ELBO CONTROLLI Nikken E346+ User manual

INSTALLATION, OPERATION AND MAINTENANCE MANUAL REV. 1.0 –01/20

2

1. GENERAL INDEX _ ELBO CONTROLLI srl

Preset E346+/V+

3

1. GENERAL INDEX

1. GENERAL INDEX .......................................................................................................................................................3

2. CERTIFICATION ........................................................................................................................................................4

3. WARNINGS ..................................................................................................................................................................5

3.1 INTRODUCTION.........................................................................................................................................................5

3.2 PURPOSE .....................................................................................................................................................................5

3.3 TYPOGRAPHICAL CONVENTION ......................................................................................................................................5

4. PRESENTATION .........................................................................................................................................................6

5. PREPARATION AND INSTALLATION...................................................................................................................8

5.1 SHIPPING LIST............................................................................................................................................................8

5.2 SAFETY NORMS.........................................................................................................................................................9

5.3 SUGGESTED USE OF THE MACHINE......................................................................................................................9

5.4 PACKING, TRANSPORT AND STORAGE................................................................................................................9

5.5 UNPACKING INSTRUCTIONS................................................................................................................................10

5.5.1 FRONT VIEW......................................................................................................................................................12

5.5.2 REAR VIEW.........................................................................................................................................................13

5.6 OPERATING CONDITIONS .....................................................................................................................................14

5.7 POWER SUPPLY .......................................................................................................................................................14

5.7.1 USB-RJ45 HUB...................................................................................................................................................15

6. MAIN FUNCTIONS DESCRIPTION.......................................................................................................................16

6.1 INTRODUCTION.......................................................................................................................................................16

6.2 POWER ON ................................................................................................................................................................16

6.3 POWERING OFF MACHINE.....................................................................................................................................17

6.4 AXIS MOVEMENT........................................................................................................................................................17

6.4.1 RAPID MOVEMENT...........................................................................................................................................17

6.4.2 ACUTE MOVEMENT..........................................................................................................................................18

6.5 THE SPINDLE............................................................................................................................................................19

6.5.1 REPLACING ROTATING SPINDLE...................................................................................................................19

6.5.2 MANUAL SPINDLE BRAKE...............................................................................................................................19

7. COLLIMATION.........................................................................................................................................................20

7.1 INTRODUCTION.............................................................................................................................................................20

7.2 IMAGE FOCUSING .........................................................................................................................................................20

8. MACHINE ORIGINS.................................................................................................................................................23

8.1 NC MACHINE ORIGINS ...........................................................................................................................................23

9. INSTALLING DYMO MINI PRINTER...................................................................................................................24

9.1 DYMO CONNECTION ..............................................................................................................................................24

9.2 PRINTER REPLACEMENT.......................................................................................................................................25

10. MAINTENANCE ......................................................................................................................................................27

10.1 ROUTINE MAINTENANCE....................................................................................................................................27

10.1.1 SPINDLE, ADAPTERS AND RESET GAUGES LUBRIFICATION ..................................................................27

10.1.2 VISION SYSTEM CLEANING ...........................................................................................................................27

10.1.3 CLEANING THE OPTICS.................................................................................................................................27

10.1.4 CLEANING THE COMPRESSED AIR FILTRED (E346V+ version only) .......................................................27

11. TROUBLE SHOOTING...........................................................................................................................................28

11.1 FOREWORD.............................................................................................................................................................28

11.2 PROBLEM, CAUSES AND SOLUTION .................................................................................................................28

PROBLEM: the presetter does not switch on.........................................................................................................28

PROBLEM: difficulty moving the Z axis upwards . ...............................................................................................28

PROBLEM: the DYMO label printer does not work..............................................................................................28

PROBLEM: The VACUUM locking of the tool does not work...............................................................................28

12. DISPOSAL OF MACHINE......................................................................................................................................29

13. ELECTRICAL DIAGRAM......................................................................................................................................30

14. PNEUMATIC DIAGRAM .......................................................................................................................................31

2. CERTIFICATION ELBO CONTROLLI srl

Preset E346+/V+

4

2. CERTIFICATION

The manufacturer, ELBO CONTROLLI Srl., under its own responsibility,

DECLARES THAT:

the pre-registration and tool management tools models E346+ ed E346V+ conforms to the following safety

standards where enforceable:

