eldoLED POWERdrive 6060/R User manual

© 2015 eldoLED. All rights reserved. V1.2 All content contained herein is subject to change without prior notice.

More product documentation and eldoLED´s terms and conditions are available at www.eldoLED.com

Design-in guide

POWERdrive 6060/R

2

Table of Contents

1. Technical characteristics 4

1.1 Input characteristics 4

1.2 Output characteristics 5

1.3 Control characteristics 5

1.4 Protection 5

1.5 Thermal characteristics 5

1.6 Thermal protection 6

1.7 Dimensions, weight and packaging 6

1.8 Standards compliance 6

1.9 Certifications 6

2. Wiring 7

2.1 Wiring specifications 7

2.1.1 General wiring specifications 7

2.1.2 Power cord requirements 7

2.1.3 Sample voltage drop calculation 8

2.2 Connections 8

2.2.1 DMX network options 9

2.2.2 LED outputs 11

2.2.3 LEDcode/NTC 12

2.2.4 0-10V 12

2.2.5 DALI 12

2.2.6 120-230V AC 12

3. Installing the POWERdrive 6060/R 13

3.1 Cable connections 13

3.2 Common practice for grounding LED wires 14

3.3 Cable trunk 15

4. Configuring POWERdrive 6060/R 16

4.1 Menu button combinations 16

4.2 Order of LED driver configuration 16

4.3 Setting the operation mode 17

4.4 Setting the LED output current and LED group configuration 17

3

Safety guidelines 20

Disclaimer 21

Warranty 22

4

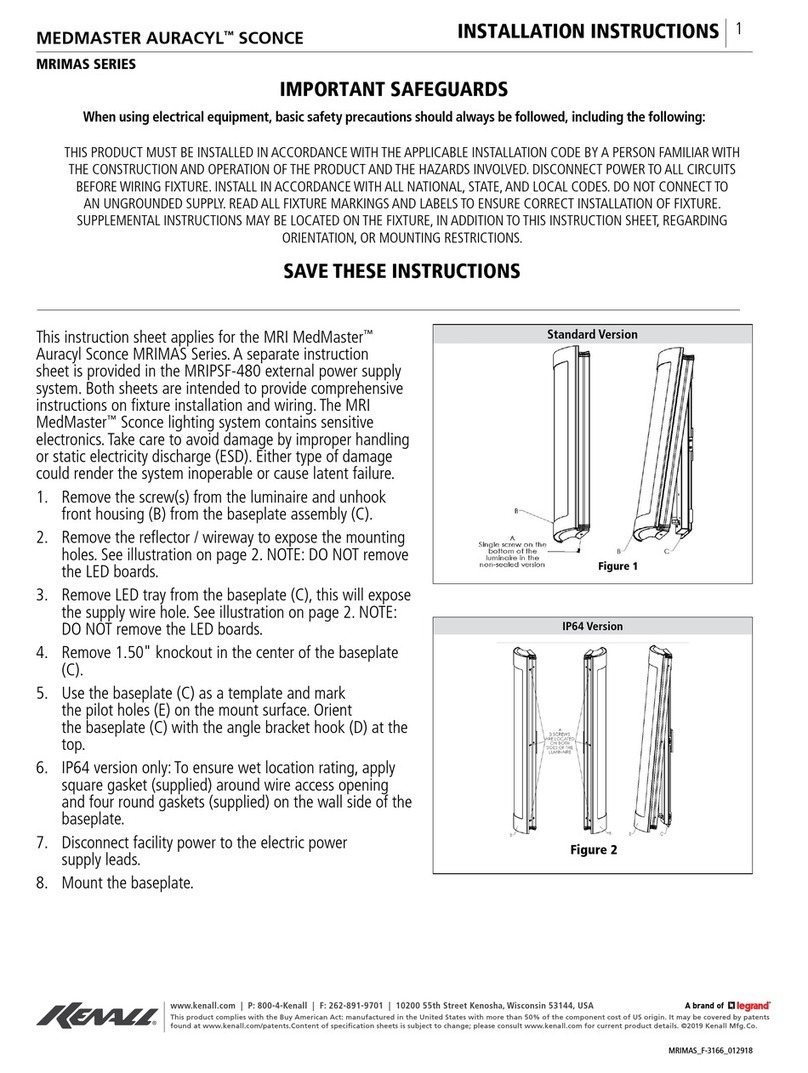

1. Technical characteristics

1.1 Input characteristics

Input voltage AC

120-230V

Input current

6.3A max @ 120V / 60Hz

5A max @ 230V / 50Hz

Input frequency

50-60Hz

Power factor

>0.9 @ 25% load and higher

Total Harmonic Distortion

<20% between 2/3 load and full load

Efficiency @ full load

91.8%

Efficiency @ 2/3 load

91.2%

Inrush current

35A @ 115V AC

70A @ 230V AC

Surge protection

EN 61000-4-5 compliant

Standby power

12.5W @ 100V AC

12.8W @ 120V AC

14.4W @ 230V AC

