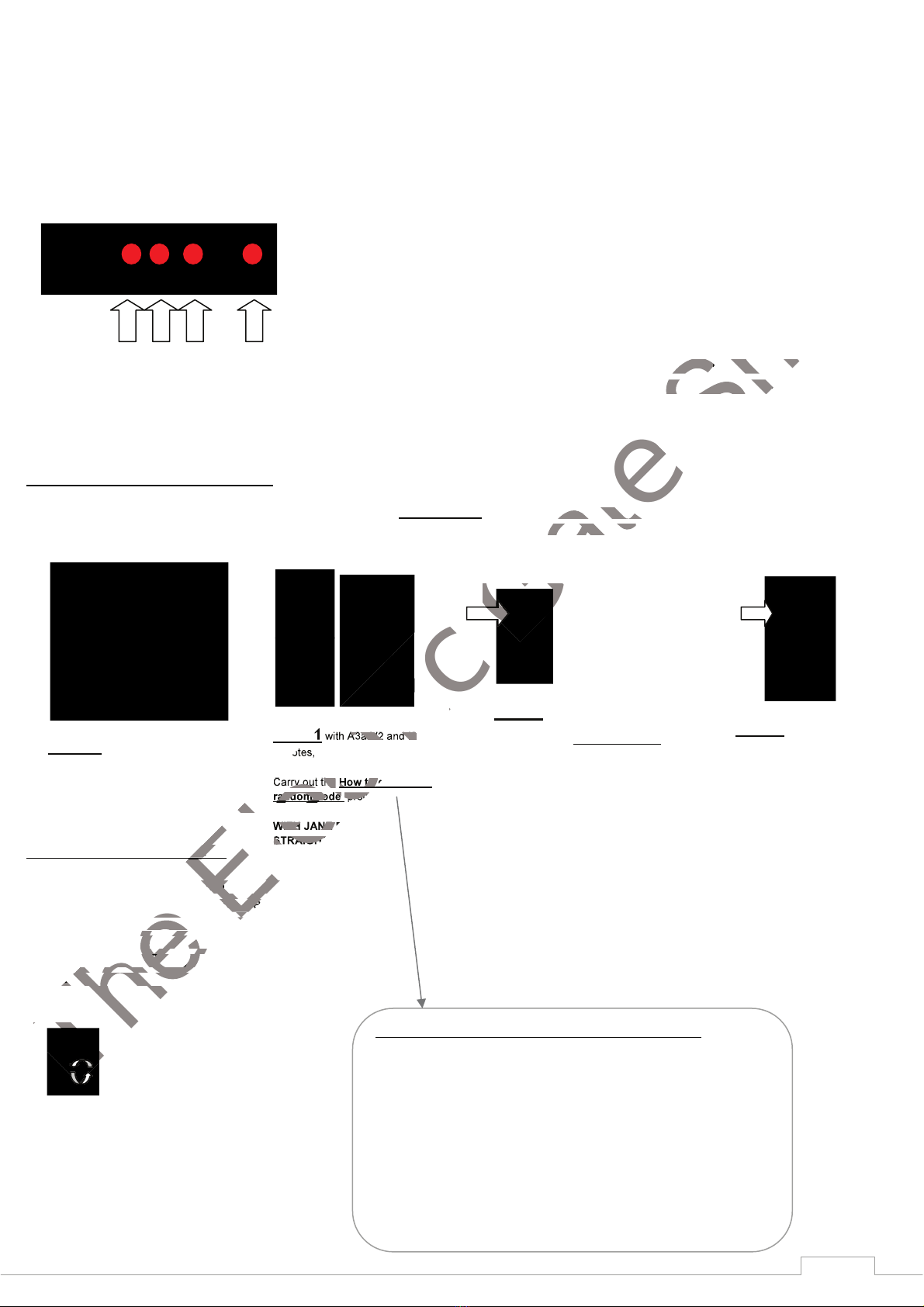

Obstacle detection syste (anti crushing)

