Elastec MediBurn30 Installation and operating instructions

MEDIBURN30 D-115 Rev 010

www.elastec.com

OPERATION & SERVICE MANUAL

MEDIBURN30

MEDIBURN30 2 D-115 Rev 010

www.elastec.com

MEDIBURN30 3 D-115 Rev 010

www.elastec.com

Introduction, Contact Information .....................................................................4

Product Description............................................................................................5

General Information............................................................................................6

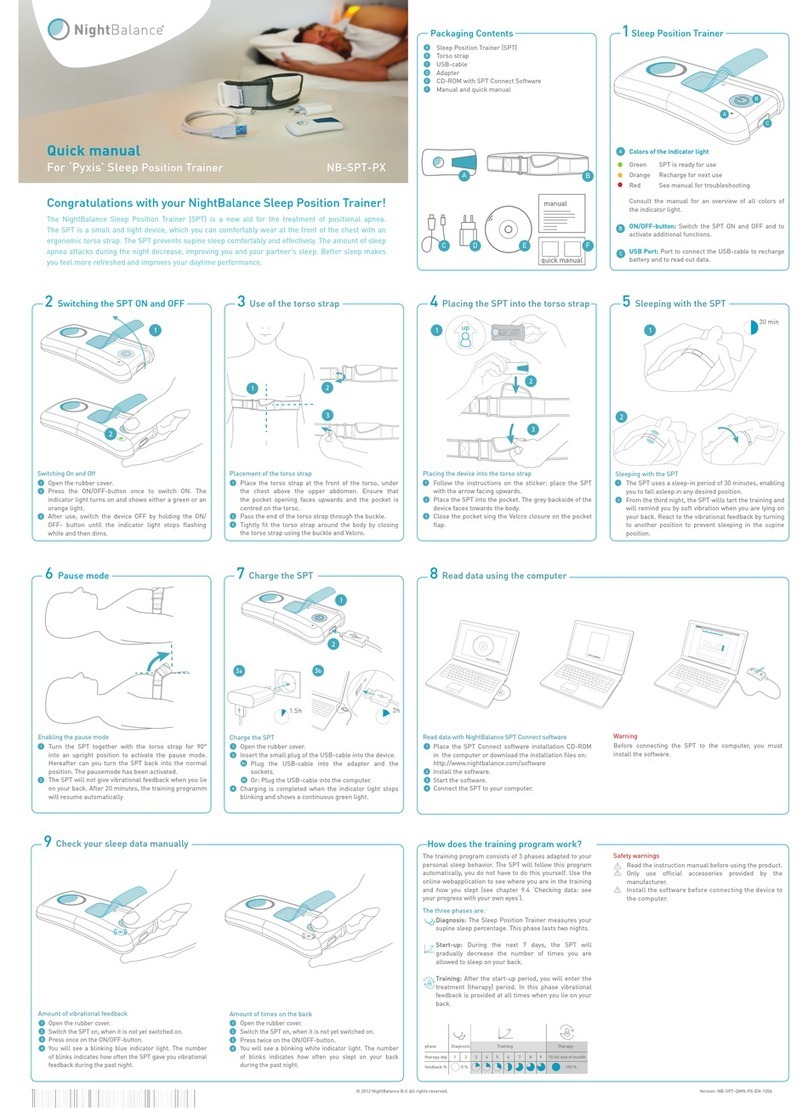

Control Panel.......................................................................................................7

How it Works .......................................................................................................8

Butterfly Assembly ...........................................................................................10

Door Lock Motor Assembly .............................................................................11

Surge Protector Assembly ...............................................................................12

Burnables ..........................................................................................................13

Safety Instructions............................................................................................14

Preparing for Disposal......................................................................................15

Cycle Completion..............................................................................................17

Ash Removal .....................................................................................................17

Error Codes .......................................................................................................18

Troubleshooting Guide.....................................................................................19

Installing Gauge, Setting Fuel Pressure .........................................................23

Maintenance ......................................................................................................24

Storage...............................................................................................................24

Fuse Identification ............................................................................................25

Controller Parts List..........................................................................................26

Chamber Parts List #1 ......................................................................................27

Chamber Parts List #2 ......................................................................................28

Chamber Brick Assemblies..............................................................................30

Chamber Brick Assembly Parts List ...............................................................31

Burner Drawing, Parts List...............................................................................32

Under Air Parts List ..........................................................................................33

Spare Parts List.................................................................................................33

Warranty ............................................................................................................34

Items Not Covered by Warranty.......................................................................35

TABLE OF CONTENTS

MEDIBURN30 4 D-115 Rev 010

www.elastec.com

This manual contains information on the Elastec MediBurn30, manufactured

by Elastec, Inc. All data in this publication is based on the latest product

information.

Elastec reserves the right to make changes at any time without notice and

without incurring any obligations. If a problem is encountered, or if you have

questions about your Elastec equipment, please call one of our consultants at

+1 (618) 382-2525.

Elastec products are USA-designed and built to provide safe and dependable

service when operated according to instructions. Please remember that

working with an incineration device can be dangerous. Read and understand

this manual before operating this system. Failure to do so may result in

personal injury and/or equipment damage.

Your MediBurn30 serial number is _________________________________

SERIAL NUMBER MUST BE INCLUDED WHEN ORDERING PARTS.

