09/2014 - Art. Nr. 4200 1040 9100A2

Overview

Contents

Page

Overview Contents .....................................................................................2

Important information .................................................................2

Burner description ......................................................................3

Operation Operation, safety function ..........................................................4

Control and safety unit BT 3xx ...................................................5

Terminal allocation chart ........................................................ 6-7

Control and safety unit BT 3xx gas operation ............................8

BT 3xx menu overview ...............................................................9

MBC SE gas train.....................................................................10

Assembly Burner assembly ......................................................................11

Gas train...................................................................................12

Checking/adjusting the burner head.........................................13

Commissioning Electrical connection ................................................................14

Checks before commissioning .................................................14

Adjustment data, Ionisation current measurement ...................15

Air regulation, MBC SE gas train setting ..................................16

Pressure regulator setting ........................................................16

Confirming the "Manual Handshake" data............................... 17

Menu 1: setting the servomotors ....................................... 18-23

Pre-setting without flame.................................................... 18-19

Setting with flame ............................................................... 20-23

Operating mode........................................................................23

Setting the gas pressure switch/air pressure switch ................24

Displaying the setting data from the manual

control display ..........................................................................25

Servicing Maintenance....................................................................... 26-27

Menu 3: Fault memory, Entering a telephone

number for the maintenance company and the

maintenance contract number............................................ 28-29

Menu 4: operating statistics......................................................30

Setting the brightness and contrast of the display....................31

Declaration of conformity

for gas burners

We, certified company No. AQF030,

F-74106 ANNEMASSE Cedex, declare

under our sole responsibility that the

products

VG4.460 M/TC

VG4.610 M/TC

conform to the following standards

EN 50165

EN 55014

EN 60335-1

EN 60335-2-102

EN 60555-2

EN 60555-3

EN 676

Belgian royal decree dated 08/01/2004

These products bear the CE mark in

accordance with the stipulations of the

following directives

2009/142/EC Gas Appliances

Directive

2004/108/EC EMC Directive

2006/ 95/EC Low Voltage

Directive

92/ 42/EEC Efficiency Directive

La Roche sur Foron, 2nd May 2012

F. DECIO

We accept no responsibility for damage

arising from:

- inappropriate use

- incorrect installation and/or repair on the

part of the buyer or any third party,

including the fitting of non-original parts.

Final delivery and instructions for use

The firing system fitter must supply the

operator of the system with operating and

maintenance instructions on or before final

delivery. These instructions should be

displayed in a prominent location at the

point of installation of the heat

generator.They should include the address

and telephone number of the nearest

customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. Depending

on the type of installation, shorter

maintenance intervals may be necessary! It

is advisable to take out a maintenance

contract to guarantee regular servicing.

