINT

USINT

01H

01H

5

Get

Device status

WORD

See table 3.4

6

Get

Serial number

UDINT

7

Get

Product name

STRING

MEM-BUS EtherNet/IP

8

Get

Present state of the device

USINT

0 Unknown

1 Device self testing

2 Standby

3 Operational

4 Recoverable fault (minor)

5 Unrecoverable fault (major)

6 –254 Reserved

255 Default (if not implemented)

9

Get

Configuration consistency

UINT

0000H

Table 3.3 –Instance 1 attributes, for object 01H

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 15

The attribute number 5, which is defined as a bit string, shows the current state of the device. The

meanings of the individual bits are shown in the table below.

Bit

Name

Meaning

0

Owned

= 1 if 1 object, at least, of the device has got an owner.

This bit is set if at least a class 1 or class 3 connection was established.

1

= 0, Reserved.

2

Configured

= 1 if 1 application attribute, at least, was changed as against the default

settings.

3

= 0, Reserved.

4 - 7

Extended device status

0000 Self-test

0001 Firmware update is active

0010 1 I/O connection, at least, is in Error status (timeout detected)

0011 There are no I/O connections in the Established status

0100 The saved configuration is defective

0101 A serious error has been detected; Bit 10 or Bit 11 is set

0110 1 I/O connection, at least, is active (RUN status)

0111 1 I/O connection, at least, is in the Established status (IDLE status)

1000…1111 Values reserved for manufacturer information, not used.

8

Minor Recoverable Fault

= 1 if the device has detected a non-serious and reparable fault (for

example a I/O connection has detected a timeout).

9

Minor Unrecoverable Fault

10

Major Recoverable Fault

11

Major Unrecoverable Fault

12 - 15

Reserved, value = 0

Table 3.4 –Device status

3.2 Position Sensor Object –23H

This object provides specific data for the encoder.

Instance 0 includes the attributes of the class itself, while instance 1 includes the device specific data.

The following services are supported:

0EH –Get_Attribute_Single

10H –Set_Attribute_Single

Table 3.5 shows the supported attributes for instance 0.

INSTANCE 0, CLASS 23H

Attribute

Access

Name –Description

Data type

Value

1

Get

Revision

UINT

0002H

2

Get

Max instance

UINT

0001H

3

Get

Number of instances

UINT

0001H

6

Get

Number ID of the last class attribute

UINT

0007H

7

Get

Number ID of the last instance attribute

UINT

0064H

Table 3.5 –Class attributes of the object 23H

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 16

Table 3.6 shows the supported attributes for instance 1.

INSTANCE 1, CLASS 23H

Attribute

Access

Name –Description

Data type

Value

10

Get

Position Value

DINT

11

Get

Position Sensor Type

UINT

2 Absolute encoder, multiturn

12

Get/Set

Direction Counting Toggle

BOOL

0 CW

1 CCW

14

Get/Set

Scaling Function Control

BOOL

0 Disabled

1 Enabled

16

Get/Set

Measuring Units per Span

UDINT

1 –8192

17

Get/Set

Total Measuring Range

UDINT

1 –536870912

19

Get/Set

Preset Value

DINT

0

21

Get

Position Status Register

(see values of attributes 22 and 23).

BYTE

Bit0Position is out of range

Bit1Over range

Bit2Under range

22

Get/Set

Position Low Limit

DINT

0 –536870911

23

Get/Set

Position High Limit

DINT

0 –536870911

24

Get

Velocity Value

DINT

25

Get/Set

Velocity Format

ENG UINT

1F04H step/s (default)

1F05H step/ms

1F0FH turns/min

26

Get/Set

Velocity Resolution

UDINT

1

27

Get/Set

Minimum Velocity Setpoint

DINT

-2147483648 –2147483647

28

Get/Set

Maximum Velocity Setpoint

DINT

-2147483648 –2147483647

41

Get

Operating status of the encoder

BYTE

Bit0 Direction (0 = CW)

Bit1 Scaling (0 = Disabled)

Bit2…7 Not used

42

Get

Physical Resolution Span

UDINT

8192 (13 Bit )

43

Get

Physical Resolution Number of Span

UINT

65535

44

Get

Alarms

WORD

Bit0 Position error

Bit1 Diagnostic error

Bit2…15 Not used

45

Get

Supported Alarms

WORD

0003H

46

Get

Alarm Flag

BOOL

0 No alarms

1 Alarm / error

47

Get

Warnings

WORD

Bit4 Battery charge

Bit6 Velocity below min. value

Bit7 Max Velocity exceeded

Bit10Position Limits exceeded

48

Get

Supported Warnings

WORD

04D0H

49

Get

Warning Flag

BOOL

0 No warnings

1 Warning

51

Get

Offset Value

(calculated by the Preset function).

