ELAP MEM40 Bus User manual

.docx

MULTI-TURN ABSOLUTE

ENCODERS

MEM40 Bus

MEM41 Bus

With CANopen Fieldbus

Instruction Manual

CERTIFICATE NO. E510647

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

I

MEM40B_CAN_Inglese_ul.docx 16/11/2020

CONTENTS

1. CAN bus & CANopen protocol......................1

1.1 CAN bus..........................................................1

1.2 CAN bus Characteristics ..............................1

1.3 CANopen ........................................................ 1

1.4 Communication Profile .................................2

1.5 CANopen Message Structure...................... 2

1.6 Service Data Communication.......................3

1.7 Process data communication....................... 5

1.8 Emergency service........................................5

1.9 Network Management (NMT)........................ 6

1.10 Layer Setting Services (LSS)...................... 8

2. Encoder communication profile..................12

2.1 Overview of encoder objects...................... 12

2.2 Parameters saving.......................................15

3. Diagnosis and useful information...............15

3.1 Error diagnosis field bus communication.15

3.2 Error diagnosis via field bus ......................16

3.3 Further useful information..........................16

3.4 Signaling LEDs ............................................16

4. Applications ..................................................17

4.1 Reading and setting objects.......................17

4.2 Configuration ...............................................18

4.3 Operation......................................................20

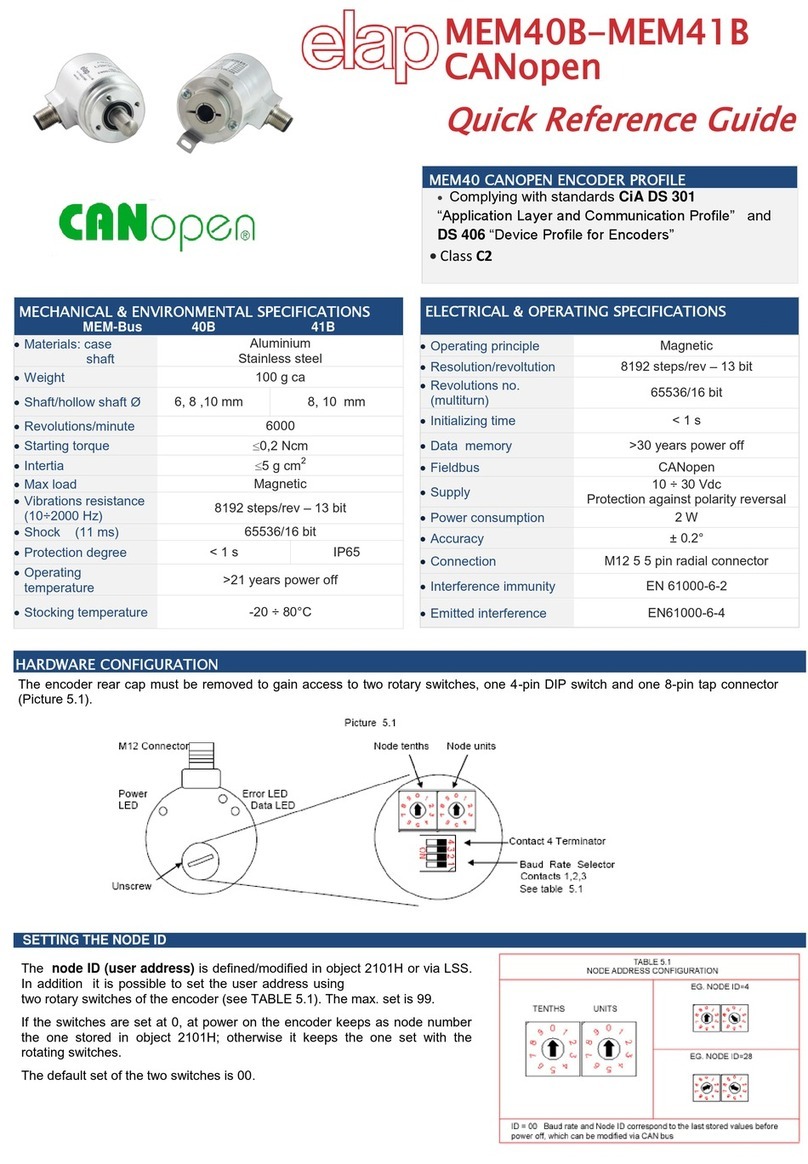

5. Hardware configuration ................................21

6. Connections...................................................22

7. Technical Specifications...............................23

SAFETY

The encoder must be installed by qualified experts only, with net voltage off and standstill shaft. Always

observe the operating instructions of the machine manufacturer. It is recommended to keep the present

manual for reference.

Always observe prevention and safety norms during the installation and operation of the device.

Use the encoder exclusively for its intended purpose.

High voltage, current and rotating parts may cause serious or fatal injuries.

Encoders must not be operated outside the specified limited values (see detailed product

documentation).

TRANSPORT AND STORAGE

Always transport or store encoders in their original packaging.

Never drop encoders or expose them to major vibrations.

MECHANICAL ASSEMBLY

Do not open the device.

Do not carry out mechanical changes on the device.

Avoid impacts or shocks on the housing and shaft.

Operate the device within its environmental specifications. Max ambient temperature 80°C.

ELECTRICAL SUPPLY

Carry out the wiring operations exclusively with unplugged voltage supply

Do not operate on the electrical plant while the encoder is on.

Ensure that the entire plant complies with EMC requirements.

CERTIFICATE NO. E510647

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

1

MEM40B_CAN_Inglese_ul.docx

Absolute Encoder with CANopen protocol, Class C2

1. CAN bus & CANopen protocol

1.1 CAN bus

The CAN bus (CAN: Controller Area Network) was originally developed by Bosch and Intel as a means of

fast, low-cost data transmission in automotive applications. The CAN bus is used today also in industrial

automation applications.

The CAN bus is a field bus (the standards are defined by CiA, the CAN in Automation Association)

through which devices, actuators and sensors from different manufacturers can communicate with each

other.

Elap encoder complies with standards CiA DS 301 “Application Layer and Communication Profile” and DS

406 “Device Profile for Encoders.”

1.2 CAN bus Characteristics

Data rate of 1 MBaud with network expansion up to 40

Network connected on both sides

The bus medium is a twisted-pair cable

„Real-Time‟ operation: a max wait time is set for high priority messages

Theoretically 127 users at one bus, but physically only 32 are possible (due to the driver).

Ensures data consistency across the network. Damaged messages are notified as faulty for all

network nodes

Message-oriented communication: the message is identified by a message identifier. All network

nodes use the identifier to test whether the message is of relevance for them.

Broadcasting, multicasting: All network nodes receive each message simultaneously. Synchronization

is therefore possible.

Multimaster capability: Each user in the field bus is able to independently transmit and receive data

without being dependent upon the priority of the master. Each user is able to start its message when

the bus is not occupied. When messages are sent simultaneously, the user with the highest priority

prevails.

