Elcomponent PowerPro User manual

PowerPro with PowerFlow Firmware

8 Channel Power Quality Datalogger

User's Guide

ii

PowerPro User's Guide

All Rights Reserved.

The information in this document is subject to change without notice.

Elcomponent Ltd has made every effort to ensure the accuracyof

this manual. However, Elcomponent Ltd makesno warranties

with respect to this documentation and disclaims any implied warranties of

merchantability and fitnessfor a particular purpose. Elcomponent Ltd

assumes no responsibility for any errors that may appear in this document.

Trademarks

IBM is a registered trademark of International Business Machines

Corporation.

Windows, Windows 95 and Windows 98 are trademarks of Microsoft

Corporation.

All other product names are copyright and may be trademarks and/or

registered trademarks of their respective companies.

Document number: CID1001.01

Date: May 2, 2002

i

Table of contents

Table of contents .............................................................................. i,ii

Introduction .........................................................................................1

Safety..................................................................................................2

Quick Start ..........................................................................................3

Hookup Configurations .......................................................................5

Hookup Diagnostic Warnings .............................................................7

Power Flow Firmware Features........................................................10

RMS Data Storage .....................................................................10

Harmonics and Waveform Storage ............................................10

Power Calculations ....................................................................10

Total Harmonic Distortion (THD)................................................10

Frequency ..................................................................................10

Event Capture ............................................................................11

Flicker (Optional) ........................................................................11

Side Panel ........................................................................................12

Front Panel .......................................................................................13

Logger Operation..............................................................................14

Turning On and Off ....................................................................14

Memory Card..............................................................................14

Setup ..........................................................................................16

Logging Setup.........................................................................16

RMS Storage Interval.........................................................16

Harmonic Storage Interval .................................................16

Connection Type (1P2W, 1P3W, 3P3W, 3P4W and 2.5E)17

Trigger Levels .........................................................................17

Line Voltage .......................................................................17

Line Frequency ..................................................................18

Over Voltage ......................................................................18

Under Voltage ....................................................................18

Over Frequency .................................................................19

Under Frequency ...............................................................19

Flicker Setup ...........................................................................19

PST Duration......................................................................19

PLT Duration ......................................................................19

Line Voltage .......................................................................20

Scale Factor ............................................................................20

Voltage Range ...................................................................20

Ext PT ................................................................................20

Phase Current ....................................................................20

Neutral CT..........................................................................21

System Setup..........................................................................21

Setup Lock .........................................................................21

ii

Logger ID ........................................................................... 21

Time and Date Setting....................................................... 21

Calibration.......................................................................... 22

Display ....................................................................................... 23

Measured Data ....................................................................... 23

Voltage, Current and Frequency ....................................... 23

Neutral Voltage and Current.............................................. 24

Real Power and Apparent Power ...................................... 24

Reactive Power and Power Factor.................................... 24

Total Power ....................................................................... 24

Flicker ................................................................................ 24

Data Statistics......................................................................... 24

Voltage Statistics ............................................................... 25

Current Statistics ............................................................... 25

Power statistics.................................................................. 26

Neutral Voltage Current Statistics ..................................... 27

Flicker Statistics................................................................. 27

Waveform Display .................................................................. 28

Harmonic Bar Chart Display................................................... 28

Memory Statistics ................................................................... 28

Logger Statistics ..................................................................... 28

Logger Operation ............................................................................. 29

Record ....................................................................................... 29

Start Recording....................................................................... 29

Stop Recording....................................................................... 29

Sleep or Low Power Mode ..................................................... 29

Downloading..................................................................................... 30

RS-232 Cable Configuration...................................................... 30

Downloading using the RS-232 Serial Port ............................... 30

Serial Communications .................................................................... 31

Notes ................................................................................................ 32

PowerPro with PowerFlow Firmware

1

Introduction

The PowerPro represents leading edge technology in the

measurement of Power Quality. From the logger front panel or, for

more detail, using Candura Instrument’s PowerView software you can

view:

• Trends in Voltage, Current, Power and Frequency

• Waveforms and harmonic activity for both voltage and current

• Voltage sags and swells

• Frequency deviations

• Flicker (IEC 868 / IEC 61000-4-15) - Optional

The PowerPro is an 8 channel power quality data logger. It

can monitor 3 phases of voltage and current as well as a neutral

voltage and current. Measured parameters are updated every ½ cycle

to ensure that nothing is missed. Most measurements can be viewed

on the front panel LCD in the field and logged data can be transferred

to a computer using the removable memory card. The memory card

interface also provides the means to program the logger and to

upgrade the PowerPro firmware. The logger is powered from the V1

voltage measurement input, or if V1 is a weak source an auxiliary

power supply may be used. The PowerPro has an internal battery

that can power the logger for up to 8 hours in the event of a power

outage. Voltage inputs are transformer isolated and protected with

metal oxide varistors and fuses for safety. The entire unit is enclosed

in a rugged water tight case for use in harsh environments.