DINT

100

Get

Rotary Switches Value

UINT

0…999

Table 3.6 –Instance 1 attributes, for object 23H

Attribute 10, Position Value

It is the output position value of the encoder, that is eventually modified by the scaling parameters (see

attributes 14, 16 and 17).

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 17

Attribute 12, Direction Counting Toggle

Rotation direction, seen from the shaft side:

0 CW, the position value increases with a clockwise rotation.

1 CCW, the position value increases with a counter clockwise rotation.

Attribute 14, Scaling Function Control

0 The scaling function is disabled. Physical resolution is used for calculations (13 bit for single

turn and 16 bit for number of revolutions).

1 The scaling function is enabled. The values of attributes 16 and 17 are used for calculations.

Attribute 16, Measuring Units per Span

It sets the number of pulses for a single turn. It is active when the scaling function is enabled (that is

attribute 14 = 1). Values lower or equal to physical resolution (that is 8192 pulses per turn) are accepted.

Note: When the scaling parameters change, it is recommended to execute a Preset function (writing of

attribute 19) in order to reset the encoder and restart it from a correct position.

Attribute 17, Total Measuring Range

it sets the total measuring range for position values. It is active when the scaling function is enabled (that is

attribute 14 = 1).

The setting value is calculated as:

Measuring Units per Revolution (6001.00) x Number of Revolutions

Values lower or equal to the global physical resolution (that is 536870912) are accepted.

Note: When the scaling parameters change, it is recommended to execute a Preset function (writing of

attribute 19) in order to reset the encoder and restart it from a correct position.

Attribute 19, Preset Value

It sets the Preset value. The Preset function, that is executed when writing the attribute 19, is used to

adjust the measuring system to any position value within a range to the total measuring length - 1.

Note:

1. When the scaling parameters change, it is recommended to execute a Preset function in order to

reset the encoder and restart it from a correct position.

2. When the scaling function is disabled (attribute 14 = 0), the Preset value shall be lower than the

global physical resolution (536870912).

3. When the scaling function is enabled (attribute 14 = 1), the Preset value shall be lower than the

total resolution (attribute 17).

Attribute 21, Position Status Register

This attribute contains the actual area status of the encoder position (see attributes 22 and 23).

Bit0 = 1, if the position value is out of range (attributes 22 and 23)

Bit1 = 1, if the position value is higher than its high limit (attribute 23)

Bit2 = 1, if the position value is lower than its low limit (attribute 22)

This function allows a replacement of external proximity switches.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 18

Attributes 22 and 23, Position Low / High Limit

These attributes define a configurable work area within the measuring range.

Attribute 24, Velocity Value

It is the encoder current speed, where the format of this value is defined in attribute 25.

Attribute 25, Velocity Format

It is the format of the velocity attribute, in engineering units.

The following values are accepted:

1F04H step/s (default)

1F05H step/ms

1F0FH turns/min

Note : If this attribute is changed, both Minimum Velocity Setpoint (attribute 27) and Maximum Velocity

Setpoint (attribute 28) are reset to their default values.

Attribute 26, Velocity Resolution

It specifies the smallest incremental change of the velocity value (attribute 24).

Attributes 27 and 28, Minimum and Maximum Velocity Setpoint

The actual velocity speed limit values with minimum and maximum can be configured in attributes 27 and

28. The corresponding flags in attribute 47 (Bit6 and Bit7) are affected.

Attribute 41, Operating Status

This attribute contains the operating status of the encoder.

Bit0 Information about rotation direction is given. Position value is increasing (0) or decreasing

(1). Attribute 12 shall be used to set the counting direction.

Bit1 Information about scaling function is given (0 Disabled, 1 Enabled). Attribute 14 shall

be used to enable/disable the scaling function.

Attribute 42, Physical Resolution

This attribute contains the number of measuring steps per revolution which can be output by the

measuring system. See attributes 16 and 17 in order to set a specific resolution.

Attribute 43, Physical Resolution Number of Spans

This attribute contains the number of distinguishable revolutions that the measuring system can output.

