ELCOS DCA-110 User manual

ELCOS- Parma- Italy - gb - DCA-110 1

Automatic faults surveillance with messages on the display

Texts in 6 languages: Italian, English, rench, German, Spanish and Portuguese

Remote control (start and stop)

Glow plugs preheating management or engine heating cooling

Clock for programming the starting or the stopping of the engine

Preventive maintenance warning

Programmable weekly selftest

Available fully programmable input for anomaly

CAN Bus SAE J1939

Possibility of starting the engine when the charge of the battery is low

Anomaly historical record (Including data from the last 100 occurred anomalies)

PARMA

ITALY

(PDLOLQIR#HOFRVLW+773ZZZHOFRVLW

)D[

7HO

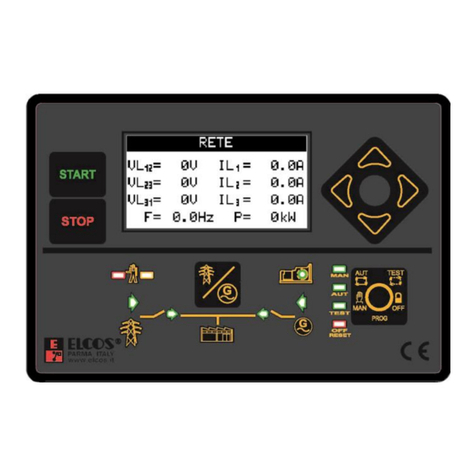

CONTROL UNIT FOR AUTOMATIC DIESEL ENGINE

TYPE DCA-110

This carries out the control and command function of a diesel engine.

It is equipped with display

to show THE

INSTRUMENTS:

(simultaneous reading of 4)

- battery voltmeter

- total hour meter

- partial hour meter

- starting counter

- starting failures counter

- fuel level

indicator

- tachometer

OPERATING AND INSTRUCTION MANUAL

or pwater pump protection (Protection device used in irrigation systems)

ELCOS- Parma- Italy - gb - DCA-110

2

OFF

AUT

MAN

6723

%

PRESS BRIEFLY

TO SHOW THE

INSTRUMENTS,

HOLD DOWN

TO VERIFY

THE LED TEST.

GENERAL ALARM

SILENCING

THE OPERATION

MODE OF THE

CONTROL UNIT IS:

• MANUAL

• AUTOMATIC

• OFF

• USER

PROGRAMMING

BATTERY

VOLTMETER

PRESS TO

STOP THE

ENGINE

WHEN THE

CONTROL

UNIT IS IN

MANUAL

OPERATION

PRESS TO

START THE

ENGINE WHEN

THE CONTROL

UNIT IS IN

MANUAL

OPERATION

MODE

ENGINE IS

RUNNING

%5,(),16758&7,216

PRESS TO

RESET

THE

CONTROL

UNIT

PREVENTIVE

MAINTENANCE

AND CUMULATIVE

ALARM WITHOUT

STOPPING

PRESS TO

SELECT THE

OPERATION MODE:

• MANUAL

• AUTOMATIC

• OFF

• USER

PROGRAMMING

STARTING

COUNTER

STARTING

FAILURE

COUNTER

,167580(176

With the running

engine the gengine

instruments are

shown.

In the event of a fault,

instead of the

measurement, the

display shows the

message of the

occurred fault.

• BATTERY VOLTMETER For voltages ranging between 9 and 38 Volt.

• TOTAL HOUR-METER With five digits and a maximum reading of 59999 (hours

and minutes).

• PARTIAL HOUR-METER With four digits and a maximum reading of 9999 (hours

and minutes). (The hours indicated are zero-set the next time

the engine is started up.)

• STARTING COUNTER Displays the number of startings that have occurred up

to 9999.

• STARTING FAILURE Displays the number of failure startings that have occurred

COUNTER up to 65535.

• FUEL LEVEL Displays the percentage of fuel present in the tank

INDICATOR

• TACHOMETER 8500 rpm.Displays the number of engine revs up to

6,08/7$1(2865($',1*2)7+(,167580(176:,7+7+(5811,1*(1*,1(

INDICATOR, .FUEL LEVEL TACHOMETER, HOUR-METER

5(9,6,216+,6725<

Date

Level of the

REVISION

Description Page

CUMULATIVE

ALARM WITH

ENGINE STOP

THE CALL

IS CLOSED

TOTAL

HOUR METER

TACHOMETER

FUEL

LEVEL

INDICATOR

ELCOS- Parma- Italy - gb - DCA-110 3

The function selected

with the key is shown by

the associated warning light.