Prioritization of messages: The identifier defines the priority of the message. This ensures that

important messages are transmitted quickly via the bus

Residual error probability: Safety procedures in the network reduce the probability of an undiscovered

faulty data transmission to below 10 -11. In practical terms, it is possible to ensure a 100% reliable

transmission.

Function monitoring: Localization of faulty or failed stations. The CAN protocol encompasses a

network node monitoring function. The function of network nodes which are faulty is restricted, or they

are completely uncoupled from the network.

Data transmission with short error recovery time: By using several error detection mechanisms,

falsified messages are detected to a high degree of probability. If an error is detected, the message

transmission is automatically repeated.

In the CAN Bus, several network users are connected by means of a bus cable. Each network user is

able to transmit and receive messages. The data between network users is serially transmitted.

Examples of network users for CAN bus devices are:

Automation devices such as PLCs

PCs

Input and output modules

Drive control systems

Analysis devices, such as a CAN monitor

Control and input devices as Human Machine Interfaces (HMI)

Sensors and actuators

1.3 CANopen

Under the technical management of the Steinbeis Transfer Centre for Automation, the CANopen profile

was developed on the basis of the Layer 7 specification CAL (CAN Application Layer). In comparison with

CAL, CANopen only contains the functions suitable for this application. CANopen thus represents only a

partial function of CAL optimized for the application in hand, so permitting a simplified system structure

and the use of simplified devices. CANopen is optimized for fast data exchange in real time systems.

The organization CAN in Automation (CiA) is responsible for the applicable standards of the relevant

profiles.

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

2

MEM40B_CAN_Inglese_ul.docx

CANopen permits:

• Simplified access to all device and communication parameters

• Synchronization of several devices

• Automatic configuration of the network

• Cyclical and event-controlled process data communication

CANopen comprises four communication objects (COB) with different characteristics:

• Process data objects for real time data (PDO)

• Service data objects for parameter and program transmission (SDO)

• Network management (NMT, Heartbeat)

• Pre-defined objects (for synchronization, emergency message)

All device and communication parameters are subdivided into an object directory. An object directory

encompasses the name of the object, data type, number of subindexes, structure of the parameters and

the address. According to CiA, this object directory is subdivided into three different parts. Communication

profile, device profile and a manufacturer-specific profile.

1.4 Communication Profile

Communication between the network users and the Master (PC / Control) takes place by means of object

directories and objects. The objects are addressed via a 16 bit index. The CANopen communication

profile DS 301 standardizes the various communication objects.

They are accordingly divided into several groups:

• Process data objects PDO for real time transmission of process data

• Service data objects SDO for read/write access to the object directory

• Objects for synchronization and error display of CAN users:

SYNC object (synchronization object) for synchronization of network users

EMCY object (emergency object) for error display of a device or its peripherals

• Network management NMT for initialization and network control

• Layer Setting Services LSS for configuration by means of serial numbers, revision numbers etc. in the

middle of an existing network

1.5 CANopen Message Structure

The first part of a message is the COB ID (Identifier).

Structure of the 11-bit COB ID :

Function code (4 bit)

Node ID (7 bit)

The function code provides information on the type of message and priority.

The lower the COB ID, the higher the priority of the message

Broadcast messages:

Function code

COB ID

NMT

0

SYNC

80H

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

3

MEM40B_CAN_Inglese_ul.docx

Other messages:

Function code

COB ID

Emergency

80H + Node ID

PDO1 (tx)

180H + Node

ID

PDO2 (tx)

280H + Node

ID

SDO (tx)

580H + Node

ID

SDO (rx)

600H + Node

ID

Heartbeat

700H + Node

ID

LSS (tx)

7E4H

LSS (rx)

7E5H

(tx) and (rx) from the viewpoint of the encoder

The node ID can be freely selected by means of the CANopen bus between 1 and 127. The encoders are

supplied with the Node ID 1.

This can be changed with the service data object 2101h or using LSS.

A CAN message is made up of the COB ID and up to 8 bytes of data:

COB

ID

DLC

Byte

1

Byte

2

Byte

3

Byte

4

Byte

5

Byte

6

Byte

7

Byte

8

Xxx

x

xx

xx

xx

xx

xx

xx

xx

xx

The message details are described at a later point.

1.6 Service Data Communication

The service data objects correspond to the standards of the CiA. It is possible to access an object via

index and subindex.

The data can be requested or where applicable written into the object.

Structure of an SDO telegram:

CO

B ID

DL

C

Comman

d

Objec

t L

Objec

t H

Subinde

x

Dat

a 0

Dat

a 1

Dat

a 2

Dat

a 3

An SDO-COB ID is composed as follows:

Master Encoder : 600H + Node ID

Encoder Master : 580H + Node ID

DLC (data length code) describes the length of the telegram. This is composed as follows:

1 byte command + 2 bytes object + 1 byte subindex + no. of data bytes (0 - 4).

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

4

MEM40B_CAN_Inglese_ul.docx

The command byte defines whether data is read or set, and how many data bytes are involved.

SDO Command

Description

Data length

22H

Download request

Max 4 byte

Transmits parameter to encoder

23H

Download request

4 byte

2BH

Download request

2 byte

2FH

Download request

1 byte

60H

Download response

-

Confirms receipt to master

40H

Upload request

-

Requests parameter from encoder

42H

Upload response

Max 4 byte

Parameter to master with max. 4 byte

43H

Upload response

4 byte

4BH

Upload response

2 byte

4FH

Upload response

1 byte

80H

Abort message

-

Encoder signals error code to master

An abort message indicates an error in the CAN communication. The SDO command byte is 80h. The

object and subindex are those of the requested object. The error code is contained in bytes 5 –8

COB ID

DLC

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

580H+Node

08H

80H

Object L

Object H

Subindex

Err.0

Err.1

Err.2

Err.3

Byte 8..5 results in the SDO abort message (byte 5 LSB, .., byte 8 MSB).

The following messages are supported:

- 05040001H Command byte is not supported

- 06010000H Incorrect access to an object

- 06010001H Read access to write only

- 06010002H Write access to read only

- 06020000H Object is not supported

- 06090011H Subindex is not supported

- 06090030H Value outside the limit

- 06070010H Inconsistent data type

Some SDO examples follow.

SDO examples

Request of a value by the master to the encoder (position value, object 6004H).

COB ID

DLC

Command

Object L

Object H

Subindex

Data 0

Data 1

Data 2

Data 3

600H+Node

08H

40H

04H

60H

00H

xx

xx

xx

xx

Response by the encoder to the request for a value (the position value is composed by 4 byte).

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data 0

Data 1

Data 2

Data 3

580H+Node

08H

43H

04H

60H

00H

FAH

59H

00H

00H

The encoder position is 000059FAH.