INTRODUCTION

1

CONTACT INFORMATION

Elastec, Inc. Telephone: +1 (618) 382-2525

1309 West Main Street Fax: +1 (618) 382-3610

USA Website: www.elastec.com

MEDIBURN30 5 D-115 Rev 010

www.elastec.com

PRODUCT DESCRIPTION

The Elastec MediBurn30 is a portable, small batch medical waste incinerator.

It enables small hospitals, clinics and laboratories to dispose of medical waste

in a safe and efficient manner. The MediBurn30 is designed to be easily and

safely operated by existing personnel with minimal training. The MediBurn30

can be used at any convenient location on existing property. Before using the

MediBurn30, the operator should read and follow the instructions in this

manual.

Length:

Width:

Height:

Weight:

Fuel Tank Capacity:

Primary Chamber Volume:

Suggested Load Volume:

79” (201 cm)

34” (86 cm)

82” (208 cm) without stack

100” (254 cm) with stack

2,440 lbs (approx. 1,107 kg)

40 gallons (151 litres)

13 cu ft (.37 cu m)

10.5 cu ft (.30 cu m)

SPECIFICATIONS

Electric:

Fuel:

Variable

2-3 gallons/hour (7-11 litres/hour)

FUEL AND POWER CONSUMPTION

Incinerates up to 30 kg per hour

Modulating burners & under-air technology provide up to 50%

fuel savings.

Ready to use upon delivery

Updated electronic control system with multiple languages

available

Dual chamber combustion & high exhaust temperatures in

excess of 1000 degrees C

Safety features such as door lock and sensor.

Replaceable ceramics

FUEL AND POWER CONSUMPTION

MEDIBURN30 6 D-115 Rev 010

www.elastec.com

CAUTION: Operators must wear gloves and safety glasses while operating unit.

CAPACITY

One MediBurn30 is capable of disposing of 10.5 cubic feet (.030 cubic meters)

of medical waste per load. Since there is a broad range of densities in waste

materials, the actual amount may vary. The waste is reduced to approximately

5% of its original volume. Ash is removed by means of a special rake (supplied

with the unit) and can be emptied directly into appropriate containers.

HOOK-UP

Electrical: In some cases, plugs may have to be installed on the end of the wires

extending from the unit to be compatible with local electrical fittings.

Fuel: There are two options for the supply of diesel to the unit:

Gravity-fed system: A large fuel tank supplies the unit. The bottom of the

tank should be higher than the top of the burner on the secondary chamber.

Mounted tank: Fuel supply is mounted under the unit with a fuel pump and

return line.

CONTROL PANEL OPERATION

The burn times are adjusted using the UP and DOWN arrows on the controller

located on the control panel (see Page 7). When the cycle time is chosen, push

the START button and the MediBurn30 will begin its operating cycle. To change

the cycle time, push the STOP button and change the cycle time. Then restart

the unit.

COMPLETE CYCLE

Unit is switched on, burn chamber door will lock and the 30-second purge

begins (fans only).

7-minute pre-heat (secondary chamber burner fires and begins the pre-heat

process).

Burn cycle begins.

After the firing cycle is complete, blowers in both primary and secondary

chambers blow cool air until the temperature of the unit is 300 degrees

Celsius. If the temperature rises again, blowers will be activated cyclically

until the temperature remains below 300 degrees Celsius.

OPERATING TEMPERATURES

Temperature readouts are visible on the control panel. The unit is designed to

preheat the secondary chamber for 7 minutes before incineration begins in the

primary chamber. Exhaust temperatures are automatically controlled to range

from 1000 degrees Celsius to 1025 degrees Celsius during the burn cycle.

Lower temperatures noted during operation indicate that the materials in the

batch load have been incinerated.

GENERAL INFORMATION

MEDIBURN30 7 D-115 Rev 010

www.elastec.com

CONTROL PANEL

Maintenance

Information

Burn

Time

Upper

Temperature

Indicator light is red

when burner is on.

