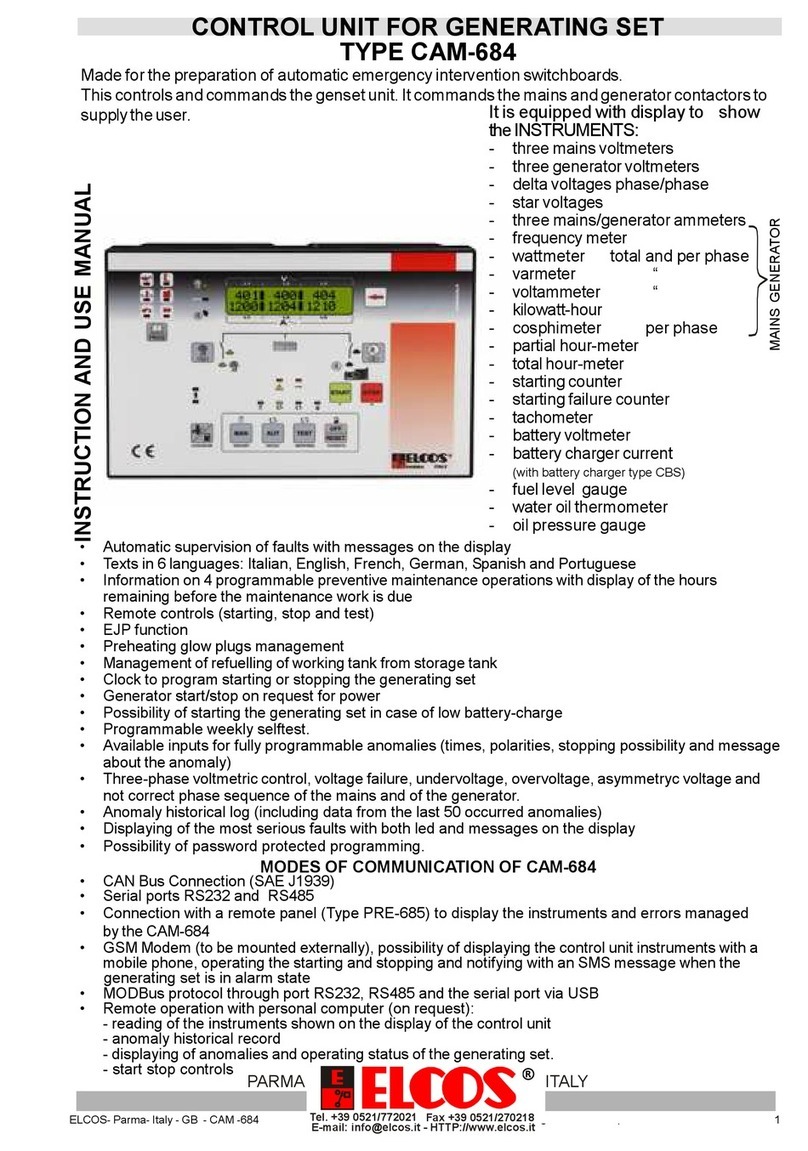

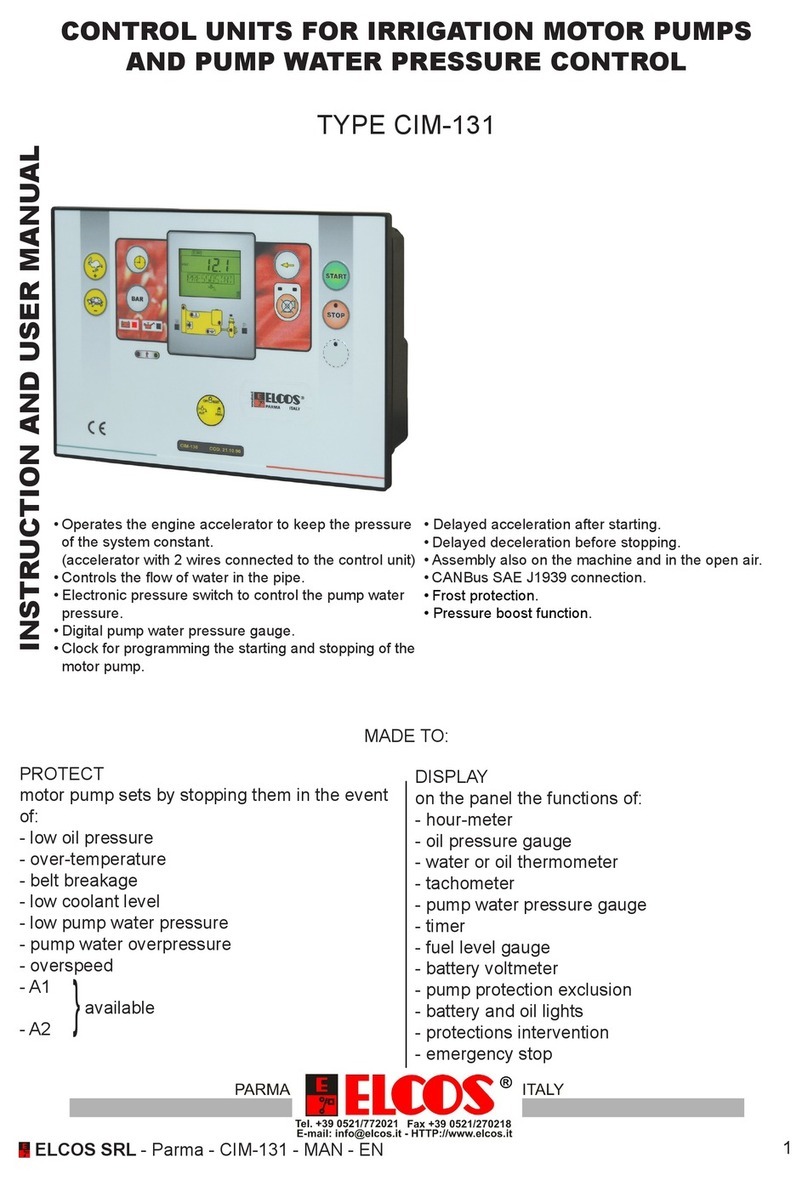

ELCOS CAM-335 User manual

GENSET CONTROL UNIT

CAM-335

Developed to equip automatic emergency panels.

It controls and operates genset, connecting the power user to the mains or generator.

USER’S MANUAL

Functions:

Complete with backlit graphic display with touch

screen to view:

Three voltmeters for the mains.

Three voltmeters for the generator.

Three mains/generator ammeters.

Mains/generator frequency meter.

Generator tachometer.

Mains/generator kW (active), kVAR (reactive)

and kVA (apparent) powers.

Battery voltmeter.

Fuel level gauge.

Water/oil thermometer.

Oil pressure gauge.

Total hour-meter.

Partial hour-meter.

Start-ups counter.

Automatic monitoring of faults with display messages.

Complete three-phase voltmetric control of mains and genset (undervoltage, overvoltage, phase asymmetry,

incorrect phase sequence, underfrequency and overfrequency).

Texts in 7 languages: Italian, English, French, German, Spanish, Portuguese and a programmable language.

CAN Bus Connection SAEJ1939.

RS232, RS485 serial ports and USB.

MOD Bus RTU Protocol.

4-maintenance management.

Management of rental hours.

Remote controls (start, stop, EJP).

Generator start and stop on power demand.

Ability to start generator when the battery charge is low.

Option of associating inputs and outputs with different functions.

Glow plug preheating management.

Management of refuelling of working tank from storage tank.

Clock for programming genset starting or stopping.

Automatic test.

Anomaly log.

Option of password protected programming.

Dimensions (LxHxW) 157x109x74mm

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 2 of 20

TABLE OF CONTENTS

CHRONOLOGY OF MANUAL REVISIONS.........................................................................2

INSTRUCTIONS IN BRIEF..................................................................................................3

INSTRUMENTS...................................................................................................................3

DISPLAY..............................................................................................................................4

OPERATION........................................................................................................................6

CONNECTION DIAGRAM.................................................................................................12

USER PROGRAMMING....................................................................................................14

FAULT LIST.......................................................................................................................17

TECHNICAL SPECIFICATIONS........................................................................................18

WARNING..........................................................................................................................19

INFORMATION FOR ORDERING.....................................................................................20

STANDARD ACCESSORIES ............................................................................................20

ACCESSORIES AVAILABLE ON REQUEST....................................................................20

DOCUMENTATION ON REQUEST ..................................................................................20

DECLARATION OF CONFORMITY....................... Provided in the manual as an attachment

CHRONOLOGY OF MANUAL REVISIONS

Date

Revision

Description

Page

27/07/2015

1.00

First release

05/09/2016

1.05

MAX mains voltage present delay =9999 sec.

12 technical prog.