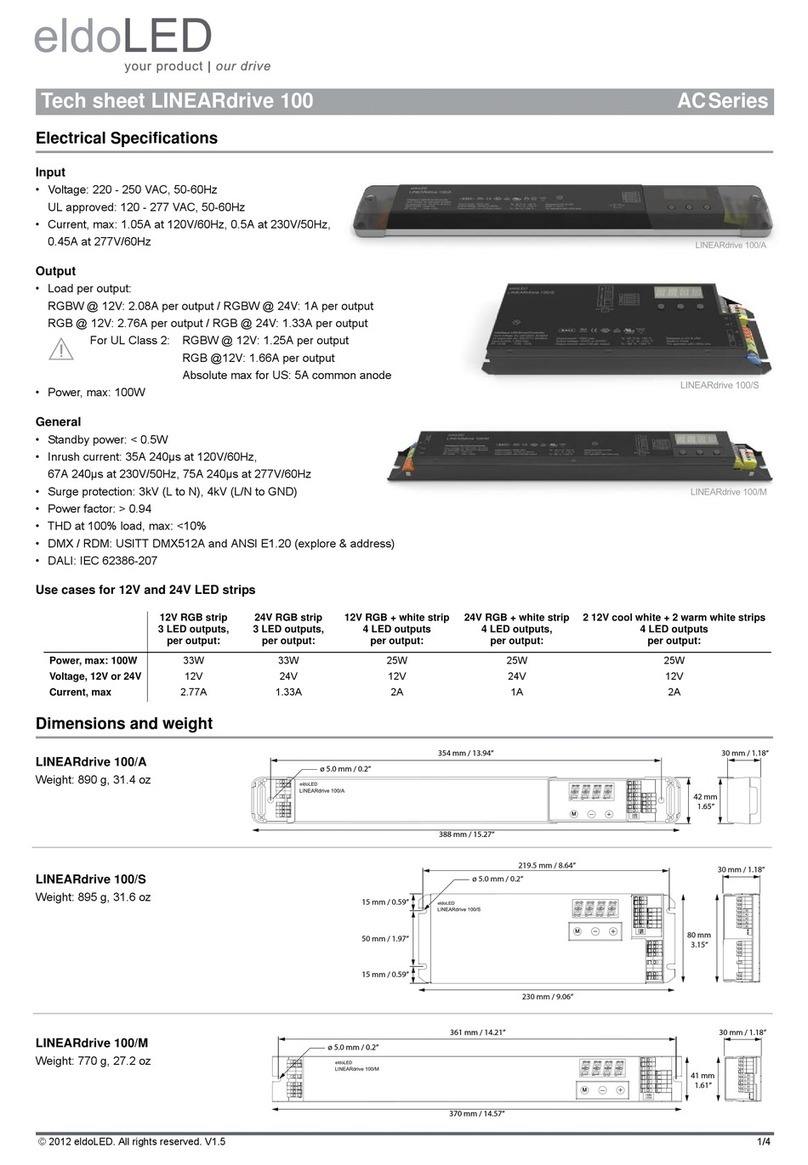

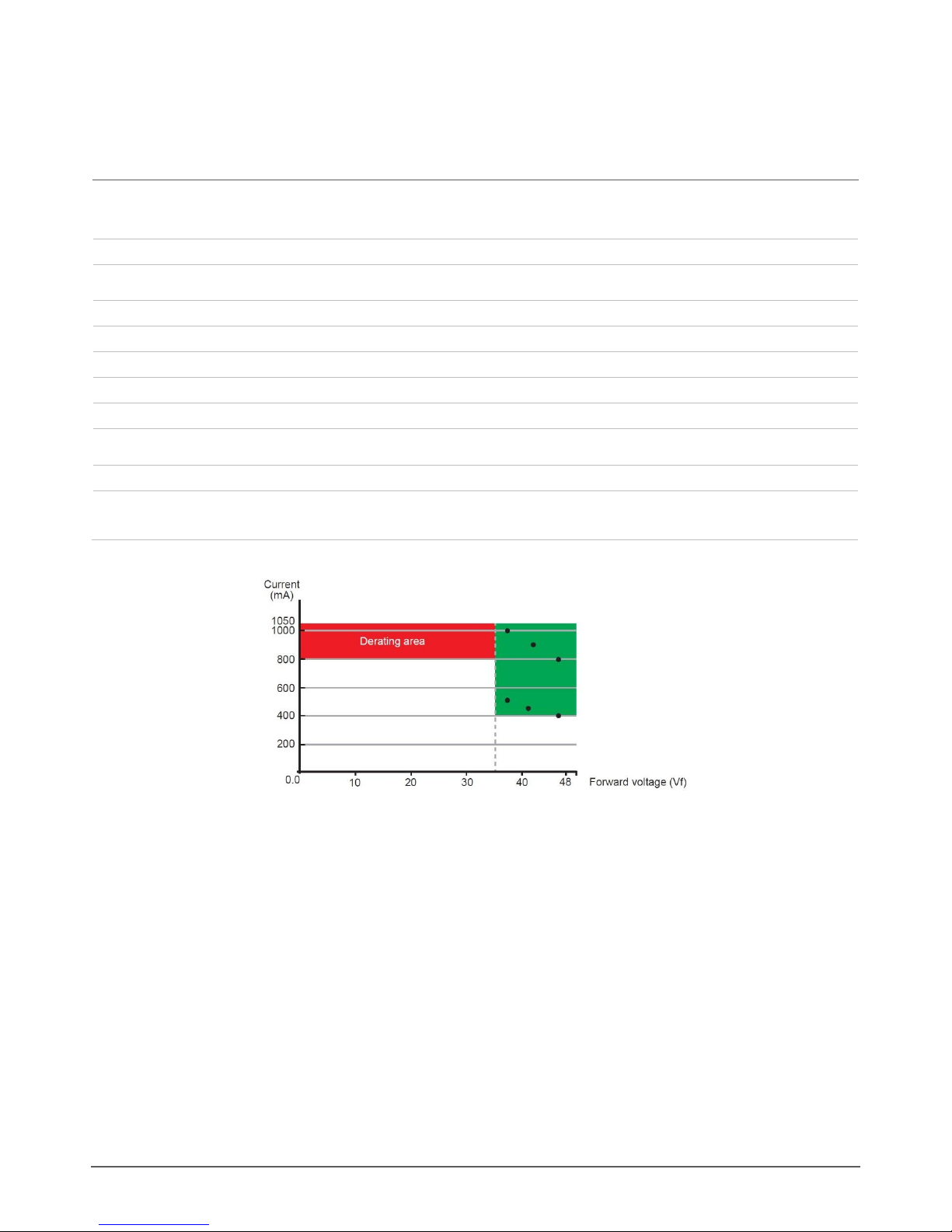

Figure 1.1 Derating diagram

To avoid temperature rise affecting lifetime, it is recommended not to use configurations in the derating area of the diagram above. The green area

indicates the highest efficiency area of POWERdrive 6060/R.

Calculation examples in the high efficiency area, using the formula (number of LED outputs) * ( Iout ) * ( VLED )

Using all 32 LED outputs:

32 LED outputs * 0.5A * 37.5V = 600W

32 LED outputs * 0.45A * 41.6V = 599W

32 LED outputs * 0.4A * 46.8V = 600W

Using 16 LED outputs:

16 LED outputs * 1A * 37.5V = 600W

16 LED outputs * 0.9A * 41.6V = 599W

16 LED outputs * 0.8A * 46.8V = 600W

5

1.2 Output characteristics

LED outputs

32

LED output power

600W max

LED output voltage range

2-48V

LED output current range

200-1,050mA

LED output current resolution

Programmable in 50mA steps

LED output current accuracy

+/- 10%

1.3 Control characteristics

Control channels

1-32 over DMX/RDM, 1-4 over DALI, 1 over 0-10V

Dimming protocol

USITT DMX512A // RDM, DALI or 0-10V

Dimming range

100%-0%

Dimming method

Hybrid HydraDrive

Dimming curve

Linear, logarithmic, square

Driver configuration

via front display and menu buttons

Isolation 0-10V to line voltage input

1500V

Isolation 0-10V to LED output

3750V

0-10V current draw

2mA

1.4 Protection

LED output short

Yes

LED output cross short

Yes

Overload

Yes

Reverse polarity

Yes, for LED output

Restart after protection

1.5 Thermal characteristics

Ta operating range

-20 °C … +50 °C / -4 °F … +122 °F

Tc max

85 °C / 185 °F

Tc lifetime

78 °C / 172 °F

6

1.6 Thermal protection

External NTC thermistor

Throttling @ 70 °C / 158 °F (settable)

External NTC thermistor value

47kOhm

Recommended NTC thermistor

238164063473 (leaded)

NTCASCWE3473J (screw)