•2006/42/CE Machinery Directive (MD)

to the harmonized standards EN ISO 12100:2010

•2014/30/UE Electromagnetic Compatibility Directive (EMC)

to the harmonized standards EN61326-1:2013, EN55011:2009+A1:2010 ISM (group 1, class A),

EN61000-3-2:2014, EN61000-3-3:2013, EN61000-4-2:2009, EN61000-4-

3:2006+A1:2008+A2:2010, EN61000-4-4:2012, EN61000-4-5:2006, EN61000-4-6:2009,

EN61000-4-11:2004

•2014/35/UE Low Voltage Directive (LVD)

to the harmonized standards EN60950-1:2006+A2: 2013, EN60204-1:2006+A1:2009, EN61010-

1:2010

•2011/65/UE Restriction of Hazardous Substances (RoHS II)

•2012/19/UE Waste Electrical and Electronic Equipment (WAEE)

as shown in the technical file and the enclosed test reports, stored at our headquarters.

MEDA, ____________ Massimiliano Tasca

General Manager

Information relating to this presetter is listed on the identification plate stamped on the left-hand side of

the machine as shown above. .

3. WARNINGS ELBO CONTROLLI srl

Preset E346+/V+

5

3. WARNINGS

3.1 INTRODUCTION

The following operation and maintenance manual of the E346+/V+ should be considered an integral part

of the apparatus and it should therefore be kept with care for future reference.

All the procedures and information contained in the manual cannot be a substitute for the end user’s

adequate tool presetting experience, but they provide the necessary information for the correct and proper

use of the PresetterE346+/V+.

Unauthorized equipment handling, non-compliance of instructions or improper or incorrect use may lead

to unforeseen results for which ELBO CONTROLLI Srl. declines all civil or criminal liability.

ELBO CONTROLLI Srl. reserves the right to modify at any time the tool presetter and the operator’s manual

without prior notification on account of the continuous technical updating of the product in pursuit of the

Company strategy aimed at perfecting presetter technology of tool measurement and presetting and of

customer satisfaction.

All suggestions for improvements of the apparatus or manual are welcome either by fax or email to our

head office.

3.2 PURPOSE

The aim of the present manual is to allow the operator of the presetter E346+/V+ to become acquainted

with the machine operating directions, routine and non-routine maintenance, the proper operating

procedures, and to show all the required necessary actions from the Presetter’s introduction until disposal

Implement only the allowed use and the configuration reported, approved by ELBO CONTROLLI Srl.; any

other use or configuration is not recommended, as it may compromise the tool’s proper functioning and/or

its safety.

The manual does not substitute or replace the experience and the technical expertise of the personnel

involved in the use of the Preset machine and is to be considered as a guide at all times.

This manual must be read following the chapters in their logical order, because the repeated

information is explained in full the first time it appears, thereafter it is only mentioned because it

constitutes knowledge already acquired.

3.3 TYPOGRAPHICAL CONVENTION

This manual is sub-divided into chapters, which contain homogeneous information; each chapter is

identified by a title in the following typographical character:

X. FIRST CHAPTER

Each chapter is sub-divided into individual paragraphs into following typographical format:

X.X FIRST PARAGRAPH

Notes or instructions of particular interest are indicated by the following typographical format:

Notes or Instructions of particular interest.

4. PRESENTATION ELBO CONTROLLI srl

Preset E346+/V+

6

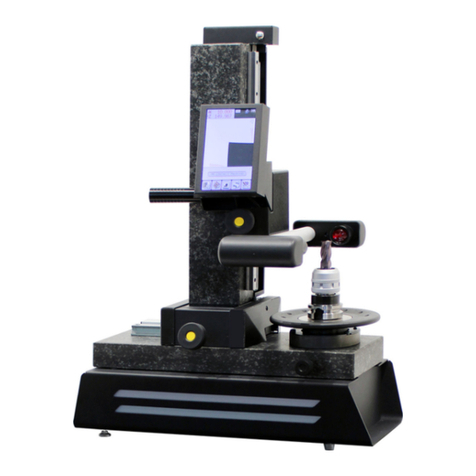

4. PRESENTATION

First, we would like to take this opportunity to thank you for your purchase of ELBO CONTROLLI’s

E346+/V+ Presetters; you will certainly have great satisfaction with the decision you have made and you

will increase the productivity of your NC machines.