Lower Burner

Reset Button

Lower

Temperature

Start

Language

Upper Burner

Reset Button

Stop

Burn time

adjustment

MEDIBURN30 8 D-115 Rev 010

www.elastec.com

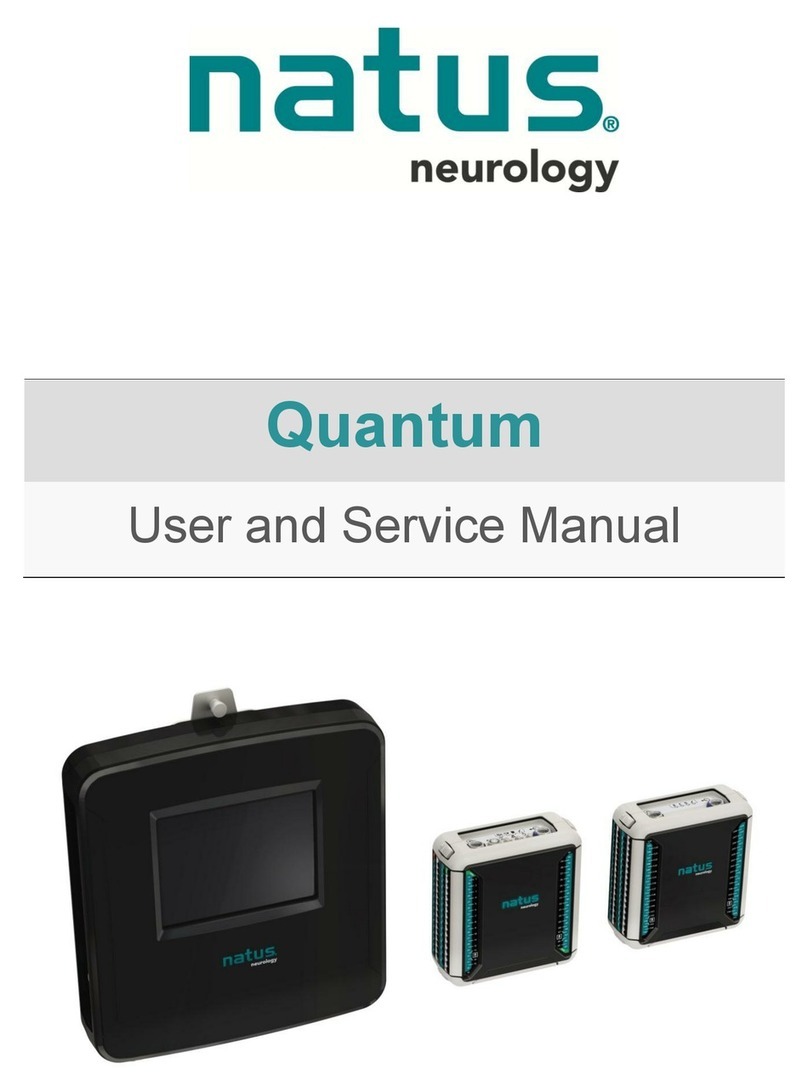

HOW IT WORKS

Under-Air

Piping

Under-Air

Blower

MEDIBURN30 9 D-115 Rev 010

www.elastec.com

The operating functions of the burners on the MediBurn30 differ from those of

the original MediBurn in that the 30 has two-stage pumps which oscillate based

on temperature, rising and falling during normal burn operation. As the unit

starts its burn cycle and the temperature climbs, the pumps decrease fuel

usage at specified temperatures. This lowers the heat output of the burners.

However, the temperature continues to rise as the under-fired air in the

primary chamber raises the load temperature by increasing the flame of the

burning material. This process increases temperature to a preset point where

the lower burner can shut off, further reducing fuel usage. The upper burner

also oscillates fuel usage as it works to keep the stack temperature at or above

1000 degrees Celsius.

The MediBurn30 incorporates two 24-volt continuous stall motors. One of

these motors is used to operate and maintain the automatic door lock, which is

activated when the START button is pushed. The other 24-volt motor is used to

open and close the under-fired air bypass.

All of these components are controlled by temperature through the system

controller. Should you as the owner or system user have problems with these

components, please refer to the Troubleshooting Guide found on Pages 19-22

or call Elastec at (618) 382-2525.

