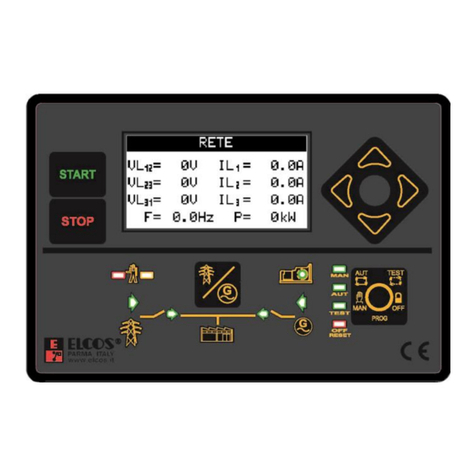

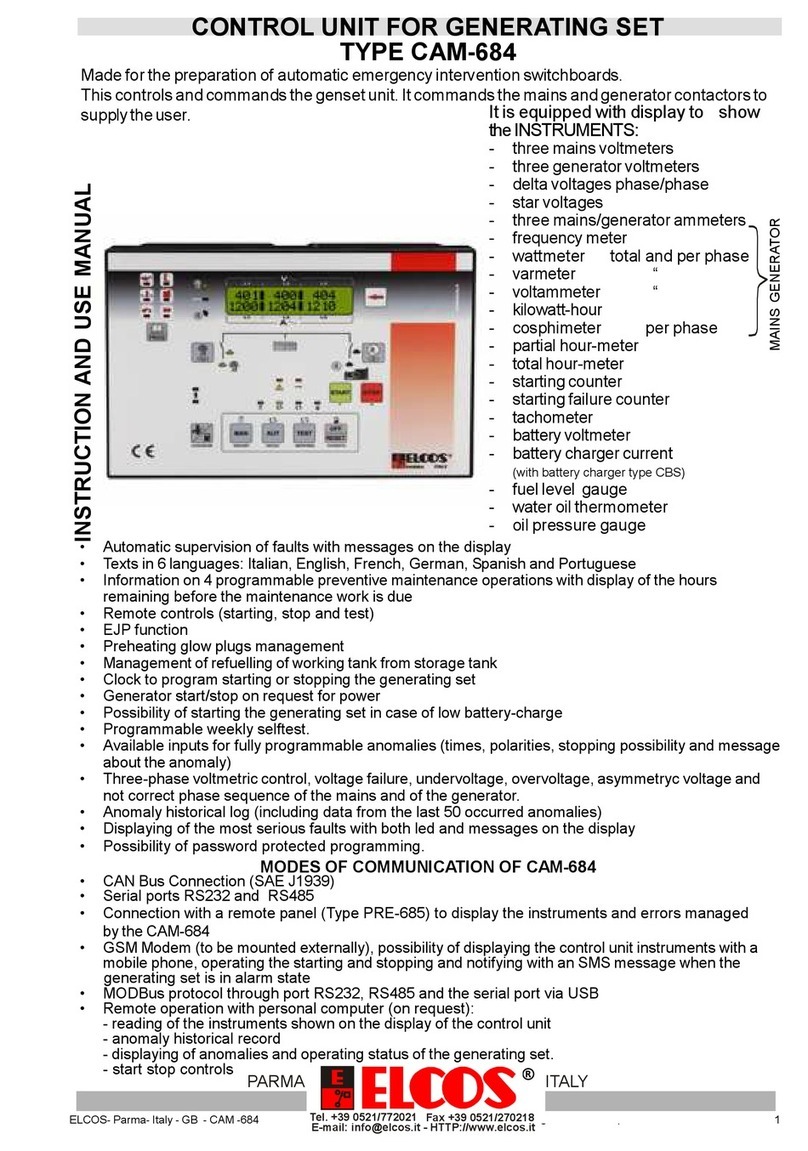

ELCOS CIM-131 Instruction Manual

ELCOS SRL - Parma - CIM-131 - MAN - EN 1

CONTROL UNITS FOR IRRIGATION MOTOR PUMPS

AND PUMP WATER PRESSURE CONTROL

TYPE CIM-131

• Operates the engine accelerator to keep the pressure

of the system constant.

(accelerator with 2 wires connected to the control unit)

•Controlstheowofwaterinthepipe.

• Electronic pressure switch to control the pump water

pressure.

• Digital pump water pressure gauge.

• Clock for programming the starting and stopping of the

motor pump.

• Delayed acceleration after starting.

• Delayed deceleration before stopping.

• Assembly also on the machine and in the open air.

• CANBus SAE J1939 connection.

• Frost protection.

• Pressure boost function.

INSTRUCTION AND USER MANUAL

MADE TO:

PROTECT

motor pump sets by stopping them in the event

of:

- low oil pressure

- over-temperature

- belt breakage

- low coolant level

- low pump water pressure

- pump water overpressure

- overspeed

- A1

}

available

- A2

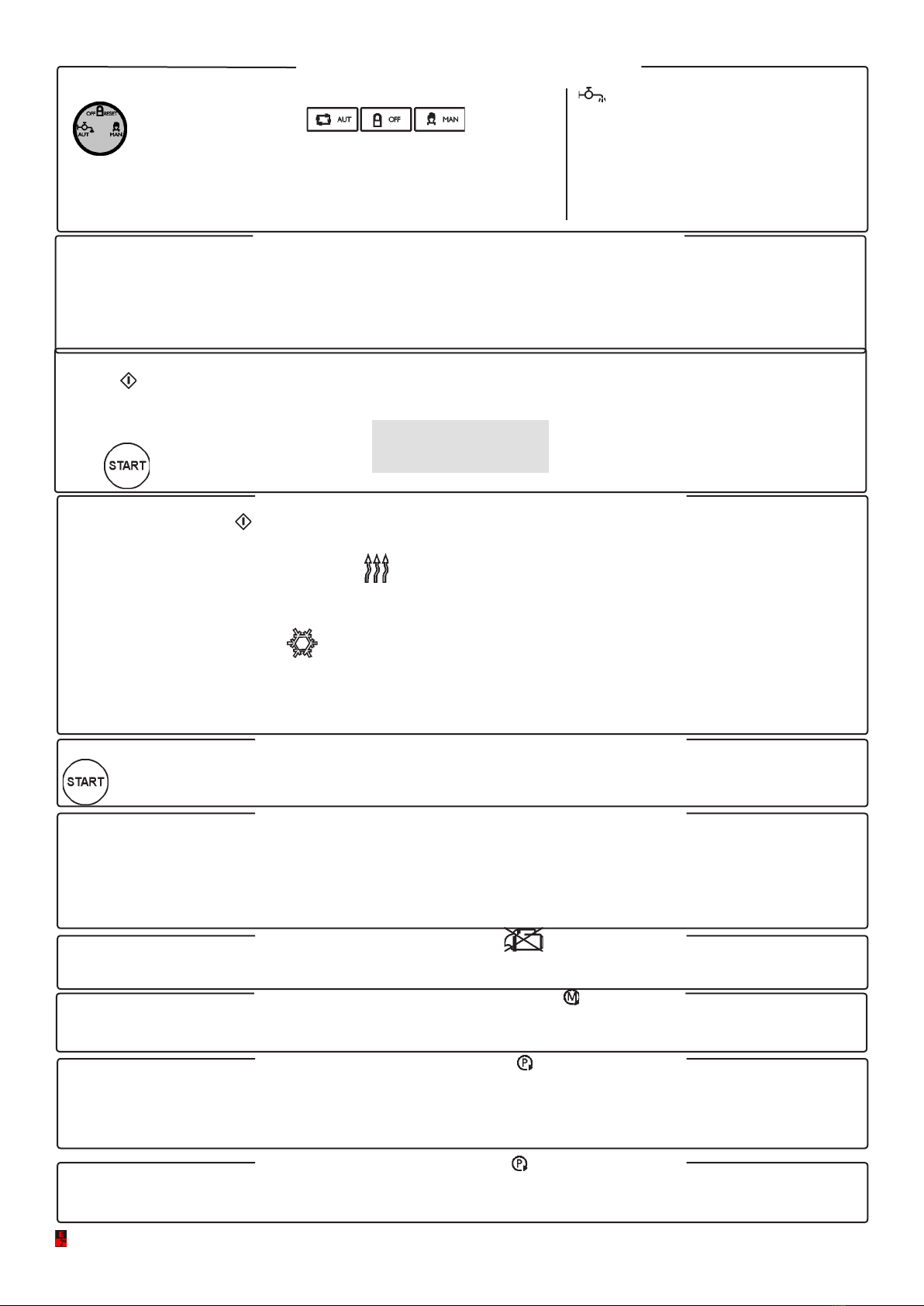

DISPLAY

on the panel the functions of:

- hour-meter

- oil pressure gauge

- water or oil thermometer

- tachometer

- pump water pressure gauge

- timer

- fuel level gauge

- battery voltmeter

- pump protection exclusion

- battery and oil lights

- protections intervention

- emergency stop

ELCOS SRL - Parma - CIM-131 - MAN - EN

2

CLOCK

After starting, the motor pump protects itself automatically.