PowerPro with PowerFlow Firmware

2

Safety

Although this instrument is designed to be as safe as possible, safety

is ultimately the responsibility of the operator. This instrument should

only be operated by suitably qualified and authorized personnel.

Please read and UNDERSTAND the following information before

operating this instrument

• The PowerPro uses a membrane keypad that could be damaged

if a sharp object is brought into contact with it. This may expose

the operator to potentially hazardous voltages.

• Frequently inspect the test leads and the instrument for damage.

If the instrument shows any signs of physical damage or functions

improperly, it should not be used.

• Never work alone with high voltage circuits. Ensure that a

qualified observer is mindful of your activities.

• When performing any measurements involving high voltage

circuits, all connections should be made to the circuits while the

power is off. To ensure personal safety, the test leads and related

connectors should not be handled while the circuit is energized.

• Do not attempt to measure any voltage higher than the maximum

rating of 750V RMS. Failure to observe the maximum rating could

result in damage to the equipment or personal injury.

• Refer servicing of this instrument to qualified personnel only.

Potentially lethal voltages may be present inside the case. If any

of the protective circuitry is improperly repaired, the safety of this

product could be compromised.

PowerPro with PowerFlow Firmware

3

Quick Start

Connecting the PowerPro to the circuit to be measured is a

straightforward process.

1. Connect the voltage leads for each phase to be measured. For

proper operation V1 must always be used. Three phase circuits

can be connected in either a ‘wye’ or 'delta’ configuration. Refer to

the ‘Hookup Configurations’ section for the various methods of

connecting the voltage leads.

2. Connect the phase CT clamps or the three phase Flex CT.

Note that only one or the other may be used – if the three phase

Flex CT is used then the phase CT clamps must be disconnected.

The neutral CT clamp may be used at the same time as the three

phase Flex CT.

3. Ensure a memory card is installed.

4. Turn the logger on (if it is turned off) by pressing and holding any

key except F6. If installed memory card has data, select 'NO'

when asked to load Setup and Data from card.

5. Use the ‘SETUP’ key and function keys to check and modify any of

the setup parameters. If a computer is connected to the serial

port, run PowerView software and select 'Logger' and 'Configure'

to check and modify any of the setup parameters.

6. Press the ‘Record’ key and then F2 to start recording. If there are

any error messages, please refer to the ‘Hookup Diagnostic

Warnings’ section.

7. The measured values can be viewed from the logger using

'DISPLAY' key and function keys. If a computer is connected to

the serial port run the PowerView software and select 'Logger' and

'Status'.

Continued....

Retract Shroud to Release

PowerPro with PowerFlow Firmware

4

Quick Start continued

8. To stop logging press the ‘RECORD’ key and then F4 followed by

F1 to confirm the stop command.

Note: Static discharges may occur when connecting leads,

communication cable or memory card, depending on

environmental conditions. This is not hazardous and will not

damage the logger. However it may affect the integrity of the data

if the logger is recording. Connection and disconnection of leads

etc. should be done while the logger is not recording. Before

handling a logger that is recording the operator should discharge

any potential static by touching a grounded object.

9. Data is transferred to a computer using the memory card. When

logging has been stopped the memory card can be removed from

the logger. The memory card can be inserted directly into an

ImageMate Card reader or, with a PCMCIA adapter, it can be

inserted into a PCMCIA slot in a laptop computer. Run

PowerView and select 'File', 'Open' and then go to the drive that

has been configured for the memory card, it will have the

description 'Power Pro'. Change the file type to 'Data Card Files'.

If there is data on the card you will then see a file that can be

opened. After opening the file a directory and file name (you can

keep the same file name) must be selected for the processed file.

PowerPro with PowerFlow Firmware

5

Hookup Configurations

The PowerPro can be used to monitor all of the most common power

distribution systems. Following are descriptions of the five most

common field setups:

Continued….