HOW IT WORKS

MEDIBURN30 10 D-115 Rev 010

www.elastec.com

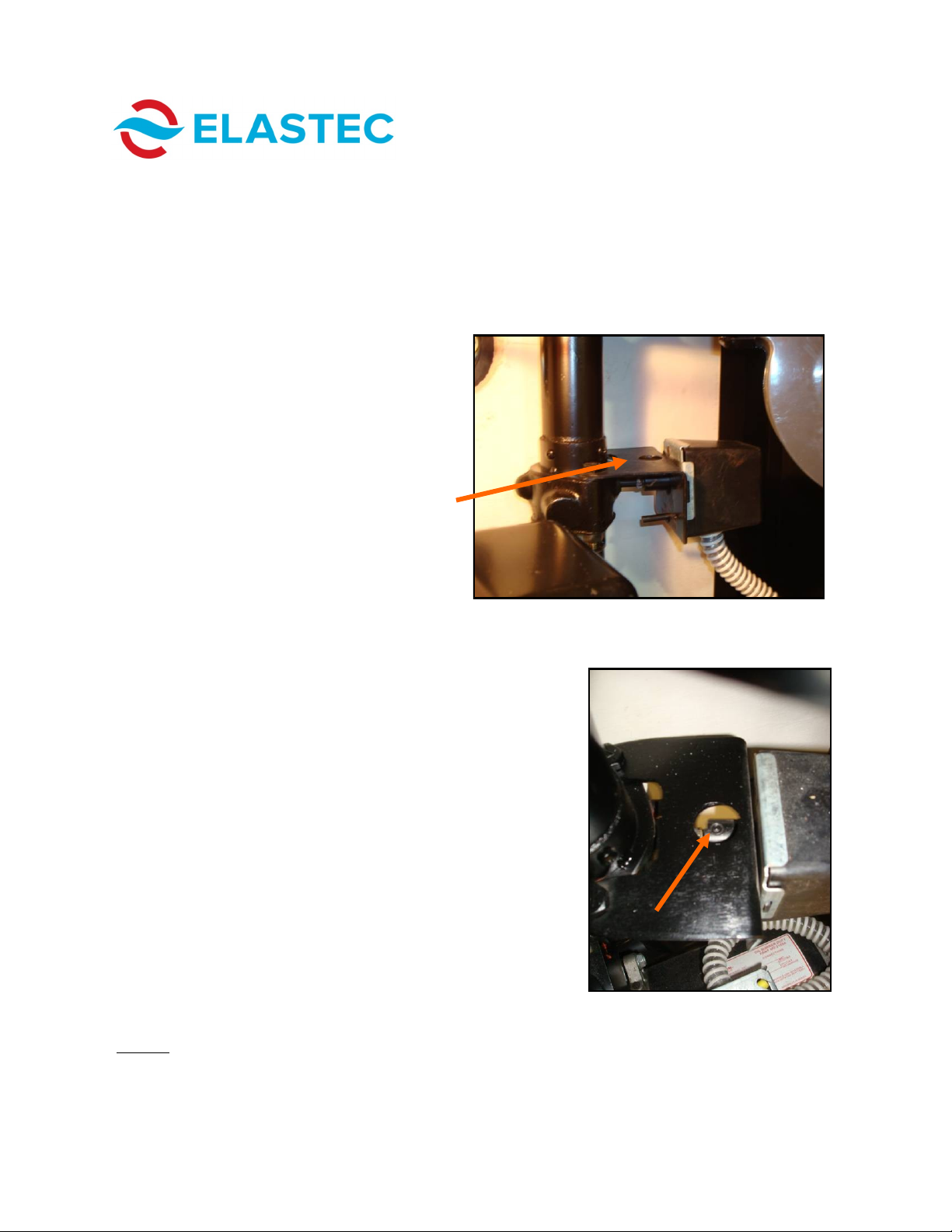

BUTTERFLY ASSEMBLY

The butterfly assembly, located just above the lower burner, is used to open

and close an air bypass. This motor function should be checked on a regular

basis to ensure that it is working properly. In the top of the motor bracket,

there is a small hole that will allow you to view the shaft coupler set screw.

This set screw will turn and disappear out of sight when the motor is activated.

This process can be easily viewed when the lower chamber temperature is

between 600° Celsius and 1000°

Celsius (1112° Fahrenheit and 1832°

Fahrenheit).

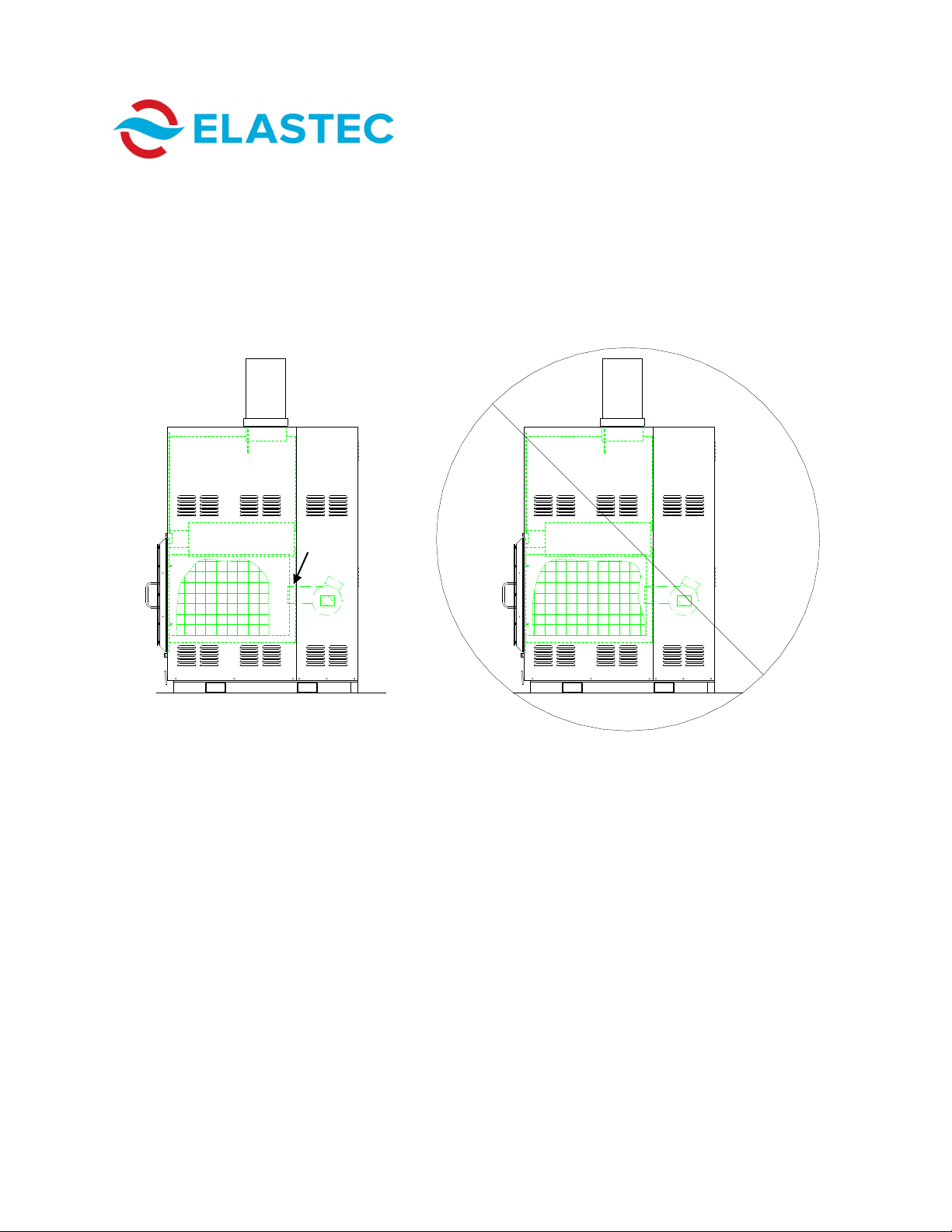

The picture to the right shows the set screw

(arrow) as it appears when the MediBurn30 is in

idle. This set screw will rotate out of view when the

temperature climbs above 600° Celsius (1112°

Fahrenheit), indicating the butterfly valve has

opened, allowing air to bypass into the under-air

system. When the lower chamber temperature

reaches 1000° Celsius (1832° Fahrenheit), the

butterfly valve will close and the set screw will

again be visible. It can also be felt by using your

finger. This bracket rarely gets very hot, due to the

cold air that passes through the tubing and

butterfly valve, making it possible to check this by

hand as well as sight. Should you have to replace

this motor, be sure to orient the set screw so that it

can be viewed through the view hole.