The 909 control board is equipped with obstacle detection and the sensitivity can be adjusted by using the trimmer marked

SENS . This trimmer controls the level set that the gate will stop and reverse away if an obstacle is met during the normal run

time. Turning the trimmer further to the – makes it more sensitive to obstacles. Turning the trimmer further to the + makes it

less sensitive to obstacles. Turning the SENS trimmer completely to the + will disable this feature and the system will then rely

solely on the POWER trimmer. The second level of safety is the power sent to the motors set by the trimmer marked POWER

Turning this trimmer further to the – sends less power to the motors and turning the trimmer further to the + sends more power

to the motors. During the slowing down period the system only uses the POWER setting trimmer.

tŚĞŶƚŚĞƐLJƐƚĞŵŝƐŝŶŽƉĞƌĂƚŝŽŶĂŶĚthe gate meets an obstacle during the opening cycle it will reverse the stroke for about

10 centimetres and it will then auto re-close after 30 seconds. If the obstacle remains the system will try again 3 times and

then finally remain open. If the automatic closing is set it will follow the set time before closing again. If the gate is at the

deceleration stage (usually around 500mm before fully open or close) it will stop and not move again until given another command. If the

gate meets an obstacle while closing it will reverse completely and it will auto re-close after 30 seconds. If the automatic

closing is set it will follow the set time. If it is at the deceleration stage it will stop and not move again until given another

command.

Full obstacle detection control throughout the full cycle of opening and closing (including the slowdown stage) can be achieved

by using a safety edge (Rib edge) through the ‘F. AP with, SW2-2 OFF = NC safety edge ON = 8K2 safety edge. Input on

terminal 9. The wired safety edge system can be used with normally closed circuits and resistor 8k2 ohm circuits. Safety edges

are used on gates in all areas where a specific risk of trapping may occur especially where there is less than a 50cm gap

behind a gate when fully open. Resistor 8k2 ohm circuits are used where CAT3 safety edges are needed. The 8k2 ohm circuit

when installed correctly will always fail to safe if damaged shorted or open circuited.

.