10/10/2016

1.06

Fault: radiator stops without cooling

8 technical prog.

19/12/2016

1.09

Semi-automatic mode, reset of maintenance cycle, acceptance

of commands via SMS from any telephone number.

6, 16, 18 technical

prog.

23/05/2017

1.10

Exclusion of current transformers

Programming of maximum number of fault SMS

messages

Keyboard error input

Programmable mains contactor fault input

Programmable genset contactor fault input

5,12,18, 20

Technical prog.

1.13

Change automatic test

1, 7, 3, 13

Technical prog.

04/06/2020

1.14

Time synchronization of other control units.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 3 of 20

INSTRUCTIONS IN BRIEF

INSTRUMENTS

The control unit has a backlit 128 x 64 dot graphic display with touch screen. It is used to view the following

instruments:

Three line-to-line mains/generator voltages.

Three star mains/generator voltages.

Three mains/generator ammeters.

Mains/generator frequency meter.

Active (kW), reactive (kVAR) and apparent (kVA) power, for both mains and generator. The powers are

displayed for each phase and as a sum of the phases.

Mains/generator power factor indicator displayed for each phase.

Mains/generator energy counter (kWh).

Battery voltage.

D+ voltage (pre-excitation alternator).

Fuel tank level indicator.

Engine temperature expressed in °C or °F.

Oil pressure expressed in BAR or kPa.

Engine revolutions (RPM).

Total hour-meter.

Partial hour-meter.

Start-ups count.

Starting failure counter.

Maintenance expirations.

Rental hours expirations.

Calendar clock.

Automatic test.

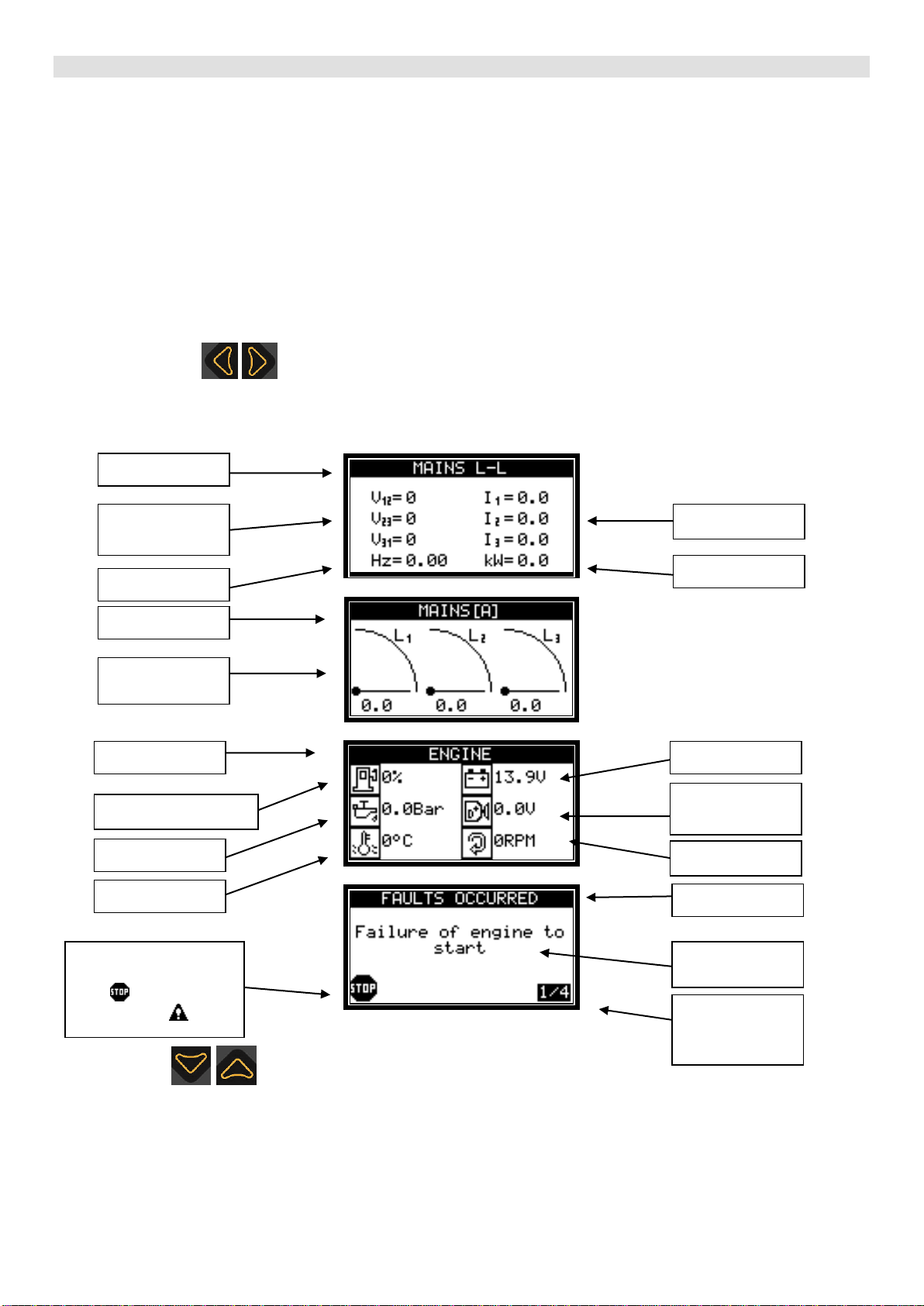

All the instruments for the mains (V, A, Hz and kW) are also displayed simultaneously. Simply pressing the arrows

displays all electrical instruments for the generator and engine. In the event of an anomaly, the display presents the

message indicating the anomaly that has occurred.

Display with

touch screen

Press to start

in manual

mode

Press to stop

in manual

mode

Cumulative

alarm without

stop (yellow)

with stop

(red)

Power from

mains

present

Mains

inserted on

power user

Generator

inserted on

power user

Power from

generator

present

Control unit is

on:

manual

automatic

test

off

Press to select

function:

manual

automatic

test

off (failure reset)

programming

Engine running

Buttons to switch the

power user to mains

or generator (in

manual mode).

Press the arrows to browse display menus.

Acknowledging the general alarm.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 4 of 20

DISPLAY

The instruments displayed on the control unit are divided into groups. The groups are:

Mains

Generator

Engine instruments

CAN Bus instruments (if CAN Bus connection is enabled)

Counters

Maintenance (if maintenance hours have been set)

Rental (if rental hours have been set)

Fuel top-up management (if function is enabled)

Anomalies

Clock

Information about the control unit.

The two arrows are used to scroll through the instrument groups on the display or to select the sub-

menus under the settings.

The following are a few examples of instrument display menus.

The two arrows are used to move within the instrument groups or to scroll through the choices in the

settings menus.

Menu name

Line-to-line

voltages

Frequency

meter

Currents

Active power

Menu name

Fuel level

Temperature

Tachometer

Battery voltage

Pressure

D+ voltage

(input 66)

Icon identifying if

anomaly causes a

stop or does not

cause a stop .

Menu name

Anomaly

occurred

Menu name

Phase currents

Number of

active

anomalies

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 5 of 20

To display instruments individually, simply touch the display on the relevant instrument. For example:

touching the D+ icon with your finger opens the menu that

displays the individual instrument.

To move inside the groups of instruments, you can either touch the arrows or the display. Each press of the button

displays the next instrument in the group.

For example:

and doing so will allow you

to browse through all the instruments.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 6 of 20