NOTE: It is important to maintain this motor in good working condition, as it is

instrumental in the process of fuel savings.

MEDIBURN30 11 D-115 Rev 010

www.elastec.com

DOOR LOCK MOTOR ASSEMBLY

The door lock motor assembly is located on the right side of the burner

compartment. It is designed to lock the burn chamber door as soon as the

START button is pushed. The door-locking system is designed as a safety

feature and is built in such a way that, if tampered with, the MediBurn30 will not

start. When the burn chamber door is open, the controller scrolls “door open,”

and if the burn chamber door is opened during the burn cycle, the unit will

automatically cycle into cool mode and the unit will have to cool to 300C before

restart can begin.

NOTE: The MediBurn30 must always be cooler than 300° Celsius (572°

Fahrenheit) before trying to load unit.

MEDIBURN30 12 D-115 Rev 010

www.elastec.com

SURGE PROTECTOR ASSEMBLY

This unit is supplied with a surge protector assembly.

This assembly consists of the following:

(1) NEMA 12 steel enclosure

(2) Dehn DG 275 surge arrestors

In the event of a sudden surge in voltage, the surge arrestors will drain the

surge to ground and protect the unit.

MEDIBURN30 13 D-115 Rev 010

www.elastec.com

BURNABLES

MATERIAL RECOMMENDATIONS

Fabrics

Gauze, Garments, Bandages, Swabs

Plastics

Trash Bags, Containers, IV Bags, Tubes, Specimen Cups

WARNING: Each load should contain no more than 25%

plastics. Burning more than the recommended

percentage of plastic causes damage to vital control

components, leading to costly repairs.

Paper

Disposable Gowns, Sheets, Pre-moistened Towels, Paper

Towels

Pathological Waste

Body Parts, Tissue

Waste Chemicals

and Drugs

Medical waste does not include any chemicals or drugs

identified as hazardous waste. Drugs and chemicals

identified as hazardous waste should not be included.

Sharps

Needles and scalpels should not be included with materials to

be put in the unit because of danger in handling. If included,

the sharps would be sterilized but will not melt.

ATTENTION:

Before operating this unit, remove all items and packing material

from the lower burn chamber. There will be some additional packing

material in the upper burn chamber. It is not necessary to remove

packing material from the upper chamber.

Run the unit with the lower burn chamber empty for a 30-minute

cycle. The MediBurn will release smoke and some particulate for a

few minutes during this initial burn.

MEDIBURN30 14 D-115 Rev 010

www.elastec.com

SAFETY INSTRUCTIONS

Before using medical waste incinerator, basic safety precautions should

always be followed to reduce the risk of fire, electric shock and personal injury.

1. Read and understand the instructions in this manual.

2. Follow all warnings and instructions marked on the product.

3. The unit must be disconnected from the power source when there is a

chance water may come into contact with the electrical connections.

4. The unit must be on stable ground and in no danger of falling or tipping.

5. The unit must stand free and clear of surrounding buildings, vegetation or

other combustible material.

6. Ensure that there are no flammable items above the exhaust stack.

7. Never touch the surfaces of the unit while in operation or during the

cool-down period.

8. Do not use the unit in the vicinity of flammable gases.

9. Never put aerosol or other pressurized cans into the unit.

10. If unsure about the safety of disposing of certain items in the unit, consult

your local distributor for details and instructions.

11. Refer servicing to qualified personnel under the following conditions:

Power supply cord is frayed or damaged.

Liquid has been in contact with the electrical system.

The product has been damaged and exhibits a distinct change in

performance.

Fuel is leaking inside the burners.

MEDIBURN30 15 D-115 Rev 010

www.elastec.com

1. Position unit on a level surface at least 2 meters (7 feet) away from existing

structures. Please ensure that there are no overhangs from the building or

overhead wires above the exhaust stack.

2. Connect the electrical plug extending from the control panel of the unit to an

appropriate extension cord. Cord should be no lighter than 12 gauge at 7.5

meters/25 feet. If a longer cord is needed, a heavier gauge wire is required.