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

5

MEM40B_CAN_Inglese_ul.docx

Writing of a value by the master into the encoder (Position setting can be performed with preset, object

6003H, at 300H).

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data 0

Data 1

Data 2

Data 3

600H+Node

08H

22H

03H

60H

00H

00H

03H

00H

00H

Encoder response to the writing of a value.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data 0

Data 1

Data 2

Data 3

580H+Node

08H

60H

03H

60H

00H

00H

00H

00H

00H

1.7 Process data communication

Process data objects are used for real time data exchange for process data, for example position or

operating status. PDOs can be transmitted synchronously or cyclically (asynchronously). The encoder

supports the PDO1 and the PDO2. Both PDOs supply the current position of the encoder and are defined

in the objects 1800H, 1801H, 1A00H, 1A01H and 6200H.

Synchronous PDO

In order to transmit the process data synchronously, a value between 1 and F0h (=240) must be written

into

the object 1800h / 1801h Subindex 2. If the value is 3, the PDO is transmitted on every third sync

telegram (if

the value 1 is entered, transmission takes place on every SYNC telegram).

In synchronous operation, the PDO is requested by the master via the Sync telegram.

COB ID

DLC

80H

00H

Cyclical PDO (asynchronous)

If you wish the PDOs to be transmitted cyclically, the value FEh must be written into the object 1800h /

1801h Subindex 2. In addition, the cycle time in milliseconds must be entered in the same object subindex

5. If the value is stored for 0 ms, the PDOs are not transmitted.

PDO1 Telegram structure

COB ID

DLC

Byte 1

Byte 2

Byte 3

Byte 4

180H+Node

04H

Xx

xx

xx

xx

PDO2 Telegram structure

COB ID

DLC

Byte 1

Byte 2

Byte 3

Byte 4

280H+Node

04H

Xx

xx

xx

xx

1.8 Emergency service

Internal device error or bus problems initiate an emergency message:

COB ID

DLC

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

80H+Node

08H

Err.Code L

Err.Code H

Register

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

6

MEM40B_CAN_Inglese_ul.docx

Byte 1 and 2 contain the error code.

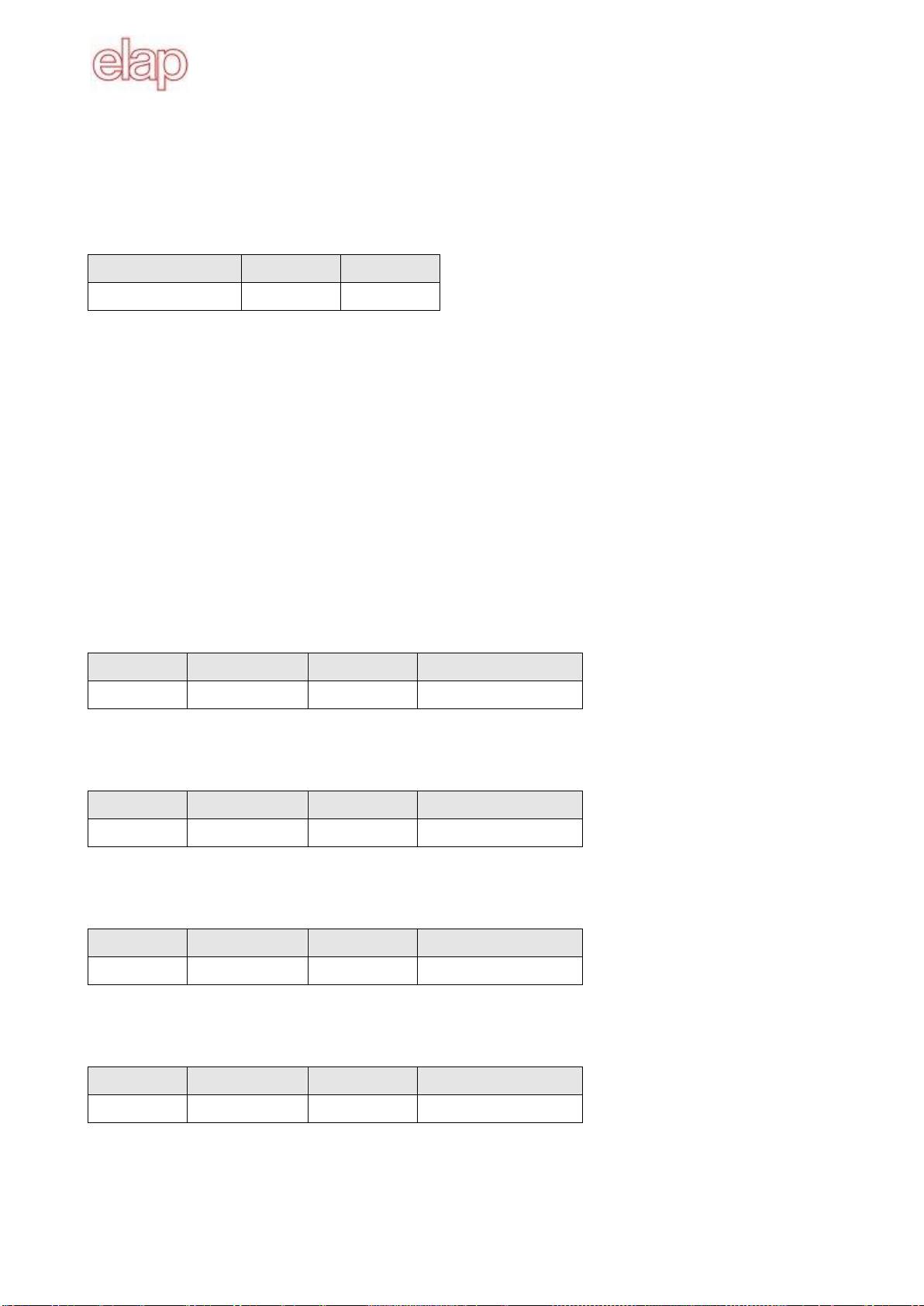

Code

Meaning

0000H

Error reset/ no error

1000H

Generic error

6010H

Software reset (watchdog)

7320H

Position error

8110H

CAN communication error (Overrun)

8120H

CAN communication error (Transmission / Reception)

8140H

Recovered Bus-Off

FF00H

Battery low (3.2 Volts)

FF01H

Data loss

Byte 3 contains the error register (object 1001H).

Bit

Meaning

0

Generic error

4

Communication error

7

Manufacturer specific

Byte 4 to 8: not used

1.9 Network Management (NMT)

Network management can be divided into two groups.

Using the NMT services for device monitoring, bus users can be initialized, started and stopped.

In addition, NMT services exist for connection monitoring.

Description of the NMT command

The commands are transmitted as unconfirmed objects and are structured as follows:

COB ID

DLC

Byte 1

Byte 2

00H

02H

Command

Node

Command byte

Command byte

Description

State

01H

Start remote node

Operational

02H

Stop remote node

Stop

80H

Enter pre-operational mode

Pre-operational

81H, 82H

Reset remote node

Boot-up

The node number corresponds to the node ID of the required users. With node number = 0, all users are

addressed.