PowerPro with PowerFlow Firmware

6

Hookup Configuration continued

PowerPro with PowerFlow Firmware

7

Hookup Diagnostic Warnings

Before the logger starts recording it does a number of checks on the

connected signals, if it detects a potential problem a message is

displayed and the operator must select either ‘Retry’ or ‘Ignore’ – if the

operator presses ‘ESC’, ‘SETUP’, ‘DISPLAY’ or ‘RECORD’ the start

process is aborted.

Possible messages and descriptions:

‘Voltage 1 Too Low’

‘Voltage 2 Too Low’

‘Voltage 3 Too Low’

-Voltage being measured is less than 35V on 240V range or

less than 90V on 600V range.

‘Voltage 1 Too High’

‘Voltage 2 Too High’

‘Voltage 3 Too High’

-Voltage being measured is greater than 300V on 240V

range or greater than 750V on 600V range.

‘Current 1 Too High’

‘Current 2 Too High’

‘Current 3 Too High’

-Current being measured is greater than 125% of the CT

rating.

‘Voltage Hookup Error’

-This indicates that the operator has selected a single phase

configuration but has connected to a three phase system or

vice versa.

‘V2 Inverted’

-Voltage leads on channel two are reversed.

Continued....

PowerPro with PowerFlow Firmware

8

Hookup Diagnostic Warnings continued

‘V3 Inverted’

-Voltage leads on channel three are reversed.

‘-ve Power Check CT#1’

‘-ve Power Check CT#2’

‘-ve Power Check CT#3’

-This usually means that the relevant CT has been

connected in reverse. To fix the problem remove the CT,

rotate it 180 degrees, reconnect it and then press ‘Retry’. In

some cases this is not an error (i.e. when measuring a

generator output) and pressing ‘Ignore’ is the correct

response.

‘Phase Sequence Error’

-This occurs for three phase installations and indicates that

the measured phase sequence is not ABC. To fix the

problem swap the B and C voltage leads and then press

‘Retry’.

‘Data Sync Error’

-This problem is internal to the logger. To fix the problem

put the logger to sleep (press ‘RECORD’ and then ‘F6’) and

then wake it up (press and hold any key except ‘F6’). If this

does not fix the problem please contact your nearest Product

Support Centre.

‘Freq Event Triggered’

-This indicates that an under/over frequency condition is

active. This may indicate that the trigger levels are not set

up properly (to view them press ‘SETUP’ and ‘F2’).

PowerPro with PowerFlow Firmware

9

Hookup Diagnostic Warnings continued

‘Volt Event Triggered’

-This indicates that an under/over voltage condition is active.

This may indicate that the trigger levels are not set up

properly (to view them press ‘SETUP’ and ‘F2’).

PowerPro with PowerFlow Firmware

10

Power Flow Firmware Features

RMS Data Storage

The PowerPro stores RMS data at set intervals which can be adjusted

from 1 to 30 seconds or 1 to 30 minutes. The minimum, maximum and

average values are stored at the end of each storage interval. The

averaged values are calculated from the sum of the RMS values

(updated every ½ cycle) over the preceding storage interval. The

minimum and maximum values are updated every ½ cycle over the

preceding storage interval.

Harmonics and Waveform Storage

The logger displays up to the 21st harmonic on its display while the

software displays up to the 64th harmonic. Storing harmonics uses a

significant amount of memory. To maximize memory usage harmonics

and waveforms can be stored at a lower rate than the RMS data. For

example, if the logger is configured for 3P4W, Neutral On, it can record

up to 14,285 records when recording harmonics and waveforms every

storage interval on a 32 M memory card. When harmonics and

waveforms are stored every 5th storage interval up to 56,490 records

can be stored.

Power Calculations

The power calculations are updated every ½ cycle. Only the averaged

values of power are recorded. Power factor displayed is the true

power factor (not the displacement power factor which is determined

from the phase angle shift between voltage and current) and is

calculated as the ratio of the real power (KW) divided by the apparent

power (KVA).

Total Harmonic Distortion (THD)

THD is calculated as the ratio between the square root of the squared

sum of the harmonic magnitudes (for harmonics 2…64) divided by the

fundamental value.

Frequency

The system frequency is measured from the signal on V1 input.

Frequency will not be measured if the voltage is below 35V in the 240V

range or 90V in the 600V range.