BRIEF INSTRUCTIONS

PUMP WATER

PRESSURE

IS DISPLAYED.

THE FUEL LEVEL

IS DISPLAYED.

THE VOLTMETER

OF THE BATTERY IS

DISPLAYED.

ACCUMULATED

OPERATION HOURS

ARE DISPLAYED.

PRESS TO ACCELERA-

TE THE MOTOR PUMP

WHEN THE CONTROL

UNIT IS IN MANUAL

MODE.

PRESS TO DECELERA-

TE THE MOTOR PUMP

WHEN THE CONTROL

UNIT IS IN MANUAL

MODE.

EMERGENCY STOP

PRESS TO ADJUST

ELECTRONIC PUMP

WATER PRESSURE

SWITCH.

THE BATTERY IS

NOT CHARGING.

LOW ENGINE

OIL PRESSURE

THE ENGINE PROTEC-

TION DEVICES ARE

ACTIVE. SWITCHED

ON 10 SEC. AFTER

DETECTION OF ENGINE

RUNNING.

STOPPING DUE TO

LOW COOLANT LEVEL.

STOPPING DUE TO

LACK OF BATTERY

CHARGING (BELT BRE-

AKAGE).

STOPPING DUE TO

HIGH ENGINE

TEMPERATURE.

PRESS IF YOU WANT

TO SET WORKING

TIME

(UP TO 96 HOURS).

CUMULATIVE ALARM

WITHOUT

STOP

WITH

STOP PRESS TO SELECT

THE FUNCTION:

AUTOMATIC

OFF/RESET

MANUAL

STOPPAGE DUE

TO LOW PRESSURE OR

PUMP WATER

OVERPRESSURE OR

ELECTRONIC

PRESSURE SWITCH

(TRANSMITTER) INTERRUPTED.

IN THIS CASE, THE ANOMALY IS

HIGHLIGHTED BY THE FLASHING

WARNING LIGHT.

STOPPING DUE TO LOW

FUEL LEVEL

STOPPING DUE TO

INSUFFICIENT

ENGINE OIL PRESSURE

PUMP PROTECTION

IS ACTIVE.

PRESS BRIEFLY,

THE LED STAYS

OFF, THE MOTOR

PUMP STOPS IF

THE CALL OR THE

TIMER ARE NOT

ACTIVE.

PRESS UNTIL THE

LED FLASHES,

THE MOTOR PUMP

STOPS AND STAR-

TING WITH THE

CALL AND THE TI-

MER IS SWITCHED

OFF.

NORMAL WORKING

PRESSURE. SWITCHED

OFF WHEN THE PRES-

SURE DIFFERS FROM

THE WORKING PRES-

SURE BY THE ALLOWED

OSCILLATION.

PRESS TO SELECT

THE DISPLAYED

FUNCTION, EACH

TIME IT IS PRESSED,

THE INSTRUMENT

INDICATED BY THE

DISPLAY CHANGES.

HOLD DOWN TO SI-

LENCE THE GENERAL

ALARM (BUZZER).

PRESS TO START

THE MOTOR

PUMP WHEN THE

CONTROL UNIT

IS IN MANUAL

MODE.

UTILIZE IN

PROGRAMMING.

PRESS UNTIL THE 2

SIGNS START

FLASHING

TO EXCLUDE PUMP

PROTECTION.

TO RE-ACTIVATE

PROTECTION, PRESS

AGAIN UNTIL THEY

SWITCH OFF.

MOTOR PUMP OPERA-

TING SPEED IS DISPLA-

YED.

ENGINE WATER OR OIL

TEMPERATURE IS

DISPLAYED.

ENGINE OIL

PRESSURE

IS DISPLAYED.

THE CALL IS

PRESENT.

THE ENGINE

IS RUNNING.

PUMP PRIMING

(ALWAYS ON)

FAILURE TO

PRIME PUMP

FLASHING.

CAN BUS PARAME-

TERS

OVERPRESS.

DISCONN’ED

LOW PRESS..

ELCOS SRL - Parma - CIM-131 - MAN - EN 3

CONTENTS

Brief instructions and contents page 2-3

Workingpressurecontrol-Pumpprotection-Failuretollpipes. “ 4

Operation: Functions selection-Glow plugs preheating-Starting with call-Starting with

start button-Starting-Starting failure-Detection of running engine-Automatic pump

priming-Pump priming failure.

“ 5

Operation: Clutch-Engine warming-Engine cooling-Stop-Emergency stop-Stop with the

Stop and Off-Reset buttons-Stopping failure-Buzzer.

“ 6

Operation: Timer-Resetting of the set time-Oil and battery warning lights-End of work-

