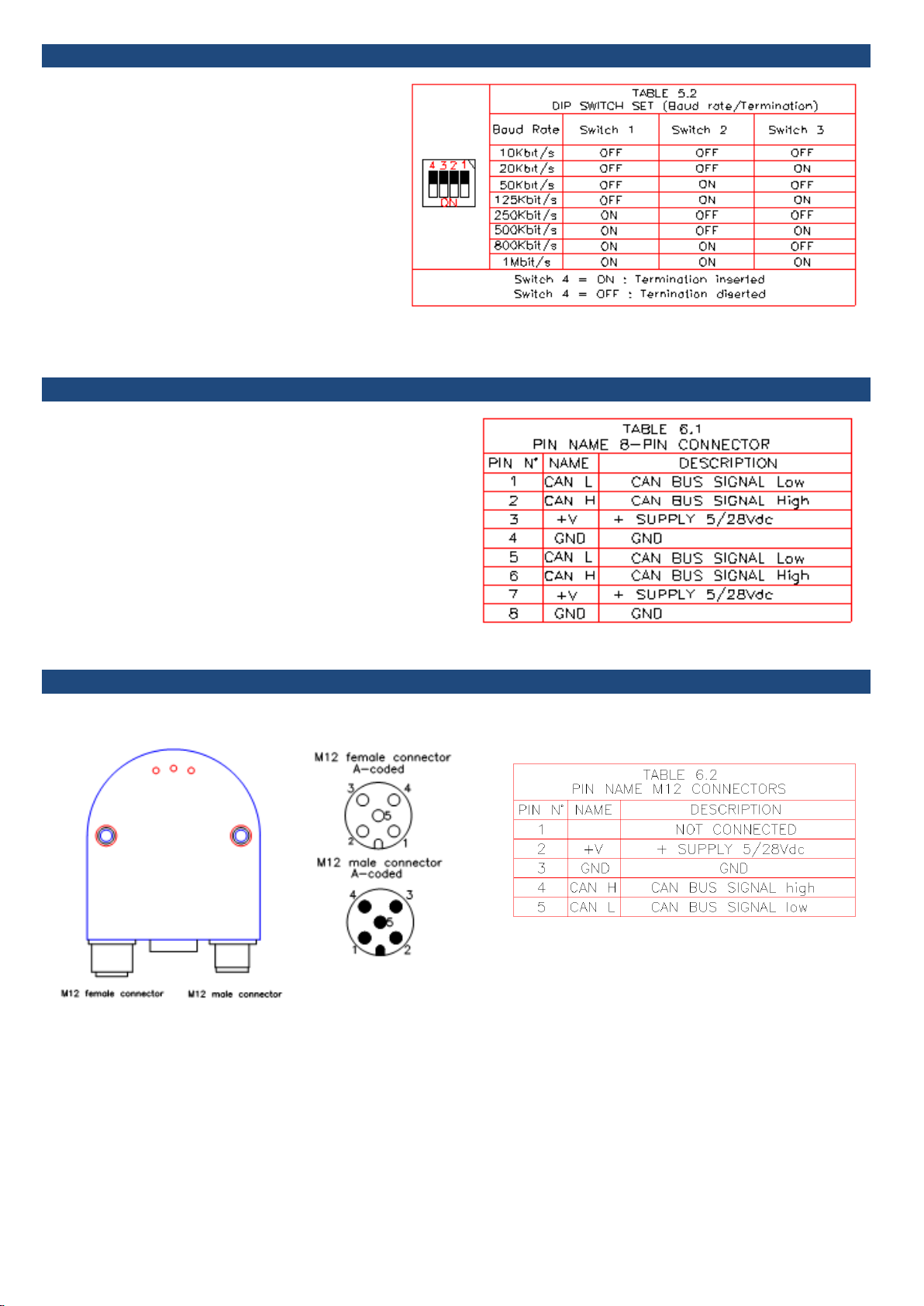

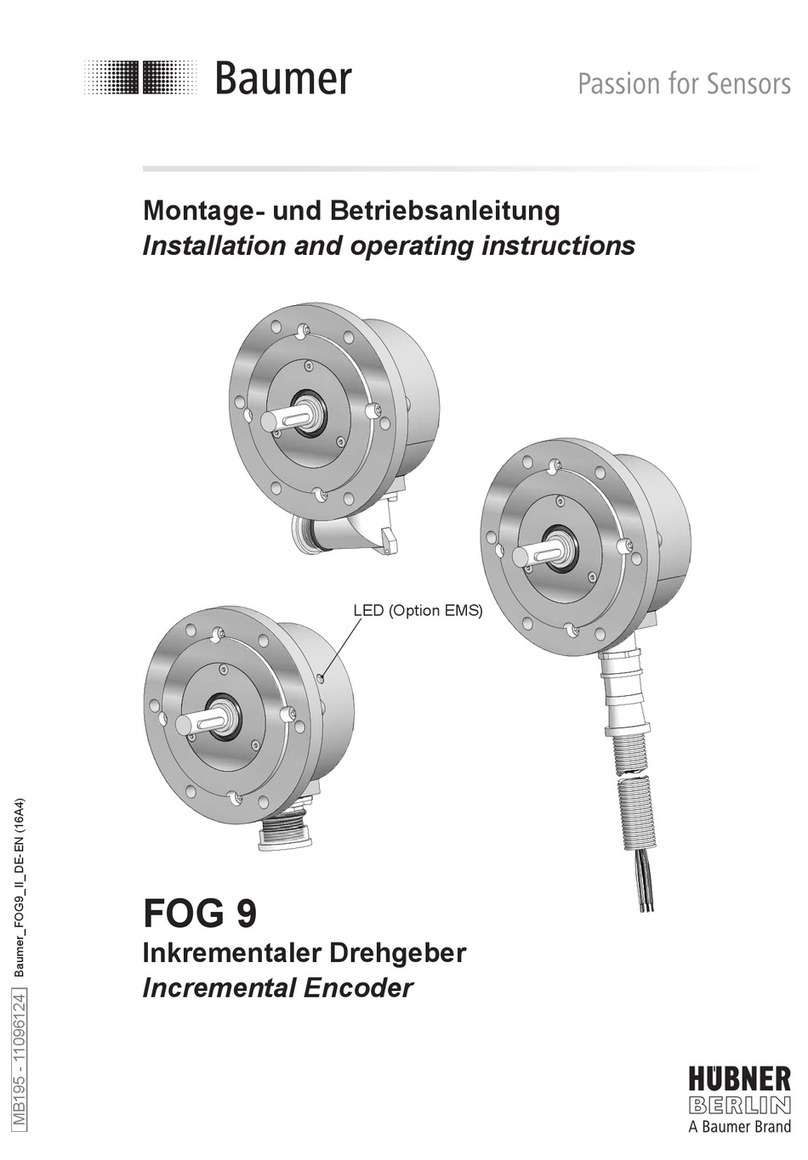

SETTING THE BAUD RATE

CONNECTIONS WITH CABLE GLAND PG9

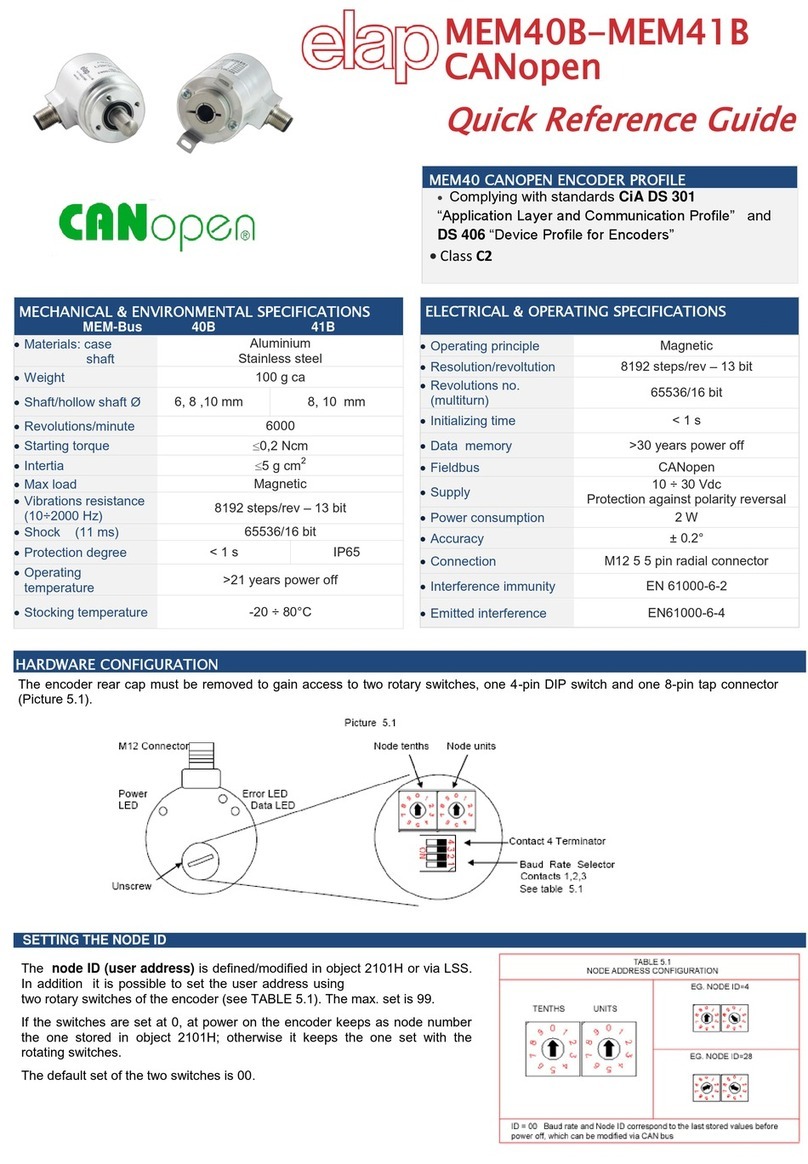

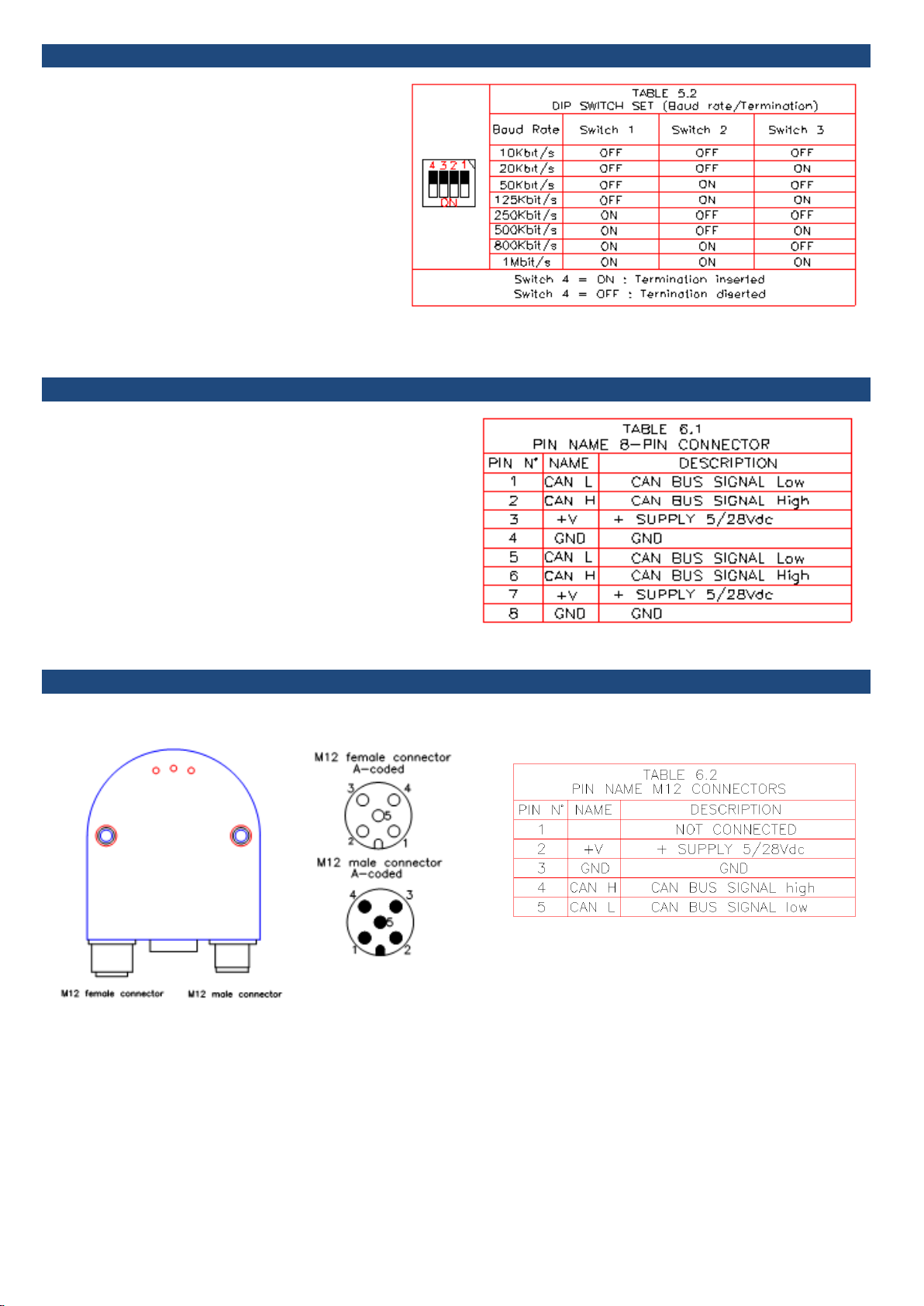

CONNECTIONS WITH M12 CONNECTORS

The bus and supply cables must be connected to the M12 connector as shown in the Picture 6.2 and in the TABLE 6.2.

s and supply cables must be connected to the M12 connector as shown in the Picture 6.2 and in the TABLE 6.2.