The control unit commands are enabled.

Starting with key stopping with key (it is obtained by pressing once the key).

0$18$/

23(5$7,21

)81&7,2166(/(&7,21

OFF

AUT

MAN

6723

67$57

$8720$7,&

On closing the call contact,

(if set) and

On the opening the call contact,

once the STARTUP DELAY AFTER CALL time (programmed to 1 sec.) has elapsed,

the control unit switches on the glow plugs then starts the engine.

and after the DELAY AFTER CALL OPENING time has elapsed, the engine stops.

:((./<6(/)7(67

ENABLED WITH POWER UNIT IN AUTOMATIC MODE (for programming see page 8 of the Technical Programming

Manual)

the engine starts and continues to run for the WEEKLY TEST TIME (programmed to 3 minutes). This test

will be repeated automatically every week on the exact day and at the hour to which it has been programmed.

During the automatic test cycle, WEEKLY TEST IN PROGRESS is shown on the display.

STOPPING OF ENGINE DURING THE TEST

Press key

If the engine remains stopped for a few days a week, we advise

extending the duration of the weekly test to charge the battery by

means of the battery charging alternator.

WEEKLY TEST STOP: the weekly test is stopped when an anomaly

is displayed on the display.

When key is pressed until Led comes on.

The engine cannot be started in any way and, if running, is stopped

2))

OFF

AUT

MAN

PROTECTIONS

The engine protection function in manual mode can be programmed in two ways:

· Display only of the fault that has intervened WITHOUT STOPPING the engine. The overspeed fault is programmed

with stopping of the engine. It cannot be programmed without stopping of the engine.

· Display of the fault that has intervened WITH ENGINE STOPPING. (The control unit is programmed in this way).

6723

67$57,1*

-

In on closing the call contact and after the STARTUP DELAY AFTER CALL time has elapsed.

To make starting easier, a special circuit establishes a series of programmable startups (programmed to 4

STARTUPS); the number of startups, the length of the pause time and the startup time can be programmed.

If the whole series of attempts is unable to start the engine, at the end of this cycle STARTING FAILURE

is shown on the display and the stop signal is activated.

DXWRPDWLF

STARTING FAILURE

'(7(&7,212)5811,1*(1*,1(

This is obtained by the detection of the battery charger alternator voltage (PERMANENT MAGNETS or PRE-

EXCITATION) or by the signal sent (CAN Bus) from the engine equipped with control unit for electronic control of

the injection system; in this case, the alternator only controls belt breakage and not engine running.

When detection has been made, this disconnects the starter motor and lights the LED .

- In with key .

PDQXDO

-

-

In with key (it is obtained by pressing once the key).

In it is activated automatically before starting.

The preheating action time can be adjusted, the preheating action stops before startup start.

The factory preheating command is inhibited as it has been programmed to zero seconds.

PDQXDO

DXWRPDWLF

*/2:3/8*635(+($7,1*

6723

- .

-

In mode using key (it is obtained by pressing once the key)

In mode on opening the call contact, or when the protection systems intervene.

Stopping can occur in two ways:

• With the solenoid deactivated while the engine is running and activated when stopped. This condition is maintained

during the STOPTIME (programmed to 20 seconds) after the engine stopped detection.

• With solenoid or electro-valve activated while the engine is running and deactivated when stopped.

This condition is maintained even when the engine is stationary.

PDQXDO

DXWRPDWLF

67$57

67$57

6723

The intervention of the fault is displayed; it can cause the engine to be stopped and activates the general alarm. See

TABLE at page 10 of the TECHNICAL PROGRAMMING manual.

When the engine is running the engine instruments are shown.

When there is a fault, instead of the reading, the display shows the intervened fault message, and the associated

LED flashes.

)$8/7',63/$<

)$8/75(6(7

It is possible to access the reading of the measurements by pressing key for 1 second.