E346+/V+ tool presetter have been manufactured in compliance with ergonomics and simplicity principles

and offer outstanding technological solutions. The mechanical systems, electronics and software deal with

tool measurement and pre-adjustment. The vision system, designed by ELBO CONTROLLI, is used to

collect measurement data automatically.

The excellent value for money and measurement precision make the E346+ e E346V+ one of a kind.

TECHNICAL FEATURES

▪Measuring range: diameter max 360 mm (radius 180 mm); height max 460 mm.

▪Base and column made of natural granite: linearity max error 2 μm/Mt certification with Taylor Hobson

res.1 μm/Mt electronic millesimal level.

▪Machine structure in electro-welded and detensioned steel.

▪ISO/BT/HSK/POLYGONAL TAPER... etc. interchangeable rotating spindle-holder (to be specified)

max run-out error < 4 μm.

▪Double vault arc prismatic slideways: N°2 X axis slideways; N°1 Z axis slideway.

▪Double re-circulating ball bearing slides lubricated for life (3) (preloaded slides/slideways: P/H class).

▪Manual mechanical braking of the interchangeable spindle-holder rotation.

▪Tool clamping with VACUUM system (Only E346V+ model).

▪Vision-system for tool measuring including:

oC-MOS sensor-framed imaged area 6,4 x 6,4 mm.

oMagnifications 25X.

oCutting inspection.

▪Machine operator interface:

oVertical Touch Screen TFT 15” colour 16:9.

oIntel Celeron Series N 4 Core.

oUBUNTU LINUX operating system.

oSSD solid state disk data storage.

▪Standard Software:

oCNC machine origin management and adapters.

oTool list creation and/or single tool.

oTool set and Post Processor universal generator.

oMagnetic chip code-holders (Balluff for example, hardware not included).

oPrintable tool set report.

oManagement of theoretical measurements and tolerances.

▪Analog comparators to measure on the fix reticule.

▪Telecentric lens and LED illuminator.

▪Axes resolution: X = 1 μm, Z = 1 μm.

▪TID (Automatic Tool Identification System) ready.

▪Overall dimensions: L = 950mm, H = 972mm, P = 430mm

▪Net weight: 90 Kg

4. PRESENTATION ELBO CONTROLLI srl

Preset E346+/V+

7

Option

Machine stand for preset model E346+ / E346V+

ISO / BT / SK / CAT Interchangeable spindle-holder available in 50, 45, 40, 30

versions.

ISO / BT / SK / CAT Interchangeable spindle-holder equipped with VACUUM

locking system available in 50, 40, 30 versions (Only E346V+ model)

HSK FORM A-C-E Interchangeable spindle-holder available in 100, 80, 63, 50, 40,

32 versions.

VDI Interchangeable spindle-holder available in 50, 40, 30 versions.

POLYGONAL TAPER ISO 26623 Interchangeable spindle-holder available in C4,

C5, C6, C8 versions.

ISO/BT/CAT to: HSK/VDI/POLYGONAL TAPER ISO 26623/KM cone reduction adapter.

ISO and HSK resetting gauge.

DYMO mini-labels printer.

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

8

5. PREPARATION AND INSTALLATION

5.1 SHIPPING LIST

Before proceeding with preparation and installation, check that the tool presetter packaging contains the

following components:

TOOL PRESETTER

Model E346+ Spindle …….......... …….....……

E346V+ ………...... …….....……

………...... …….....……

RESETTING GAUGES

………… …………

………… ….…….

CONE REDUCTION ADAPTER

ISO ........... ISO ..…........ other .........…………………….……….......

ISO ........... ISO ..…........ other .........………….………….………......

ISO ........... HSK ..…........

ISO ........... HSK ..…........

ISO ........... VDI ..…........

ISO ........... VDI ..…........

MINI PRINTER LABELS

DYMO

LABELS PACK

POWER SUPPLY

OPERATION MANUAL CD

TEST CERTIFICATE

WARRANTY

CHECKED BY..............................................

