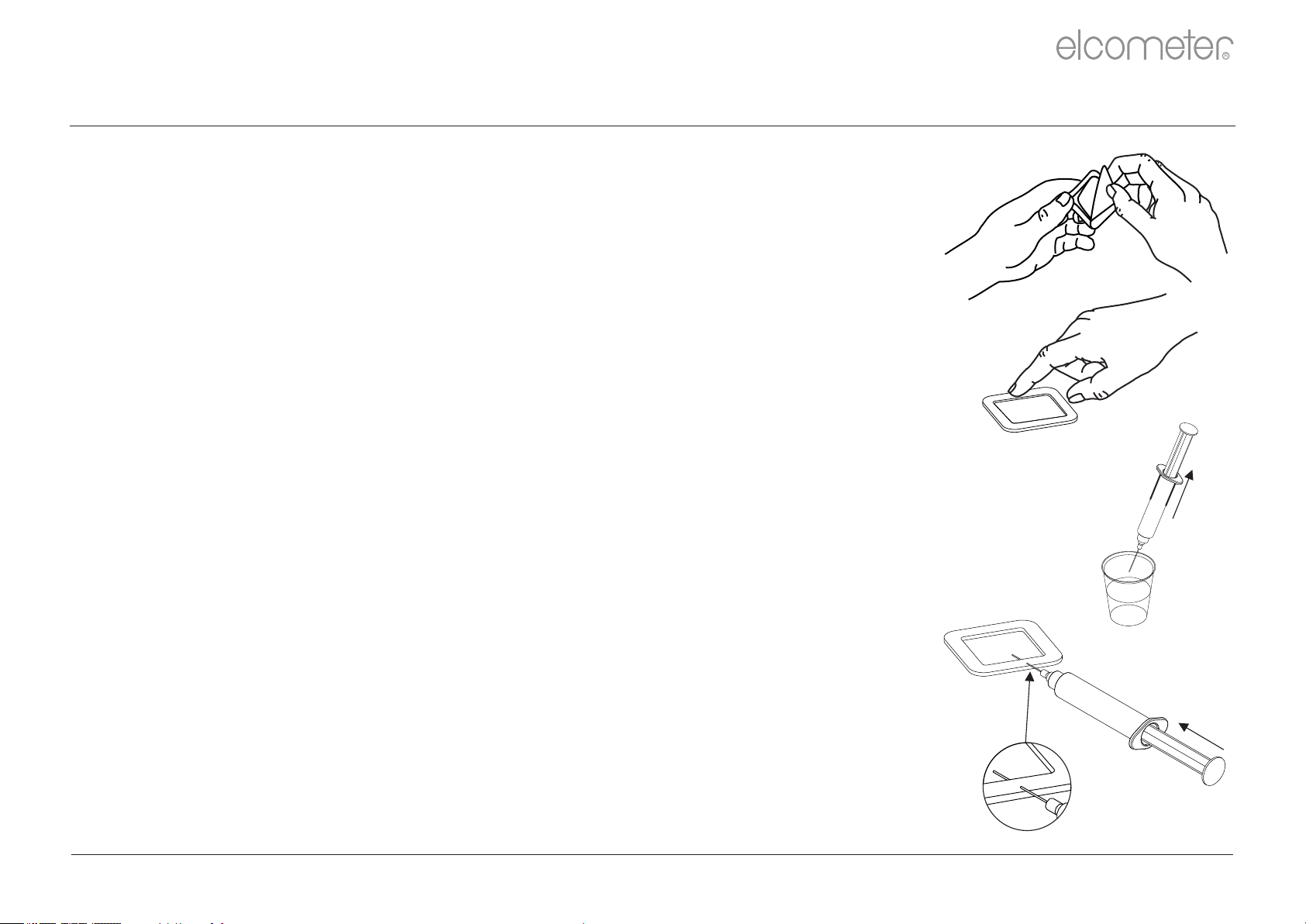

2 Apply the patch to the surface pressing firmly around the perimeter of the

patch to ensure a complete seal. If using the Elcometer 135C Bresle Test

Patch, remove the clear protective film cover using the orange tab.

3 As the test is extremely sensitive, clean latex or nitrile gloves should be

worn during the extraction of soluble salts to prevent contamination of the

surface.

4 If necessary, any air can be evacuated into the syringe and allowed to stay above the

water in the syringe. Take care not to re-insert the air during steps 6 and 7.

5 Inject the pure water into the patch. Do not remove the needle.

1 Remove the printed protective backing and foam centre from the Bresle

patch.

3 Fill a syringe with 3ml of pure water.

3.2 TEST PROCEDURE

4 Insert the syringe into the patch through the spongy foam perimeter at an

angle of approximately 30° to the test surface so that it passes through the

foam into the compartment formed by the elastomer film and the test

surface. If the patch is positioned in a difficult position bend the needle as

required.

2 Calibrate the Elcometer 138 Meter, see Appendix A Section A5 on

page en-19.

1 If using the Elcometer 138 Bresle Salt Meter, press the MEAS button to set

the measurement mode to ISO.

3.1 BEFORE YOU START

3 : 8502-6 / 8502-9TEST PROCEDURE ISO ISO

www.elcometer.com

R

en-4