The display will resume showing the previous fault 10 seconds after the last pressing of the key.

On pressing the key , the protection devices and all the locked functions are reactivated.

+2:726((7+(,167580(175($',1*6$*$,1

(1*,1(3527(&7,21'(9,&(6

Can be combined with the GLOW PLUG PREHEATING (factory programming) or functions (to

combine the function see page 5 of the technical programming manual).

HEATING: after starting the engine stays decelerated for a time.

COOLING: the engine is decelerated for a time before manual or automatic stopping. Cooling does not take place

when the engine stops due to a fault.

+($7,1*&22/,1*

287387

terminal

Can be combined with AVAILABLE FAULT (factory programming) or INHIBITION OF PROTECTION DEVICES.

,1387

terminal

ELCOS- Parma- Italy - gb - DCA-110

4

&$1%XV,167580(176

These are read by the injection control unit and shown on the display when the engine is running.

SOME MAKES OF

ENGINE DO NOT

PROVIDE FOR THE

DISPLAY OF ALL THE

LISTED INSTRUMENTS

All anomalies regarding these instruments are managed by the .

LQMHFWLRQFRQWUROXQLW

0(66$*(6$1',167580(176

6HQW6$(-SURWRFRO%XVIURPWKHHQJLQHHTXLSSHGZLWKFRQWUROXQLWIRUHOHFWURQLFFRQWURORIWKHLQMHFWLRQ

V\VWHP

All the messages or instruments displayed on the display regarding the injection control unit and the CAN Bus, are

identified by the presence of the characters at bottom right.

$120$/<0(66$*(6

The anomaly messages managed by the injection control unit are indicated on the display.

SPN...............................

FMI.......... ANOMALY

CAN Bus

ANOMALY

Problems with connection to

the CAN Bus

23(5$7,21

*(1(5$/$/$50

This is produced by mounting an acoustic signal, linked to the appropriate terminal.

It can be arranged so that it is activated continually or for a set time.

When key is pressed the general alarm is silenced.

Before starting automatically the engine activates the intermittent general alarm for 8 seconds, followed by a pause of

3 seconds. This function can be switched off: see TECHNICAL PROGRAMMING OPERATIONS manual on page 8.

35(9(17,9(0$,17(1$1&(

When preventive maintenance operations need to be carried out, the yellow LED flashes while the number of

the intervened maintenance appears.

The timing for the maintenance operations and the procedure for zeroing the time up maintenance indication

can be programmed by the manufacturer of the engine.

(0(5*(1&<6723

The emergency stop can be activated in all working conditions, by mounting one or more click down push-button.

The stop is immediate, does enable the general alarm and EMERGENCY STOP is shown on the display.

67233,1*)$,/85(

This intervenes if the engine running signal is detected 60 seconds after the stop command.

STOPPING FAILURE will be read on the display.

3266,%,/,7<2)(1*,1(67$57,1*:,7+%$77(5<:,7+/2:&+$5*(

(with control unit in automatic mode)

Starts or stops the engine depending on the voltage measured on the battery terminals.

.

When than the minimum threshold, the engine starts.

When the maximum threshold after the intervention delay, the engine stops. To change the

programming of the thresholds and of the delay see the TECHNICAL PROGRAMMING OPERATIONS manual on

page

WKHYROWDJHPHDVXUHGRQWKHEDWWHU\LVORZHU

WKHYROWDJHH[FHHGV

10.

Before starting automatically, the generator set activates the intermittent general alarm for 8 seconds, followed by a

pause of 3 seconds.

'RQRWXVHWKHHPHUJHQF\EXWWRQFRPELQHGZLWKDVWRSSLQJV\VWHP

WKDWLVQRWHQHUJL]HGLQUXQPRGH

&808/$7,9($/$506

LED (red) STEADY LIGHT: anomaly managed by the injection control unit the engine .

ZLOOFDXVH WRVWRS

LED (yellow) : .STEADY LIGHT anomaly managed by the injection control unit the engine

ZLOO127FDXVH WRVWRS

LED (red) FLASHING LIGHT: anomaly managed by the control unit DCA-110

ZLOOFDXVH WRVWRS

the engine .