Following initialization, the encoder is in the pre-operational mode. In this status, SDO parameters can be

read and written. In order to request PDO parameters, the encoder must first be moved to the operational

mode status by the command Start.

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

7

MEM40B_CAN_Inglese_ul.docx

NMT states

Initialization

Following initialization, the encoder logs on to the CAN bus with a BootUp message. The encoder then

goes automatically to the pre-operational mode status.

The COB ID of the BootUp message is made up of 700H and the node ID.

COB ID

DLC

Byte 1

700H + Node

01H

00H

Pre-operational mode

In the pre-operational mode, SDOs can be read and written.

Operational mode

In the operational mode, the encoder transmits the requested PDOs. In addition, SDOs can be read and

written

Stopped mode

In the stopped mode, only NMT and LSS communication is possible. No SDO parameters can be read or

written.

Status change

Start command

With the start command, the encoder is switched to the operational mode status.

COB ID

DLC

Command

Node

00H

02H

01H

00H, …, 7FH

Stop command

With the stop command, the encoder is switched to the stopped mode status.

COB ID

DLC

Command

Node

00H

02H

02H

00H, …, 7FH

Pre-operational mode command

The encoder switches to the pre-operational mode status

COB ID

DLC

Command

Node

00H

02H

80H

00H, …, 7FH

Application reset command

With the reset command the encoder is re-initialized and switches to the pre-operational mode status.

COB ID

DLC

Command

Node

00H

02H

81H

00H, …, 7FH

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

8

MEM40B_CAN_Inglese_ul.docx

Communication reset

The encoder re-initializes the communication and switches to the pre-operational mode status.

COB ID

DLC

Command

Node

00H

02H

82H

00H, …, 7FH

Heartbeat Protocol

The encoder (Heartbeat producer) transmits the Heartbeat message cyclically with the frequency defined

in the object 1017H.

One or more Heartbeat Consumer may receive the indication. The relationship between producer and

consumer is configurable via Object Dictionary entries.

The heartbeat messages consist of the COB ID and one byte. In this byte, the NMT status is supplied.

COB ID

DLC

Byte 1

700H+Node

01H

7FH

- 00H Boot-up

- 04H Stopped state

- 05H Operational state

- 7FH Pre-operational state

In the above example the encoder is in the pre-operational state (7FH).

1.10 Layer Setting Services (LSS)

The encoder is provided with default values for node number (1) and baud rate (50 kBaud). Since several

encoders can be connected to the same CAN network with the same node number, the LSS protocol

allows to address each individual encoder. In other words different encoders with the same node number

can be connected to the system to be initialized via LSS protocol.

Both the node number and the baud rate can be modified (see Layer Setting Services and Protocol, CiA

Draft Standard Proposal 305). LSS commands can only be executed with the encoder in the stopped or

pre-operational mode state.

Message structure

COB ID:

Master Slave: 7E5H

Slave Master: 7E4H

The COB ID is followed by the LSS command specifier and seven data bytes.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Global Switch mode

With this command the master sets all the LSS slave in the network to the waiting status (0) or configuring

mode (1). No response follows.

COB ID

DLC

Command

Mode

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

04H

00H / 01H

Reserved

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

9

MEM40B_CAN_Inglese_ul.docx

Selective Switch Mode

With this command the master sets the LSS addressed node to the configuring mode. The response if the

addressed device follows.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

40H

Vendor ID

reserved

7E5H

08H

41H

Product code

reserved

7E5H

08H

42H

Revision number

reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

44H

Reserved

Vendor ID ELAP: 000002B4H

Product code: Encoder inside code (see label)

Revision number: Current encoder revision (see label)

Setting the node ID

After setting the encoder in the configuration mode, it is possible to modify the node ID.

Accepted node numbers: 1 to 127.

The response telegram by the slave with result in byte 1 follows (0 ok, 1 Node ID outside range).

COB ID

DLC

Command

Node

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

11H

01H,…,7FH

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

11H

Result

Reserved

Setting the baud rate

After setting the encoder in the configuration mode it is possible to modify the baud rate.

The response telegram by the slave with result in byte 1 follows (0 ok, 1 baud rate outside range).

