5EN1R--9181 0104R1--NE

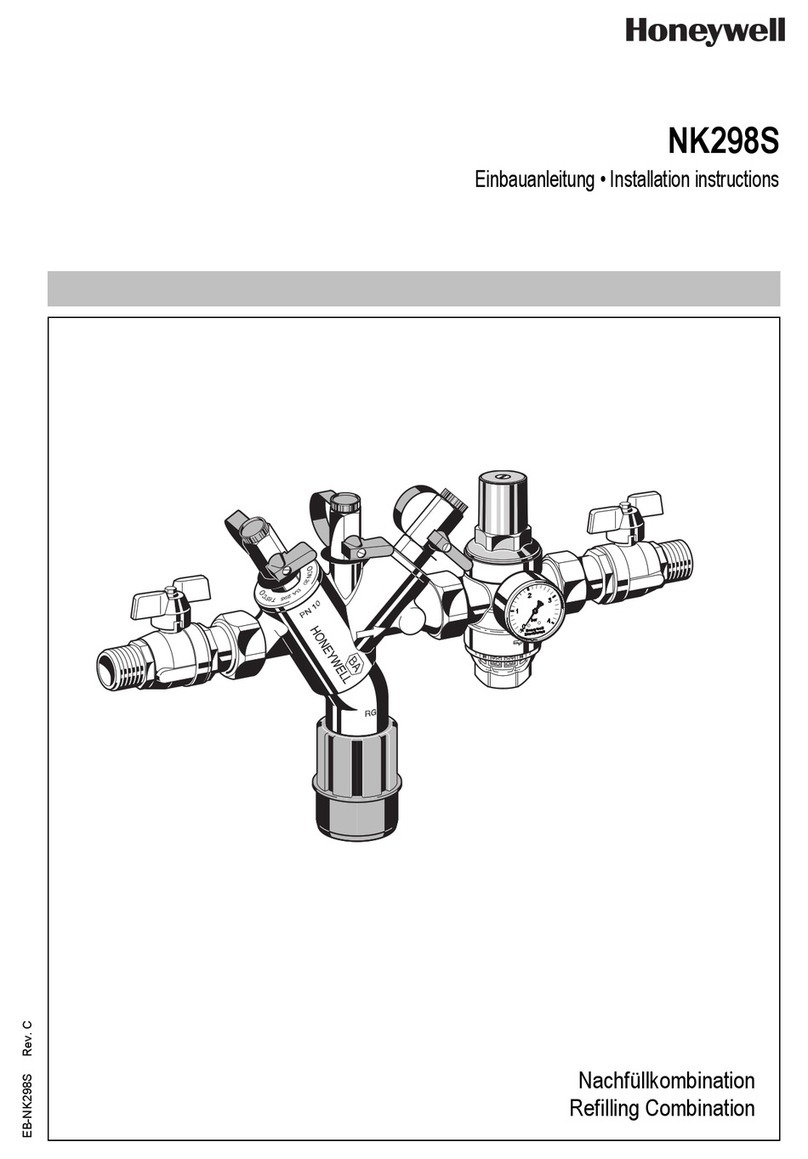

Adjusting minimum pressure setting (see fig. 3.)

Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

Disconnect electrical connection of Modureg.

Energize operator, set control in operation and wait until an

outlet pressure is recorded on pressure gauge.

If minimum rate pressure needs adjustment then use

a 9 mm wrench to turn adjustment screw for minimum

pressure setting clockwise to increase or

counter--clockwise to decrease pressure, until the desired

minimum outlet pressure is obtained.

Check if main burner lights easily and reliable at minimum

pressure.

Check maximum pressure setting and readjust if

necessary.

Mount cap.

Adjusting maximum pressure setting (see fig. 3.)

Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

Disconnect electrical connection of Modureg.

Energize operator, set control in operation and wait until an

outlet pressure is recorded on pressure gauge.

Push shaft gently downwards to the maximum adjustment

screw and hold it on.

If maximum rate pressure needs adjustment then use

a 7 mm wrench to turn adjustment screw for maximum

pressure setting clockwise to increase or

counter--clockwise to decrease pressure, until the desired

maximum outlet pressure is obtained.

Release shaft.

Mount cap.

If minimum and maximum pressures are set, wire Modureg in

circuit.

Adjusting intermediate pressure setting

Some controls, such as W9335, are able to provide

modulating control as well as a fixed setting.

In case this intermediate pressure setting should be set, it is

necessary to follow the suppliers instructions regarding the

adjustment of the concerned control. It deals with the

switching from modulating mode to fixed setting mode which

is in most cases is a potentiometer.

The fixed setting mode is very often used for central heating,

where on/off adjustable pressure to burner is required.

This intermediate outlet pressure can in general be electrically

set as follows:

Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

Energize operator, set control in operation and wait until an

outlet pressure is recorded on pressure gauge.

Make sure Modureg is wired in the circuit.

Bring system in fixed setting mode.

Adjust current as low as needed to obtain the lowest

pressure by using pressure setting means of control.