LED ( ) T: DCA-110

, or indicates a preventive maintenance operation.

yellow FLASHING LIGH anomaly managed by the control unit the engine

LED OFF ALL OK.

ZLOO127FDXVH

WRVWRS

,167580(176

TACHOMETER

OIL PRESSURE

GAUGE

THERMOMETER

USED

FUEL

INSTANTANEOUS

CONSUMPTION

FUEL

TEMPERATURE

TURBO-

OIL TEMPERATURE

INTERCOOLER

TEMPERATURE

INTAKE

TEMPERATURE

COOLANT

LEVEL

FUEL

PRESSURE

ENGINE TORQUE

ENGINE LOAD

ENGINE POWER

81,72)

rpm

'(6&5,37,21

Displays the number of engine revolutions

Displays the pressure of the engine oil

Displays the engine water or oil

temperature

Total amount of litres of fuel used

Amount of fuel consumed by the engine

per unit of time (l/h)

Temperature of the fuel from the inlet of

the injectors

Temperature of turbocharger lubricant

Temperature of the engine lubricant oil

Temperature of intercooler liquid after

the turbocharger

Temperature of the pre-combustion air

Level of the coolant expressed in %

Pressure of the fuel between the supply

pump and the injection pump

Pressure of the liquid in the cooling

system

Torque percentage at engine outlet

Load percentage delivered by the engine

kW

%

Nm

bar

bar

kPa

kPa

%

°C °F

°F

°C

°F°C

l/h

I

°F°C

0($685(

0(17

bar kPa

CHARGER

TEMPERATURE

Torque percentage at engine outlet

°C °F

°C °F

COOLANT

PRESSURE

ELCOS- Parma- Italy - gb - DCA-110 5

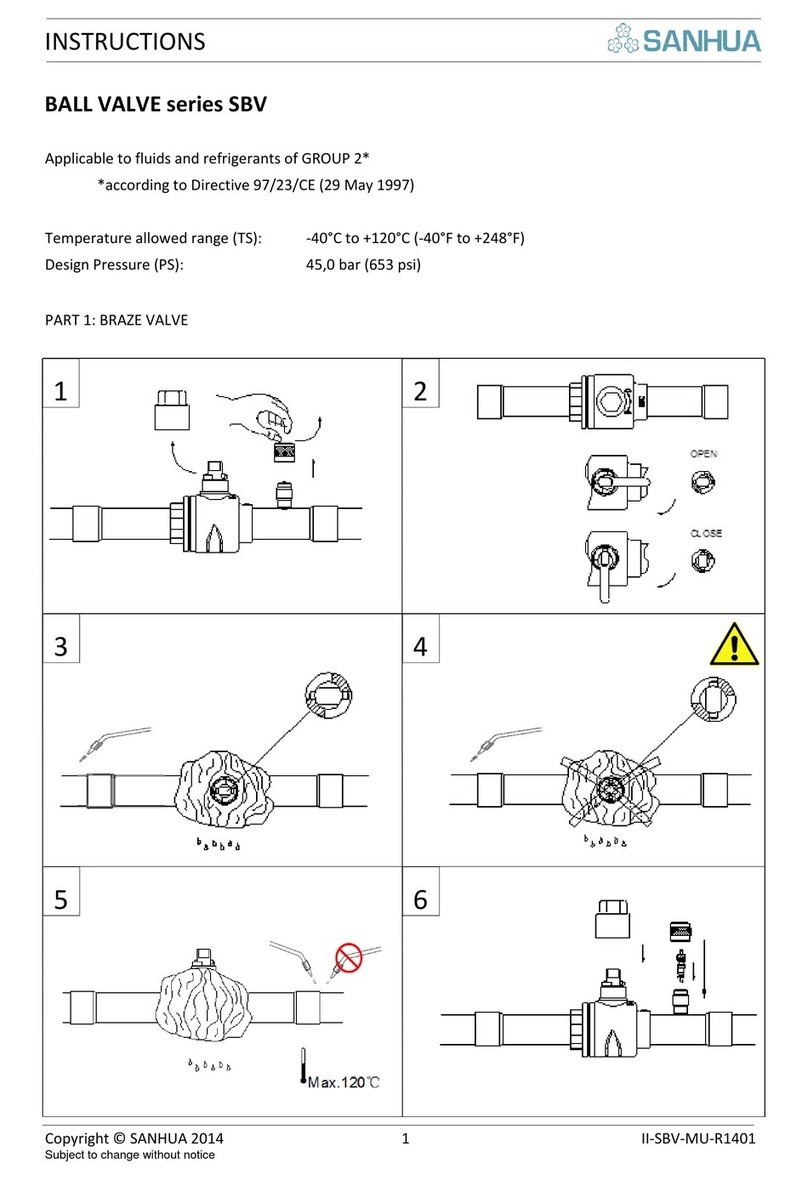

EMERGENCY

PUSH-BUTTON

2. 5mm min.

10m MAX

FU1

$

30 85

87 86

PREHEATING

50

30

+-

START-

MOTOR

30 85

86

STOP

C

O

N

S

U

L

T

S

T

A

N

D

A

R

D

S

C

E

I

4

4

-

5

(

E

N

6

0

2

0

4

)

F

O

R

I

N

F

O

R

M

A

T

I

O

N

C

O

N

C