COB ID

DLC

Command

Sel,Table

Sel.Baud

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

13H

00H o 80H

xx

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

13H

Result

Reserved

Table selection : 00H Standard CiA table

80H Vendor specific table

Encoder MEM40B –MEM41B with CANopen protocol –Instruction Manual

10

MEM40B_CAN_Inglese_ul.docx

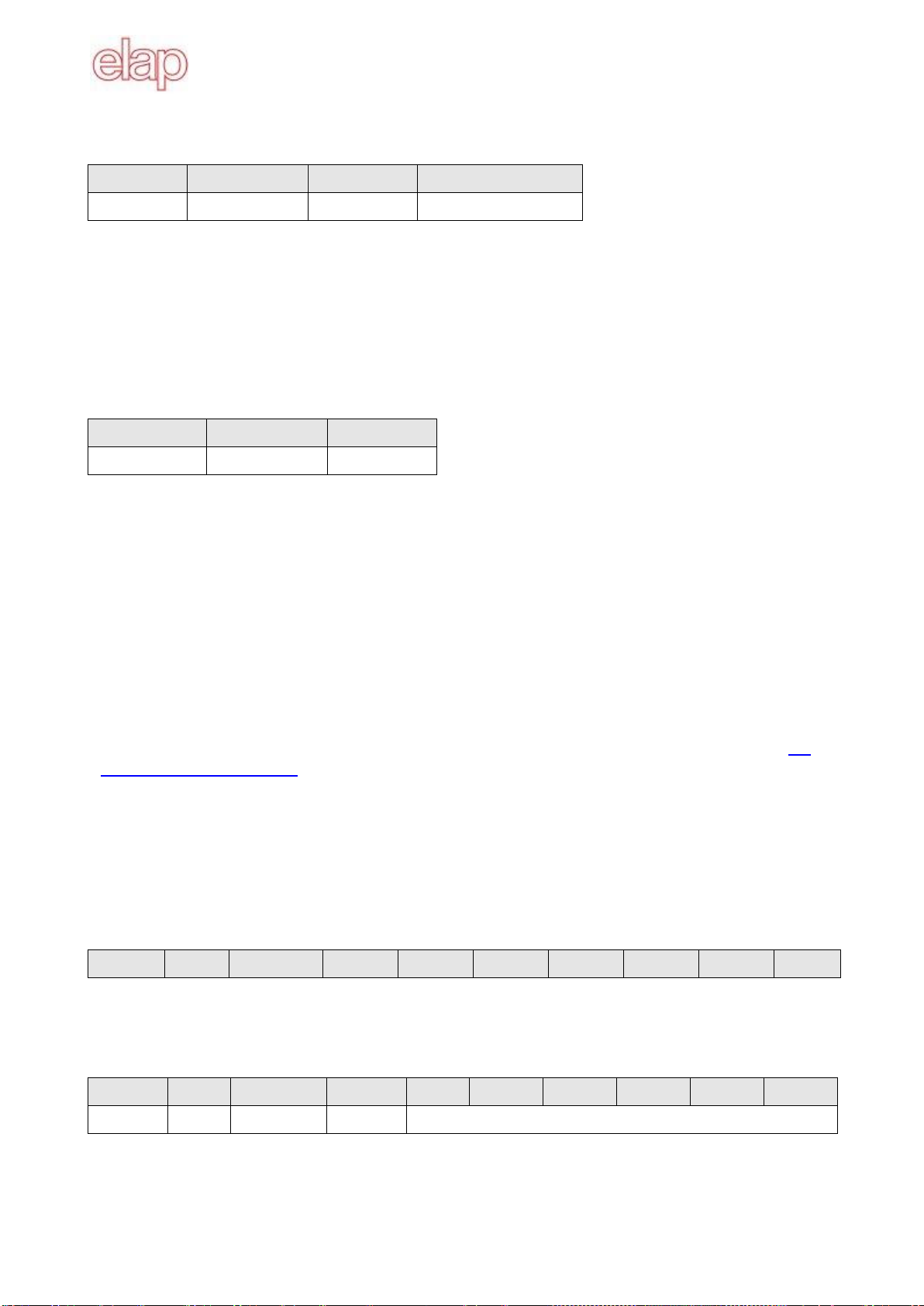

Standard CiA table (Sel.Table = 00H)

Baud Rate

Index

1000 kBaud

0

800 kBaud

1

500 kBaud

2

250 kBaud

3

125 kBaud

4

-

5

(reserved)

50 kBaud

6

20 kBaud

7

10 kBaud

8

Elap Table (Sel.Table = 80H)

Baud Rate

Index

10 kBaud

0

20 kBaud

1

50 kBaud

2

125 kBaud

3

250 kBaud

4

500 kBaud

5

800 kBaud

6

1000 kBaud

7

Configuration saving command

With this command the master requires to save the modified data (node identification and baud rate).

The response telegram by the slave with result in byte 1 follows (0 ok, 1 saving not supported, 2

access error).

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

17H

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

17H

Result

Reserved

Activating the new baud rate

The new baud rate set with the relevant LSS command is activated by this command. Bytes 1 and 2

contain a delay in ms. No response follows by the slave.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

15H

Delay time (ms)

Reserved

The encoder waits the set time before re-initializing the baud rate records. Then it still waits the same time

span before sending the messages with the new baud rate to the network.

Requesting the Vendor ID

With this message the master requests the selected slave (that is in the configuration state) the vendor ID

code. The slave response with the requested data in bytes 1 to 4 follows.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

5AH

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

5AH

B4H

02H

00H

00H

Reserved

ELAP Vendor ID code is 000002B4H.

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

11

MEM40B_CAN_Inglese_ul.docx

Requesting the product code

With this message the master requests the selected slave (that is in the configuration state) the product

code. The slave response with the requested data in bytes 1 to 4 follows.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

5BH

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

5BH

32 bit product code

Reserved

Requesting the revision number

With this message the master requests the selected slave (that is in the configuration state) the vendor ID

code. The slave response with the requested data in bytes 1 to 4 follows.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

5CH

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

5CH

32 bit revision number

Reserved

Searching for a device

The encoder can be searched for in the network. The master sends the following telegrams in sequence.

The response of the relevant slave follows.

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E5H

08H

46H

Vendor ID

Reserved

7E5H

08H

47H

Product code

Reserved

7E5H

08H

48H

Revision number (low)

Reserved

7E5H

08H

49H

Revision number (high)

Reserved

COB ID

DLC

Command

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

7E4H

08H

4FH

Reserved

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

12

MEM40B_CAN_Inglese_ul.docx

2. Encoder communication profile

2.1 Overview of encoder objects

According to CiA (CAN in Automation), objects are subdivided into three groups:

• Standard objects (see DS 301, Application Layer and Communication Profile):

o1000H, 1001H, 1018H

• Manufacturer-specific objects (see DS 301):

o2000H - 5FFFH

• Device-specific objects(see DS 406, Device Profile for encoders):

oAll other objects from 1000H - 1FFFH, 6000H - FFFFH

The following table provides a summary of all SDO objects supported by the encoder.

Object Object number in Hex

Name ===

Type U/I = Unsigned/Integer, No. = number of bits, ARR = Array, REC = structure

Attr access attributes: ro = read only, wo = write only, rw = read write

Default Default value on first init

Object

Name

Type

Attr

Default

Info

1000H

Device type

U32

ro

00020196H

00010196H

Byte 0-1:

Profile 0196H = 406

Byte 2-3:

Encoder type=2(absolute, multiturn)

Encoder type=1 (absolute single turn)

1001H

Error register

U8

ro

00H

Bit0 generic error

Bit4 communication error

Bit7 battery voltage low

1003H

00H

01H

…

04H

Predefined error field

Biggest Subindex

Latest error

…

Oldest error

ARR

U8

U32

…

U32

rw

ro

…

ro

Contains the last 4 errors/warnings

Number of stored errors (0 –4)

Error or warning:

1000H Generic error

6010H Watchdog

7320H Position Error

8110H CAN Error (overrun)

8120H CAN Error (tx / rx)

8140H Recovered Bus-Off

FF00H Buffer battery ( < 3.2V)

FF01H Lost Data

1005H

COB ID SYNC message

U32

rw

00000080H

COB ID of the SYNC object

1008H

Device name

U32

ro

“MEMC”

1009H

Hardware Version

U32

ro

“n.nn”

Hardware Version in ASCII

100AH

Software Version

U32

ro

“n.nn”

Software Version in ASCII

1010H

00H

01H

Store parameters

Max sub-index

Save all parameters

ARR

U8

U32

ro

rw

01H

Single turn encoder only

Save possibility (1)

“save” (0x73617665) to save

1010H

00H

01H

Restore default parameters

Max sub-index

Restore default values

ARR

U8

U32

ro

rw

01H

Single turn encoder only

Restore possibility (1)

“load” (0x6C6F6164) to restore

1014H

COB ID emergency

U32

ro

80H+Node

COB ID of the Emergency object

1017H

Heartbeat time

U16

rw

07D0H

Heartbeat cycle time in ms

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

13

MEM40B_CAN_Inglese_ul.docx

Object

Name

Type

Attr

Default

Info

1018H

00H

01H

02H

03H

Identity Object

Biggest Subindex

Vendor ID

Product code

Revision No.