Instruments-CAN Bus messages and instruments-Anomaly messages-CAN Bus instru-

ments- Cumulative alarms

“ 7

Engine and pump protection devices “ 8-9

Wiring diagram “ 10-11

Automatic pump priming connection “ 12

Notices “ 13

User programming “ 14

Dimensions - Technical data “ 15

Ordering data - Accessories supplied - Conformity declaration “ 16

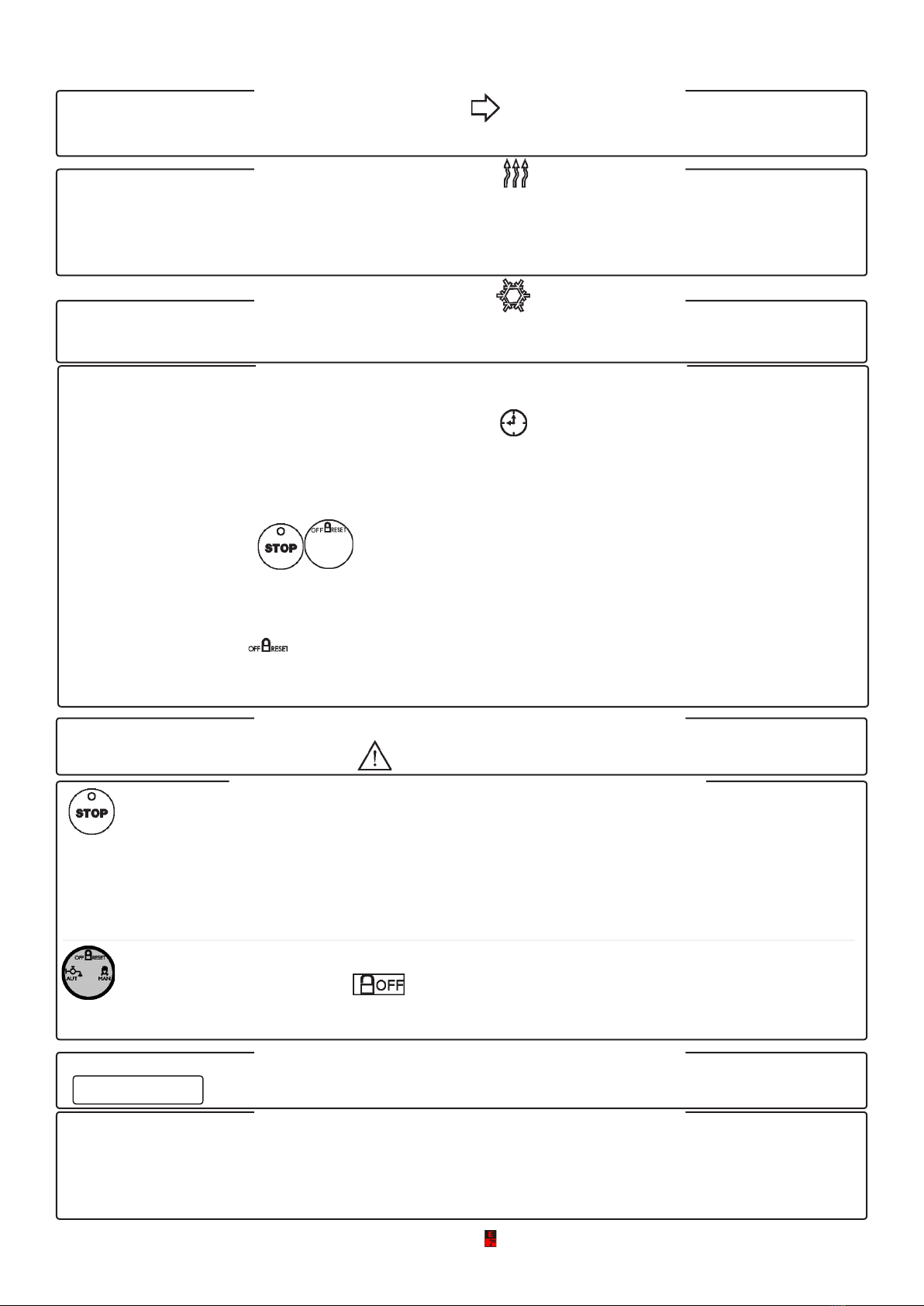

STOP DUE TO INSUFFICIENT PRESSURE

OR

PUMP WATER OVERPRESSURE

STOPPING DUE TO LOW

COOLANT LEVEL.

ENGINE OVERSPEED

AND UNDERSPEED

FAULT

OVERPRESS.

LOW PRESS

ALARM DUE TO

STARTING

FAILURE.

STOPPING DUE

TO HIGH ENGINE

TEMPERATURE.

STOPPING DUE TO

INSUFFICIENT

ENGINE OIL

PRESSURE.

STOPPING DUE TO

LACK OF BATTERY

CHARGING (BELT

BREAKAGE).

ENGINE WARMING

IN PROGRESS.

DECELERATION IN

PROGRESS.

ACCELERATION IN

PROGRESS.

CLUTCH ENGAGED

ENGINE COOLING IN

PROGRESS

ALARM OR STOP DUE TO:

• FUEL RESERVE

• NO FUEL.

PUSH-BUTTON PANEL LOCK see page 18.

UNDERSPEED

FAULT A1 - A2

OCCURRED

SWITCHING OFF OF PUMP PROTECTION DEVICES

Button switches off the pump protection devices:

• failure to prime main pump

•failuretollpipes

•insufcientpumpwaterpressure

• pump water overpressure

• abnormal acceleration

• adjustment error

- switching off is obtained by holding it down for at least 3 consecutive seconds; the function is indicated by the two intermittent

Indicators.

- this switching off is deleted by pressing the button again.

ELCOS SRL - Parma - CIM-131 - MAN - EN

4

Select the MANUAL operating mode, start the motor pump with button .

Set the required pressure with buttons after 10 seconds BAR STORED is displayed.

Waituntilthepipesarelledandthepressurehasstabilizedatthechosenvalue.Afternishingsetting,SELECTOPERATING

MODE , the pressure of the system will remain set at the chosen pressure.

The chosen pressure value can be corrected with the system under pressure, by pressing buttons .

The working pressure setting is deleted, when the engine is stopped by selecting operating mode .

SEQUENCE OF OPERATIONS

start up

running pump

PRIMING

IN PROGRESS

OVERPRESSURE remains set to two bars, this value is

added to the working pressure

(for example, working pressure 9 bars overpressure 11 bars)

Waituntilthepipesarelled.

When the working pressure has

stabilized, select .

The working pressure

is regulated automati-

cally.

Set the required

pressure.

Press to select the

pump water pressure

gauge.

example

Working

pressure

PUMP PROTECTION

NO ADJUSTING IS REQUIRED.

Pump water

overpressure

or

Insufcient

pressure

(subpressure)

INSUFFICIENT

PRESSURE

OVERPRESSURE

However it is possible to change the two bars of pressure

lowering (subpressure), by pressing button .

This change is deleted, when the engine is stopped, by selecting the

OFF/RESET operating mode.

WORKING PRESSURE

Press to

set the sub-

pressure value

(PRESSURE

SWITCH)

Press to select the

pump water pressure

gauge

FAILURE TO FILL PIPES FAULT

The acceleration starts with the engine running, with pump primed.

ThemotorpumpreachestheredenedWORKINGPRESSURE(see BARS STORED ) within the TIME OF FAILURE TO

FILL PIPES, set to 120 seconds. If air is present in the pipes, the acceleration will be alternated with pauses (of 15 seconds), if

the pressure remains steady for 5 seconds. This situation will be repeated several times until the WORKING PRESSURE is rea-

ched. If the pressure is not reached within the FAILURE TO FILL PIPES time (120 sec.), FAILURE TO FILL PIPES is displayed

on the display and the engine stops.

ABNORMAL ACCELERATION

(Pipe leakage controlled within the limits of the system).

As a result of a leakage, the engine tends to increase the revolutions to bring it back to WORKING PRESSURE. If the revolutions

increase by 10% for a time longer than 120 seconds, ABNORMAL ACCELERATION is displayed on the display and the engine

stops

WORKING PRESSURE CONTROL

9

9

PRESSOSTAT

BAR 6

Always on: pump primed.

Flashing: failure to prime.

The pump protection is enabled when warning lights PUMP PROTECTION ACTIVE and water pressure normal come on

after the water pressure has remained stable for 2 consecutive minutes, in any case 10 minutes after the engine started.

Intervention of the protection (5 seconds after the pressure goes up or down by two bars ) stops the engine and is

shown on the display:

Factory Setting

The motor pump starts up if

the motor pump is primed.

The priming probe senses

water presence (pump primed).

Select

MAN Automatic

pump

priming.

ELCOS SRL - Parma - CIM-131 - MAN - EN 5

T

HE STARTING OF THE MOTOR PUMP CAN BE OBTAINED IN THREE WAYS

:

• CALL

• TIMER The starting procedures are similar to each other.

•KEY

GLOW PLUGS PREHEATING

A

CTIVATED BEFORE STARTING

(GLOW PLUG

IS SHOWN ON THE DISPLAY

)

The duration of the preheating action can be set, the preheating action ceases before the beginning of the

starting process. The preheating control is disabled at the factory since it has been programmed to zero

seconds.

When the call contact closes and the DELAY AFTER CALL CLOSED has elapsed,

the control unit controls the glow plugs (if preset) and then the starting. If preset, the motor pump stays on

idle for the whole ENGINE WARMING , time, when this time has elapsed the motor pump reaches

and maintains the preset working pressure. When the call contact opens once the STOP DELAY after

CALL OPENING has elapsed, if preset the motor pump slowly decelerates, when the motor pump is on

idle the ENGINE COOLING time starts.

When this time has elapsed the motor pump stops. During its operation the motor pump is protected from

the faults controlled by the probes connected to the control unit.

STARTING WITH START BUTTON

Tostart,apulseonthebuttonissufcient.

Blocks the startup cycle if the pump has not started up after the fourth pulse.

It is obtained with measurement of the voltage and frequency of the battery charging alternator. Disables

the starter motor.

The priming pump starts; when the priming probe senses the presence of water, the pump stops and after

15 seconds the engine starting begins.

This takes place on closing of the CALL contact, or with Timer.

Before beginning the starting process, a buzzer is activated for 8 seconds, and after a 3-second pause the

starting process begins. To facilitate startup, a special circuit emits a series of four, 5-second pulses, with a

5-second delay between each pulse.

To activate the

control unit press

the button.

}

DETECTION OF ENGINE RUNNING

AUTOMATIC PUMP PRIMING (ALWAYS ON)

STARTING FAILURE

STARTING WITH CALL

The priming probe does not sense the presence of water and a time higher than 240 seconds has

elapsed.

PUMP PRIMING FAILURE (FLASHING)

OPERATION

FUNCTIONS SELECTION

The function selected with the key is

shown by the associated warning light.

•AUT Automatic pressure control.

•OFF The engine cannot be started and if

running it is stopped.

•MAN Operation without automatic

pressure control.