OPERATION

FUNCTION SELECTION

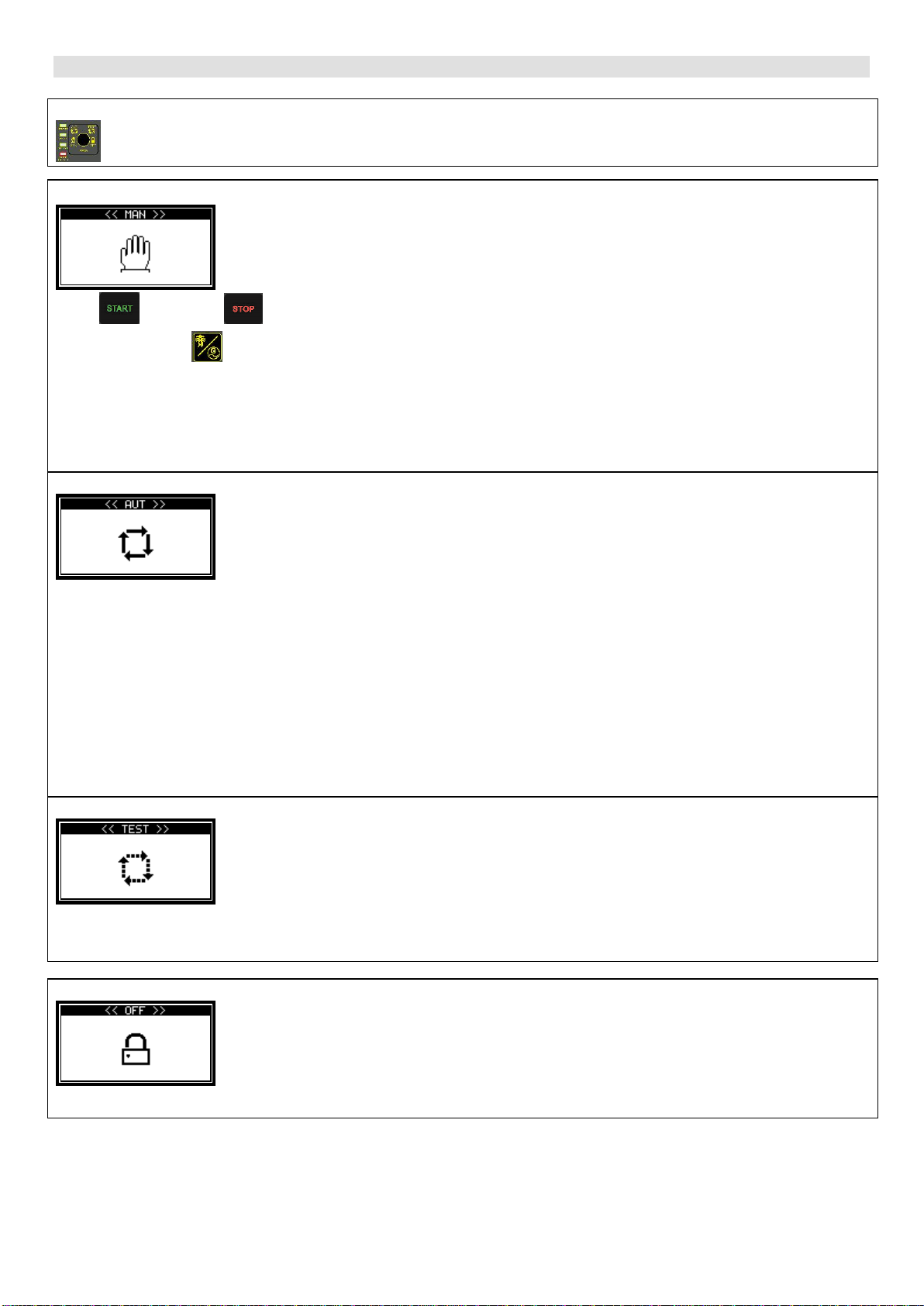

The function selected using the key is indicated by its light which goes on.

MANUAL

Image displayed when switched to manual.

Press to start and to stop (a quick press is sufficient).

Pressing the button switches the load from the mains to the generator and vice versa.

In manual mode, the generator protection function can be programmed in two ways:

Display the fault recorded and stop the engine (this is the default setting).

Only display the fault recorded, without stopping the engine. Generator overspeed and emergency anomalies

are programmed to shut down the engine; they cannot be programmed without engine shutdown.

AUTOMATIC

Image displayed when switched to automatic.

When a mains anomaly occurs —detected by the internal voltage relay inside the control unit or when the

external call delay has elapsed —the control unit commands the mains contactor to open and the genset to start.

With the engine running and with correct generator voltage and frequency, once the G.S. VOLTAGE PRESENT

DELAY has elapsed, the generator contactor is closed. When operating, the genset is protected from any anomalies.

When the mains voltage is restored and the MAINS VOLTAGE PRESENT DELAY has elapsed, the control unit

commands the generator contactor to open and after the GENERATOR MAINS INTERLOCK time has elapsed, the

mains contactor closes.

The COOLING TIME enables and facilitates subsequent engine cooling before it shuts down.

To facilitate start-up, a special circuit determines a series of start-up attempts, the number, pause duration and start-

up duration of which can be programmed. If running of the entire series of start-up attempts is unable to start the

engine, when the cycle is completed, STARTING FAILURE is displayed and the stop cycle starts.

TEST

Image displayed when switched to test.

In testing, the engine start-up cycle is obtained as in automatic mode, with the exception that the user remains

powered from the mains. If, during the test, a mains anomaly occurs, the control unit remains in test mode but

commands the generator contactor to close.

OFF

Image displayed when switched to off. When set to OFF, the engine cannot be started in any

way and, if it is running, it stops without the engine cooling step.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 7 of 20

PROGRAMMABLE OUTPUTS

WARNING!

Outputs 6, 19 and 70 can be associated to many functions (see programming manual under the section

“PROGRAMMABLE OUTPUTS”). It is NOT possible to simultaneously associate more than one function to an

output. For example, if fuel filling is associated to output 70, it is not possible to manage the general alarm from this

terminal and vice-versa. By default, management of glow plugs is associated to output 6, the signal that simulates the

15/54 to output 19, and the general alarm to output 70.

GLOW PLUG PREHEATING

Activation of the glow plug output is adjustable —from a minimum of 0 seconds (command off) to a maximum of

60 seconds —for both automatic and manual mode. Once activation has been completed, the engine start-up

procedure begins. Glow plug post-heating can also be managed, i.e. maintaining output live for a set amount of time,

even after the engine has been started (see programming manual).

ENGINE TYPES

The control unit can manage start-up of both diesel and petrol engines. Diesel engines allow for the connection of

the CAN bus line to the control units with electronic injection. For choice of engines, see the programming manual.

AUTOMATIC TEST

The automatic test is enabled only with the control unit on automatic. During the test, the generator set starts up

and stays running for the AUTOMATIC TEST DURATION time (programmed at 3 minutes). If a mains anomaly

occurs, the generator contactor closes. The display shows AUTOMATIC TEST during the test cycle. You can also

choose whether to run a commutation or not during the test (default setting: no commutation). Press STOP to stop the

engine during the test. The test will not be run if there is an anomaly. The automatic test can be performed in two

ways:

WEEKLY: the test will be run weekly at the time and on the day set.

MEASURED: the test can be programmed to run at cycles ranging from 1 to 30 days. The default setting is 7 days.

To enable the test, just enter User Programming and include the function. Once any one of the test parameters has

been set, it starts for the first time when one minute after quitting the setting mode has elapsed. If at that time the

conditions for starting the test are not present (e.g. because the control unit is not on automatic), the test will be run

at the next deadline. The time count starts all over again when the control unit is reset.

ENGINE RUNNING DETECTION

Engine running is detected by revealing the residual generator frequency and voltage and by detecting the

voltage and frequency of the battery charger alternator (permanent or pre-excitation magnets). When an engine with

electronic management is connected to the control unit, detection of the running engine occurs when the RPM read by

the CAN Bus line exceed the RUNNING ENGINE THRESHOLD RPM. Once detected, the starter motor switches off

and the green LED lights up

STOPPING SYSTEMS

Stopping can be achieved in two ways:

With the electromagnet or solenoid valve energized when the engine is running and de-energized when the

engine is stopped (default setting).

With the electromagnet de-energized when engine is running and energized when it is stopped, remaining in

this condition for the entire STOPPING TIME after engine not running has been detected.

If, after 120 seconds from receipt of the stop command, the control still detects the engine running signal, the

STOPPING FAILURE trips.

EMERGENCY STOP

This is available in all operating modes. It is possible to install (hook mount) one or more buttons. Stopping is

immediate, without engine cooling; it activates the general alarm and EMERGENCY STOP is displayed.

Do not use the emergency button in combination with a stopping system that is not energized while

running.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 8 of 20

GENERAL ALARM

The general alarm can be obtained by installing a signal at the appropriate alarm terminal. It can be programmed

so that it is always on or remains on for a specific amount of time. It trips whenever the control unit detects an

anomaly. Pressing one of the arrows silences the alarm.

GENSET AND USER PROTECTIONS

Tripping of an anomaly is shown on the display and can cause the engine to cut out and activates the general

alarm. See the FAULT LIST table on page 17.

Normally the display shows the genset instruments; in the event of an anomaly, it displays the anomaly message

triggered. If the anomaly causes a stop, the red LED flashes and the icon lights up; if the anomaly does not cause

a stop, the yellow LED flashes and the icon lights up

If the anomalies are detected by the CAN Bus line connected to the engine’s electronic injection control unit, the

yellow and red LEDs light up and remain steady on.

Press the ARROW to review the instruments on the display and, at the same time, silence the general alarm, use one

of the 4 navigational arrows. After 20 seconds have elapsed since the last time the key was pressed, the display

reverts back to displaying the anomaly/anomalies that have occurred.

When OFF RESET lights up, the anomalies can be reset by pressing the key . If the OFF function is disabled,

press the key to reset the anomalies.