ARR

U8

U32

U32

U32

ro

ro

ro

ro

03H

000002B4H

Manufacturer Id (by CiA)

0AH multiturn, 0BH single turn

Current revision

1029H

00H

01H

Error behavior

Biggest Subindex

Communication error

ARR

U8

U8

ro

rw

01H

00H

Object present from 1.10 version

(see 100AH, software version)

00H change to pre-operational

01H no change of NMT state

02H change to Stop mode

1800H

00H

01H

02H

05H

Transm. PDO1 parameters

Biggest Subindex

COB ID

PDO type

Event timer

REC

U8

U32

U8

U16

ro

rw

rw

rw

05H

180H+node

FEH

0064H

PDO ID = 180H + node

Cyclic PDO

Cycle time in ms

1801H

00H

01H

02H

05H

Transm. PDO2 parameters

Biggest Subindex

COB ID

PDO Type

Event timer

REC

U8

U32

U8

U16

ro

rw

rw

rw

05H

280H+node

01H

01F4H

PDO ID = 280H + node

Synchronous PDO

Cycle time in ms

1A00H

00H

01H

PDO1 Mapping

Biggest Subindex

Content of PDO1

ARR

U8

U32

ro

ro

01H

60040020H

ro, although for CiA it is rw

Byte 0-1:

0020H = 32 bit

Byte 2-3:

6004H = object index (position)

1A01H

00H

01H

PDO2 Mapping

Biggest Subindex

Content of PDO2

ARR

U8

U32

ro

ro

01H

60040020H

ro, although for CiA it is rw

Byte 0-1:

0020H = 32 bit

Byte 2-3:

6004H = object index (position)

2100H

Baud rate

U8

rw

02H

Init is required after setting a value:

00H 10 kBit/s

01H 20 kBit/s

02H 50 kBit/s

03H 125 kBit/s

04H 250 kBit/s

05H 500 kBit/s

06H 800 kBit/s

07H 1000 kBit/s

2101H

Node ID

U8

rw

01H

Accepted values: 01H to 7FH.

Init is required after setting a value

2110H

Options

U16

rw

08H

Bit0 rotation direction

(see object 6000H, Bit0)

Bit1 not used

Bit2 scaling function

(see object 6000H, Bit2)

Bit3 Bus-Off automatic recovery

0 disabled

1enabled

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

14

MEM40B_CAN_Inglese_ul.docx

Object

Name

Type

Attr

Default

Info

6000H

Operational parameters

U16

rw

0000H

Bit0 rotation direction

0 clockwise rotation

1 anti-clockwise rotation

Bit2 scaling function

0 disabled

1 enabled

6001H

Resolution –single turn

U32

rw

00002000H

13 bit resolution; accepted values: 01H

to 2000H.

6002H

Overall measuring range

U32

rw

20000000H

20000000H 29 bit (multiturn)

00002000H 13 bit (singleturn)

6003H

Preset value

U32

rw

00000000H

Preset in increments

6004H

Encoder position

U32

ro

Encoder position, inclluding offset by

the preset value

6200H

Cycle time for PDO1

U16

rw

0064H

In ms, identical to object 1800H,

subindex 05H.

6500H

Operational state

U16

ro

0000H

Bit0 rotation direction

Bit2 scaling function

6501H

Max Single turn resolution

U32

ro

2000H

13 bit resolution

6502H

Revolutions number

U16

ro

Absolute number of performed rotations

6503H

Alarms

U16

ro

0000H

The following alarms are evaluated:

Bit0 Position error

6504H

Supported alarms

U16

ro

0001H

The following alarms are supported:

Bit0 Position error

6505H

Warnings

U16

ro

0000H

The following warnings are evaluated

Bit2 Watchdog (single turn)

Bit4 Battery charge (multiturn)

6506H

Supported warnings

U16

ro

0004H

0010H

The following warnings are supported

Bit2 Watchdog (single turn)

Bit4 Battery charge (multiturn)

6507H

Profile & software version

U32

ro

01000302H

Byte 0-1:

Profile version 0302H 3.02

Byte 2-3:

Software Version = 0100H 1.00

6508H

Operating time

U32

ro

00000000H

Time in 1/10 hours since last reset

6509H

Offset

U32

ro

00000000H

Offset calculated from preset

(object 6003H)

650BH

Serial number

U32

ro

FFFFFFFFH

Not used

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

15

MEM40B_CAN_Inglese_ul.docx

2.2 Parameters saving

The objects below are saved via object 1010H. In order to prevent unintentional saving, the message

"save" must be written in subindex 1. The saving operation is necessary to store modifications performed