The global physical resolution of the ELAP MEM-BUS encoder is calculated as follows

Single Turn Resolution x Number of revolutions = 8192 x 65536 = 536870912

See attributes 16 and 17 in order to set a specific total resolution.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 19

Attribute 44, Alarms

An alarm is set when the encoder has detected a status which can result in an incorrect position. As soon

as an alarm status is detected, the corresponding bit is set to logical high.

Bit0 Position error

Bit1 Diagnostic error

Bit2, …, Bit11 Reserved

Bit12, …, Bit15 Not used

Attribute 45, Supported Alarms

This attribute contains information about the alarms supported by the device.

ELAP MEM-BUS encoder supports the position error only (Bit 0); so this attribute value is 0001H.

Attribute 46, Alarm Flag

It indicates that an alarm error has occurred (attribute 44 is not zero).

Attribute 47, Warnings

Warnings are signaled by the encoder when the tolerance for certain internal parameters have been

exceeded. In contrast to alarms (attribute 44), warnings don’t imply incorrect position values.

Bit4 Battery charge too low.

Bit6 Velocity has dropped below its minimum value (attribute 27).

Bit7 Velocity has exceeded its maximum value (attribute 28).

Bit10 Position limits exceeded (see attributes 22 and 23).

Attribute 48, Supported Warnings

This attribute contains information about the warnings supported by the device.

ELAP MEM-BUS encoder supports the warnings of battery charge (Bit 4), Position limits exceeded (Bit 10)

and Velocity limits exceeded (Bit6, Bit7); so this attribute value is 04D0H.

Attribute 49, Warning Flag

It indicates that a warning error has occurred (attribute 47 is not zero).

Attribute 51, Offset Value

The offset value attribute is calculated by the preset function and shifts the position value attribute. It is

stored automatically by the device and can be read from the encoder for diagnostic purposes.

It is

Offset (attr.51) = Preset (attr.19) –Position Value (attr.10)

Attribute 100, Rotary Switches Value

The value corresponding to the position of the three rotary switches can be read for diagnostic purposes.

These rotary switches are used by the encoder only at power on. So, it is possible to change their position

when the encoder is powered, in order to check them.

MEM-BUS EtherNet/IP™ENCODER Instruction Manual

ENIP_Manual_ENG 17/07/2018 20

3.3 Assembly Object –04H

The Assembly Object binds attributes of multiple objects, which allows data to or from each object to be

sent or received over a single connection. Assembly objects can be used to bind input data or output data,

where the terms ‘input’ and ‘output’ are defined from the network’s point of view.

An input will produce data on the network, while an output will consume data from the network.

Instance 0 includes the attributes of the class itself.

The following services are supported:

0EH –Get_Attribute_Single

Table 3.7 shows the supported attributes for instance 0.

INSTANCE 0, CLASS 04H

Attribute

Access

Name –Description

Data type

Value

1

Get

Revision

UINT

0002H

2

Get

Max instance

UINT

006EH

3

Get

Number of instances

UINT

0005H

6

Get

Number ID of the last class attribute

UINT

0007H

7

Get

Number ID of the last instance attribute

UINT

0004H

Table 3.7 –Class attributes of the object 04H

The following table contains all supported instance attributes of the assembly object.