E

R

N

I

N

G

P

R

O

T

E

C

T

I

O

N

A

G

A

I

N

S

T

O

V

E

R

L

O

A

D

C

U

R

R

E

N

T

S

I

N

T

H

E

E

L

E

C

T

R

I

C

A

L

E

Q

U

I

P

M

E

N

T

U

S

I

N

G

B

A

T

T

E

R

Y

V

O

L

T

A

G

E

D

E

T

E

C

T

I

O

N

O

F

R

U

N

N

I

N

G

E

N

G

I

N

E

A

N

D

T

A

C

H

O

M

E

T

E

R

,

0

3

2

5

7

$

1

7

WHEN USING A PRE-EXCITATION

ALTERNATOR TURN THE DIVERTER

TO THE POSITION THAT

CORRESPONDS TO THE NOMINAL

VOLTAGE OF THE BATTERY (12 - 24V

)

.

DO NOT HOOK WITH OTHER

TYPES OF ALTERNATOR

DETECTION OF

RUNNING ENGINE

OUTPUT

100 m

MAX

GENERAL ALARM

OUTPUT (+)

3W MAX 100m MAX

3

0

8

5

8

7

8

6

FUEL

FLOAT

T

H

E

R

M

O

-

S

T

A

T

I

C

S

W

I

T

C

H

O

I

L

P

R

E

S

S

U

R

E

G

A

U

G

E

G

E

N

E

R

A

L

A

L

A

R

M

87

CONNECT

DIRECTLY

TO THE ( )

BATTERY

TERMINAL

12 24

VOLT

&

2

1

7

5

2

/

8

1

,

7

7

<

3

(

'

&

$

CAN Bus

$

+

SUPPLY

C

O

N

N

E

C

T

I

O

N

T

O

B

E

M

A

D

E

W

H

E

N

E

M

E

R

G

E

N

C

Y

P

U

S

H

-

B

U

T

T

O

N

I

S

N

O

T

I

N

S

T

A

L

L

E

D

G

L

O

W

P

L

U

G

S

P

R

E

H

E

A

T

I

N

G

E

N

G

I

N

E

O

R

H

E

A

T

I

N

G

,

C

O

O

L

I

N

G

S

T

A

R

T

I

N

G

S

T

O

P

E

N

A

B

L

E

D

W

I

T

H

E

N

G

I

N

E

S

T

A

R

T

I

N

G

O

R

R

U

N

N

I

N

G

D

I

S

A

B

L

E

D

W

I

T

H

E

N

G

I

N

E

O

F

F

OUTPUTS (+)

0,25A MAX

FUEL LEVEL FLOAT programmed

NOT USED

OIL PRESSURE SWITCH

ENGINE THERMOSTATIC

SWITCH

REM

O

T

E

C

O

N

T

A

C

T

W

I

T

H

C

O

N

T

R

O

L

U

N

I

T

(

1

,

5

A

M

A

X

)