PREVENTIVE MAINTENANCE

When preventive maintenance operations are to be carried out, the flashing alarm light goes on and the

maintenance number that intervened is displayed along with the description set beforehand. If programmed, stopping

is also achieved with PROTECTION IN MANUAL bypassed and with the PROTECTION INHIBITION input active. The

procedure for resetting expired maintenance is to be performed only by genset manufacturer.

RENTAL FUNCTION

It is possible to programme the number of genset rental hours; after this time has elapsed, the control unit can

immediately block genset operation or can block it at the next start-up. If programmed, stopping is also achieved with

PROTECTION IN MANUAL bypassed and with the PROTECTION INHIBITION input active. Rental hours are counted

down when the engine is running.

STARTING GENSET WITH LOW BATTERY

When the battery is low, the genset can only be started up in automatic mode. When the voltage measured at the

battery terminals is below the minimum threshold, the engine will start and remain running until the maximum

threshold has been exceeded and the programmable delay time has elapsed.

START ON POWER REQUEST

The genset can only be started up on power request function when in automatic mode. When the power

absorbed by the power user is higher than the set threshold for the whole duration of the cut-in delay, the control unit

starts the generator set and switches the user to the generator. When the power absorbed by the power user is lower

than the set threshold for the whole duration of the cut-in delay, the control unit stops the generator set and switches

the user to the generator.

DAILY STARTING-STOPPING

The functions managed by the control unit’s internal clock are only active in automatic mode. Up to 10 genset

starts can be programmed, with relative switching of the power user to the generator at certain daily time slots.

It is also possible to program a genset lockout at a certain daily time slot.

CALL INPUT (TERMINAL 30)

Call input is active with control unit in automatic and test modes. When the contact closes to ground, operation is

the same as that of a mains failure.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 9 of 20

START INPUT (terminal 32)

The start input is active with control unit in automatic mode. When the contact closes to ground, REMOTE

START is shown on the display. When the REMOTE START DELAY time elapses, operation is the same as that of a

mains failure. When the start contact opens, operation is the same as when the mains power is restored. Other

functions can be associated to this input; see the programming manual.

STOP INPUT (TERMINAL 33)

The stop input is active with control unit in automatic mode. When the contact closes to ground, REMOTE STOP

is shown on the display. The control unit does not permit any start-up and, if the genset is running, it stops. Other

functions can be associated to this input; see the programming manual.

PROGRAMMABLE INPUTS (TERMINALS 41 and 42)

Inputs 41 and 42 are completely programmable (see the programming manual). The following settings are

possible:

Function, Text, Intervention delay, Stop, Cooling, Storage, Polarity, Activation.

MESSAGES AND CAN BUS INSTRUMENTS

Every message or instrument appearing on the display having to do with the injection control unit and read by the

CAN Bus line can be identified by the characters [ECU] shown in the lower right corner.

Anomaly messages are shown on the display as SPN, FMI and OC: SPN is a number identifying a particular

component of the diesel engine; FMI is a number identifying the failure or malfunction of the SPN component; OC

identifies the number of times this particular problem occurred in the engine.

If CAN Bus line connection between the two control units is interrupted, the message CAN Bus ANOMALY will

appear.

The instruments managed and displayed by the CAM-335 control unit are:

Instrument

Description

U.M.

Tachometer

Engine revolutions.

RPM

Oil pressure

Engine oil pressure.

BAR

kPa

Engine temperature

Engine water or oil temperature.

°C

°F

Fuel consumption

Amount of fuel consumed by the engine per unit of time.

l/h

Fuel temperature

Fuel temperature at injector inlet.

°C

°F

Turbo temperature

Temperature of turbo compressor oil.

°C

°F

Oil temperature

Temperature of engine oil.

°C

°F

Intercooler temperature

Temperature of fluid in the intercooler downstream the turbo

compressor.

°C

°F

Intake temperature

Temperature of pre-combustion air.

°C

°F

Coolant level

Coolant level.

%

Fuel pressure

Pressure of the fuel between the fuel pump and the injection

pump.

BAR

kPa

Coolant pressure

Pressure of coolant in the cooling system.

BAR

kPa

Engine torque

Engine output torque percentage.

Nm

Engine power

Power developed by the engine.

kW

Fuel level

Indicates fuel level

%

Oil level

Level of oil in the engine.

%

Electronic engines currently managed are: John Deere, Perkins, Scania, Volvo, Deutz, FPT, VM, Cummins and MTU.

ENGINE HEATING

Function can be activated in SCANIA engines with CAN Bus connection. It warms up the engine at idling speed

after it starts. The function takes both engine temperature and set time into account. When the engine reaches the set

temperature or set time, the control unit speeds up the engine to rated speed. This default function is disabled. See

the programming manual for instructions on how to set the temperature threshold and time. Heating can also be

managed for mechanical engines by activating the function in a programmable output and connecting an

electromagnet to the engine.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 10 of 20

EJP FUNCTION

To activate the EJP function, see the programming manual. It is only active in automatic mode. When the contact

connected to terminal 32 closes to ground, EJP STARTUP is shown on the display. After the EJP STARTING DELAY

has elapsed (set to 25 minutes), the start-up cycle begins. When the contact connected to terminal 33 closes to

ground, EJP SWITCHING CONSENT is shown on the display and operation is the same as that of a mains failure.

When the two contacts open, operation is the same as when mains power is restored.

VOLTMETRIC CONNECTIONS

The control unit can be configured to manage THREE-PHASE, TWO-PHASE and SINGLE-PHASE voltages. This

selection is valid both for the mains and for the generator; therefore, it is possible to manage, for example, three-

phase voltage from the mains and two-phase from the generator. When the mains power is three-phase, the phases

must be connected to terminals 91, 92 and 93 and the neutral to terminal 90. With two-phase connection, terminals

91 and 92 must be connected and the neutral must not be connected. Instead, with the single-phase connection, the

phase must be connected to terminal 92 and the neutral to terminal 90. Likewise, when the generator power is three-

phase, the phases must be connected to terminals 96, 97 and 98 and the neutral to terminal 95. With two-phase

connection, terminals 96 and 97 must be connected and the neutral must not be connected. Instead, with the single-

phase connection, the phase must be connected to terminal 97 and the neutral to terminal 95.

MAINS/GENERATOR VOLTMETRIC RELAYS

The voltmetric relays are located inside the control unit and serve to control the mains and genset voltages and

frequencies. The parameters considered are: power failure, undervoltage, overvoltage, asymmetrical voltages,

incorrect phase sequence, under-frequency and overfrequency.

Mains voltmetric relay: when each parameter has been accepted individually, after the mains voltage present

delay has elapsed (programmed to 100 seconds), if the genset is running, it stops and the mains contactor is

energized.

Generator voltmetric relay: when each parameter has been accepted individually, after the generator voltage

present delay has elapsed (programmed to 7 seconds), the generator contactor closes. It takes just one

parameter outside the normal range to de-energize the generator contactor.

FUEL FILLING MANAGEMENT

When the automatic fuel filling function is enabled, a dedicated menu is displayed. With filling, the fuel is

transferred from a storage tank to the genset tank. Either automatic mode, manual mode or filling lockout can be

selected using the display touch screen. The filling function is managed independently, meaning it does not depend

on the control unit’s operation mode. It is possible to enable filling either when the genset is powered or when the

user is powered. A contact float controls the maximum safety level. Another float with variable resistance (terminal

37) manages activation and deactivation of the output for pump and/or solenoid valve piloting. If the function is

enabled by default, the pump relay piloting output is associated to terminal 70, while the maximum level float input is

associated to terminal 41.

To change the filling management operation mode, simply press “AUT”, “MAN” or “OFF” on the display. The mode is

saved in the control unit even if the battery gets disconnected.

Automatic filling: when the level of fuel drops below the “minimum level”, the output is

enabled and MINIMUM FUEL LEVEL appears on the display. When the “maximum level” is

exceeded, the output is disabled and MAXIMUM FUEL LEVEL appears on the display.

Manual filling: pressing the START button on the display enables the filling output; taking the

finger off the button disables the output.

Filling OFF: turns filling off; the output, if enabled, is disabled.

Request the connection diagram, which can also be downloaded from the website www.elcos.it.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 11 of 20

FICTITIOUS LOAD MANAGEMENT

This allows inserting a minimum load when the power absorbed by the power user does not exceed the

threshold. When the function is enabled and with the engine running and normal electrical parameters, the “fictitious

load” output and, where required by the mode, the genset’s contactor, are activated simultaneously. Fictitious load

remains on as long as the power absorbed by the power user does not exceed the off threshold. When the power

exceeds the threshold, fictitious load is disabled. It will be enabled once again when the user power drops below the

activation threshold. Request the connection diagram, which can also be downloaded from the website www.elcos.it

IMMINENT START WARNING

With the exception of start-ups due to power failure or closing of a call contact, every automatic start-up is

preceded by the intermittent activation of the general alarm output for 8 seconds; then, 3 seconds later, the start-up

cycle begins. If a buzzer is connected to this output, the operator is notified that start-up is imminent. This function

can be bypassed. Warning: the output can be associated to other functions; see the programming manual.