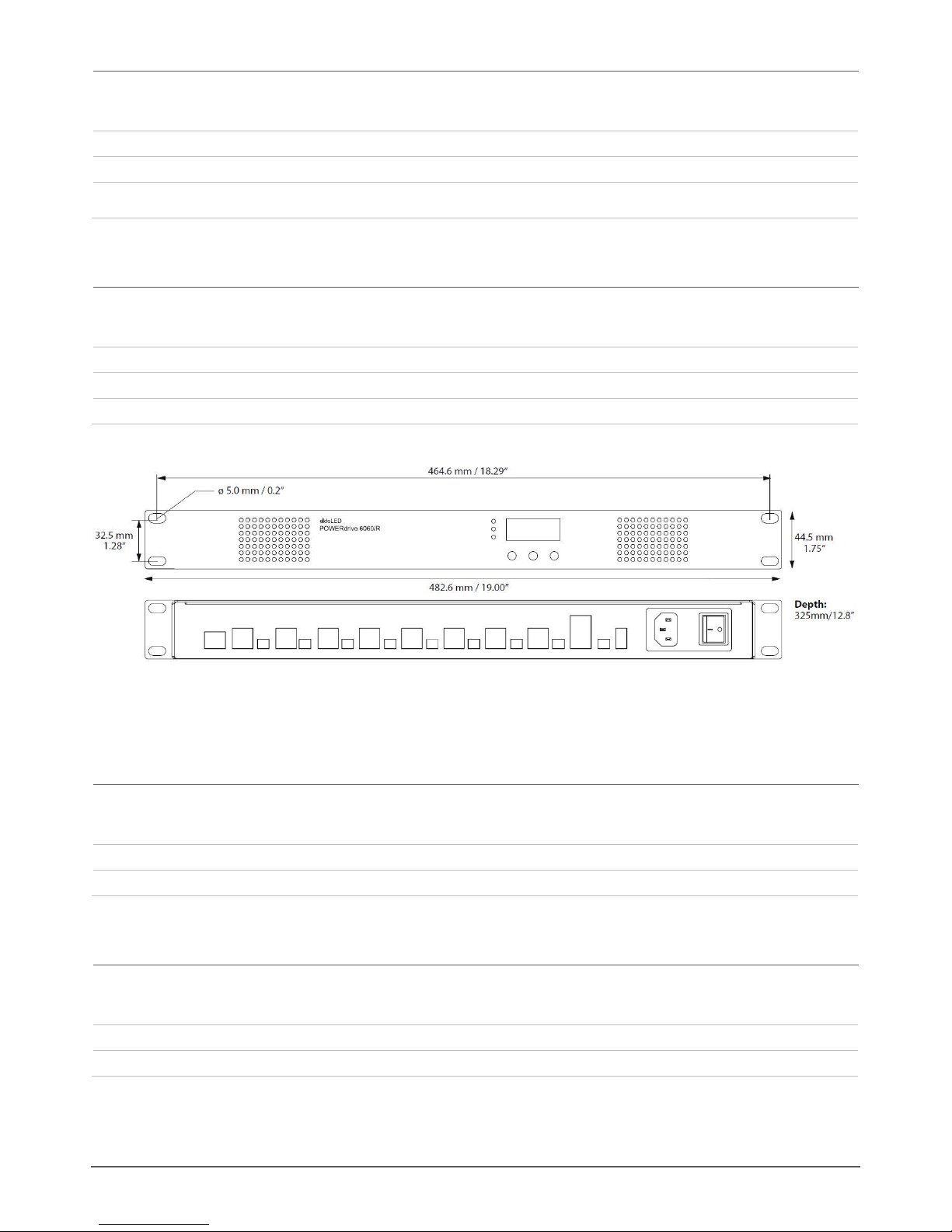

1.7 Dimensions, weight and packaging

L x W x H

482.6 x 325 x 44.5mm / 19 x 12.8 x 1.75in

Weight

6.3kg / 13 lb, 14.23 oz

Packaging

1 pc

Figure 1.2 POWERdrive 6060/R dimensions

1.8 Standards compliance

EN

EN 55022, EN 62386-101/102/207, EN 60929 Annex E

RoHS

RoHS2

1.9 Certifications

CE

Directives 2004/108/EC, 2006/95/EC, 2011/65/EU

UL

Pending

7

2. Wiring

2.1 Wiring specifications

2.1.1 General wiring specifications

Wire type

AWG20 –AWG16, 0.5-1.5mm2

Wire core type

Solid or stranded copper

Wire strip length

9mm, 0.35in

The maximum length of LED wiring is 100m / 328ft from LED output to LED load when using 16 AWG type wires.

Refer to the table below for the maximum LED wiring length for other wire types:

AWG value

20

19

18

17

16

Distance (m)

14

18

22

28

36

Distance (ft)

46

59

72

92

118

Please observe a voltage drop over long wire lengths: the longer the wire length between LED output and LED load, the lower the forward voltage is

that is available to you per LED output.

2.1.2 Power cord requirements

Europe excluding UK

certified according to EN50525 norm

CEE7 mains plug

IEC60320 C13 connector

H05VV F3 x 0.75mm2cable

United Kingdom

certified according to EN50525 norm

BS1363A mains plug

IEC60320 C13 connector

H05VV F3 x 1.0mm2cable

USA

UL listed

NEMA 5-15P mains plug

IEC60320 C13 connector

S 3x 18AWG/16AWG VCTF3x 0.75mm2cable

Type SP-2, Type SPE-2, Type SPT-2, or heavier cord, minimum 1.5 m

(5 ft) in length

8

2.1.3 Sample voltage drop calculation

Situation ‘X’:

Wire resistance (Rwire): 0.02Ohm/m (check the specifications of the wire you are using)

Distance from LED output to LED load (L): 100m

LED load used (If): 1.05A

Calculation of available forward voltage for situation X:

Vf max =

48V - (2 * Rwire * L * If)

48V - (2 * 0.02 * 100 * 1.05) = 43.8V

From the above follows that in situation X you have a voltage drop of 48V - 43.8V = 4.2V per LED output

EMI susceptibility will increase with longer wire lengths.