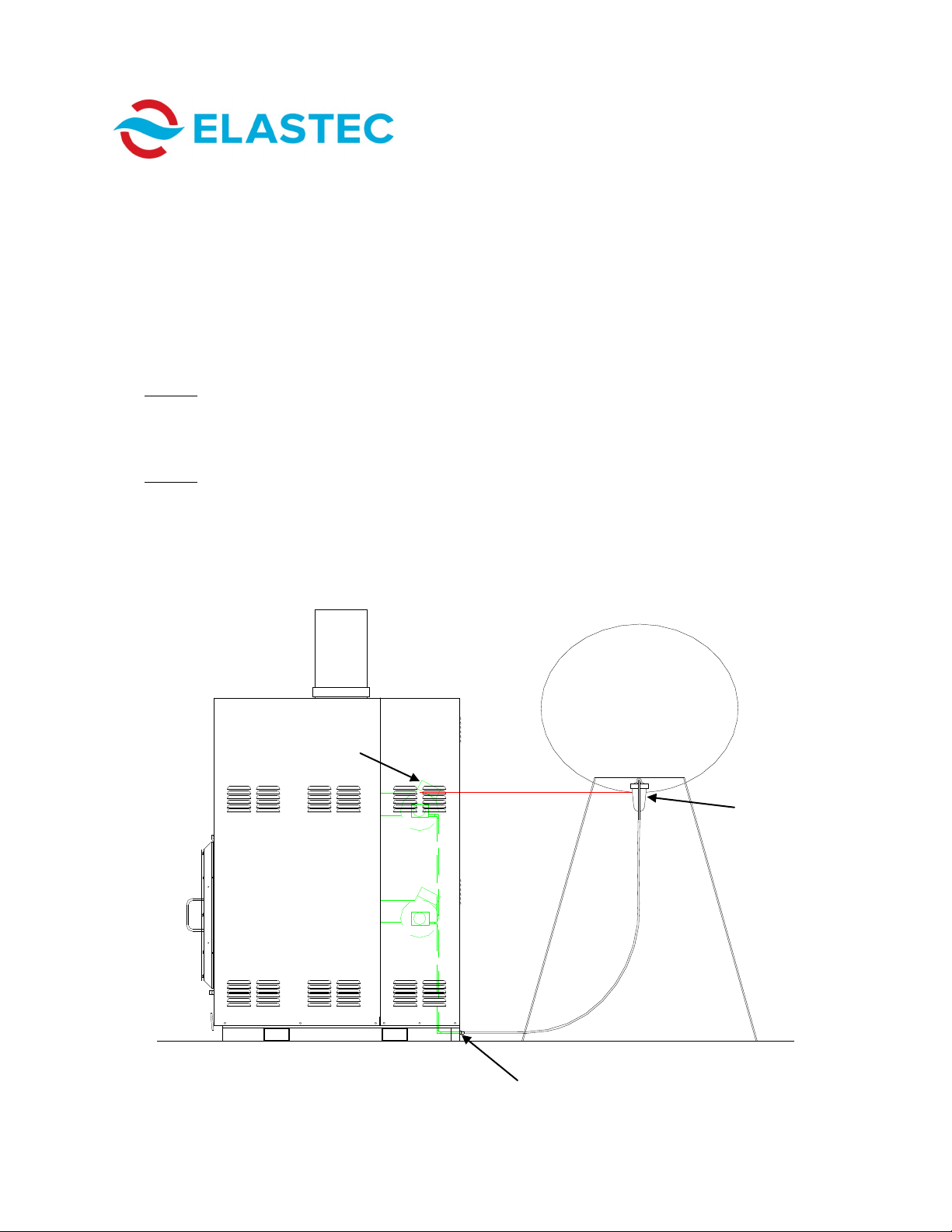

3. If you chose the gravity-fed option (see “Hook-Up,” Page 6), connect the fuel

supply to the burners on the unit with the quick-connect couplings provided.

NOTE: You may be required to bleed air from the fuel system before the first

burn. Refer to the burner parts list for instructions. See below for

connecting a gravity fuel supply system. The fuel tank should be mounted

so that the bottom of the fuel tank is higher than the secondary burner.

NOTE: If the unit has an on-board fuel tank, the gravity fuel supply system

will not be needed.

4. Check door gasket before each use.

Quick-Connect for Optional

Gravity Fuel System

Minimum

Height

Gravity Fuel Supply

System

Fuel Filter

Mounted Tank

(If Applicable)