Attribute

Access

Name –Description

Data type

Value

3

Get

Data of the assembly instance

BYTE ARRAY

See table 3.9

4

Get

Number of bytes in attribute 3

UINT

See table 3.9

Table 3.8 –Assembly object, instance attributes

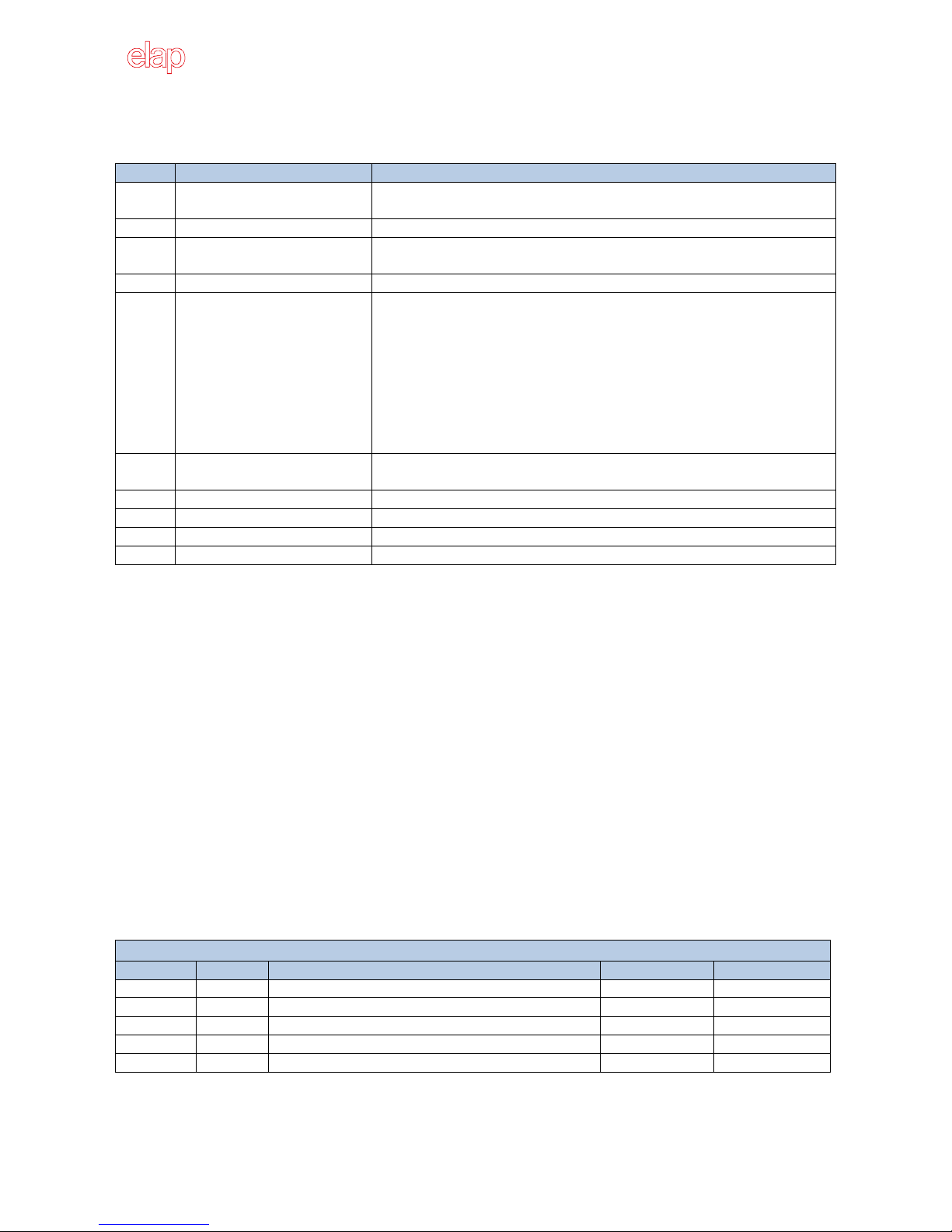

ELAP MEM-BUS encoder supports 4 I/O assembly instances. Assembly instances are also called connection

points. Two connection point types are defined:

O T (Originator Target = Encoder): These connection points represent output data from the

control system (PLC).

T O (Target = Encoder Originator): These connection points represent input data for control

system (PLC). The instances T O contain, for example, the position and velocity values of the

encoder.

According to the Encoder Device Profile, instances 1, 2 and 3 are provided for input data. Instance 110 is

vendor specific.

Instance 100 is defined as the configuration assembly instance. Use of this assembly instance when

establishing class 1 connections is one possibility for configuration of the encoder.

The following table shows the values of attributes 3 and 4, for the assembly instances.

Instance

Type

Attribute 3 (data)

Attribute 4 (size)

1

Input

Position Value (23H, attr.10)

4 Byte

2

Input

Position (23H, attr.10) + Alarm Flag (23H, attr.46) + Warning Flag (23H,

attr.49)

5 Byte

3

Input

Position Value (23H, attr.10) + Velocity Value (23H, attr.24)

8 Byte

100

Output

Configuration Data (see table 3.11)

28 Byte

110

Input

Position Value (23H, attr.10) + Velocity Value (23H, attr.24) + Position Status

Register (23H, attr.21) + Warnings (23H, attr.47)

12 Byte

Table 3.9 –Attributes 3 and 4 of the assembly instances

This manual suits for next models

4

Table of contents

Other ELAP Media Converter manuals