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

9

5.2 SAFETY NORMS

The personnel destined to use the Presetter E346+/V+ are not required to use any particular protection;

however, they must be informed of the following potential dangers:

•In particular during the vertical axis measurement positions, the vision system of the support

structure can be a hazardous obstacle at head height if the machine is used without the neccessary

care and attention.

•We recommend the careful handling of tools due to their sharp and potentially dangerous nature.

The person responsible for employee safety should train the people required to use the tool presetter by

insisting on the reading of this manual. (per l’Italia vedi D.Lgs. 81/2008 come modificato da D.Lgs. n.

106 del 3 agosto 2009).

5.3 SUGGESTED USE OF THE MACHINE

The E346+/V+ Tool Presetter is an instrument to preset and measure the tools surveying their dimensions

along X-Z-axes, in accordance with the axes definition of the machine using the above-mentioned tools.

The measurable tools are to be compatible with the presetter spindle; any attempt to adapt the tool presetter

spindle taper without using the appropriate adaptors supplied by ELBO CONTROLLI Srl. is to be considered

improper use.

The maximum weight of the tool to be measured should be no more than 30Kg.

Any other use is to be considered improper and potentially compromising to the operator’s safety.

The E346+/V+ Presetter is to be handled by a single person in conditions of tested and controlled

efficiency, in respect of all procedures described in this manual.

5.4 PACKING, TRANSPORT AND STORAGE

The instrument must be handled inside its proper cardboard box, which prevents it from normal mechanical

stresses.

Stated on the outside of the packaging are the shipping instructions, particularly the specified total weight,

transport position and using symbols, vulnerability to atmospheric agents and the need to handle with care.

Keep the original packing and use it for further transportation of the instrument.

Tool Presetter transportation is to be carried out by qualified carriers able to grant the correct handling of

the transported goods, observing the following precautions:

•lift only with trolleys or pallet jacks;

•do not bump, throw, drop, roll or drag the case;

•do not overcharge the packing by piling more than three cases;

•avoid exposure to atmospheric agents;

•maintain the prescribed transportation position.

The storage environment must fall within the following environmental conditions:

•safe from atmospheric agents;

•temperature between -10 and 50 °C;

•relative humidity between 20% e 95% without condensation.

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

10

5.5 UNPACKING INSTRUCTIONS

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

11

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

12

5.5.1 FRONT VIEW

Vision system

illuminator

Handle for fast

movement to block and

unblock axis Z

Rotating spindle-holder

brake

Adjustment wheel for

axis X

Adjustment knob/wheel

for axis Z

C-MOS image sensor

Vertical LCD Monitor

Touch-screen 15”

Knob to block/unblock

axis X

Rotating spindle-holder

Adjustable feet

Adjustable feet

3 USB + 1 RJ45

HUB Connections

Start button

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

13

5.5.2 REAR VIEW

(k)(l)

Start button

ON/OFF switch

Power cable for DYMO

mini printer, supplied

with the machine

DYMO mini printer

power connection

Ground terminal

24Vdc Power Supply

connection

Rotating spindle-holder

Vision system

illuminator

Vertical LCD Monitor

Touch-screen 15”

C-MOS image sensor

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

14

5.6 OPERATING CONDITIONS

The E346+/V+ Presetter is a precision instrument, it shall be positioned in a trouble-free site (free from

dust / or corrosive air substances, excessive vibrations, extreme temperature fluctuations), away from direct

sunlight and far from windows and skylights. Preferably, it should be positioned in rooms with diffused

artificial lighting and suitable working space for measurement taking.

The instrument does not generate acoustic emissions.

The recommended climatic conditions are as follows:

•away from atmospheric agents;

•temperature between 10 and 40 °C;

•relative humidity between 20% and 95% without condensation.

The best performance is obtained in a constant-temperature environment.

5.7 POWER SUPPLY

The power supply points are located on the back of the preset (also pneumatic for E346V+ version).

E346 + / V + Presetter is powered at 24 Volt in direct current through an external power supply, supplied

as standard, to be connected to the electrical network 115 / 230V AC, 50 / 60Hz, 75W.

Connection procedure

Connect the power supply to E346 + / V + by inserting the round plug of the power supply into the power

socket of the preset, then connect the preset to the grounding terminal using a yellow / green conductor

section min 1.5 mmq and fix to the appropriate connector.