Factory Setting

The motor pump starts up if

the motor pump is primed.

ELCOS SRL - Parma - CIM-131 - MAN - EN

6

The control unit has its own buzzer. Before starting automatically the motor pump activates

the buzzer intermittently for 8 seconds, followed by a pause of 3 seconds (this function can be

switched off). This buzzer also operates for the intervention of the protection devices listed on

page 8-9. It is possible to place a buzzer externally to be connected to the relevant output.

• On pressing briefly, the led stays off, the motor pump stops if the call or the timer are not

active.

• On pressing (3 seconds) until the LED flashes, the motor pump stops and starting by call and

by timer are disabled, with the engine stopped the warning light remains flashing. The deletion of

this switching off occurs on pressing the stop button (3 seconds) until the flashing warning light

goes out.

Press until switching on of .

The engine cannot be started in any way and if it is running it is stopped. Reactivates the protec-

tion devices and all the locked functions.

Stopping is obtained:

• Through intervention of the protection devices.

• Through end of work of the clock and of the timer .

• By pressing the emergency button (to be fitted externally).

• On opening of the call contact.

• At end of work through intervention of the underspeed or the flow switch.

.

• On pressing buttons , the engine stops after slow deceleration.

Stopping can be obtained in two ways:

• With electromagnet de-energized with engine running and energized with it stopped, remaining

in this condition for 15 sec. after detection of engine stopped.

On pressing button the stopping electromagnet stays energized for 60 seconds.

• With electromagnet or electro-valve activated while the engine is running and deactivated

when stopped. This condition is maintained even when the engine is stationary.

OPERATION

CLUTCH

ENGINE WARMING

(factory-excluded)

EMERGENCY STOP

STOPPING FAILURE

BUZZER

ENGINE COOLING

STOP

This is engaged on reaching a certain engine speed. This clutch disengages when the engine

speed drops below the set value.

After closing of the call contact or TIMER or SMS pump priming takes place, the engine stays on

idle for the time necessary to allow warming of the engine. After this time has elapsed the engine

slowly reaches the working pressure. During heating the protection devices are active.

This intervenes if the running engine signal is detected 60 seconds after the stop command.

STOPPING FAILURE will be read on the display.

On opening of the call contact or TIMER the engine slowly decelerates. When

the engine is on idle the COOLING TIME starts, and after this time has elapsed the engine stops.

This can be obtained in any operating condition, by installing one or more (latching) buttons. This

is indicated by the optical indicator .

STOPPING WITH THE STOP AND OFF-RESET BUTTONS

ELCOS SRL - Parma - CIM-131 - MAN - EN 7

MESSAGES AND CAN Bus INSTRUMENTS

Sent (SAE J1939 protocol Bus) from the engine equipped with control unit for electronic control

of the injection system.

ANOMALY MESSAGES

The anomaly messages managed by the injection control unit are indicated on the display

example

SPN 1234-12 CAN Bus.

Problems of connection ANOMALY CAN Bus to the CAN Bus.

CAN Bus INSTRUMENTS

TACHOMETER - OIL PRESSURE GAUGE - THERMOMETER

The control unit incorporates seven instruments that can be selected in sequence by pressing button .

HOUR-METER - total hours of operation witht he engine running the signal pulsates, to indicate the

correct functioning of the HOUR-METER).

PRESSURE GAUGE - Engine oil pressure

THERMOMETER - Engine oil and water temperature

TACHOMETER - Speed of motor pump

PRESSURE GAUGE - Engine water pressure

INDICATOR - Fuel level percentage

VOLTMETER - Battery voltage

OPERATION

TIMER

OIL AND BATTERY WARNING LIGHTS

CUMULATIVE ALAR

INSTRUMENTS

END OF WORK

(Flow stopped)

Always enabled, allows if necessary the motor pump to be operated for a settable time (maximum 96 hours), at the

end of which it is stopped and on the display the end of work time indicator comes on.

The work time is set by pressing the push-button ( lights up) until the desired value appears on the

DISPLAY .

On releasing the push-button, the timer automatically starts working, continously displaying the remaining work time

.

CANCELLING THE SET TIME

To zeroing the set time, tkeep the push-button pressed until it reaches zero.

Switched on with the automatic or manual function these switch off with the engine running with oil pressure

and battery recharging system normal. Control unit in Stand by, warning light pulses .

When the engine revolutions fall by 10% and the WORKING PRESSURE stays constant for 120 seconds END OF

WORK is displayed on the display and the engine stops.

Ifthereisnotthiscondition,aowswitchmustbeinstalled(Endofworkwithowswitchseeonpage9).

LED (red) STEADY LIGHT: anomaly managed by the injection control unit will cause the engine to stop.

LED (red) FLASHING LIGHT: anomaly managed by the control unit CIM-131 will cause the engine to stop.

LED (yellow) STEADY LIGHT: anomaly managed by the injection control unit will NOT cause the engine to

stop.

LED (yellow) FLASHING LIGHT: anomaly managed by the control unit CIM-131 will NOT cause the engine

to stop, or indicates a preventive maintenance operation.

LED OFF ALL OK.

}

TRANSMITTERS MOUNTED ON THE ENGINE

ON REQUEST

ELCOS SRL - Parma - CIM-131 - MAN - EN

8

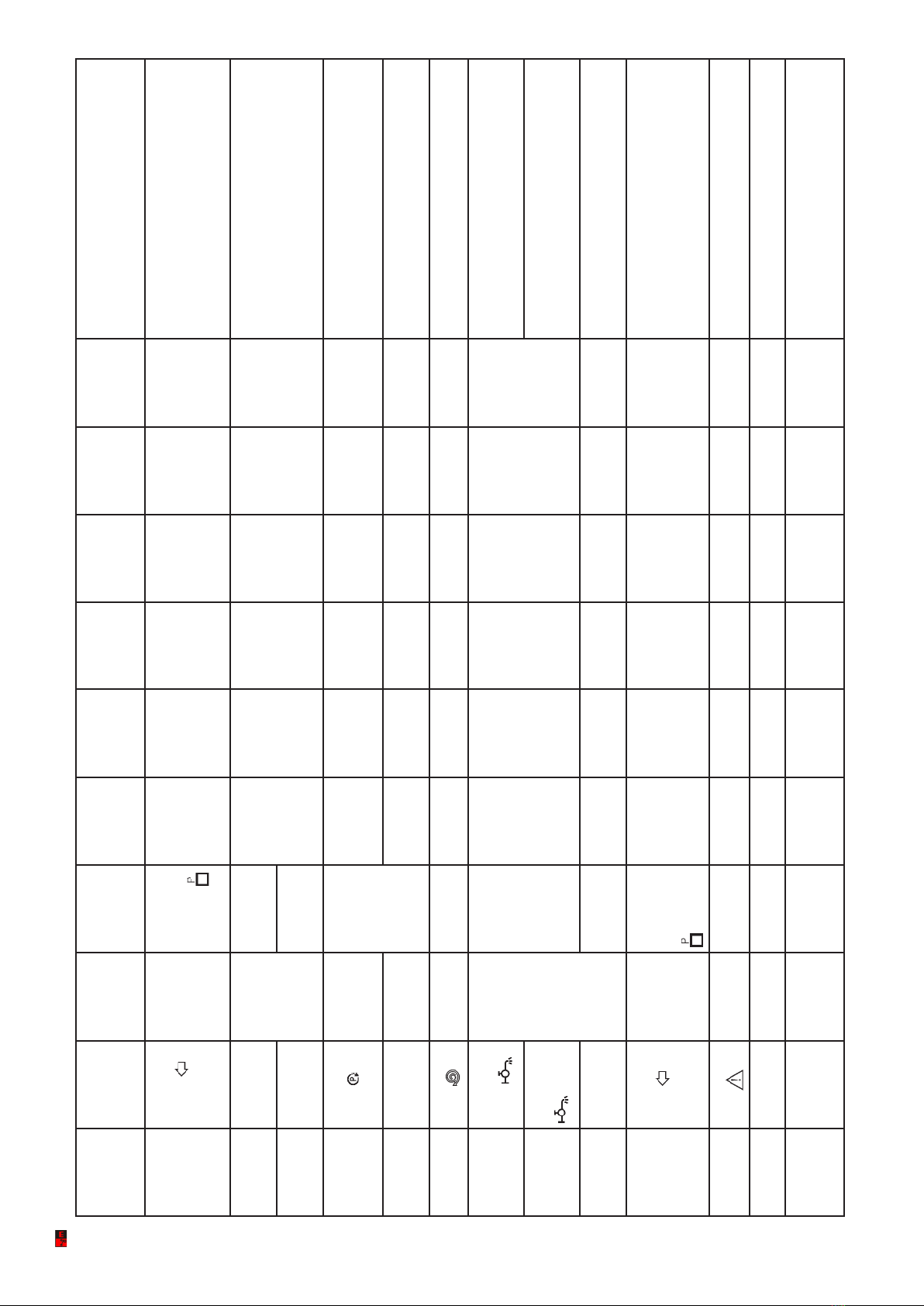

ENGINE AND PUMP PROTECTION DEVICES

The ENGINE PROTECTION DEVICES are enabled when indicator comes on (10 seconds after detection of engine running ). The PUMP PROTECTION is enabled when