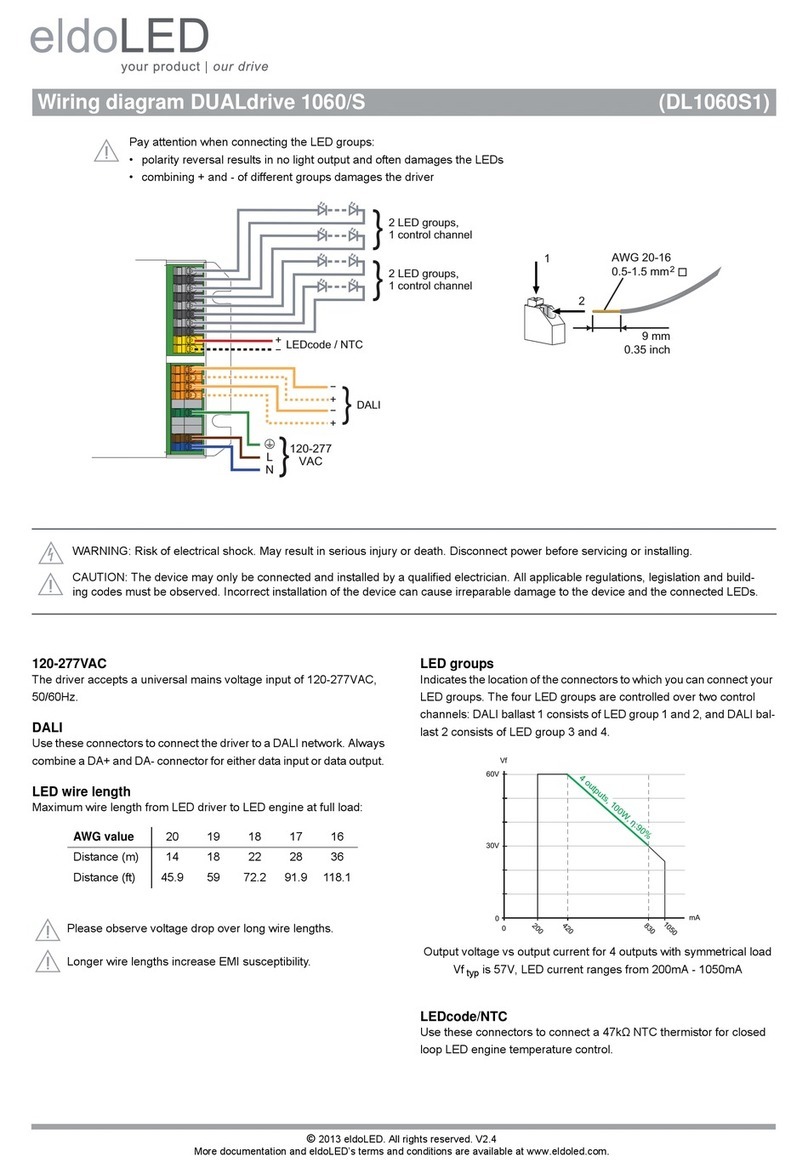

2.2 Connections

Figure 2.1 POWERdrive 6060/R connections

WARNING: risk of electrical shock. May result in serious injury or death. Disconnect power before servicing or installing.

CAUTION: the device may only be connected and installed by a qualified electrician. All applicable regulations, legislation and building

codes must be observed. Incorrect installation of the device can cause irreparable damage to the device and the connected LEDs.

CAUTION: pay attention when connecting the LEDs: polarity reversal results in no light output and often damages the LEDs.

9

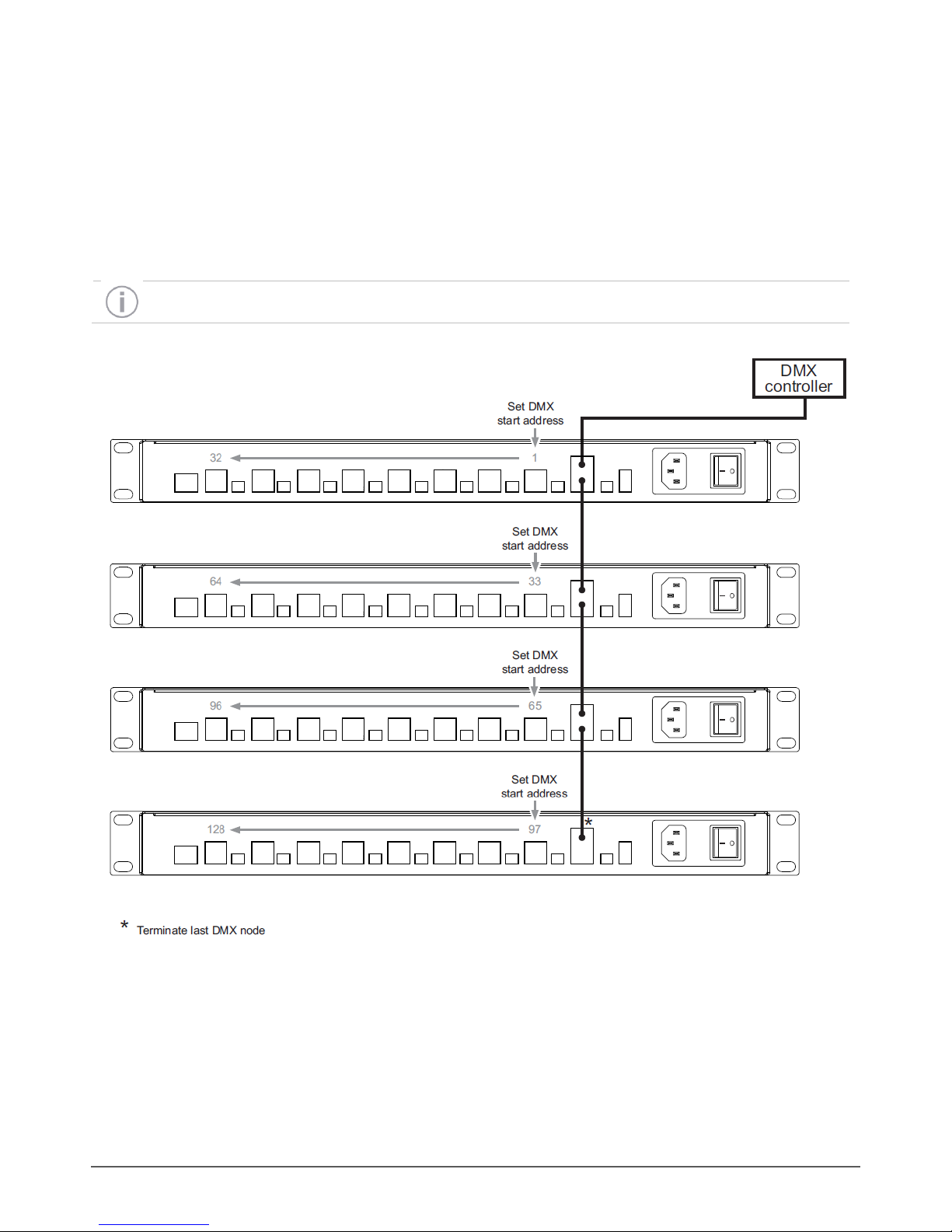

2.2.1 DMX network options

Bussed DMX

To set up a bussed DMX network:

Use the ‘DMX in’ and ‘DMX thru’ connectors as shown in the diagram below

Set the correct DMX start address for each POWERdrive

Make sure you terminate the last POWERdrive 6060/R with a resistor that matches the impedance of the cable used as close to its ‘DMX

in’ connector as possible.

DMX+, DMX- and DMX Shield (the orange-white, orange and brown wire in a CAT5 cable) are pin 1, 2 and 7 of the RJ45 connector.