PASSWORD

Access to technical settings is password activated. There are 7 password levels, each level gives access to

different settings. The default password settings are all “0000” and it is possible to enter the settings without entering

any other codes, except for level 7. To change the codes and activate the passwords, see the programming manual.

The list of the 7 levels is given below:

1. The operator can read all the settings but cannot edit them.

2. Access in editing mode to rental hours and history log from maintenance hours.

3. Access only for resetting expired maintenance.

4. Access only for resetting expired rental blocks and for GSM block.

5. The operator can read and edit all settings.

6. Access in editing mode to total operating hours.

7. Access to the device menu.

For example: if we wish to prevent the operator from modifying the total operating hours, we must set a different

password to “0000” in level 6, for example “1234”. Doing this, we can enter the technical settings using the default

password (“0000”), but will not have access to the operating hours. To access the operating hours menu we must

enter the password “1234”.

SERIAL NUMBER (ID)

It is possible to programme an alphanumeric serial code in the control unit. This number is displayed every time

the control unit is switched on; it can be read in the INFORMATION menu or by pressing the left arrow for 4 seconds.

Refer to the programming manual.

SERIAL PORTS

The control unit has 4 serial ports: RS232, RS485, USB 2.0 and CAN Bus.

RS232: used to connect the control unit:

oto a personal computer, for setting parameters with the ZW-100-PR software

oto a personal computer for the ZW-100 remote operation software

oto Ethernet interface with the ZW-100 remote operation software

oto GSM modem for text message management.

RS485: used to communicate with:

oinput/output expansion modules

othe remote panel

othis port can be used in slave mode so that an external device can poll the control unit using the MOD

Bus RTU protocol.

USB 2.0: used to connect the control unit:

oto a personal computer, for setting parameters with the ZW-100-PR software

oto a personal computer for the ZW-100 remote operation software.

CAN Bus: used to connect the control unit to the CAN Bus line of electronic engines with SAE J1939 protocol.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 12 of 20

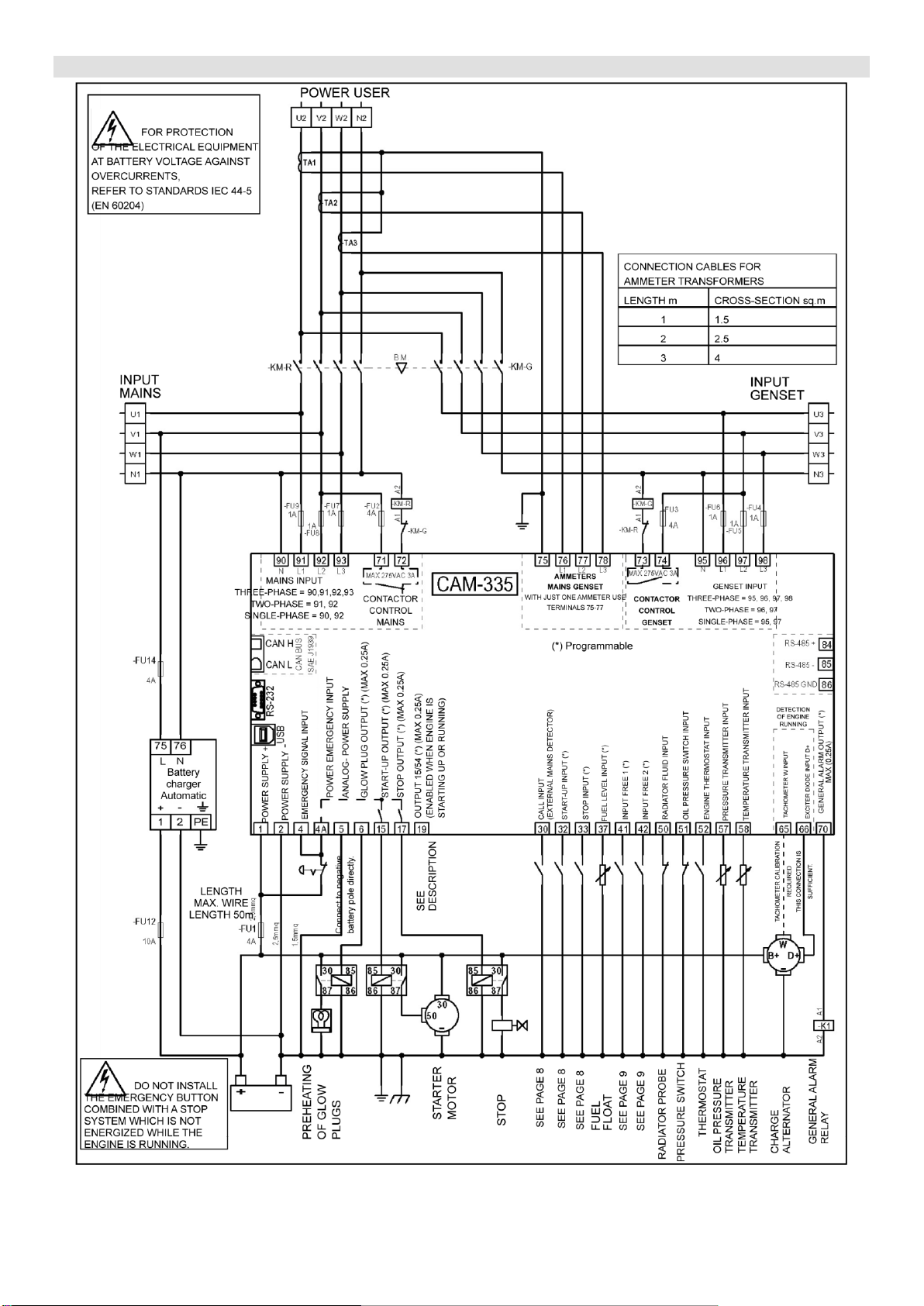

CONNECTION DIAGRAM

Basic diagram for illustration purposes, subject to change without notice.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 13 of 20