IN A

U

T

O

M

A

T

I

C

M

O

D

E

1

0

m

M

A

X

&

$

/

/

with

v

a

r

i

a

b

l

e

r

e

s

i

s

t

a

n

c

e

l

e

v

e

l

i

n

d

i

c

a

t

o

r

PRO

T

E

C

T

I

O

N

I

N

P

U

T

OR

P

U

M

P

W

A

T

E

R

P

R

O

T

E

C

T

I

O

N

D

E

V

I

C

E

INH

I

B

I

T

I

O

N

O

F

P

R

O

T

E

C

T

I

O

N

D

E

V

I

C

E

S

INHIBITION

OF

PROTECTION

DEVICES

A

V

A

I

L

A

B

L

E

O

R

:,5,1*',$*5$0

W

e

r

e

s

e

r

v

e

t

h

e

r

i

g

h

t

t

o

c

h

a

n

g

e

t

h

e

c

h

a

r

e

c

t

i

s

t

i

c

s

a

t

a

n

y

moment and without warning.

I

N

S

T

R

U

M

E

N

T

S

S

U

P

P

L

Y

(

)

DET

E

C

T

I

O

N

O

F

R

U

N

N

I

N

G

ENG

I

N

E

A

N

D

C

H

A

R

G

I

N

G

ALT

E

R

N

A

T

O

R

P

R

E

-

E

X

C

I

-

TAT

I

O

N

(

W

I

T

H

O

U

T

T

H

I

S

CO

N

N

E

C

T

I

O

N

T

H

E

A

L

T

E

R

N

A

T

O

R

D

O

E

S

(

)

STARTING WITH

CLOSED CONTACT

CAN

H

CAN

L

YOUR ELECTRICAL TECHNICIAN

CAN ASK US ANYTHING ABOUT

THIS PRODUCT BY TELEPHONING

ONE OF OUR TECHNICIANS

ACTUATOR

ACCELE-

RATOR

AVAI LABLE

PROTECTION

DEVICE

!

FOR DETECTION

OF RUNNING

ENGINE WITH

PRE-EXCITATION

ALTERNATOR THIS

CONNECTION

IS SUFFICIENT

SEE N

E

C

E

S

S

A

R

Y

P

R

O

G

R

A

M

M

I

N

G

ON

P

A

G

E

6

O

F

T

H

E

TE

C

H

N

I

C

A

L

PR

O

G

R

A

M

M

I

N

G

OP

E

R

A

T

I

O

N

S

MA

N

U

A

L

G

L

G

+

B

R

C

R

+

R

E

D

Y

E

L

L

O

W

D

+

B

+

P

R

E

-

E

X

C

I

T

A

T

I

O

N

A

L

T

E

R

N

A

T

O

R

R

E

G

U

L

A

T

O

R

P

E

R

M

A

N

E

N

T

M

A

G

N

E

T

S

A

L

T

E

R

N

A

T

O

R

F

O

R

D

I

F

F

E

R

E

N

T

R

E

G

U

L

A

T

O

R

S

A

S

K

F

O

R

D

I

A

G

R

A

M

W

S

T

A

R

T

T

H

E

E

N

G

I

N

E

O

N

L

Y

B

Y

T

H

E

C

O

N

T

R

O

L

U

N

I

T

.

A

V

O

I

D

T

O

U

S

E

:

S

T

A

R

T

K

E

Y

S

,

B

U

T

T

O

N

S

e

t

c

.

.

HAVING MADE THE

CONNECTIONS, THE CO

N

T

R

O

L

UNIT IS IN MODE.

TO SELECT OTHER OP

E

R

A

T

I

N

G

MODES, SEE PAGE 3.

O

F

F

N

O

T

U

S

E

D

Y

E

L

L

O

W

NEVER INSTALL THE

EMERGENCY PUSH-

BUTTON LINKED TO A

STOP SYSTEM WHICH IS

NOT ENERGIZED WHEN

THE UNIT IS RUNNING.

N

O

T

C

H

A

R

G

E

CONNECT USI NG

TWI STED OR SHIELDED

CABLES MAX 10m LONG.

TERMINATION RESISTANCE (120 Ohm)

Check in the control unit manual (ECM/ECU)

if the resistance must be inserted

(engine side) between the CAN-H

and CAN-L wires.

ELCOS- Parma- Italy - gb - DCA-110

6

67$57,1*&216(172SHUDWLRQREWDLQHGDVGXULQJDXWRPDWLFPRGH

67236WRSVVWDUWLQJRUUXQQLQJRIHQJLQH

$'-8677+(&$/(1'$5&/2&.