in the objects below.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

600H+node

08H

23H

10H

10H

01H

73H „s‟

61H „a‟

76H „v‟

65H „e‟

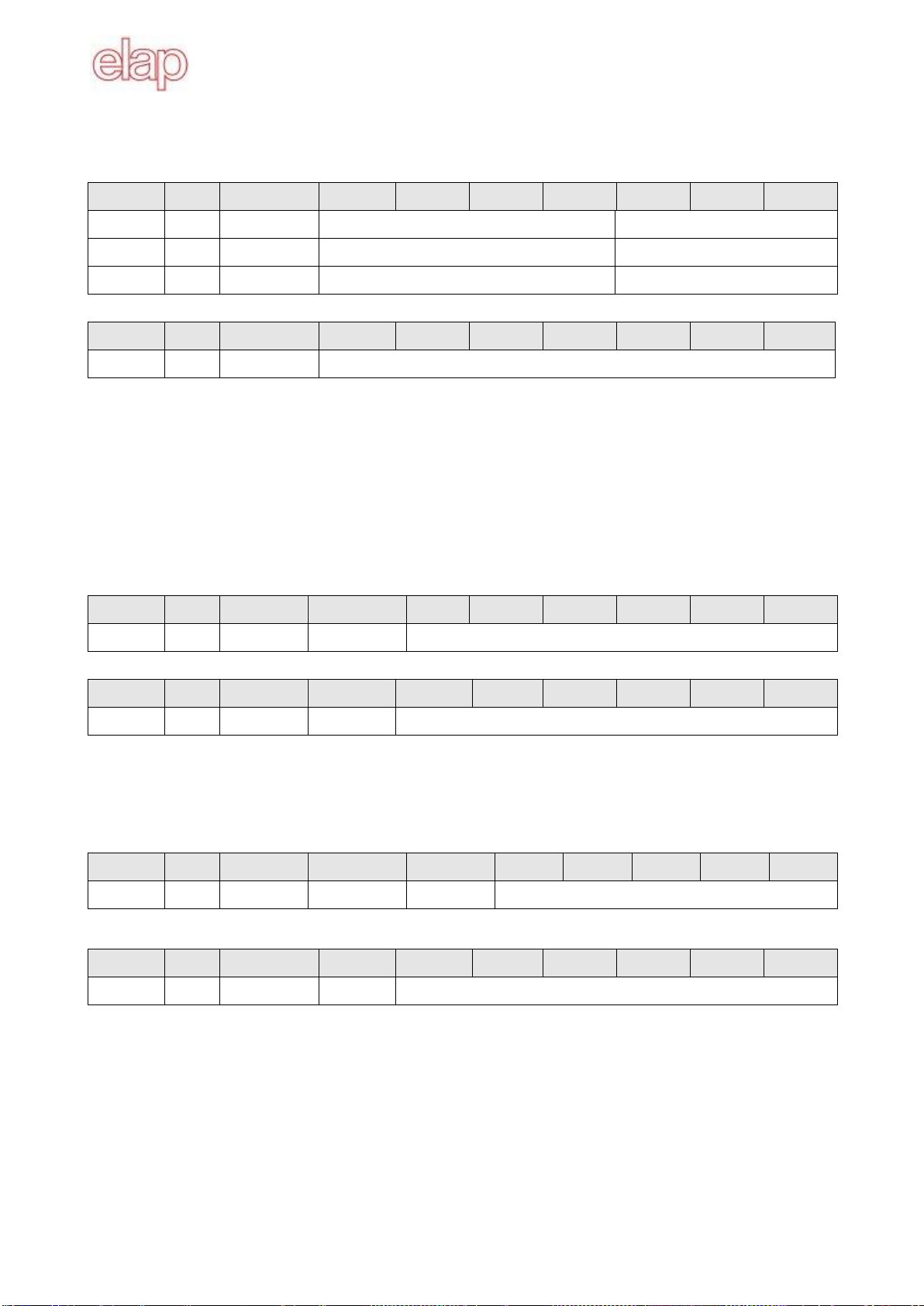

Saved objects

Object

Sub-index

Description

Default values

1005H

00H

COB ID SYNC message

80H

1017H

00H

Heartbeat time

07D0H (2000 ms)

1029H

01H

Behavior in case of communication error

00H (change to pre-operational)

1800H

01H

COB ID PDO1

180H + node

1800H

02H

Type PDO1

FEH (PDO cyclical asynchronous)

1800H

05H

Timing PDO1

0064H (100 ms)

1801H

01H

COB ID PDO2

280H + node

Object

Sub-index

Description

Default values

1801H

02H

Type PDO2

01H (PDO synchronous))

1801H

05H

Timing PDO2

01F4H (500 ms)

2100H

00H

Baud rate index

02H (50 kbps)

2101H

00H

Node identification

01H

2110H

00H

Manufacturer options

08H

6000H

00H

Operating parameters

00H

6001H

00H

Single turn resolution

2000H (13 bit)

6002H

00H

Total measuring range

2000H

6003H

00H

Preset value

0000H

6200H

00H

PDO1 cycle time

0064H (100 ms)

6509H

00h

Offset value

0000H

The default values of the save parameters can be restored via object 1011H. In order to prevent

unintentional restoring, the message "load" must be written in subindex 1. Default values will be used by

the slave after resetting.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

600H+node

08H

23H

10H

10H

01H

6CH „l‟

6FH „o‟

61H „a‟

64H „d‟

3. Diagnosis and useful information

3.1 Error diagnosis field bus communication

If the encoder cannot be addressed via the CANopen bus, first of all check the terminals. If the

terminals are not in order, field bus operation should be tested next. For this purpose, a CAN

monitor is required which records CANopen communication and shows the telegrams.

The encoder should now place a BootUp message when switching the power supply off and on again.

Should no BootUp message appear, check whether the baud rates of the encoder, the CAN monitor

and the bus system are in agreement.

If you have difficulty in establishing the connection to the user, check the node number and baud rate.

The baud rate must be set the same throughout. The node number (node ID, node address) must be

between 1 and 127. Each bus user must be unambiguously assigned a node ID, i.e. it is strictly

prohibited to assign the same node ID more than once.

The node ID and baud rate can also be set conveniently using the LSS service.

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

16

MEM40B_CAN_Inglese_ul.docx

3.2 Error diagnosis via field bus

The encoder has at its disposal several objects and messages which transcribe the status or error status

of

the encoder.

- Object 1001H: This object is an error register for the device error status.

- Object 1003H: In this object, the last four error codes and warnings are stored.

- Object Emergency (80H + Node): High-priority error message of a user with error code and error

register.

- SDO: If SDO communication does not run correctly, the SDO response contains an error code. A list of

the possible errors follows:

o05040001H Command byte is not supported

o06010000H Incorrect access to an object

o06010001H Read access to write only object

o06010002H Write access to read only object

o06020000H Object is not supported

o06060000H FLASH memory writing/reading error (single turn only)

o06090011H Subindex is not supported

o06090030H Value outside limits

o06070010H Inconsistent data type

o08000020H Incorrect “save”/“load” code

3.3 Further useful information

Modifying the node number:

1. The node can be set in Elap specific object 2101H

2. The new node number is saved into RAM buffer.

3. On next initialization, the sensor logs on with the new node ID.

Modifying the baud rate:

1. The baud rate can be set in Elap specific object 2100H

2. The new baud rate is saved into RAM buffer.

3. On next initialization the encoder logs on with the new baud rate.

4. PAY ATTENTION: the MASTER must also be set with the same baud rate.

3.4 Signaling LEDs

The encoder is provided with a green LED (DATA), indicating the encoder state within the CANopen

network, a red LED (ERROR), indicating the error state, and a green LED (POWER) indicating the supply

state. The three signaling LEDs are shown in the picture 5.1.

DATA LED (green)

It flashes with a frequency of about 10 Hz (50 ma light, 50 ms off): the encoder is in the LSS setup

state (the red LED also flashes with the same frequency in this case).

It flashes with a frequency of about 2.5 Hz: the encoder is in the pre-operative state

It flashes every one second: the encoder is stopped.

Fixed light: the encoder is in the operative state.

ERROR LED (red)

Light off: the encoder is running correctly.

It flashes with a frequency of about 10 Hz (50 ma light, 50 ms off): the encoder is in the LSS setup

state (the green LED also flashes with the same frequency in this case).

It flashes every one second: there are errors in the CAN communication (frame errors, overrun, …)

Fixed light: the CAN controller is in the bus off state.

POWER LED (green)

Fixed light: the power supply is on.

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

17

MEM40B_CAN_Inglese_ul.docx

4. Applications

4.1 Reading and setting objects

In order to overwrite an object (SDO) or to read it, two telegrams always have to be transmitted: one

request from the master and one confirmation by the slave.

Example: setting an object

Setting the Heartbeat time (object 1017H, default = 2000 ms) 1500 ms (= 05DCH).

Master command telegram:

- Command: 2BH, 2 byte writing request

- Object address node: low byte first, then high byte

- Object sub-index: 0

- Value to be set: low byte first, then high byte

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

600H+node

08H

2BH

17H

10H

00H

DCH

05H

xx

xx

The slave confirmation telegram follows:

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

580H+node

08H

60H

17H

10H

00H

xx

xx

xx

xx

Example: reading an object

Reading the encoder position (object 6004H).