comesonafter2consecutiveminutesofsufcientwaterpressure,indicatedbyNORMALPRESSUREindicator and in any case 10 minutes after the pump started. Intervention

due to a fault enables the GENERAL ALARM.

DESCRIP-

TION OF

FAULTS OR

FUNCTIONS

INDICATION

ON THE

FRONT PANEL

MOTOR PUMP

PROBE

INSTANT OF

ACTIVATION

(seconds)

INTERVEN-

TION DELAY

(seconds)

PRO-

GRAMMED

THRESHOLD

(FACTORY

SETTING)

STORES THE

FUNCTION

DECELE-

RATION

ENGINE

COOLING

STOP INTERVENTION OCCURS WHEN:

BATTERY

UNDER-

VOLTAGE

BATTERY

UNDER-VOL-

TAGE

BATTERY Always active

2

11 (12V)

22 (24V) NOT = NOT

DOES

NOT STOP

Battery voltage remains lower than the program-

med threshold for the whole of the intervention

delay time.

BATTERY

OVER-

VOLTAGE

BATTERY

OVER-

VOLTAGE 5

16 (12V)

32 (24V) YES SLOW NOT Battery voltage exceeds the programmed threshold

for the whole of the intervention time.

OVER-

HEATING

DETECTED BY

THERMOSTA-

TIC SWITCH

OVER-

HEATING THERMOSTA-

TIC SWITCH

With running

engine 2 = YES SLOW YES WITH

STOP

The temperature detected by the transmitter

exceeds the set threshold.

FUEL

RESERVE FUEL

RESERVE

Flashing

FUEL

FLOAT

TERMINAL T

Always active

5 10% NOT = NOT DOES

NOT STOP

The fuel level remains lower than the threshold for

the whole of the intervention delay time.

NO FUEL

NO FUEL

Always

on

FUEL

FLOAT

TERMINAL W

5 1% YES SLOW YES WITH

STOP

LOW OIL

PRESSURE

LOW OIL

PRESSURE OIL PRESS-

URE SWITCH

10 after detec-

tion of running

engine

2 = YES QUICK NOT WITH

STOP

The pressure is lower than the threshold set by the

pressure switch.

STOPPING

FAILURE

STOPPING

FAILURE

ELECTRO-

VALVE OR

ELECTRO-

MAGNET

After the stop

command 60 = YES = NOT DOES

NOT STOP

The engine running signal is detected after the

stop command and the intervention delay time has

elapsed.

LOW

RADIATOR

FLUID

LEVEL

LOW

RADIATOR

LEVEL

LEVEL

PROBE Always active 5 = YES SLOW NOT WITH

STOP

The coolant falls below the electrode and the inter-

vention delay has elapsed.

CHARGING

ALTERNATOR

FAULT (BELT

BREAKAGE)

CHARGING

ALTERNATOR

FAULT ALTERNATOR

10 after detec-

tion of running

engine

5 = YES SLOW NOT WITH

STOP

Alternator does not recharge the battery and the

intervention delay time has elapsed.

STARTING

FAILURE

STARTING

FAILURE

BATTERY

-Starting

Motor

Always active = = YES QUICK NOT WITH

STOP

The whole series of starting attempts is unable to

start the engine.

ELCOS SRL - Parma - CIM-131 - MAN - EN 9

DESCRIP-

TION OF

FAULTS OR

FUNCTIONS

INDICATION

ON THE

FRONT PANEL

MOTOR PUMP

PROBE

INSTANT OF

ACTIVATION

(seconds)

INTERVEN-

TION DELAY

(seconds)

PROGRAM-

MED

THRESHOLD

(FACTORY

SETTING)

STORES THE

FUNCTION

DECELE-

RATION

ENGINE

COOLING

STOP INTERVENTION OCCURS WHEN:

THE END

OF WORK

FUNCTION

DUE TO FLOW

SWITCH IN-

TERVENTION

END OF

WORK FLOW

SWITCH

FLOW

SWITCH

When the

pump protec-

tion active

warning light

comes on

20 = NOT SLOW YES WITH

STOP

Thereisnowaterowandtheinterventiondelayhas

elapsed.

AVAILABLE

FAULT INPUT

A1

A1

=

Always active

5 = YES SLOW YES WITH

STOP

The input is negative (-) and the intervention delay has

elapsed.

AVAILABLE

FAULT INPUT

A2

A2 With running

engine

FAILURE TO

PRIME MAIN

PUMP

FAILURE TO

PRIME

(ashing)

PUMP PRI-

MING LEVEL

PROBE

With running

engine

240 =

YES =NOT WITH

STOP

The priming probe does not sense water presence and

the intervention delay has elapsed.

FAILURE TO

FILL PIPES

FAILURE TO

FILL

ELECTRONIC

PRESSURE

SWITCH

120 =YES SLOW NOT WITH

STOP

The working pressure is not reached and the interven-

tion delay has elapsed.

OVERSPEED OVER-

SPEED

ALTERNATOR

TERMINAL W Always active 24000 RPM YES = NOT WITH

STOP

The speed remains higher than the programmed thresh-

old for the entire duration of the intervention delay.

INSUFFICIENT

PUMP WATER

PRESSURE

INSUFFICIENT

WATER PRES-

SURE

ELECTRONIC

PRESSURE

SWITCH

After detection

of working

pressure and in

any case 600”

after the pump

started

5 = YES SLOW YES WITH

STOP

The pump water pressure remains lower for the entire

duration of the intervention delay.

PUMP WATER

OVERPRES-

SURE

PUMP OVER-

PRESSURE The pump water pressure remains higher for the entire

duration of the intervention delay.

ABNORMAL

ACCELER-

ATION

ABNORMAL

ACCELER-

ATION

With running

engine 60

Allowed accel-

eration percen-

tage 20%

YES SLOW NOT WITH

STOP

The speed remains higher than the programmed thresh-

old for the entire duration of the intervention delay.

END OF

WORK DUE

TO UNDER-

SPEED INTER-

VENTION

UNDERSPEED

END OF

WORK

ALTERNATOR

TERMINAL W

When the

pump protec-

tion active

warning light

comes on.

120

Allowed

deceleration

percentage

10%

NOT SLOW YES WITH

STOP

The speed drops below the programmed threshold and

the working pressure remains constant for the entire

duration of the intervention delay.

EMERGENCY

STOP

EMERGENCY

STOP

EMERGENCY

BUTTON Always active = = YES = NOT WITH

STOP Emergency button is pressed.

ADJUSTMENT

ERROR

ADJUSTMENT

ERROR

ALTERNATOR

TERMINAL W

With running

engine 120 = YES = NOT WITH

STOP

The rotation speed of the engine has not changed after

120 seconds.

PUMP WATER

PRESSURE

TRANSMIT-

TER

TPA

DISCON-

NECTED

ELECTRONIC

PRESSURE

SWITCH

ALWAYS

ACTIVE 60 = YES SLOW NOT WITH

STOP The pressure transmitter circuit is disconnected.