Figure 2.2 Bussed DMX

10

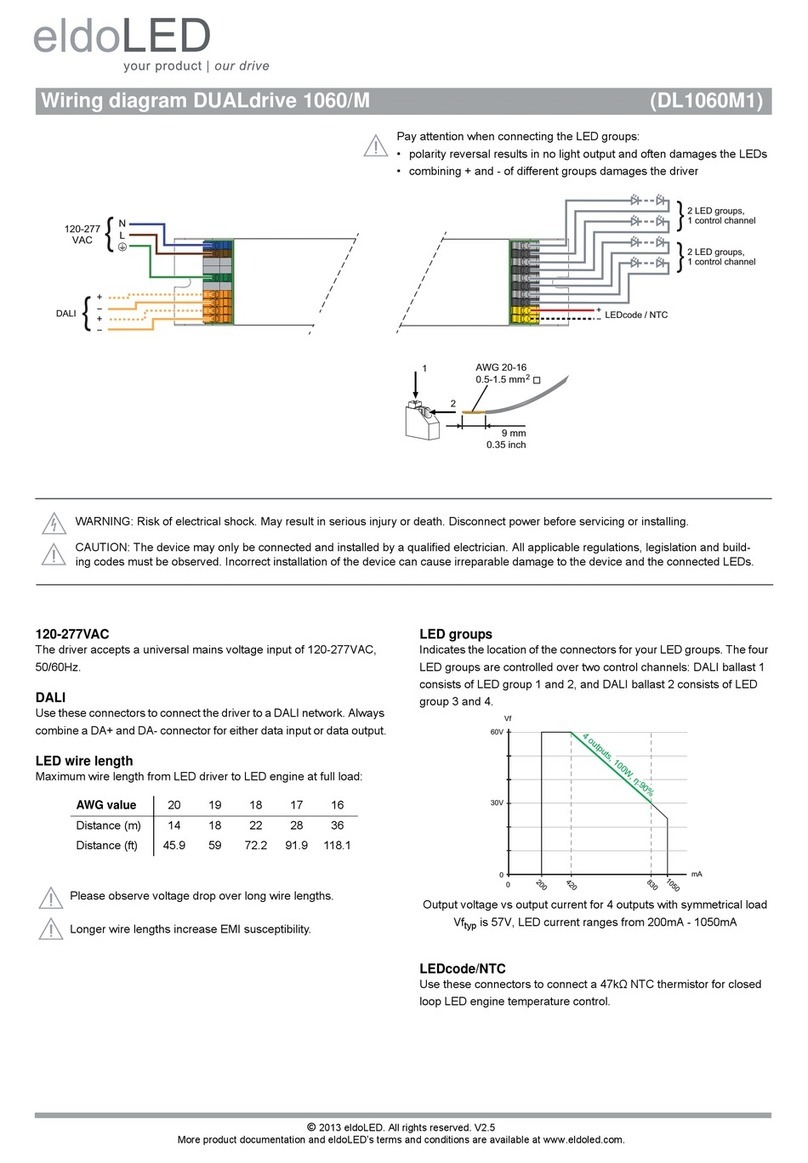

Daisy-chained DMX

To set up a daisy-chained DMX network:

Use the ‘DMX in’ and ‘DMX out’ connectors as shown in the diagram below

Set the correct DMX start address for the first POWERdrive in a group

Make sure you terminate the POWERdrives at their ‘DMX in’connector when the wire length between drivers is over 20m. Use a resistor

that matches the impedance of the cable that has been used.

DMX+, DMX- and DMX Shield (the orange-white, orange and brown wire in a CAT5 cable) are pin 1, 2 and 7 of the RJ45 connector.

Figure 2.3Daisy-chained (buffered) DMX

11

2.2.2 LED outputs

POWERdrive 6060/R features 32 LED outputs. Note that if you want to connect an LED load to every LED output, the maximum current per output

is 800mA. Refer to Chapter 1, Technical Characteristics, for more information on derating and LED wiring.

LED outputs controlled over DMX/RDM

When you are using the DMX or RDM protocol, you can assign a DMX address to every single LED output. For configuration options such as LED

output current, however, the LED outputs are grouped according to the corresponding current sources.

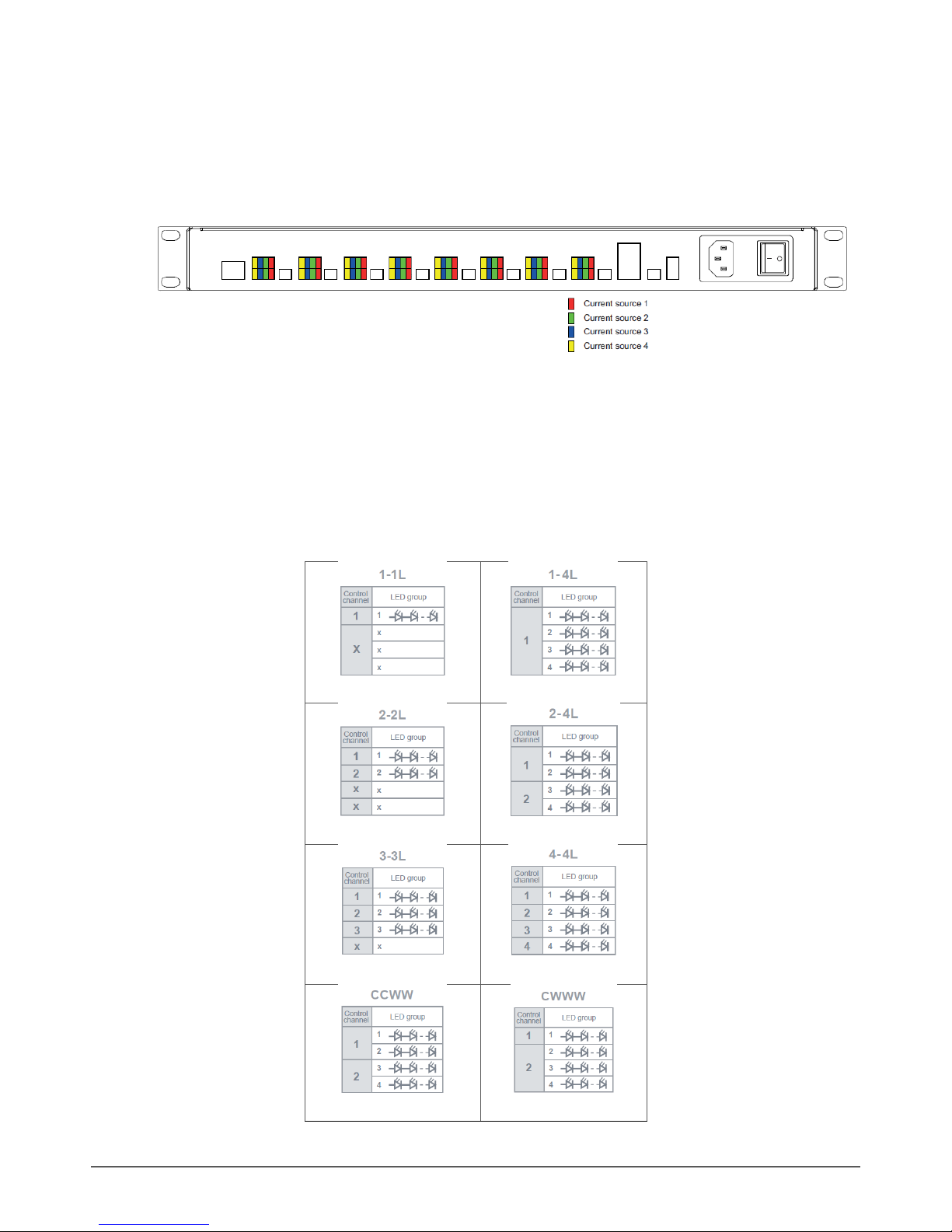

Figure 2.4 POWERdrive 6060/R LED outputs and corresponding current sources

LED outputs controlled over DALI

When you are using the DALI protocol, you can define up to 4 DALI ballasts for every POWERdrive 6060/R with your DALI commissioning tool.