PowerPro with PowerFlow Firmware

11

Power Flow Firmware Features

Event Capture

Under/over voltage events and under/over frequency events are stored

when they occur. The trigger levels are set from the Setup menu under

‘TRIGGER LEVELS’. The duration of the events are recorded with a ½

cycle resolution. Voltage events are tagged as sags/swells if they are

under 2 seconds in duration and under/over if they are longer. The

Power View software reports their duration in number of cycles for

events less then 10 seconds and in seconds for longer events.

The logger uses a hysteresis value of 0.1% of full scale to determine

when the event has finished. For example if the under-voltage trigger

level is set at 228.0 volts the logger will start recording an event when

the voltage reaches 228.0 volts and will stop recording the event when

the voltage goes up to 228.3 volts.

Flicker (Optional)

Flicker is an optional extra to the Power Flow firmware. If the logger

has been enabled for recording flicker the words ‘FLICKER METER’

will be printed on the display on the right hand side of the main screen

(pressing ‘ESC’ a number of times will access the main screen).

Flicker is calculated according to IEC 868 / IEC 61000-4-15

specifications. Both PST (short term flicker) and PLT (long term flicker)

are calculated for each of the 3 voltage channels.

PowerPro with PowerFlow Firmware

12

Side Panel

The voltage and current connections are colour coded according to

phase and polarity (for voltage).

Phase 1 or Phase A Red

Phase 2 or Phase B Yellow

Phase 3 or Phase C Blue

Neutral Current Grey

Neutral Voltage White

There is a dedicated connector for a three phase Flex CT. This

connector supplies the power to the Flex CT and receives the 3

isolated current signals. There is an auxiliary connector that is used to

connect to an external DC power supply (for use when V1 is connected

to a weak source) and to a modem.

When measuring less than 3 voltages V1 must always be used. V1

zero crossing is used to synchronize the data sampling and measure

frequency. In the event of an outage on V1 the logger has an internal

digital phase lock loop that simulates the zero crossing until V1 is

restored.

Either phase CT’s or a three phase Flex CT may be used to

monitor phase current. Only one type of CT may be connected to

the logger at a time – if the three phase Flex CT is used then the

phase CT’s MUST be disconnected from the logger. Leaving the

phase CT’s connected will cause errors in the Flex CT readings.