Secondary

Burner

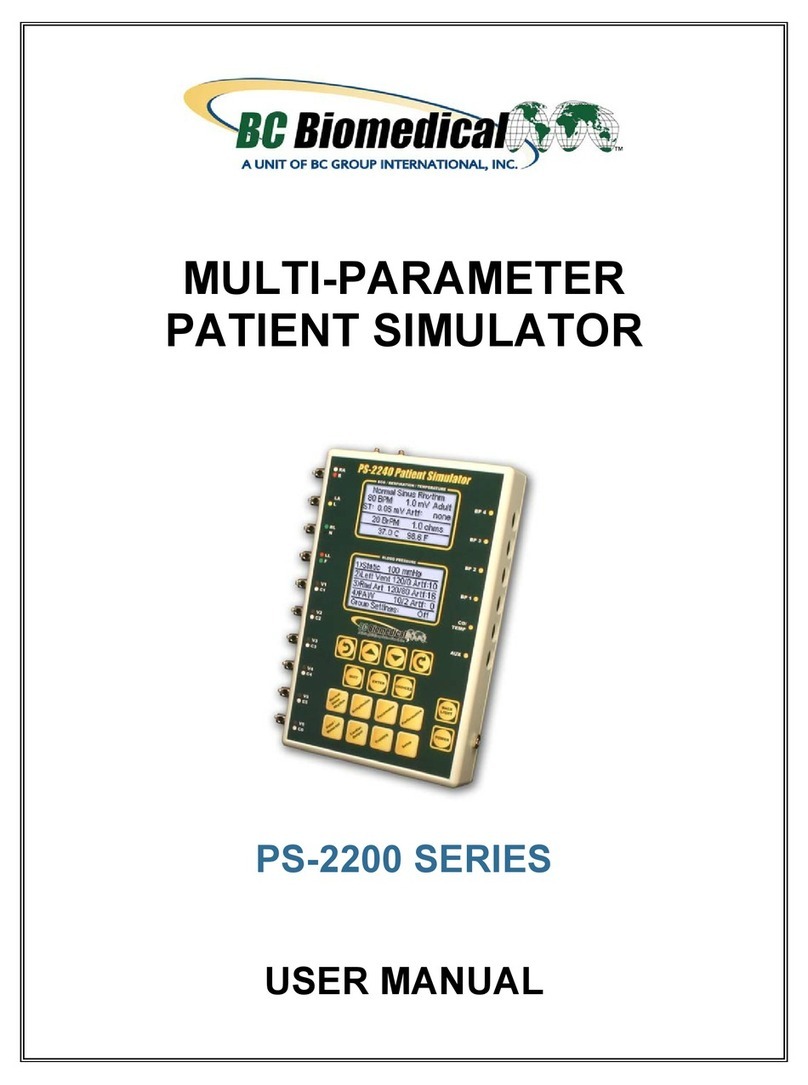

PREPARING FOR DISPOSAL

MEDIBURN30 16 D-115 Rev 010

www.elastec.com

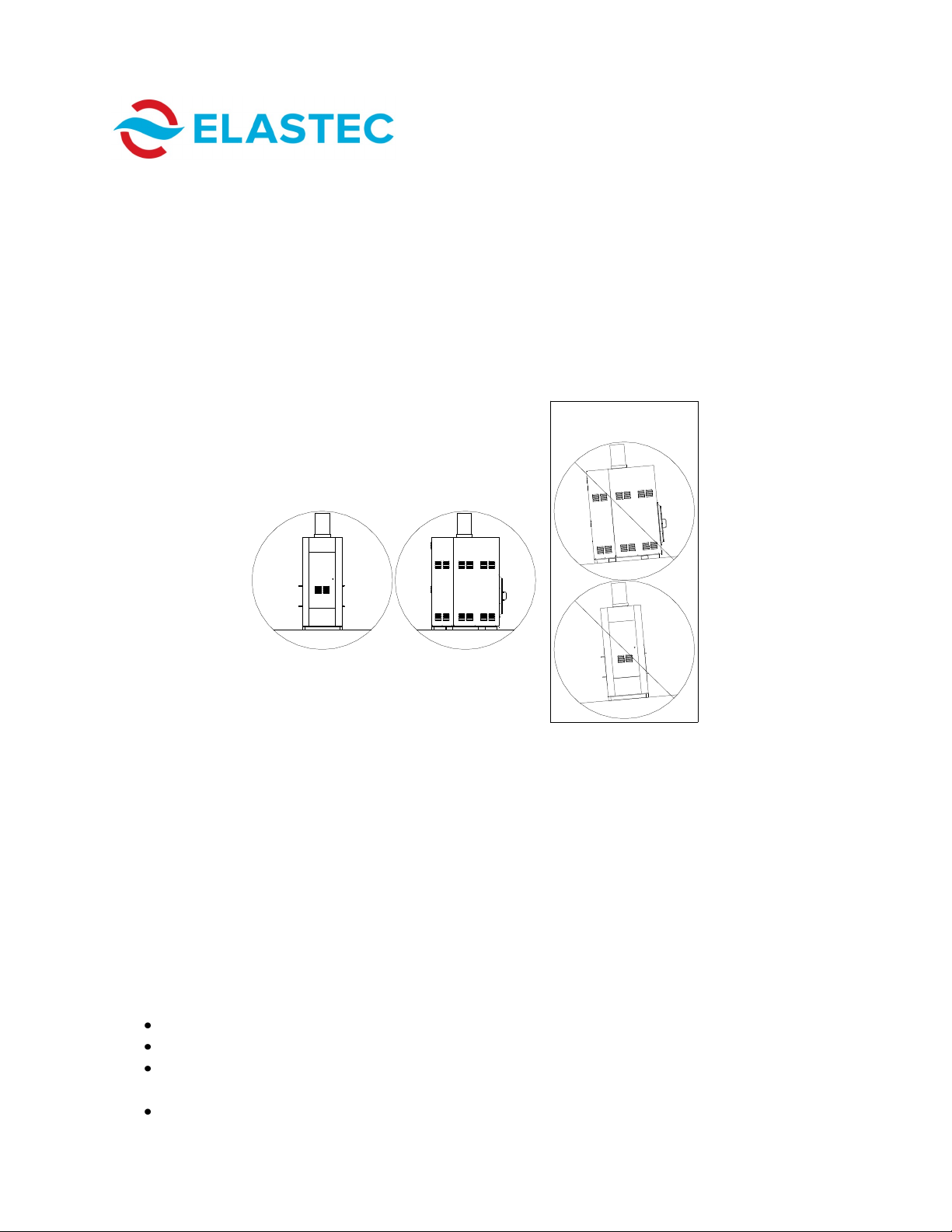

5. Load medical waste material into primary chamber. See below for

recommended loading procedure.

CORRECT

In Figure 1, waste has been loaded

correctly. The operator must allow a 6

inch/15 cm space between burner head

and medical waste.

In Figure 2, waste has been loaded

incorrectly. It is too close to the burner

head.

INCORRECT

Figure 1 Figure 2

6. Securely close door.

7. Choose appropriate cycle time on control panel. See Page 7 for control

panel identification.