Figure 2.5 Up to 4 DALI ballasts

LED outputs controlled over 0-10V

When you are controlling the POWERdrive 6060/R over 0-10V, all LED outputs are controlled over the same channel, i.e. all LED outputs will show

the same behavior.

Figure 2.6 One 0-10V control channel

12

2.2.3 LEDcode/NTC

For extensive thermal management purposes, you can use an NTC thermistor. This sensor can be fastened on or near the LED engine, and its

wires connected to the LEDcode/NTC connectors.

Figure 2.7 Examples of NTC thermistors

The NTC thermistor feeds the temperature values that it detects to the driver. Whenever these values exceed the predefined NTC temperature limit,

the driver will gradually decrease the light output until normal operating temperatures are reached.

You can connect a 47kOhm NTC thermistor to the LEDcode/NTC interface for this closed loop thermal control. Recommended NTC thermistors

include:

238164063472 (leaded)

NTCASCWE3473J (screw)

2.2.4 0-10V

Connect your 0-10V control device to the ‘0-10V+’and ‘0-10V-’connector on the POWERdrive 6060/R.

2.2.5 DALI

Use the DALI connectors to connect the POWERdrive 6060/R to a DALI network. Always combine a DA+ and DA- connector for either data input or

data output. You can address the LED outputs over a total of 4 DALI ballasts.

2.2.6 120-230V AC

The LED driver has been designed for use with universal mains voltage input of 120-230V AC, 50-60Hz.

13

3. Installing the POWERdrive 6060/R

This chapter gives guidelines for the installation of POWERdrive 6060/R with regard to cable connections, grounding the LED output wires and use

of cable trunks.

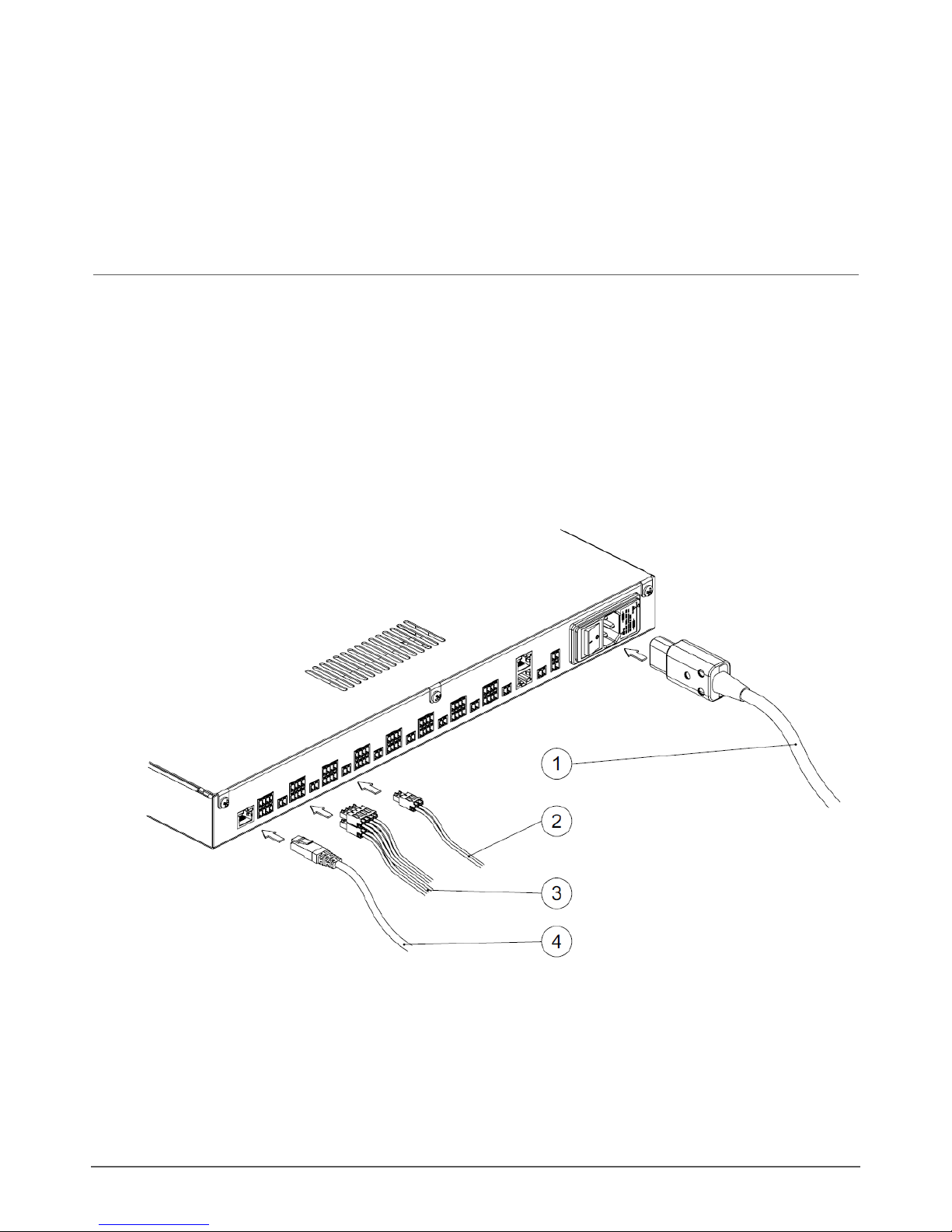

3.1 Cable connections

It is recommended that you use shielded cabling for the LED output wires that connect the 19” rack unit to the LED loads in order to reduce EMI

(Electromagnetic Interference). This will enable the installing party to meet EMC requirements.