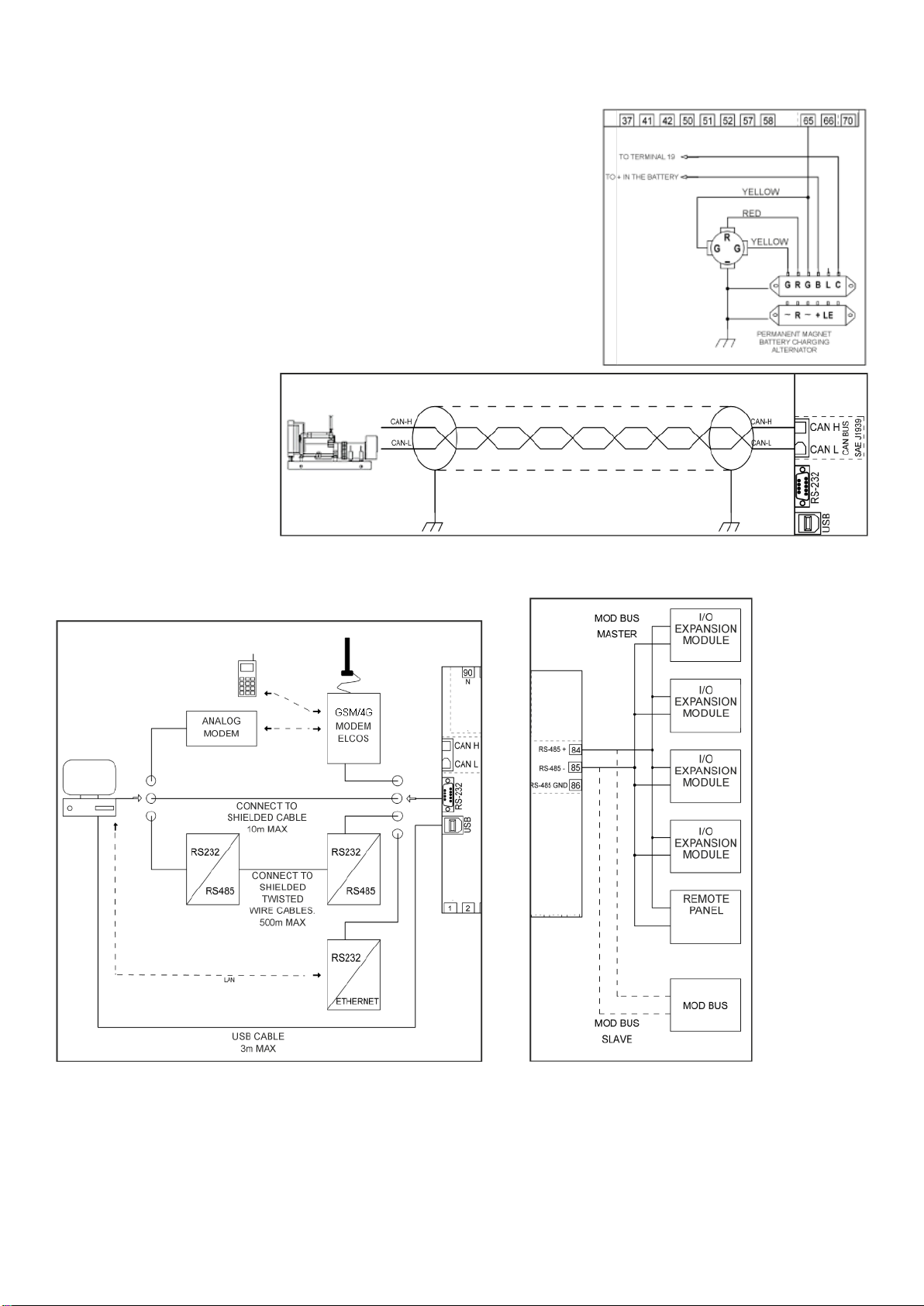

Detail of connection of the control unit to a permanent magnet battery charger alternator. For different controllers,

request diagram.

Detail of connection of the

control unit to an electronic

engine via CAN Bus. Use an

insulated twisted-wire cable

not longer than 40 metres. For

additional details, request the

diagrams for the specific

engines.

In the manual for the control unit (ECU/ECM), read if inserting the 120ohm 1/4W termination resistor, engine side,

between the CAN-H and CAN-L wires is required.

Once the connections have been made and powered, the control unit is set to OFF. See programming to

change this status.

The above diagram indicates the different

types of connections for the RS232 port.

The RS485 serial port can act as a master

to manage expansions and / or time

synchronization of other control units,

horaire, as a slave to be polled by external

devices.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 14 of 20

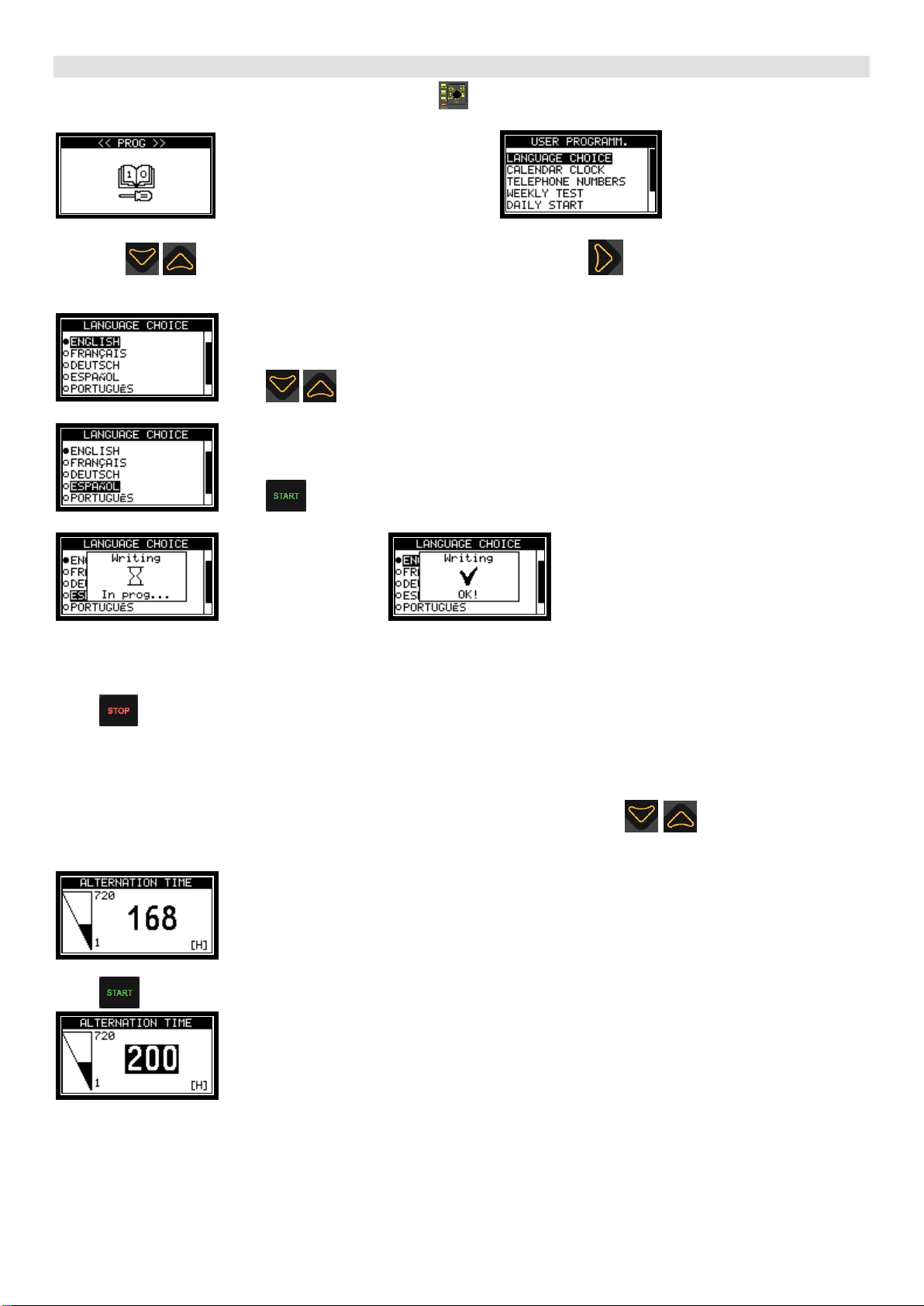

USER PROGRAMMING

To access user programming, press the FUNCTION key and keep it pressed until “PROG” appears on the

display.

Release the button. After a few seconds appears

Press the arrows to scroll through the programming menus. Press to enter the desired sub-menu. For

example:

Press to scroll through the programming items. For example:

Press to confirm the selection. The following appears:

Wait for a few seconds:

The chosen parameter is now programmed in the control unit. The settings are stored in a non-volatile memory, and

are therefore maintained even if the power is switched off. The value can be modified at any time by repeating the

procedure as described above.

Press to return to the previous menu and then proceed to program the other parameters.

Programming a numerical parameter.

When programming a numerical parameter, such as a threshold or a time, press to increase or decrease

the parameter.

Press to confirm the value. When the number is saved in the control unit, it changes colour.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 15 of 20