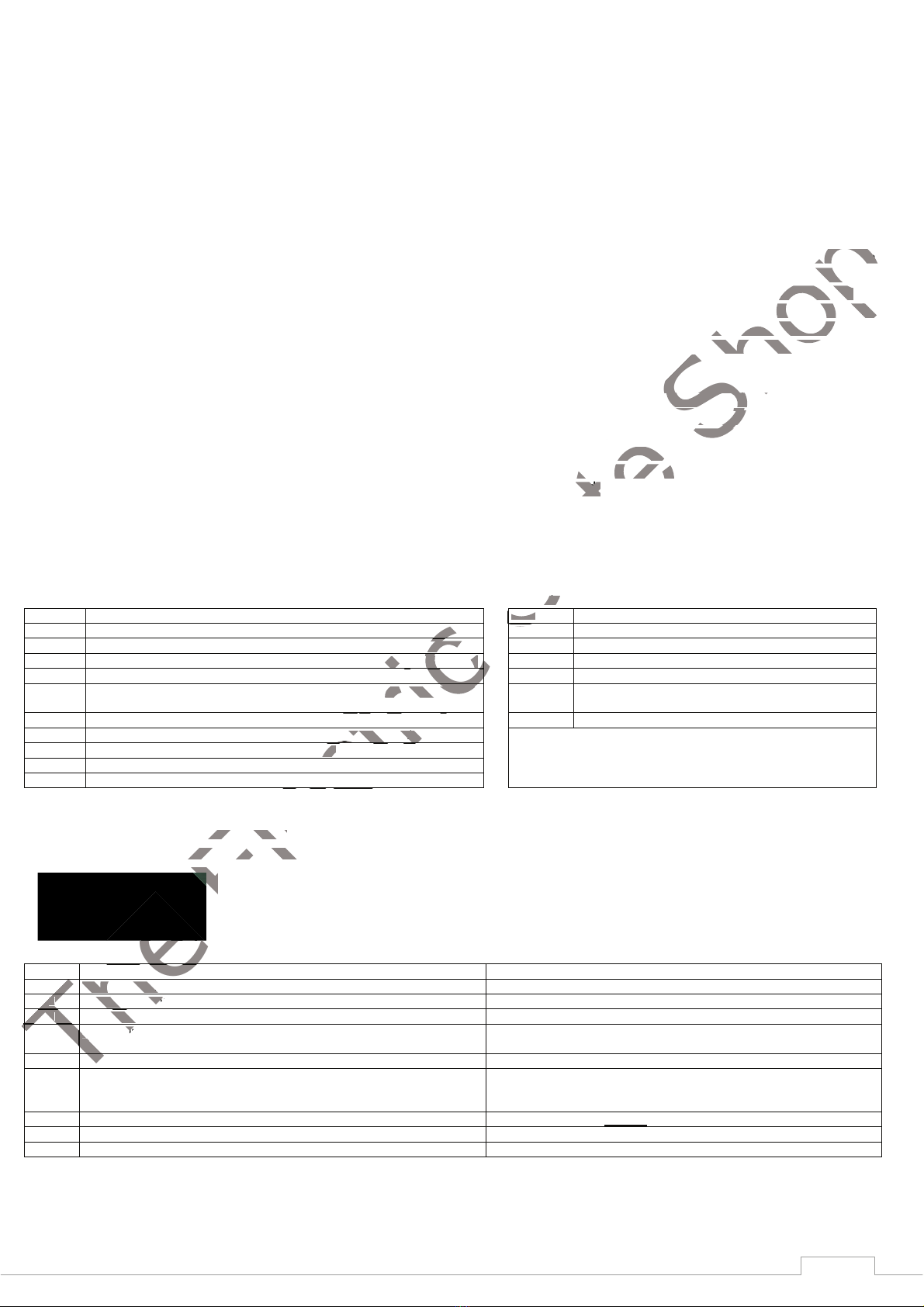

DESCRIPTION OF THE MAIN COMPONENTS LED’S INDICATING STATUS

F1 2A fuse protecting Low voltage accessories PED Always off, lights up with pedestrian control

F2 5A fuse protecting the mains power input START Always off, lights up with start control

BREAK Trimmer for ad usting the open pause time before automatically closing STOP Always on, triggered off by stop

SENS Trimmer for ad usting the obstacle detection.+ harder, -softer, full + =off FOTO Always on, triggered off by gate closing photocell

POWER Trimmer for ad usting the power sent to the motors FOTO AP Always on, triggered off by opening photocell

SET Button for setting remotes and automatic work time parameters F.AP

COSTA

Always off unless connected NC limit switch, always

off when used with 8K2 limit switch

P1 Button for setting working time FINE CH Always off unless connected to open limit switch

P2 Button for clearing codes with (SET) and changing START/PED logic The LED's status of board input can be checked after powering

the control panel.

If the lights above do not correspond, check the connections and

make sure the various connected devices are working properly.