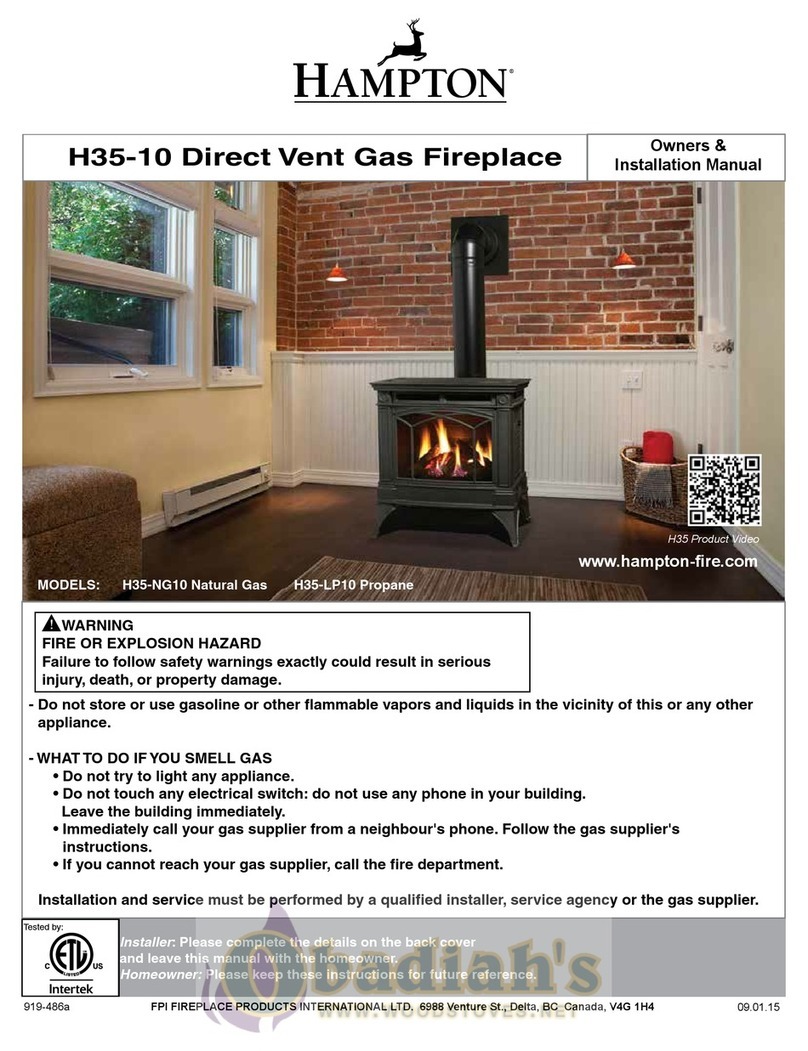

Important information

VG4.460/610 M/TC burners are designed

for the low-pollutant combustion of natural

gas and propane gas. The design and

function of the burners meet standard EN

676. They are suitable for use with all heat

generators complying with standard EN 303

or for use by hot air generators complying

with standard DIN 4794 or DIN 30697 within

their respective performance range. Any

other type of application requires the

approval of ELCO.

Installation, start-up and maintenance must

only be carried out by authorised specialists

and all applicable guidelines and

regulations must be complied with.

Burner description

VG4.460/610 M/TC burners are

modulating, fully automatic, monoblock type

burners with electronic cam. The special

design of the combustion head enables

combustion with low levels of nitrogen oxide

and increased output. Class 3 type-

approval in accordance with EN676 certifies

that the lowest emission values have been

achieved and means that the national

environmental regulations have been met

AT: KFA 1995, FAV 1997

CH: LRV 2005

DE: 1.BImSChV

Emissions values may differ, depending on

furnace dimensions, furnace load and the

firing system (three-pass boilers, boilers

with reverse firing). For specifying warranty

values, the conditions for the measuring

equipment, tolerances and humidity must

be observed.

Packaging

The burner is supplied in three packaging

units:

- Burner housing with operating

instructions, circuit diagram and spare

parts list.

- Burner head with flange seal and

securing screws.

- Compact gas train with integrated filter

The following standards should be

observed in order to ensure safe,

environmentally sound and energy-efficient

operation:

EN 226

Connection of fuel oil and gas burners with

blast air to a heat generator

EN 60335-1, -2-102

Specification for safety of household and

similar electrical appliances, particular

requirements for gas burning appliances

Gas lines

When routing the gas lines and fittings, the

general installation instructions and

guidelines, as well as the following national

regulations, must be observed:

CH: - G1 instruction text from SSIGE

- EKAS form no. 1942,

liquefied gas directive, part 2

- Cantonal authority guidelines (e.g.

directives for the pilot valve)

DE: - DVGW-TVR/TRGI

Installation location

The burner must not be used in rooms with

aggressive vapours (e.g. hair spray,

tetrachloroethylene, carbon tetrachloride),

high levels of dust or high air humidity (e.g.

laundry rooms).

If no connection to an air exhaust system is

provided for the air supply, there must be a

supply air inlet measuring:

DE: up to 50 kW: 150 cm2

for each additional kW: + 2.0 cm2

CH: QF [kW] x 6= ...cm2; but 150 cm2

minimum.

Variations may arise as a result of local

regulations.