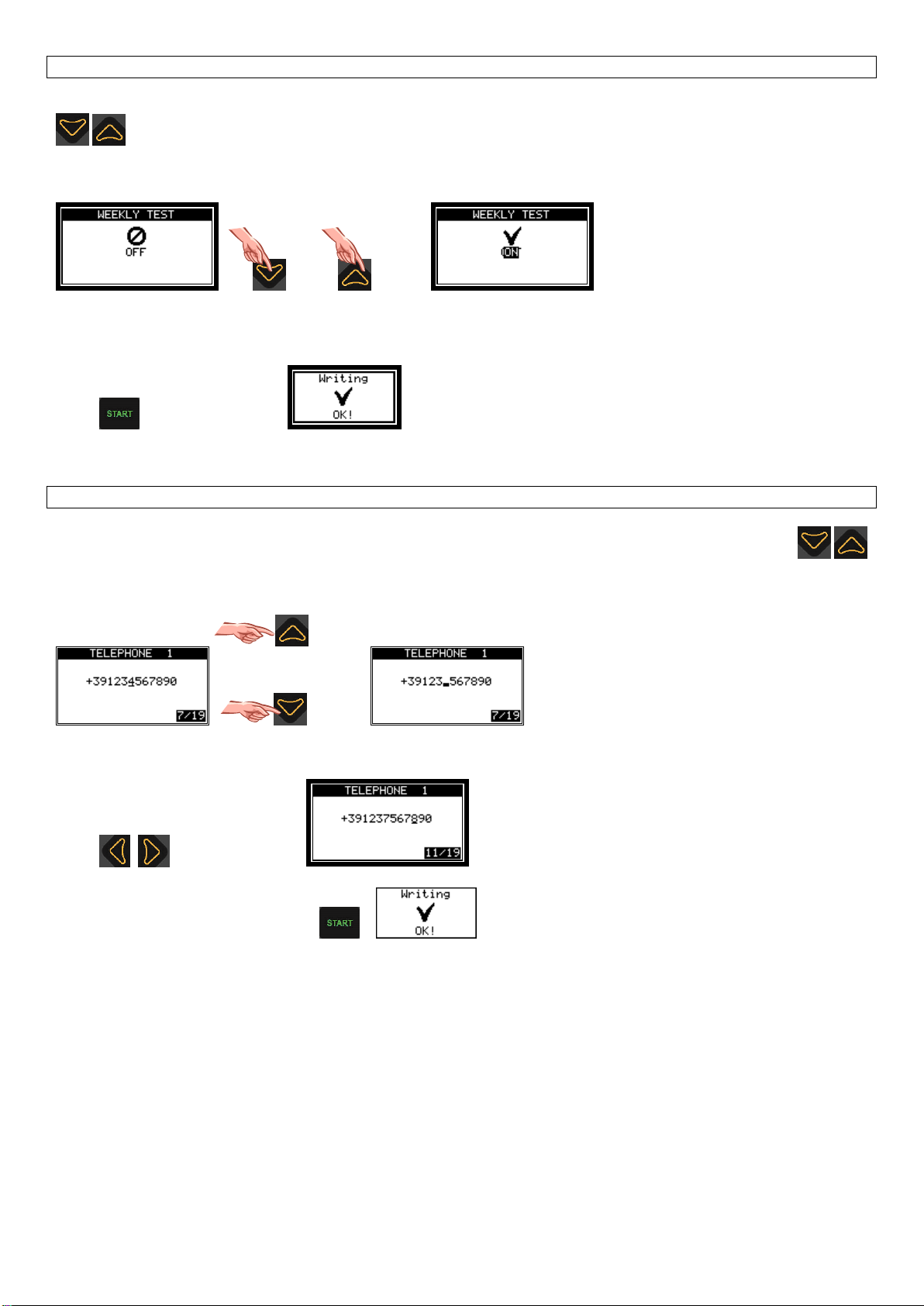

Enabling/disabling a parameter.

When programming a binary parameter (enabled/disabled), for example, enabling the weekly automatic test, press

to enable or disable the parameter. For example:

or

Press to confirm the value.

Programming a number.

When programming a numerical code such as, for example, telephone numbers for the GSM modem, press

to edit the number indicated by the cursor. For example:

Press to move the cursor

Confirm the programming by pressing .

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 16 of 20

User-programmable parameters are:

Parameter

Range

Default setting

Notes

LANGUAGE CHOICE

ITALIAN

ITALIAN

A CUSTOM language

cannot be selected unless

the messages have been

programmed with the

software

ZW-100-PR.

ENGLISH

FRENCH

GERMAN

SPANISH

PORTUGUESE

CUSTOM

CLOCK/CALENDAR

Standard

Calendar clock adjustment.

TELEPHONE NUMBERS

TELEPHONE 1

16 digits

Empty

Telephone numbers to

which text messages will be

sent with the GSM modem.

TELEPHONE 2

16 digits

Empty

TELEPHONE 3

16 digits

Empty

WEEKLY TEST

OFF

OFF

ENGAGED

DAILY START

START 1

00:00 ÷ 23:59

--:-- ÷ --:--

With --:-- ÷ --:-- starting is

off.

START 2

00:00 ÷ 23:59

--:-- ÷ --:--

START 3

00:00 ÷ 23:59

--:-- ÷ --:--

START 4

00:00 ÷ 23:59

--:-- ÷ --:--

START 5

00:00 ÷ 23:59

--:-- ÷ --:--

START 6

00:00 ÷ 23:59

--:-- ÷ --:--

START 7

00:00 ÷ 23:59

--:-- ÷ --:--

START 8

00:00 ÷ 23:59

--:-- ÷ --:--

START 9

00:00 ÷ 23:59

--:-- ÷ --:--

START 10

00:00 ÷ 23:59

--:-- ÷ --:--

DAILY STOP

00:00 ÷ 23:59

--:-- ÷ --:--

With --:-- ÷ --:-- stopping is

off.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 17 of 20

FAULT LIST

The complete list of anomalies managed by the control unit is given below.

Fault

code

Description

Occurs when:

111

MAINTENANCE 1

Maintenance 1 expired.

112

MAINTENANCE 2

Maintenance 2 expired.

113

MAINTENANCE 3

Maintenance 3 expired.

114

PROGRAMMED MAINTENANCE

Programmed maintenance expired.

115

RENTAL HOURS

The rental hours have expired.

120

BATTERY UNDERVOLTAGE

The battery voltage is lower than the set threshold.

121

BATTERY OVERVOLTAGE

The battery voltage is higher than the set threshold.

122

ENGINE LOW TEMPERATURE

The engine has not reached the set temperature.

123

OVERTEMPERATURE PRE-ALARM

The engine has exceeded the overtemperature pre-alarm threshold.

124

PRE-ALARM

The engine has exceeded the overtemperature threshold read by the

transmitter.

125

THERMOSTAT OVERTEMPERATURE

The engine thermostat has cut in.

126

MAXIMUM FUEL LEVEL

The maximum top-up level contact float has cut in.

129

FUEL RESERVE

The fuel level is lower than the reserve threshold.

130

NO FUEL

The fuel level is lower than the set threshold.

131

LOW OIL PRESSURE PRE-ALARM

The engine oil pressure does not exceed the set threshold.

132

LOW OIL PRESSURE

The engine oil pressure switch has cut in.

133

STOPPING FAILURE

Detects that engine is running even if the stopping system has been

activated.

135

LOW RADIATOR LEVEL

Insufficient radiator coolant.

136

CHARGING ALTERNATOR

The output “D+” or “W” on the charging alternator does not work.

137

STARTING FAILURE

The control unit has attempted to start the generator, but the engine is not

running.

139

OVERSPEED

The RPMs detected by the control unit have exceeded the set threshold.

140

FUEL FLOAT INTERRUPTED

The electrical circuit for the fuel float is interrupted.

141

OIL PRESSURE SWITCH ANOMALY

The oil pressure switch contact is open with the engine switched off.

220

GENERATOR UNDERVOLTAGE

The genset voltage is lower than the set threshold.

221

GENERATOR OVERPOWER

The power absorbed by the generator has exceeded the alarm threshold.

222

GENERATOR OVERVOLTAGE

The genset voltage is higher than the set threshold.

223

GENERATOR UNDERFREQUENCY

The genset Hz value is lower than the set threshold.

224

GENERATOR OVERFREQUENCY

The genset Hz value is higher than the set threshold.

225

GENERATOR OVERLOAD PRE-ALARM

The current absorbed by the genset has exceeded the pre-alarm

threshold.

226

GENERATOR OVERLOAD

The current absorbed by the genset has exceeded the alarm threshold.

227

GENERATOR NOT DELIVERING

Although running, the genset does not deliver voltage.

228

GENERATOR CONTACTOR FAULT

The generator contactor does not open or close.

230

GENERATOR PHASE SEQUENCE

The sequence of the three genset phases is not correct.

231

GENERATOR ASYMMETRY

The voltages between the three genset phases are not similar.

322

MAINS CONTACTOR FAULT

The mains contactor does not open or close.

323

MAINS PHASE SEQUENCE

The sequence of the three mains phases is not correct.

325

MAINS OVERLOAD

The current absorbed by the mains has exceeded the alarm threshold.

419

EMERGENCY STOP

The emergency button has been pressed.

421

AVAILABLE ANOMALY 41

The anomaly associated with programmable input 41 has occurred.

422

AVAILABLE ANOMALY 42

The anomaly associated with programmable input 42 has occurred.

426

AVAILABLE ANOMALY 32

The anomaly associated with programmable input 32 has occurred.

427

AVAILABLE ANOMALY 33

The anomaly associated with programmable input 33 has occurred.

430

CAN BUS

The control unit does not receive data from the CAN Bus line.

431

ENGINE CONTROL UNIT

Engine fault detected by the electronic control unit (ECU).

443

FUEL FLOAT TABLE ERROR

The float table has been programmed with errors.

446

OIL PRESSURE TRANSMITTER TABLE ERROR

The oil pressure transmitter table has been programmed with errors.

447

TEMPERATURE TRANSMITTER TABLE ERROR

The temperature transmitter table has been programmed with errors.

449

KEYBOARD ERROR

The control unit turns on with at least one button pressed.

500

NO GSM MODEM

The GSM modem does not communicate with the control unit.

501

SIM NOT INSTALLED

There is no SIM card installed in the GSM modem.

502

SIM BLOCKED

The PIN code of the SIM Card installed in the modem is active.

503

GSM CODE ERROR

The GSM modem has detected a coded error.

504

GENERIC GSM ERROR

The GSM modem has detected a non-coded error.

505

NO REMOTE PANEL COMMUNICATION

The remote panel does not respond to the control unit data request.