Only or the version E346V+: connect the preset to the compressed air system and adjust the pressure

between 5 and 6 bar.

ON/OFF switch

24Vdc Power Supply

connection

Grounding terminal

Pressure gauge

Compressed air

connection 5/6 bar

Pressure regulator

Only for E346V+ version

5. PREPARATION AND INSTALLATION ELBO CONTROLLI srl

Preset E346+/V+

15

Also, on the rear panel, the attachment is available to power the DYMO mini printer (optional) with the

relative cable supplied.

5.7.1 USB-RJ45 HUB

In the support column of the LCD monitor, there is a HUB equipped with:

•3 USB ports for connecting any external peripherals (e.g. mouse, keyboard, DYMO mini

printer, …).

•1 RJ45 port to permit connection to the company data network.

DYMO mini printer

power connection

Power cable for DYMO

mini printer, supplied

with the machine

RJ45 connector

ethernet network input

Nr. 3 USB Port

6. MAIN FUNCTIONS DESCRIPTION ELBO CONTROLLI srl

Preset E346+/V+

16

6. MAIN FUNCTIONS DESCRIPTION

6.1 INTRODUCTION

Before turning on the machine, it is necessary to connect it to the electrical (and pneumatic for the E346V+

version) as described in paragraph 5.7.

6.2 POWER ON

Turn the main switch on the back of the machine to the ' I' position, then

press the power button on the right side of the machine and wait for the

software to commence.

For use, refer to the software manual supplied with the machine.

ON/OFF

switch

Start button

Help on-line

Axis quote

Setup Preset

Fixed grid

Autotargeting

Measurement

“freezing”

Camera system

Date and time

Machine origins

Tool set

Exit program

Rapid label printing

Radius/Diameter

Absolute/Incremental

Manual insertion of

axes values

VACUUM tool

clamping

(E346V+ only)

Tool clamping status

(E346V+ only)

Measuring ares

Wait for “zero axis”

acquisition

6. MAIN FUNCTIONS DESCRIPTION ELBO CONTROLLI srl

Preset E346+/V+

17

6.3 POWERING OFF MACHINE

It is advisable not to leave the machine turned on for long periods (day after day), it is recommended to

turn it off in the evening at the end of the working day. To do this, press the power button on the right side

of the machine and wait for the machine to turn off, then turn the main switch on the back of the machine

to the position ‘O ‘.

6.4 AXIS MOVEMENT

Axes movements are manual and provide two options: rapid and acute.

The rapid movement is used to move the tool to the visual field and to return it at the end of the

measurement. The acute movement is used to collimate the tool profile and to acquire the measurement.

The transition from rapid movement to the acute movement occurs by unlocking and locking the respective

axes: axis unlocked = rapid movement; axis blocked = acute movement.

6.4.1 RAPID MOVEMENT

In order to rapidly move the axis, rotate the respective

unblocking handle/wheel until the white bullet marker

is positioned on the front part of the machine.

Grip the rapid movement handle (see figure), then

manoeuvre it in the direction desired (X o Z).

As noted in the figure, the handle for

blocking/unblocking the Z axis is integrated into the

handle of axes movement. Unblocking both axes makes

it possible to move quickly to the measuring zone of the

tool.

In order to prevent damage to the Presetter, do not

strike the limit stops at the end of the stroke.

Handle to block/unblock

axis X and indicates when

axis X is blocked

Rapid movement axis

handle

Handle/Wheel to block/unblock

axis Z and indicates when axis

Z is blocked

6. MAIN FUNCTIONS DESCRIPTION ELBO CONTROLLI srl

Preset E346+/V+

18

6.4.2 ACUTE MOVEMENT

After having approached or framed the tool profile with

the rapid movement, to manoeuvre an axis with

precision rotate the respective blocking wheel handles

until the black bullet marker is positioned on the front

part of the machine.

Rotate the acute movement handle of the axis to the area

of interest on the screen to carry out the measurement.

Acute movement

handle axis X

Acute movement

handle axis Z

Handle to block/unblock

axis X and indicates when

axis X is blocked

Handle to block/unblock axis Z

and indicates when axis Z is

blocked

6. MAIN FUNCTIONS DESCRIPTION ELBO CONTROLLI srl

Preset E346+/V+

19

6.5 THE SPINDLE

E346+/V+ is equipped with an interchangeable rotating spindle system making it is possible to insert

different rotating spindles of a pre-selected shape and size (ISO, BT, HSK, POLYGONAL TAPER ISO

26623, VDI).