7KH7,0(5SHUPLWVWRSURJUDPPHWKHRSHUDWLRQRUWKHE RFNRIWKHHQJLQH

:((. <$8720$7,&7(67:KHQ:((. <$8720$7,&7(6721SURJUDPPLQJLVILQLVKHGZLWKFRQWURO

XQLWLQDXWRPDWLFPRGHWKHHQJLQHVHWH[HFXWHVWKHWHVWF\FOH

H[DPSOH

FROM 12:15

TO 15:20

H[DPSOH

FROM 23:00

TO 07:30

23:00

TO 07:30

FROM

FROM 12:15

TO 15:20

Intervention

delay

Intervention

delay

'$,/<67$57

7,0(5

'$,/<6723

7,0(5

:((./<$8720$7,&

7(67

Decreases

Decreases

Increases

Increases

Press and wait for

PROGRAMMED to be written

Press and wait for

PROGRAMMED to be written

Press and wait for

PROGRAMMED to be written

Press when the arrow is next

to the time to be corrected.

Press when the arrow is next

to the time to be corrected.

Press to choose

86(5352*5$00,1*

6723

To

H[LWWKH

SURJUDPPLQJPRGH

Press to select:

352*5$00,1*

23(5$7,216

86(5

352*5$00,1*

/$1*8$*(&+2,&(

:((./<$8720$7,&

7(67

'$,/<6723

7,0(5

'$,/<67$57

7,0(5

35(6672',63/$<7+(

5(48,5('352*5$00,1*

Decreases

/$1*8$*(&+2,&( 7KHODQJXDJHVHWXSLV,7$/,$1 WKHODQJXDJHVWKDWFDQEHVHOHFWHGDUH (1*/,6+)5(1&+

*(50$163$1,6+32578*8(6(

6(/(=,21(/,1*8$

,7$/,$12 6(/(&7/$1*8$*(

(1*/,6+

Press and wait for

PROGRAMMED to be written

Press to select.

Press to display.

2))

(1*$*('

2))

Factory setting

Press to display.

6723

6723

Press to display.

6723

$&&(6672352*5$00,1*02'(

select

- MAN

- AUT

- OFF

OFF

AUT

MAN

(led )off

&$ (1'$5& 2&.$'-8670(17

$'-8670(17,65(&200(1'('

The time and date are used when the anomaly

log events are displayed.

&$/(1'$5&/2&.$'-8670(17

$'-8670(17

'$<0217+<($5

+2850,187(6

Press (2 sec.) until

the cursor flashes

If the power is cut off,

adjustment of the calendar clock

must be repeated

6723

Moves the

cursor

Increases

(;,7)520352*5$00,1*02'(

OFF

AUT

MAN

ELCOS- Parma- Italy - gb - DCA-110 7

127,&(6

Used only to check a diesel engine, while operating, commanding stopping if there are anomalies

in the parts controlled by the probes.

Designed to be installed inside dashboards, electric panels etc..

:DUQLQJ

$GKHUHFORVHO\WRWKHIROORZLQJDGYLFH

- When making connections always follow the instructions and the Wiring Diagram on page 5.

- Any interventions on the unit must be performed with the engine stationary and terminal 50 of

the starting motor disconnected.

- Check that the consumption of the connected equipment are compatible with the described

technical characteristics.

- Install in such a way that there is always adequate heat disposal.

- Always install under other equipment which produces or spreads heat.

- Handle and connect without mechanically stressing the electronic card.

- Make sure that no copper conductor cuttings or other waste material fall inside the control unit.

- Never disconnect the terminals of the battery with running engine.

- Never use a battery charger for the emergency start-up; the control panel could be damaged.

- In order to safeguard people and equipment, before connecting an external battery charger,

disconnect the electrical system terminals from the battery poles.

7+,6 &21752/ 81,7 ,6 127 68,7$%/( )25 23(5$7,1* ,1 7+( )2//2:,1*

&21',7,216

:

- Where the environmental temperature is outside the limits indicated in the manual.

- Where the air pressure and temperature variations are so rapid as to produce exceptional

condensation.