PowerPro with PowerFlow Firmware

13

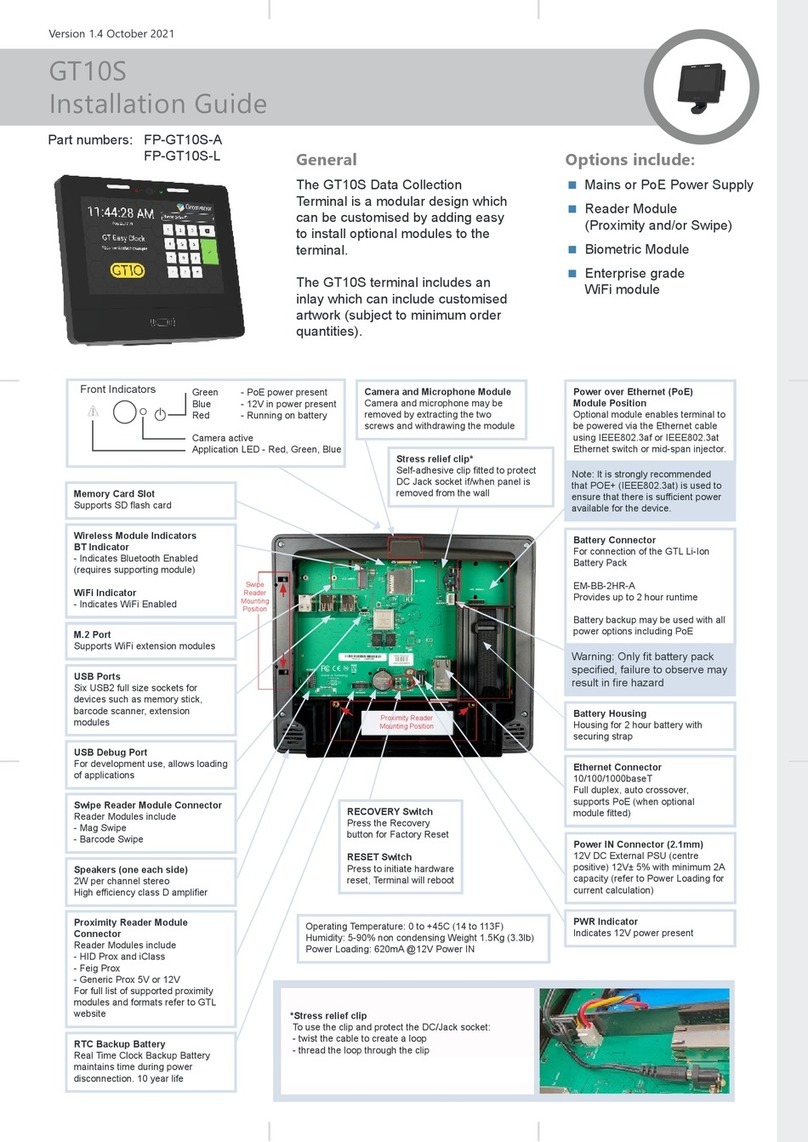

Front Panel

The front panel of the PowerPro has a graphics display, a 10 button

keypad, an RS-232 communications port and a memory card interface.

The graphics display is 240x64 pixels with an LED backlight. Text on

the display is organized in 8 lines by 40 characters (small characters)

or in 4 lines by 20 characters (large characters), some screens

incorporate both types of characters. Graphics (waveforms and

harmonic bar chart) are also displayed with text.

The keypad has two types of buttons. The bottom row of 4 keys are

fixed function buttons and the top row of 6 keys are function keys that

change function depending on the active screen on the display. In

most screens the bottom line of the display is in inverse video and is

used to describe the functions associated with the six function keys.

The RS-232 communications port is a 3 wire (Rx, Tx, Gnd) serial

interface. Data is sent and received using the software package

PowerView. The Xmodem communications protocol is used to

transfer data.

The memory card interface is used to reprogram the PowerPro’s

internal firmware from a firmware card (for new applications or to

upgrade the firmware) and to store recorded data on a memory card.

The PowerPro will not begin a survey without a memory card installed.

Once a survey has been started the memory card may not be removed

until the survey has been stopped.

PowerPro with PowerFlow Firmware

14

Logger Operation

Turning On and Off

The PowePro should be put into low power (or sleep) mode when not

in use. In low power mode only the real time clock and keypad

interface are active. Current consumption from the battery is reduced

to less than 100 microamps. The logger is put in low power mode by

pressing the ‘RECORD’ button followed by the F6 (SLEEP) button.

The logger will put itself into low power mode when it detects a low

internal battery voltage. If the logger was recording at the time it will

close the data files as if the operator had stopped recording before

going into low power mode. After going into low power mode due to a

low battery voltage the battery will have enough capacity to keep the

real time clock functioning for over 6 months.

To turn the logger on any key (except F6) must be pressed and held

for approximately 1 second. When the logger powers up it does a self

diagnostic on internal functions, if an error is detected a diagnostic

screen is displayed and the logger waits for an operator to elect to put

the logger back into sleep mode or to re-initialize the logger (reboot).

Memory Card

The logger continually checks the memory card interface to see if a

card has been inserted or removed. When it detects a card being

inserted (or a card in the socket immediately after power up) the logger

checks the card size and looks for valid data on the card. If no valid

data is on the card it displays the Memory card size with the message:

‘No Setup or Data On Card PRESS ANY KEY’.

The operator must press any key to continue. The logger can now be

used to start a survey and data will be stored on the memory card. If

there was data from a previous survey on the card the logger will

display the Memory card size with the message:

‘Load Setup and Data From Card?’

The operator can select ‘YES’ or ‘NO’. If ‘NO’ is selected then the

logger will not load any data from the card and if a survey is started the

data on the card will be overwritten. If ‘YES’ is selected then data from

the previous survey will be loaded back into the logger including all the

setup parameters that were in the logger when the previous survey

was done.

PowerPro with PowerFlow Firmware

15

Logger Operation (Memory Card)

When the logger detects a card being removed it changes the screen

to the initial screen if the logger was not recording. If the logger was

recording when the memory card is removed it displays an error

message:

‘RAM Card Error Please Re-Insert RAM Card

or Survey will end in xx seconds’.

The number of seconds depends on the time until the next storage

time. Even if the card is re-inserted in time it is possible that data on

the card may be corrupted.

The Memory card should NEVER be removed while data is being

recorded, ALWAYS stop recording before removing the Memory

card.