ELCOS SRL - Parma - CIM-131 - MAN - EN

10

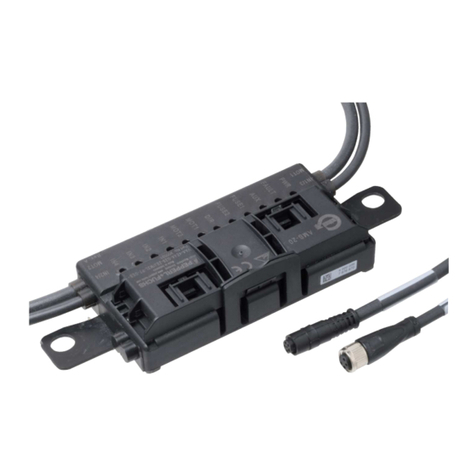

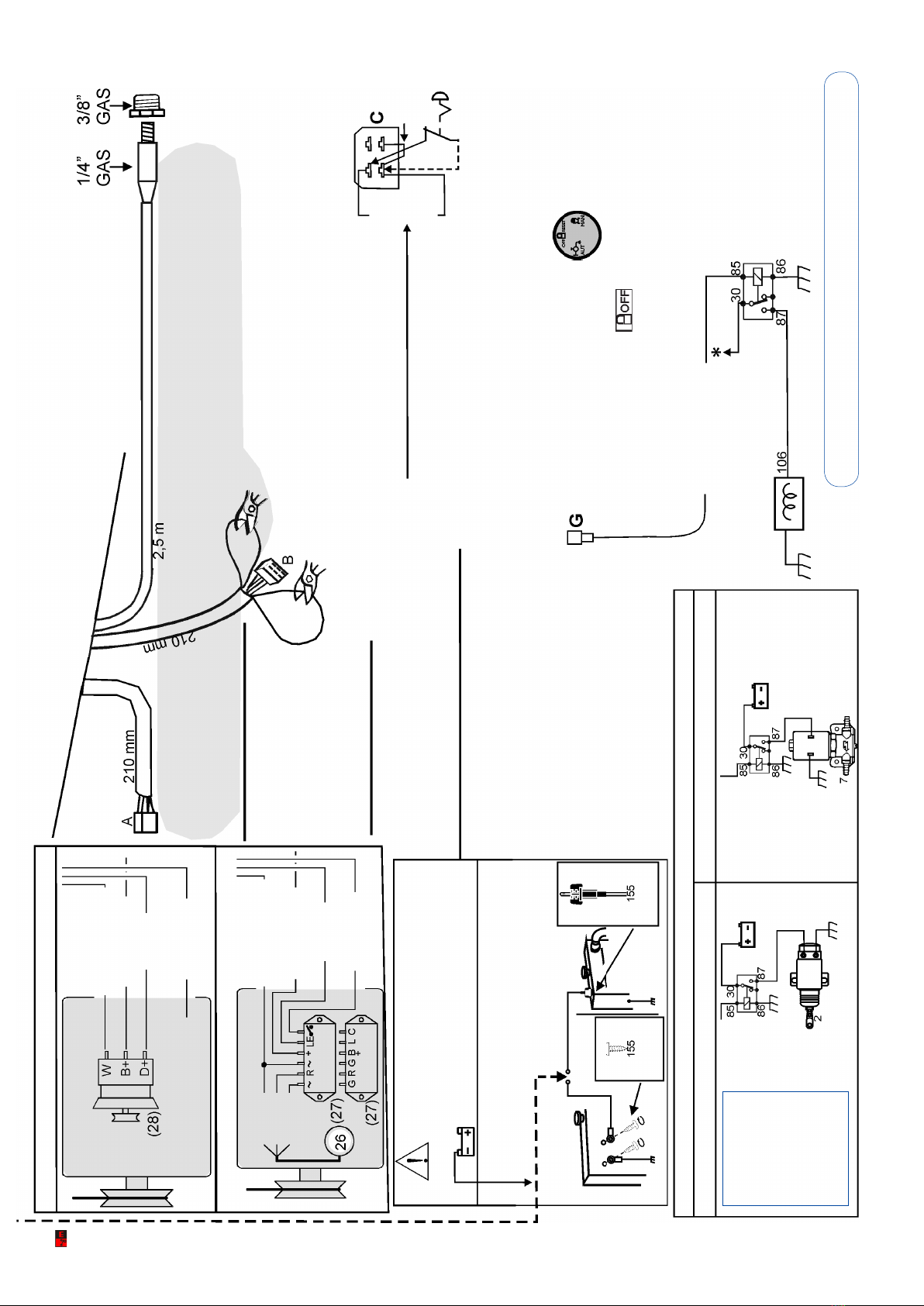

CAN BE USED FOR

AUXILIARIES

WHITE/RED

BROWN (Only for permanent magnets)

RED

BATTERY

GREY

WIRING DIAGRAM

GREEN

WHITE

YELLOW

ORANGE

BLACK

BLACK/BLUE

ORANGE/BROWN

WHITE/VIOLET

LIGHT BLUE

WHITE/GREEN

YELLOW/ORANGE RED/GREEN

BROWN/BLUE

WHITE/YELLOW

BROWN/RED

BROWN/GREEN

STOP

SYSTEMS

SEE PAGE 11

ORANGE/BLUE

INDICA-

TOR

WRESERVE

ACCELERATOR

YELLOW GREEN

CABLE 1,5m

FUSE

YELLOW/BLUE

WHITE/RED

GREEN

BROWN (Only for permanent magnets)

WHITE

YELLOW

GREY

RED/GREEN

BROWN/BLUE

BLACK/

GREEN

GREY

YELLOW/ORANGE

ORANGE

BLACK

RED

BATTERY

STOP

SYSTEMS

SEE PAGE 11

YELLOW GREEN

BLACK/BLUE

ORANGE/BROWN

WHITE/VIOLET

TO THE GLOW

PLUG RELAY

ORANGE/BLUE

INDICA-

TOR

WRESERVE

ACCELERATOR

FUSE

USED ONLY FOR AUTO-

MATIC PUMP PRIMING

see page 12.

CAREFULLY INSULATE ANY WIRES THAT

ARE NOT CONNECTED, INSERTING THE

BATTERY CUT OUT SWITCH

THE CONTROL UNIT IS IN OFF MODE. TO

ENABLE THE OTHER FUNCTIONS PRESS

THE RELEVANT BUTTON .

CABLE 2,5m

LIGHT BLUE

GREY

WHITE/YELLOW

BROWN/RED

BROWN/GREEN

WHITE/GREEN

YELLOW/BLUE

CALL

10m MAX

VIOLET

PUMP

CLUTCH

SELF-

PROPELLED

IRRIGATOR

SELF-

PROPELLED

IRRIGATOR

SELF-

PROPELLED

IRRIGATOR

GREY

OPERATES

ON

CLOSING

OF THE

CONTACT

FLOW SWITCH

installation

The straight pipe

must be 5 times

the diameter of the

pipe. The direction

oftheowswitch

must match the

arrow on the cover.

INSTALL THE FLOW SWITCH

ON THE INTAKE.

Use the highest possible

number of paddles.

FUSES

F1 25A POSITIVE POWER SUPPLY TO

ENGINE CONTROL UNIT.

F2 3A POSITIVE POWER SUPPLY TO

ENGINE CONTROL UNIT.

F3 7,5A POWER SUPPLY TO CIM CONTROL

UNIT...

TO CHANGE THE FUSES,REMOVE THE

RELEVANT COVER OF THE CONTROL UNIT

ELCOS SRL - Parma - CIM-131 - MAN - EN 11

PUMP WATER PRESSURE TRANSMITTER CABLE

STOP SYSTEMS SET UP

To stop with the SOLENOID VALVE

cut and isolate the BLUE/BROWN lead

ELIMINATE THE BRIDGE WHEN CON-

NECTING THE EMERGENCY BUTTON

EMERGENCY STOP

THIS CAN BE OBTAINED WITH A

LATCHING BUTTON. ON RELEASING

THE EMERGENCY BUTTON, STAR-

TING OR MOTION OF THE ENGINE

IS STOPPED. TO RESET, RELEASE

THE BUTTON, PRESS .

AND SELECT

ORANGE/VIOLET

GLOW PLUG

RELAY

EMERGENCY

BUTTON

The control unit has

been designed to

control stopping with

an ELECTROMAGNET

SET UP

• WATER OR OIL

THERMOMETER

• OIL PRESSURE GAUGE

To view the water/oil THERMOMETER and the

oil PRESSURE GAUGE, connect the

transmitters to the respective wires of the unit,

then CUT and isolate the BLACK/VIOLET wire.