8. Push START button to begin cycle.

9. Controller will read IDLE once cycle is complete.

Burner

Head

PREPARING FOR DISPOSAL

MEDIBURN30 17 D-115 Rev 010

www.elastec.com

Once the cycle is complete and the cool-down phase has taken place, the door

lock will disengage. The unit can then be loaded for another cycle. At this

time, the unit is still hot. Care should be taken to avoid touching the surfaces of

the burn chambers. Gloves should be worn at all times.

If refuse from a previous cycle remains in the primary chamber, additional

medical waste may be added to the remains.

If the operator has chosen a cycle that is too short to completely destroy the

load, simply restart the unit. It is not necessary to add more waste.

Before moving the unit, at least a 30-minute cool-down time should be allowed.

For best results, the manufacturer recommends that ash be removed while the

unit is cool and before the incineration of more waste.

CYCLE COMPLETION

ASH REMOVAL

Ash should be removed before the first burn of the day when the unit is cool,

rather than at the end of the day when the unit is hot.

The supplied rake can be used for removing ash from inside the lower

chamber.

MEDIBURN30 18 D-115 Rev 010

www.elastec.com

ERROR CODES

DISPLAY

(Example) CONDITION

DISPLAY

Upper In

Sensor failure on Input 1. (Temperature too

high)

Lower In

Sensor failure on Input 2. (Temperature too

high)

Ambient Sensor

Ambient-temperature surrounding the controller

is too high or too low.

Defaults

Controller EEPROM initialization (first time use).

(Restart)

When an error is active and able to be displayed, the control will replace the

normal display with the appropriate error text.

MEDIBURN30 19 D-115 Rev 010

www.elastec.com

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Fans do not start, burners do not

light and smoke is coming from

the air intake on the burners.

Press the BURNER RESET button, which is located on the burner. It

cannot be seen by the operator but can be reached by placing the

fingers on the round motor housing on the burner. It is unlikely that

this will be a problem, but if it occurs, other burner damage may

result. Please check with the manufacturer if burners continue to

malfunction after the BURNER RESET button is pushed.

Burner ignites but shuts down

after short period Fuel supply is low. Add fuel.

Supply hose is kinked and/or

obstructed. Eliminate kink or obstruction.

Fuel filter is clogged. Replace filter

Cad cell is faulty or not reading

flame.

Cad cell may need to be cleaned.

Wipe clean the eye of the cad

cell. If this does not solve the

problem, replace the cad cell.

Refer to the burner parts list for

location of the cad cell.

Excess material near loading

door not burned

Burn time not long enough Increase burn time.

Not enough air flow through

lower burner

Increase air flow through lower

burner in small increments until

problem ceases.

Upper chamber not burning at

1000° Celsius

Too much air through upper

chamber burner

Close air shutter on burner in

small increments until problem

ceases.

Not enough burn material in load

chamber

Verify load chamber is burning

properly and lower burner is

functioning properly.

Lower burner not functioning

properly

Unit using an excessive amount

of fuel

Air shutters on burners not

adjusted properly

Lower: Look through rear of

burner while adjusting air and set

at brightest point. Adjust air until

smoke is gone from smoke stack.

Fuel bypass solenoids are bad Check solenoid for damage.

Replace if needed.

The under-air fan or blower is not

functioning correctly.

Check to see whether it is work-

ing correctly. If not, check fuses

and replace any blown fuses. If

this does not solve problem, the

motor may need to be replaced.

The next four pages summarize some of the problems that may arise with

your MediBurn unit, as well as the potential causes and some solutions:

MEDIBURN30 20 D-115 Rev 010

www.elastec.com

PROBLEM CAUSE SOLUTION

Burner will not ignite. No spark Check/adjust electrodes.

Ensure that there is power to the

power supply.

Check and clean cad cell.

Too much air Check/adjust air flow. (Factory set

numbers: Top burner bulk air

band is set at 1 and air shutter is

set at 4. Lower burner bulk air

band is set at 1 and air shutter is

set at 3.])

There is air in the fuel supply

system.

Push RESET button on burn

control. Ensure that all fuel line

connections are tight. Air should

purge after repeating this step

two or three times.

Fuel pump coupler is damaged. Replace coupler.

Fuel pump is bad. Low pressure. Check fuel pressure (see setting

for fuel pressure on Page 23).

Set fuel pressure.

Replace pump.

Possible air lock on fuel line. If fuel lines are tight and there is

plenty of fuel; and if the fuel filter

is good and still no fuel, unscrew

filter cap. Fill up halfway with fuel.

Carefully screw cap back and

restart cycle. You may have to do

this two or three times to help

purge and prime pump if system

is airlocked.

Dark smoke is emitted from the

unit.

Adjust airflow to upper burner. The airflow can be adjusted by

rotating the air inflow bracket on the side of the motor. The air flow

adjustments are factory-set but may need to change, depending on

the type of material you are burning. [Factory set numbers: Top

burner bulk air band is set at 1 and air shutter is set at 4. Lower

burner bulk air band is set at 1 and air shutter is set at 3.]To

eliminate smoke, increase the amount of air supplied to the top

burner and decrease the amount of air to the lower burner until the

optimum setting is reached. As the bracket is rotated, larger

numbers on the scale indicate more air intake; lower numbers on the

scale indicate less air intake. For normal operation, the operator will

learn which setting for air intake best suits the typical load.

TROUBLESHOOTING GUIDE

Table of contents