The Memory card offers a fast and convenient method to transfer

recorded data to a computer. To transfer data from the memory card

to a computer, remove the card from the logger and insert into the

PCMCIA slot of the computer using a PCMCIA adapter or insert

directly into an ImageMate card reader. Select ‘File’ from the

PowerView toolbar and then select ‘Open'. Change the directory to

the drive that has been configured for the memory card, it will have the

description 'Power Pro'. Change the file type to 'Data Card Files'. If

there is data on the card you will see a file that can be opened. After

opening the file, a directory and the file name (you can keep the same

file name) must be selected for the processed file.

PowerPro with PowerFlow Firmware

16

Logger Operation

Setup

Pressing the ‘SETUP’ button calls up the main setup screen. From the

main setup screen you can select ‘LOGGING SETUP’, ‘TRIGGER

LEVELS’, ‘FLICKER SETUP’, ‘SCALE FACTOR’, ‘SYSTEM SETUP’ or

‘COMM SETUP’. If a computer is connected to the serial port, then run

PowerView software and select 'Logger' and 'Configure' to check and

modify any of the setup parameters.

Logging Setup

Pressing F1 to select ‘LOGGING SETUP’ allows the operator to select

and change the RMS storage interval, the harmonic storage interval

and the wiring configuration. The operator must press ‘NEXT VALUE’

until the desired setup parameter is highlighted and then press

‘CHANGE VALUE’ to be able to modify the selected setup parameter.

To exit press ‘ESC’ and the display will return to the parameter list

screen.

If the logger is recording and ‘CHANGE VALUE’ is selected the screen

will change to the modification screen, ‘Recording On’ will be printed

on the bottom and no changes will be allowed.

If the Lock function is on and ‘CHANGE VALUE’ is selected the screen

will change to the modification screen, ‘LOCK On’ will be printed on the

bottom and no changes will be allowed.

RMS Storage Interval

The RMS storage interval appears on the left side of the screen and

can be adjusted to between 1 and 30 seconds in increments of 1

second or 1 and 30 minutes in increments of 1 minute. The harmonic

storage interval appears on the right, see description for ‘Harmonic

Storage Interval’.

Harmonic Storage Interval

This selects the same screen that the RMS storage Interval selection

accesses. The harmonic storage interval is displayed on the right side

of the screen. The harmonic storage interval can be set between the

RMS storage interval and 60 seconds (if recording interval is in

seconds) or 60 minutes (if recording interval is in minutes). The

increment value is the RMS storage interval.

Table of contents

Other Elcomponent Data Logger manuals

Popular Data Logger manuals by other brands

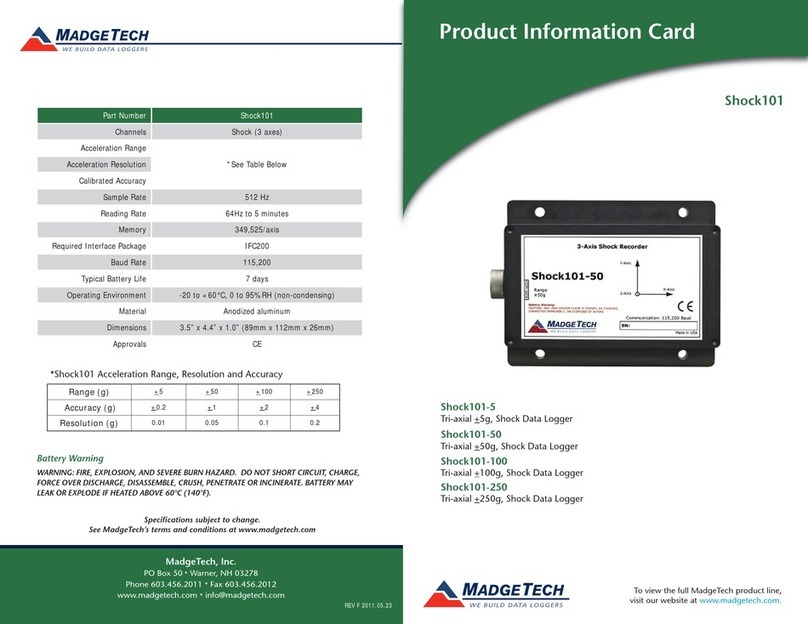

MadgeTech

MadgeTech Shock101 Product Information Card

Lascar Electronics

Lascar Electronics EasyLog EL-EnviroPad-TC quick start guide

EUPRY

EUPRY DW1STM user guide

Davis Instruments

Davis Instruments WeatherLink 6510USB Getting started guide

Bosch

Bosch TDL140 operating instructions

Micro-Aide

Micro-Aide VDL S7?300 user manual