WARNING! :

IT IS NOT

POSSIBLE

TO MOUNT THE

EMERGENCY

STOP BUTTON ON

A STOP SYSTEM

WITH ELECTRO-

MAGNETS ELECTROMAGNET to

activate the engine STOP lever.

SOLENOID

to close

the fuel

YELLOW

YELLOW

EXCITED IN STOP MODE EXCITED WHILE RUNNING

STOP SYSTEMS

ROD

ELECTRODE

SCREW

ELECTRODES

COOLANT LEVEL PROBE

FOR RADIATORS WITH

PLASTIC EXPANSION TANK

FOR RADIATORS WITH

METAL EXPANSION TANK

IF THE FUNCTION- LOW COO-

LING LIQUID LEVEL

IS NOT USED CONNECT

YELLOW/ORANGE WIRE

TO EARTH

PERMANENT MAGNETS

YELLOW

YELLOW

RED

BROWN

GREEN

+ BATTERY

WHITE/RED

DO NOT USE

PRE-EXCITATION

WHITE/RED

+ BATTERyY

GREEN

BROWN

CHARGE ALTERNATOR:

BROWN

BLUE/BROWN

BLACK/VIOLET

BLACK

SETTING THE TACHOMETER see page 14

ELCOS SRL - Parma - CIM-131 - MAN - EN

12

AUTOMATIC PUMP PRIMING CONNECTIONS

ACCESSORIES

ON REQUEST

(2/7) ELECTROMAGNET OR ELECTRO-VALVE

(3) OIL PRESSURE SWITCH

(4) THERMOSTATIC SWITCH

(18) FUEL FLOAT FOR INDICATOR AND RESERVE

(97) OIL PRESSURE TRANSMITTER

(102) WATER FLOW SWITCH

(112) TEMPERATURE TRANSMITTER

(155) RADIATOR LIQUID LEVEL PROBE

(163) SPEED VARIATOR

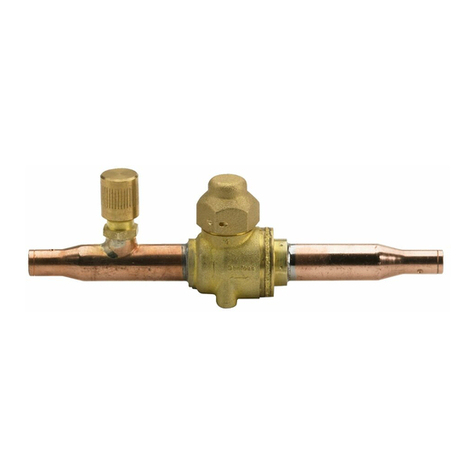

(173) PUMP WATER PRESSURE TRANSMITTER

(SUPPLIED)

PRIMING PROBE

EXCLUSION

connect to ground the

BROWN/BLUE wire.

SELF-

PROPELLED

IRRIGATOR

SELF-

PROPELLED

IRRIGATOR

SELF-

PROPELLED

IRRIGATOR

OPERATION

AUTOMATIC PRIMING

The priming pump (P2) starts,

when the water reaches the priming

probe, lthe pump stops.

PRIMING FAILURE

The pump is stopped if the priming

probe does not sense the presence

of water within 240 sec..

To connect

PUMP PRIMING, remove

the male connector,

insert the connector with

the wires brown/blue

yellow/blue.

GREY

CABLES

2,5 m

Manual

priming

BROWN/GREEN

WHITE/YELLOW

YELLOW/BLUE

BROWN/RED

BROWN/BLUE

BROWN/BLUE

YELLOW/BLUE

FEMALE

CONNECTOR

PRIMING

PROBE

Male

connector

CLUTCH

WHITE/YELLOW

(26) PERMANENT MAGNETS CHARGE ALTERNATOR

(27) ALTERNATOR REGULATOR

(28) PRE-EXCITATION CHARGE ALTERNATOR

(40) STARTING MOTOR

(41) BATTERY

(106) GLOW PLUGS

(157) VISUAL INDICATOR (GENERAL ALARM)

(191) A1 AVAILABLE FOR PROTECTION PROBE

(192) A2 AVAILABLE FOR PROTECTION PROBE

(207) PRIMING PUMP

(212) NON-RETURN PRIMING VALVE.

ELCOS SRL - Parma - CIM-131 - MAN - EN 13

YOUR ELECTRICAL TECHNICIAN CAN ASK US ANYTHING ABOUT THIS CONTROL

UNIT BY TELEPHONING ONE OF OUR TECHNICIANS

Only for starting and surveillance of the diesel motor pump and stops it if there are anomalies in

the parts controlled by probes.

It has been designed to be installed also on the machine.

Warning:

adhere closely to the following advice

- Connect always following the wiring diagram shown on page 10-11.

- Each technical operation must take place on the motor pump unit with the engine stopped and

with terminal 50 of the starter motor disconnected.

- Check that the line loading and the consumption of the connected equipment are compatible

with the described technical characteristics.

- Install in such a way that there is always adequate heat disposal.

- Always install under other equipment which produces or spreads heat.

- Make sure that no copper conductor cuttings or other waste material fall inside the control unit.

- Never disconnect the battery terminals with the engine running.

- Never use a battery charger for the emergency start-up, this could damage the control unit.

- To protect the safety of persons and the equipment, before connecting an external battery

charger, disconnect the electrical plant terminals from the battery poles.

THIS CONTROL UNIT IS NOT SUITABLE FOR OPERATING IN THE FOLLOWING

CONDITIONS:

- Where the environmental temperature is outside the limits indicated in the Technical Data.

- Where the air pressure and temperature variations are so rapid as to produce

exceptional condensation.

- Where there are high levels of pollution caused by dust, smoke, vapour, salts and

corrosive or radioactive particles.

- Where there are high levels or heat from radiation caused by the sun, ovens or the like.

- Where attacks from mould or small animals are possible.

- Wherethereistheriskofreorexplosions.

- Where the control unit can receive strong vibrations or knocks.

ELECTROMAGNETIC COMPATIBILITY

This control unit functions correctly only if inserted in plants which conform with the CE marking

standards; it meets the exemption requirements of the standard EN61326-1 but it cannot be

excluded that malfunctions could occur in extreme cases due to particular situations.

The installer has the task of checking that the disturbance levels are within the requirements of

the standards.

CONDUCTION AND MAINTENANCE

The following maintenance operations should be performed every week:

- check that the indicators function;

- check the batteries;

- check that the conductors are tight, check the condition of the terminals.

UNLESS WE MAKE A WRITTEN DECLARATION STATING THE CONTRARY, THIS CONTROL

UNIT IS NOT SUITABLE FOR USE AS A CRITICAL COMPONENT IN EQUIPMENT OR PLANTS

RESPONSIBLE FOR KEEPING PERSONS OR OTHER LIVING BEINGS ALIVE.

NOTICES

ELCOS SRL - Parma - CIM-131 - MAN - EN

14

TACHOMETER ADJUSTMENT WITH CHARGING ALTERNATOR FREQUENCY W.

Press until

the LED

comes on.

(CALIBRATION

RPM)

EXIT FROM

PROGRAMMING MODE.

Press until

the LED

goes out.

LANGUAGE

TACHOMETER

SETTING

USER

PROGRAMMING

TIMER

BUTTON LOCK

_ _ _ _

RPM

3000 RPM

ADJUSTMENT

IN PROGRESS OK

3000 RPM

CLOCK SETTING

TIMER Allows up to 10 starts/stops to be programmed over

a period of 24 hours. This programming stops the TIMER

function.

1 0 : 2 1

CLOCK

Decreases Increases

LANGUAGE CHOICE. The language set up is ITALIAN; the languages that can be selected are: ENGLISH - FRENCH - GERMAN

- SPANISH - PORTUGUESE.

BUTTON LOCK. With the push-button panel locked, buttons

remain active.

LANGUAGE

00:00 09:15 09:15

00:00 10:22 10:22

LOCKED BUTTON RELEASED

START 1 :START 1 OK

STOP 1 OK

LOCKED

RELEASED

ENGLISH

Language choice:

Italian German

English Spanish

French Portuguese

Press to select the language.