SW1/2 DIP switch for programming the control panel

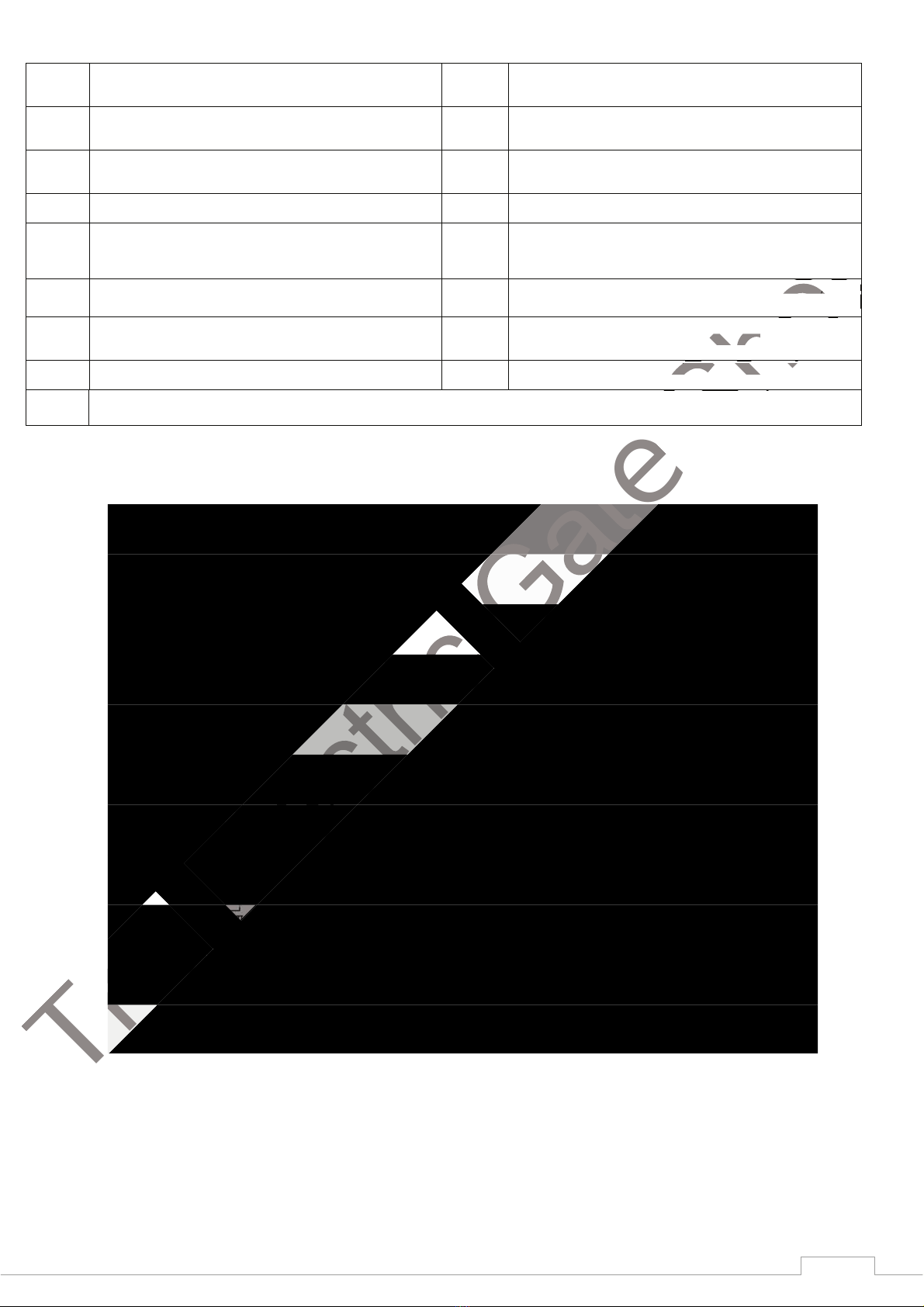

DIP SWITCH PROGRAMMABLE FUNCTIONS

DIP SWITCH must a ways be programmed with the contro pane switched off (not powered)

SW1 ON OFF

1 Operation with one motor (motor 1 output enabled) Operation with two motors

2 With faster slowdown period With slower slowdown period

3 Disables the slowing down function Enables the slowing down function

4 Condominium/Residential feature (while opening the control panel does

not accept any other Start impulse).

Condominium/Residential feature disabled

SW2 ON OFF

1

Enables the take off during starting 2sec. Not normally needed, but used

where some gates may need this to overcome the initial inertia on start

up.

Disables take off during starting

2 Enables safety edge 8K2 function Enables safety edge without 8K2 function. NC switch type

3 Reverse push to unlock the electro-lock enable . (Not norma y needed) Reverse push disabled

4 Additional push at the end of the stroke enable. (Not norma y needed) Additional push at the end of the stroke disabled