6.5.1 REPLACING ROTATING SPINDLE

In case different rotating spindles are available, follow the instructions for their replacement.

Procedure for the replacement of rotating spindle

•Position the column to make it easier to dismantle the spindle: axis X all to the left, Z all

above;

•remove the tool from the spindle making sure that it isn’t blocked by the brake (see par.

6.5.2);

•remove the rotating spindle upwards keeping it parallel to the column;

•clean the removed spindle and lubricate the parts with antioxidant liquid (eg. PRO-setral-KS

spray) before storing;

•clean the spindle and insert it into the presetter;

•introduce the new spindle into the holder, during insertion keep it parallel with the column.

•If you have adapters instead of rotating spindles, follow the procedure below.

Procedure for replacing spindle adaptors

•Remove, if present, the other adaptor, clean and lubricate the rectified parts with antioxidant

liquid (es. PRO-setral-KS spray), then put it in a protected place;

•clean the spindle and its new adaptor;

•insert the new adaptor into the spindle.

6.5.2 MANUAL SPINDLE BRAKE

The spindle brake allows the locking at any point of the rotation of

the spindle of the presetter.

It will then be possible to lock the rotation of the spindle in the

exact measuring point of the tool (see para. 7.2), the micrometric

adjustment of a pre-adjustable reamer will be possible without

causing measurement mistakes due to an involuntary movement of

the spindle.

In order to activate the rotating spindle brake, rotate the wheel in

clockwise direction; wheel rotation in a counter clockwise

direction releases the brake, allowing the spindle to rotate freely.

Do not exceed the torque force of 5 N/m in order to avoid any

damage to the preset spindle.

Pomello freno

rotazione mandrino

7. COLLIMATION ELBO CONTROLLI srl

Preset E346+/V+

20

7. COLLIMATION

7.1 INTRODUCTION

Collimation is the operation that detects the point in which you have to carry out the measurement.

E346+/V+ is equipped with an industrial vision system, which was exclusively designed for tool

measurement/prerecording without contact.

Its operating principle is similar to the one of the optical profile projector; by means of a specific shooting

lens, a collimated light source projects the profile of the tool to be found between the two elements over a

C-MOS image sensor, through an appropriate lens, the profile of the tool is interposed between the two

elements. The tool outline acquired by the image sensor is displayed in real time on to a colour LCD screen;

the framed field equals approximately 6,4 x 6,4 mm, which establishes an image visual scale ratio in the

screen of about 25 times (25X).

Furthermore, there are two bars to monitor image focusing: one bar detects the focus of the X-axis

measurement point, while the other detects the focus of the Z-axis measurement point. This way the

operator can easily detect the point of maximum tangency of the tool.

The real advantage, if compared to an optical profile projector, is the exclusion of measurement subjectivity,

which makes measurements objective and repetitive. In fact, E346+/V+ can analyse the cutting edge of the

tool and find out its measurement points in the profile with a resolution of 1m., it is the task of the operator

to decide whether to carry out the measure on the central reticule, assisted by the compared electronics, or

in whichever position on the screen: E346+/V+ establishes the measurements in real time from the addition

between the coordinates of reticule centre and image position.

The measurements are continuously displayed on the screen in order to have all necessary pieces of

information available in the same area.

7.2 IMAGE FOCUSING

With the E346+/V+ measurements are carried out in a way

similar to those made with optical profile projectors; you

have to frame the tool outline in the screen by placing it in

the light beam using rapid manual displacements.

Before carrying out the measurement, it is necessary to rotate

the spindle to search for the point that has the best image

focusing.

The screen always displays two control bars for image

focusing (one for each axis); it is sufficient to rotate the

cutting edge until reaching the highest possible value on the

bar of the specific axis, to obtain the best focus.

The dimensions taken as the reference for focusing are the ones relating to the two X and Z measurement

points, which were detected by the two pointers.

This manual suits for next models

1

Table of contents

Other ELBO CONTROLLI Industrial Equipment manuals