For connection of LED, NTC and LEDcode wires, use the mating connectors listed below:

2-pole terminal block, Phoenix contact FMC 1.5/2-ST-3.5-1952267 P1334

4-pole terminal block, Phoenix contact FMC 1.5/4-ST-3.5-1952283 P1348

Figure 3.1 Cable connections: mains cable (1), NTC and LEDcode wires (2), LED wires (3) and DMX cable (4)

14

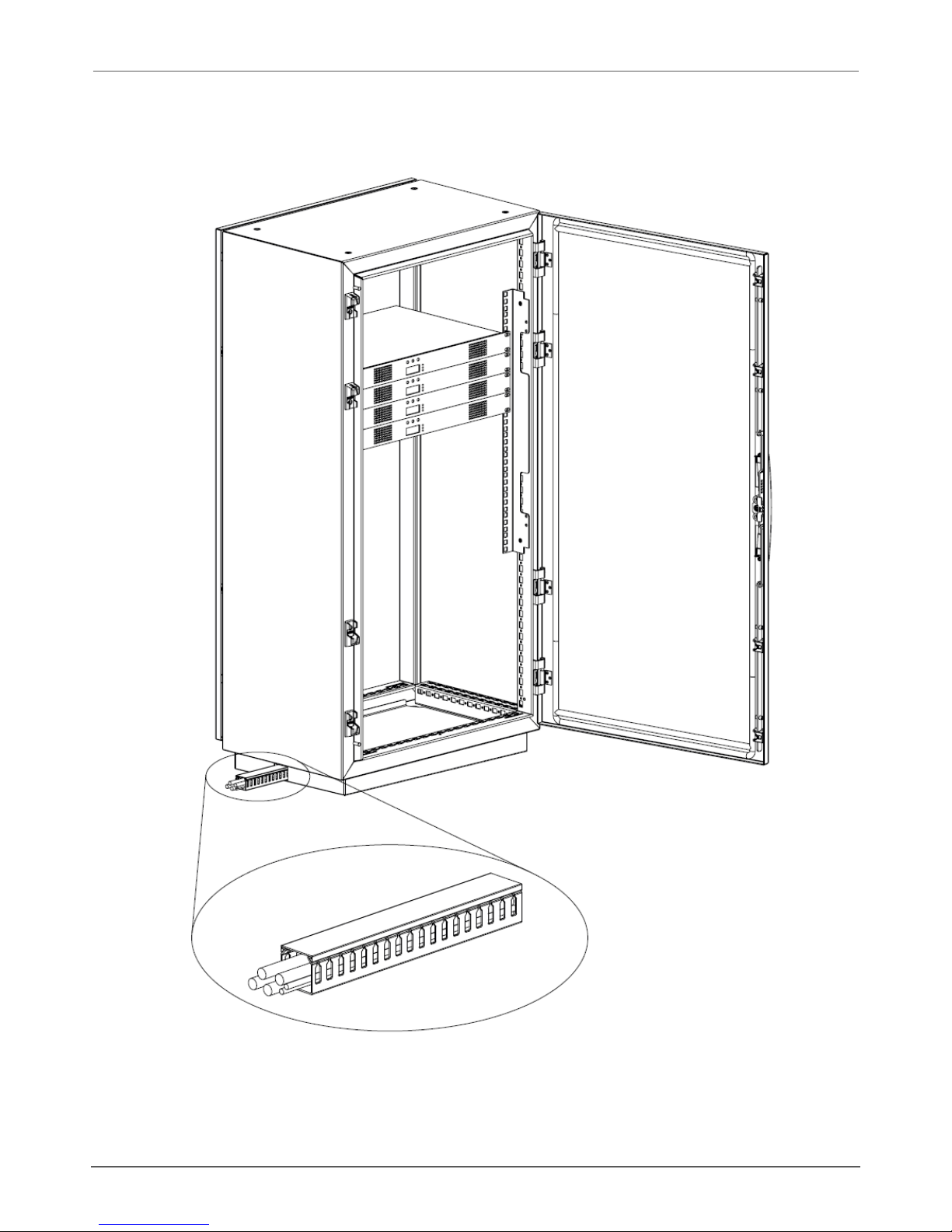

3.2 Common practice for grounding LED wires

POWERdrive 6060/R has been designed for installation in a 19” rack. It is recommended to ground the shielded LED output cables both at the

19”rack unit and close to the LED load.

Inside the 19” rack unit, ground the LED wires as depicted in Figure 3.3 by leading them though an earthing clamp (2) that is attached to a C-rail (1).

Ground the LED wires a second time as close to the LED load as possible.

Figure 3.2 Grounding LED wires inside 19” rack unit

15

3.3 Cable trunk

Cable trunks as depicted in Figure 3.3 will facilitate leading the wires over longer distances inside the building.

Figure 3.3 Using cable trunks

16

4. Configuring POWERdrive 6060/R

Configure the POWERdrive 6060/R over its intuitive, 3-button user interface with display. The easy-to-navigate menu allows you to set parameters

such as number of LED groups, DMX or DALI settings for networked mode and show/colour/dim values for standalone operation. You can also lock

the driver’s configuration and perform a test run of the connected LED groups.

This chapter explains how to work with the user interface, and lists the various menu items and selectable values.

4.1 Menu button combinations

POWERdrive 6060/R features three menu buttons on its front side (M, - and +) with which you can navigate the configuration menu. The display

above the buttons shows the menu options and values that can be selected for every option.

Pressing the M button

shows the current mode or the next menu option; use the M button to browse menus and settings without making any changes.

saves a changed value.

turns off the display after the last menu option has been displayed.

Pressing the + (plus) or - (minus) button

changes a value. The changed value is only saved when M is pressed.

Have you accidentally changed a value but haven’t confirmed it yet by pressing M? By refraining from pressing the buttons for at least 8 seconds,

you will leave the menu (display is turned off) without changing the value.

If you are in a menu and want to change to another menu, refrain from pressing the buttons for at least 8 seconds (display is turned off), and

subsequently press the button combination for the menu you want to change to.

4.2 Order of LED driver configuration

The very first time the LED driver is powered on, the display will show the LED driver type (POWER RACK), for a couple of seconds. Next, the

display shows “SET MODE”. Set the mode of operation before you move on to the other menu items.

If the power is interrupted to a POWERdrive 6060/R that has already been configured, the display will only show the driver type when the power

comes back on, but will not go to the Set Mode menu, as the driver’s configuration has been saved to memory.

Basic configuration of the POWERdrive 6060/R includes the following steps:

1. Set the mode of operation (see 4.3 Setting the operation mode).

2. Set the LED output currents and LED group configuration (see 4.4 Setting the LED output current and LED group configuration).

3. Configure or view the operation mode you have chosen (see 4.5).

4. Optional:

You can do a test run of all connected LEDs by simultaneously pressing the M, - and + buttons

You can hard or soft lock the configuration by simultaneously pressing the M and + button and holding this combination down for 5

seconds

You can reset the driver’s configuration to the factory defaults by simultaneously pressing the M, - and + buttons and holding this

combination down for 5 seconds

17

4.3 Setting the operation mode

To enter the SET MODE menu:

1. The very first time the driver is powered on, the display will show the driver type/name for a couple of seconds and then automatically

enter the SET MODE menu.

To manually enter the SET MODE menu, press the M button for 5 seconds

The display shows “SET”- “MODE”, followed by the name of the currently active operation mode

2. Using the minus or plus button, go to the operation mode of your choice (COLR, SHOW, DMX, DALI or 10V).

3. Press M to save your choice. The display will turn off after you have pressed the M button.

Figure 4.1 Set mode menu

If you have confirmed COLR as the mode of operation, it is recommended to set the LED groups and the LED output current first,

before entering the COLR menu to set the color of your choice: if the LED current is not set correctly (e.g. too low), there might not

be any light output for you to verify the color.