506

I/O EXP. 1 FAULT

The input/output expansion module does not respond to the data request.

507

I/O EXP. 2 FAULT

The input/output expansion module does not respond to the data request.

508

I/O EXP. 3 FAULT

The input/output expansion module does not respond to the data request.

509

I/O EXP. 4 FAULT

The input/output expansion module does not respond to the data request.

510

RTCK SYBCHR.1 FAILED

RTCK synchronization of control unit 1 failed.

511

RTCK SYBCHR.2 FAILED

RTCK synchronization of control unit 2 failed.

512

RTCK SYBCHR.3 FAILED

RTCK synchronization of control unit 3 failed.

513

RTCK SYBCHR.4 FAILED

RTCK synchronization of control unit 4 failed.

556

BLOCK VIA GSM

The control unit is blocked by a text message command.

-

MDE-088 [01 –32]

The error associated to I/O module programmable input has occurred.

-

EEPROM ERROR

Failed access to the static memory.

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 18 of 20

TECHNICAL SPECIFICATIONS

Power supply

Suitable for batteries

12Vdc

24Vdc

Operating range

8 ÷ 48Vdc

Absorption with engine not running

130mA to 12Vdc

90mA to 24Vdc

Voltage dip on battery power supply

From 10Vdc to 0Vdc for 250ms

Digital inputs

Type of input

Negative

Maximum current supplied

0.30mA

Voltage threshold for low signal

≤ 0.2Vdc

Voltage threshold for high signal

≥ 2Vdc

Terminal input 65

AC voltage

5.5 ÷ 65Vac

Measurement range

50 - 1500Hz

Mains and generator voltmetric inputs

Dielectric strength voltage between battery voltage circuits and

mains/generator voltage circuits

3750Vac 50Hz 1sec

Rated insulation voltage

Mains voltage terminal

600Vac

Genset voltage terminal

600Vac

Battery voltage terminal

48Vac

Insulation class

1

Measurement range

80 ÷ 570Vac (three-phase)

45 ÷ 340Vac (single-phase)

Accuracy

±1%

Frequency meter

Measurement range

45 - 85Hz

Accuracy

±0.1Hz

Amperometric inputs

Measurement range

20mA ÷ 6Aac

Amperometric transformer ratio

/5

Maximum displayable current

4800Aac

Accuracy

±1%

Digital outputs

Type of output

Positive (battery voltage)

Maximum load

Terminal 6, 15, 19, 70.

0.25 A

Terminal 17

1.5 A

Contactors command outputs

Type of output

Dry contact

Maximum applicable voltage

275Vac

Maximum load

3 A

Displayed powers (kW, kVAR, kVA, kWh)

Accuracy

±2%

Engine instruments

Oil pressure

0 ÷ 360Ohm

0.0 ÷ 9.0BAR

0 ÷ 900kPa

Temperature

0 ÷ 3000Ohm

0 ÷ 140°C

0 ÷ 284°F

Fuel level

0 ÷ 360Ohm

0 ÷ 100%

Accuracy (pressure gauge, thermometer, fuel level)

±2%

Lines of communication

RS232 (No optoisolator)

Baud-rate

1200 ÷ 115200 bps

Parity

None/even

RS485 (No optoisolator)

Baud-rate

1200 ÷ 115200 bps

Parity

None/even

USB 2.0 (Micro USB-B)

Interface

Not isolated. Maximum cable length 3 m.

CAN Bus (No optoisolator)

Baud-rate

250kbps

Protocol

SAE J1939

Environmental conditions

Operating temperature

-20 ÷ 60°C

Storage temperature

-20 ÷ 60°C

Relative humidity

≤ 80%

Vibration resistance

1g on the 3 axes (CEI EN 60068-2-6)

Impact resistance

15 on the 3 axes (CEI EN 60068-2-27)

Protection class

Back

IP 20

Front

IP 64

Container

Weight

480g

Dimensions (LxHxW)

157x109x74mm

Perforations

137x88 mm

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 19 of 20

WARNING

Performs only genset control and command functions. It controls the mains and generator contactors for user power supply. It is

designed solely to be built into an electrical panel and connected to the other components (contactors, fuses, thermal magnetic

switches, etc.) the installer has arranged to complete the system.

Attention: Parts powered with dangerous voltages

The control unit can only be accessed by specifically assigned, duly trained personnel. Maintenance

operations cannot be performed unless the system is disconnected from the mains and the battery. As an

additional protection measure, we recommend grounding the system phases.

Notwithstanding the above, only specifically assigned, duly trained personnel can perform the following

operations with the system powered:

-visual inspection of control unit connections and markings;

-taking voltage and/or current measurements;

-function programming.

These works must always be performed using equipment that ensures appropriate electrical protection.

Warning:

Compliance with the following recommendations is obligatory

- Always make connections following the wiring diagram shown on page 12-13.

- All works performed on the unit must be carried out with the engine off and with starter motor terminal 50 disconnected.

- Check the consumption of the connected devices is in line with the described technical specifications.

- The installation must always guarantee adequate dissipation of heat.

- Always install the device at a lower position than any other devices that produce or dissipate heat.

- Handle and connect without exposing the electronic circuit board to mechanical strain.

- Do not let cuttings of copper conductors or other metal residues drop onto the control unit.

- Never disconnect the battery terminals while the engine is running.

- Strictly avoid using a battery charger for emergency start-up; this could damage the control unit.

- To safeguard persons and equipment, always disconnect the electrical system terminals from the battery poles before

connecting an external battery charger.

THIS UNIT IS NOT SUITABLE FOR WORKING UNDER CONDITIONS WHERE:

- The room temperatures exceeds the limits specified in the technical data sheet.

- Abrupt shifts in temperature and air pressure produce exceptional condensation.

- There is high pollution caused by dust, fumes, vapour, salts and corrosive or radioactive particles.

- There is high radiation of heat due to direct sunlight, ovens or the like.

- You suspect the presence of mould or pests.

- There is a danger of fire or explosion.

- Strong shocks or vibrations can be transmitted to the control unit.

- The control unit is protected by barriers or casings with a protection rating below IP40.

ELECTROMAGNETIC COMPATIBILITY

This control unit works correctly only if it is installed in systems that comply with regulations governing CE marking; in fact,

it complies with the immunity requirements given in EN61326-1, but this does not rule out the possibility that

malfunctions could occur in extreme cases that may arise in particular situations.

The installer is responsible for checking that the level of perturbation does not exceed that specified in standards.

OPERATION AND MAINTENANCE

We recommend the following maintenance on a weekly basis:

-signal operation checks;

-battery status checks;

-conductor tightness and terminal status checks.

IN THE ABSENCE OF OUR WRITTEN DECLARATION ATTESTING TO THE CONTRARY, THIS UNIT IS NOT SUITABLE FOR USE AS A

CRITICAL COMPONENT IN EQUIPMENT OR SYSTEMS VITAL TO THE LIFE OF PEOPLE AND OTHER LIVING THINGS.

YOUR ELECTRICIAN MAY TELEPHONE OUR TECHNICAL SERVICE WITH ANY QUESTIONS REGARDING THIS CONTROL

UNIT

________________________________________________________________________________________________________

ELCOS –Parma –Italy –CAM-335 Valid for firmware revision 1.14 and above Page 20 of 20

INFORMATION FOR ORDERING

Type

Item Code

CAM-335

00242262

STANDARD ACCESSORIES

Type

Item Code

KIT MU CAM-335

40804479

ACCESSORIES AVAILABLE ON REQUEST

Type

Item Code

EXPANSION MODULE MDE-088

00242269

ETHERNET INTERFACE ZE-100

00070227

GSM MODEM AMD-RB900 PRO

00070218

Programming software ZW-SMART

00070212

DOCUMENTATION ON REQUEST

Downloadable from the website www.elcos.it/

Diagram

number

Petrol engine diagram

00000731

Automatic fuel filling diagram

00000732

Fictitious load diagram

00000733

Connection diagram with expansion modules

00000734

Connection diagram with voltage transformers

00000735

Connection diagram with contact float

00000736

List of MOD Bus CAM-335 addresses

Other manuals for CAM-335

1

Table of contents

Other ELCOS Control Unit manuals

ELCOS

ELCOS DCA-110 User manual

ELCOS

ELCOS CAM 684 User manual

ELCOS

ELCOS CAM-685 User manual

ELCOS

ELCOS DCA-120/10 Owner's manual

ELCOS

ELCOS CIM-137/4G Instruction Manual

ELCOS

ELCOS CEP-337 User manual

ELCOS

ELCOS CIM-130 Instruction Manual

ELCOS

ELCOS CIM-131 Instruction Manual

ELCOS

ELCOS CAM-432 Instruction Manual

ELCOS

ELCOS CEP-090 User manual