- Where there are high levels of pollution caused by dust, smoke, vapour, salts and corrosive or

radioactive particles.

- Where there are high levels or heat from radiation caused by the sun, ovens or the like.

- Where attacks from mould or small animals are possible.

- Where there is the risk of fire or explosions.

- Where the control panel can receive strong vibrations or knocks.

- Where the control panel is protected by barriers or casing with protection level less than IP40.

(/(&7520$*1(7,&&203$7,%,/,7<

This control unit functions correctly only if inserted in plants which conform with the CE marking

standards; it meets the

exemption requirements of the standard EN61326-1 but it cannot be excluded that malfunctions

could occur in extreme

cases due to particular situations.

The installer has the task of checking that the disturbance levels are within the requirements of the

standards.

&21'8&7,21$1'0$,17(1$1&(

The following maintenance operations should be performed every week:

- check that the indicators function;

- check the batteries;

- check that the conductors are tight, check the condition of the terminals.

81/(66:(0$.($:5,77(1'(&/$5$7,2167$7,1*7+(&2175$5<7+,6&21752/

81,7,612768,7$%/()2586($6$&5,7,&$/&20321(17,1(48,30(17253/$176

5(63216,%/()25.((3,1*3(562162527+(5/,9,1*%(,1*6$/,9(

YOUR ELECTRICAL TECHNICIAN CAN ASK ANY QUESTIONS ABOUT

THIS CONTROL UNIT BY TELEPHONING OUR TECHNICIAN

ELCOS- Parma- Italy - gb - DCA-110

8

7(&+1,&$/'$7$

Battery power supply 12 Vdc and 24 Vdc

Supply voltage 8 ÷32V

Selfconsumption with engine stopped 6 mA at 12V 4 mA at 24V

Selfconsumption with stopped engine and pressed

emergency button

170 mA at 12 V 100 mA at 24V

Max consumption 210 mA at 12V 145 mA at 24V

Rated insulation voltage:

• Terminal board of battery

32V

15 (starting) 0,25A, 6 (glow plugs) 0,25A,

17 (stopping) 1,5A, 19 (key) 0,25A,

Max load of the outputs

70 (general alarm) 0,25A.

Degree of rear protection IP00

Degree of front protection IP64

Temperature range −20 ÷ + 50 ºC

Weight 410 g

Dimensions (LxHxP)mm 157x109x52

Hole mm 88x137

Hour-meter 5 digits

Tachometer Max 4000 RPM precision ± 10 RPM

ORDERING DATA

Type DCA- 110 code 24.22.63

CONFORMITY DECLARATION

ELCOS s.r.l. assumes full responsability for de laring that the ontrol unit:

type DCA-110

installed and used in the ways and for the purposes des ribed in the

instru tion and user manual, is in onformity with the following dire tives:

- 2006/95/CE related to the ele tri al materials destined to be used within

ertain voltages limits

- 2004/108/CE related to the ele tromagneti ompatibility and that repeals

the dire tive 89/336/CEE,

be ause it is built and fun tions in a ordan e with the harmonized Standards:

EN61010-1, EN61326-1, EN61326/A1, EN61000-4-2, EN61000-4-3,

EN61000-4-4, EN61000-4-5, EN61000-4-6, EN60529.

®

(PDLOLQIR#HOFRVLW+773ZZZHOFRVLW

9LD1DYLJOLR$OWRD

3$50$,7$/,$

6UO

)D[

7HO

Walter Consigli

Parma, 20/02/2009

President

ACCESSORIES SUPPLIED

KIT MU-DCA-110 code 80.44.33

Table of contents

Other ELCOS Control Unit manuals

ELCOS

ELCOS CIM-131 Instruction Manual

ELCOS

ELCOS CIM-130 Instruction Manual

ELCOS

ELCOS CAM 684 User manual

ELCOS

ELCOS CEP-337 User manual

ELCOS

ELCOS CEP-090 User manual

ELCOS

ELCOS CAM-685 User manual

ELCOS

ELCOS CAM-335 User manual

ELCOS

ELCOS CIM-137/4G Instruction Manual

ELCOS

ELCOS DCA-120/10 Owner's manual

ELCOS

ELCOS CIM-137 Instruction Manual