4.4 Setting the LED output current and LED group configuration

In the setup menu, you can configure the LED output currents per current source, set the LED group configuration, and define the NTC

temperature.

Ensure that the LEDs you’re connecting to the driver can handle the LED output current! For instance, connecting 500mA LEDs to a

driver that has been configured for a 700mA output current will blow up the LEDs!

Figure 4.2 Configuring LED output current, LED group configuration, NTC temperature

18

To set LED output currents and LED group configurations:

1. Press M and the plus button simultaneously.

2. In the first menu (CUR1), select the LED output current for the current source 1. Figure 4.3 shows which current sources the LED outputs

are connected to. By pressing the plus or minus button you can go up or down in 50mA steps.

Figure 4.3 Current sources and corresponding LED outputs

3. Press M to save your choice, and repeat the same exercise for the LED outputs connected to current source 2 (CUR2), 3 (CUR3) and 4

(CUR4). Always save your selection by pressing M.

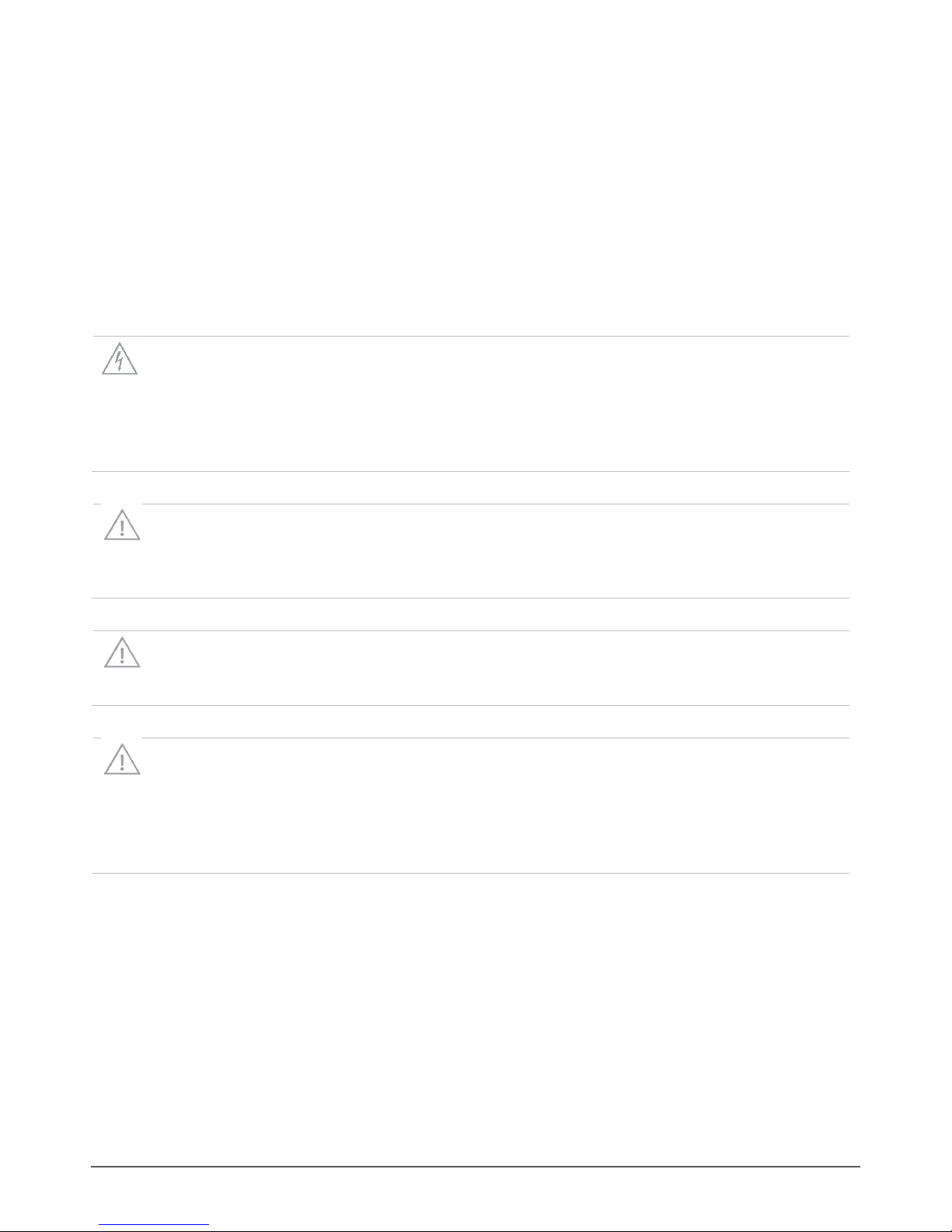

4. In the LED menu item, select the configuration of the LED groups that best fits your application. The below figures show the possibilities

offered in this menu item.

The LED group in pictures below refers to the Figure 4.3, which shows which current sources the LED outputs are connected to.

19

20

Safety guidelines

Before installing or performing routine maintenance upon this equipment, follow the general precautions listed in this Appendix. Installation should

be performed by a qualified licensed electrician. Maintenance should be performed by qualified person(s) familiar with the products’ construction

and operation and any hazards involved.

Do not install damaged product! This product has been properly packed so that no parts should have been damaged during transit. Inspect to

confirm.

WARNING: RISK OF ELECTRIC SHOCK:

- Disconnect or turn off power before installation

- Verify that supply voltage is correct by comparing it with the product information

- Make all electrical and grounded connections in accordance with all applicable local code requirements

- All wiring connections should be capped with UL approved recognized wire connectors

- All unused connector openings must be capped.

WARNING: RISK OF BURN OR FIRE:

- Do not exceed maximum wattage, ratings, or published operating conditions of product

- Do not overload

- Follow all manufacturer’s warnings, recommendations and restrictions to ensure proper operation of product

CAUTION: RISK OF DAMAGE DUE TO ESD (ELECTROSTATIC DISCHARGE):

- ESD can damage product(s). Personal grounding equipment must be worn during all installation of the unit.

- Do not touch individual electrical components as this can cause ESD and affect product performance.

CAUTION: RISK OF PRODUCT DAMAGE:

- Do not stretch or use cable sets that are too short or are of insufficient length.

- Do not tamper with contacts.

- Do not modify the product.

- Do not change or alter internal wiring or installation circuitry.

- Do not use product for anything other than its intended use.

Table of contents

Other eldoLED Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

GAME OF BRICKS

GAME OF BRICKS Thor's Hammer 76209 instruction manual

Rosco

Rosco DMX IRIS Operation manual

Ovation

Ovation C19 user manual

Melink

Melink ML1B5W20-GU15RGBCCT instruction manual

HUBBELL LIGHTING

HUBBELL LIGHTING DUAL LITE EVHC Series installation instructions

Gama Sonic

Gama Sonic 143iP2902KIT instruction manual