Press to choice

Set hours and minutes

Decreases Increases

Set hours and minutes

Decreases Increases

Decreases Increases

Set the engine revolutions read

on the portable tachometer.

Press and wait for

OK to be written.

Press and wait for

OK to be written.

Press and wait for OK to be written.

Aftertherstprogrammingsettinghas

beennishedtheother9programming

settings can be repeated,

by pressing .

Press and wait for

OK to be written.

Press and wait for

OK to be written.

Press to

display.

Press to

display.

Press to

select

START 1

2

-

-

-

10

To stop exit the

programming mode and

press stop

CLOCK allows up to 10 STARTS/STOPS to be programmed over a period of 24 hours. Carry out setting operations with the

engine stopped. The control unit accepts only complete programming settings: START 1 STOP 1

START 2 STOP 2 and so on

If a start is programmed, but a stop is not programmed,

ERROR is written on the display. While running with the engine started by clock, indicator stays on.

During stopping by clock, indicator comes on and stays on until the next start.

_ _ _ _

Setting

set to zero.

USER PROGRAMMING

NECESSARY PROGRAMMING

When the white/red wire is connected.

Factory setting

RPM/W CALIBRATION PRESS START

Start the primed motor pump

with delivery

closed

with button .

TACHOMETER ADJUSTMENTS

Bring the engine to idle at constant known

speed for example via a portable tachometer.

ELCOS SRL - Parma - CIM-131 - MAN - EN 15

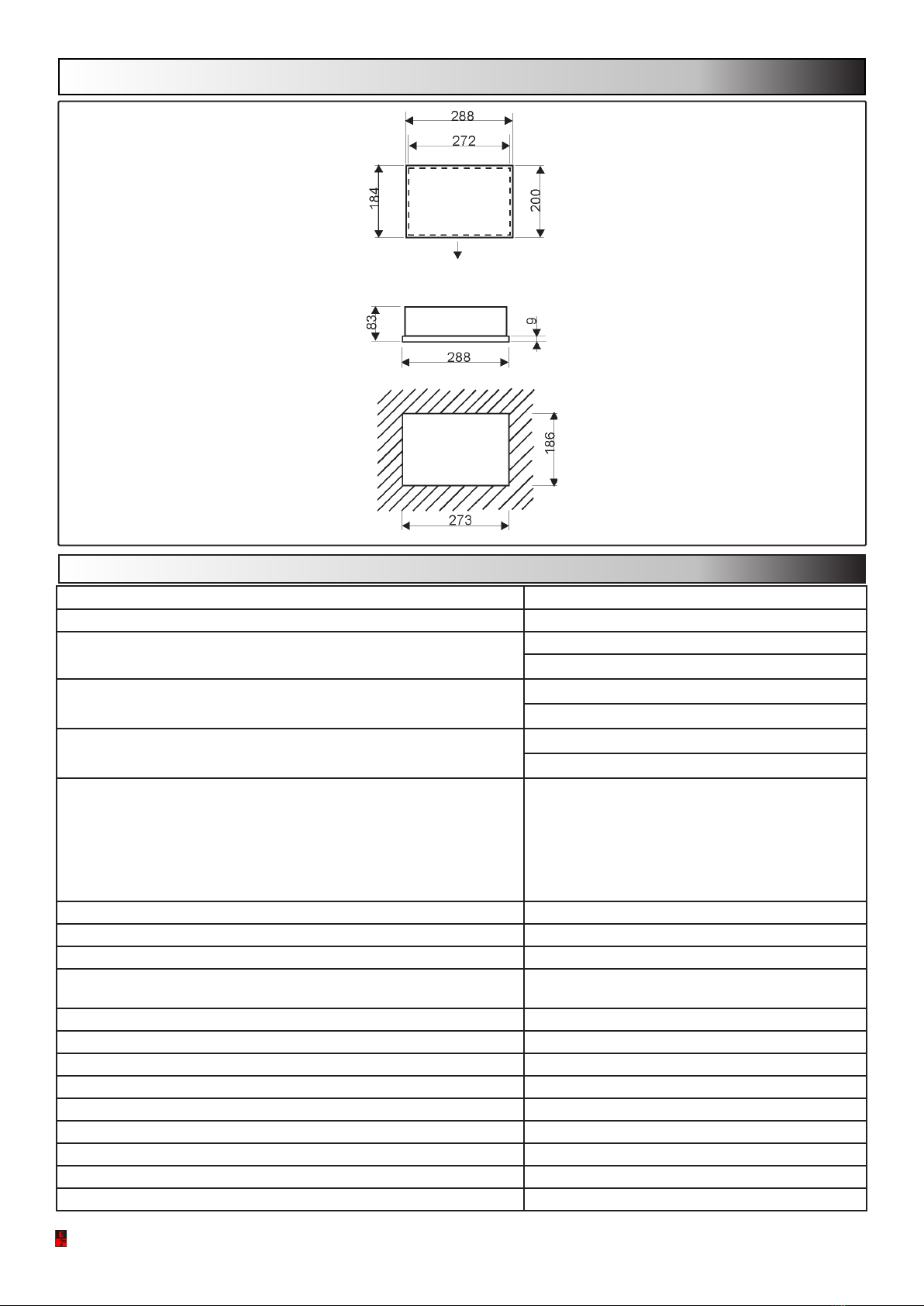

DIMENSIONS

Connectors output

see page 10-11

PANEL

HOLE

TECHNICAL DATA

Battery power supply 12 Vdc 24 Vdc

Supply voltage 8÷ 32V

Consumption in standby 3.5mA at 12V

2.5mA at 24V

Consumption with engine stationary 250mA at 12V

150mA at 24V

Max. Consumption 850mA at 12V

550mA at 24V

Max load of the output:

• (stopping) yellow

• (starting motor) black

• (general alarm) red/green

• (auxiliary) brown

• priming pump yellow/blue

• pump clutch white/yellow

3A

40A

3A

3A

3A

3A

Temperature range -10 ÷ +60 °C

Hour-meter 4 digits

Engine oil pressure gauge 0 ÷ 9 bar

Pump water pressure transmitter:

• allowed max. pressure 21 bar

Engine water and oil thermometers +20 ÷ +145°C

Tachometer 4000 rpm

Timer 1’ ÷ 24 h

Serial communication parameters 9600 baud, 8 bit data,1 bit stop, even parity

Rechargeable batteries 2x1,2V type AAA

Installation conditions for external use

Degree of protection box/connector IP54/IP20

Control unit weight 2,2 kg

Weight with control unit mounted on the support 4,6 kg

ELCOS SRL - Parma - CIM-131 - MAN - EN

16

ACCESSORIES ON REQUEST

Type Code

- Support KIT CRU-CIM 40493383

- Speed variator VAR-140 12V 00571543

- Flow switch FAP-100 00500312

ORDERING DATA ACCESSORIES SUPPLIED

Type CIM-131 Codice 00211101

- PRE-WIRED CONNECTOR CIM-130/1/6/7

CODE 70804397

- PUMP WATER PRESSURE

TRANSMITTER TYPE TPA-200 “ 70500255

- NIPPLE F1/4” GAS -M3/8”GAS “ 70190241

- NUTS KIT “ 40179906

support on request

BASE FITTING

Table of contents

Other ELCOS Control Unit manuals

ELCOS

ELCOS CIM-130 Instruction Manual

ELCOS

ELCOS CAM-432 Instruction Manual

ELCOS

ELCOS CAM-685 User manual

ELCOS

ELCOS CIM-137 Instruction Manual

ELCOS

ELCOS CEP-337 User manual

ELCOS

ELCOS CEP-090 User manual

ELCOS

ELCOS CAM 684 User manual

ELCOS

ELCOS DCA-110 User manual

ELCOS

ELCOS DCA-120/10 Owner's manual

ELCOS

ELCOS CIM-137/4G Instruction Manual

Popular Control Unit manuals by other brands

Wheelock

Wheelock ZC-9 installation instructions

Emerson

Emerson EX4 operating instructions

Honeywell

Honeywell VR4920Z 1000 instruction sheet

Wilo

Wilo JetValve Installation and operating instructions

Moxa Technologies

Moxa Technologies WAPN008 user manual

GAMA Electronics

GAMA Electronics PB3-DRC instruction manual