Mechanical setting of Modureg will prevent too low setting.

Increase the current until desired pressure is obtained by

using pressure setting means of modulating control.

Mount cap.

Checkout

After any adjustment, set appliance in operation and observe

through a complete cycle to ensure that burner system

components function correctly.

Maintenance

It is recommendable to check yearly the minimum and the

maximum setting and readjust them if necessary.

Dismounting and remounting flanges

Though by careful handling the “O”--rings could be re--used

when they are undamaged, it is advisable to use new

“O”--rings to be sure to have a reliable tight connection.

SPECIFICATIONS VR4920P

Model

VR4920P: line voltage gas control, fast opening with

High--Low regulator.

Ambient temperature

0 ... 70 _C

Minimum operating pressure

Between inlet and outlet: 3 mbar

Adjustment points and dimensions

See fig. 4. page 6

Maximum operating pressure

The Pmax. indication 30 mbar on the housing of the

combination gas control is the maximum pressure at which

the gas control functions safely. However the maximum

operating pressure is limited by the pressure range of the

High--Low pressure regulator concerned.

30 mbar for pressure range 3 ... 20 mbar

Regulator outlet pressure range V4336A

Pressure range

(mbar)

Low setting

(mbar)

High setting

(mbar)

3 ... 20 3 ... max. setting 7 ... 20

The outlet pressure setting should never be above the

range specified.

Electrical data gas control

Nominal voltage Current (mA) Power

consumption

(W)

15 Vdc

240/240 Vac, 50 Hz

313

20.4/24

4.7

3.4/4.5

Electrical data High- Low regulator V4336

Supply

voltage

(Vac)

Color of

coil

Current

(mA)

Power

consumption

(W)

220/240 V,

50 Hz

black 17.4/19 3/3.2

The High/Low regulator should never be covered in such

a way that temperature will raise beyond acceptable

limits.

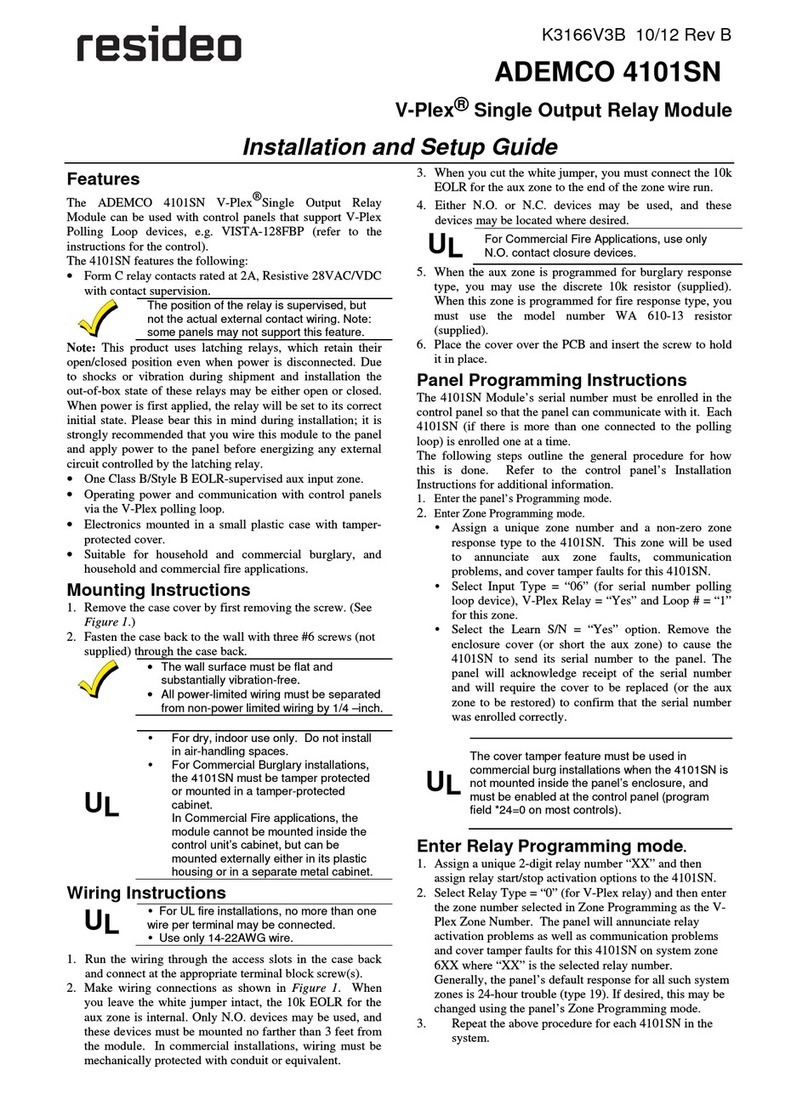

Electrical connection

The electric servo on/off operators are provided with: 6.3 mm

quick connect terminals suitable for 6.3 mm receptacles. (e.g.

”Series 250” AMP fasteners)