Master command message:

- Command: 40H, request for reading

- Object address node: low byte first, then high byte

- Object sub-index: 0

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

600H+node

08H

40H

04H

60H

00H

xx

xx

xx

xx

The slave response telegram follows:

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

580H+node

08H

43H

04H

60H

00H

04H

03H

02H

01H

The encoder value starts from the less significant byte, therefore in this case it is 01020304H ( =

16909060).

When the encoder is entered into the network, it starts with the BootUp message. The encoder must be

adjusted and configured for the environment it works in.

Changing the node ID and baud rate with LSS

The node ID and baud rate can be changed without having to use these to address the encoder. With the

LSS service, the sensors are addressed and configured via the vendor ID, product code, and revision no.

(object 1018H)

Encoder MEM-Bus con protocollo CANopen –Manuale di istruzioni

18

MEM40B_CAN_Inglese_ul.docx

Changing the node ID (node no.)

The node ID can be changed in object 2101H between 1 and 127. On the next initialization, the encoder

logs on with the new node ID.

Example: node no. Modification from 01H to 02H (writing 1 byte, value 02H)

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

601H

08H

2FH

01H

21H

00H

02H

xx

xx

xx

The encoder confirmation telegram follows.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

581H

08H

60H

01H

21H

00H

xx

xx

xx

xx

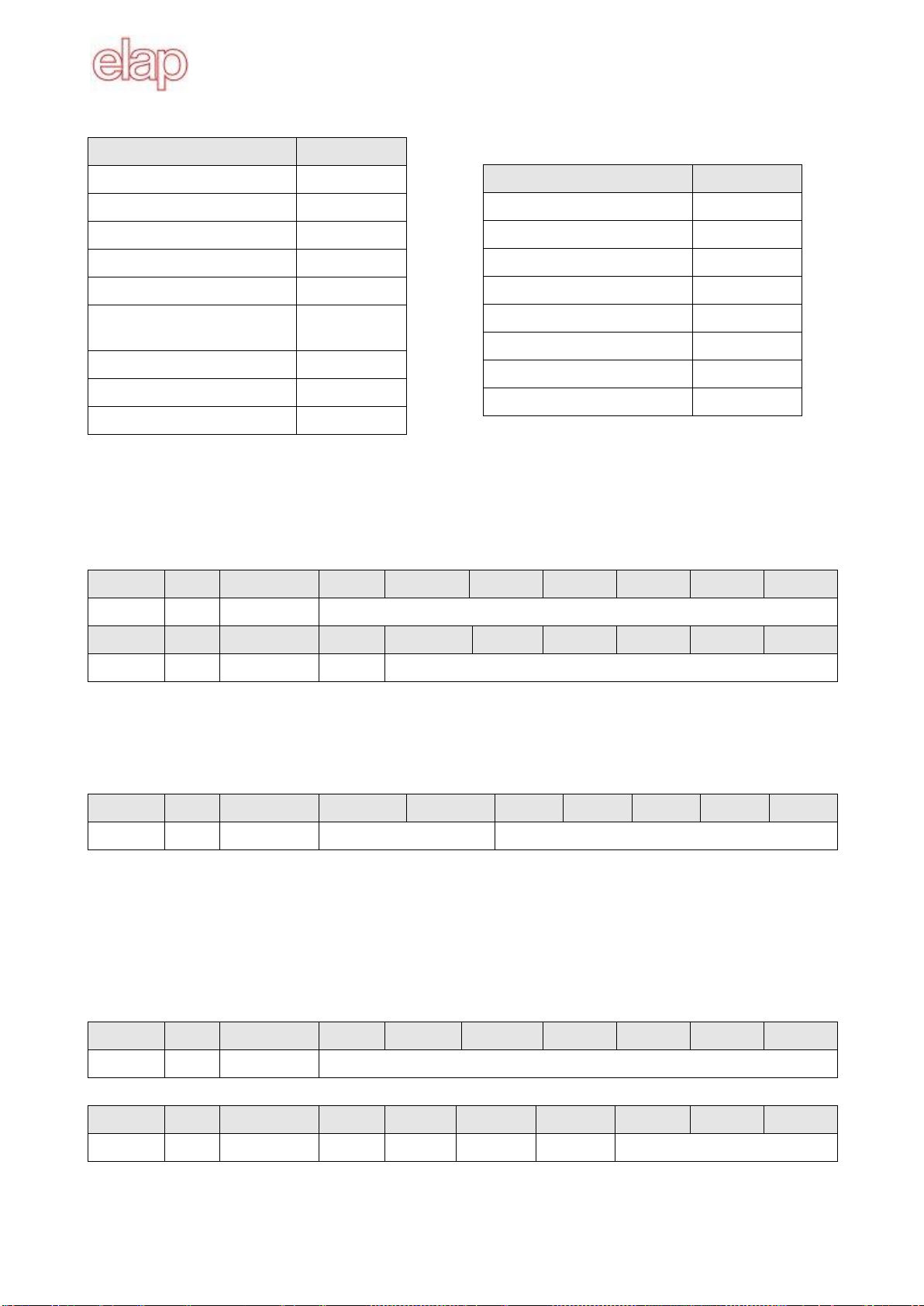

Changing the baud rate

The baud rate can be changed in the object 2100H. An index is written into the object, not the effective baud

rate. On next initialization, the encoder logs on to the new baud rate. The baud rate of the master must also

be changed accordingly.

Baud rate

Index

Baud rate

0

10 kBaud

1

20 kBaud

2

50 kBaud

3

125 kBaud

4

250 kBaud

5

500 kBaud

6

800 kBaud

7

1000 kBaud

Example: baud rate modification from 02H (50 kBaud) to 03H (125 kBaud): writing 1 byte, value 03H

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

601H

08H

2FH

00H

21H

00H

03H

xx

xx

xx

The encoder confirmation telegram follows.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

581H

08H

60H

00H

21H

00H

xx

xx

xx

xx

4.2 Configuration

Setting the preset value

Command message: writing 4 byte, value 0400H.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

600H+node

08H

23H

03H

60H

00H

00H

04H

00H

00H

The encoder confirmation telegram follows.

COB ID

DLC

Command

ObjectL

ObjectH

Sub-ind

Data0

Data1

Data2

Data3

580H+node

08H

60H

03H

60H

00H

xx

xx

xx

xx

This manual suits for next models

1

Table of contents

Other ELAP Media Converter manuals

Popular Media Converter manuals by other brands

Lynx Studio Technology

Lynx Studio Technology Aurora(N) user manual

CYP

CYP DCT-40 Operation manual

Extron electronics

Extron electronics IN1608 Setup guide

Hagstrom

Hagstrom KE18 user manual

Sony

Sony VGF-WA1/W - Vaio Wireless Digital Music... Specifications

urmet domus

urmet domus IPerVoice 1039 quick start guide