As mentioned previously, the baud rate is

defined/modified in object 2100H . In addition, it is

possible to set the baud rate by means of contacts 1,

2 and 3 of the encoder DIP switch (see TABLE 5.2).

If the switches relating to the baud rate are set at 0, at

power on the encoder keeps as baud rate the one

stored in object 2100H; otherwise it keeps the one set

with the DIP switch.

The default set of the DIP swicht contacts 1, 2 and 3

is: OFF ON OFF.

Terminating resistor

If the connected encoder is the last device in the bus

line, the bus must be terminated with a resistor. The

resistor can be connected by the contact 4 of the

encoder DIP switch (see TABLE 5.2).

The default set of the DIP swicht contact4 is: OFF.

The bus and supply cables must be connected to the 8-pin tap

connector as shown in the Picture 5.1 and in the TABLE 6.1.

The pins mentioned with the same indication in the table 6.1 are

common inside the encoder.

The following procedure is recommended to connect the cables

to the encoder:

•Unfasten and remove the encoder rear cover

•Arrange the cables as shown in the Picture 6.1 and fasten them

in the relevant nuts in the cover

•Unplug and wire the 8-pin tap connector

The male connector pins and the female connector pins with same number are common inside the encoder (except pins 1)

Across the pins +V and GND of one connector and the corresponding pins of the other connector the current must not exceed 2 A.