Introduction

Appendix G describes assembly of the K2/100 transceiver's internal 100-

watt final output stage (KPA100 board). The PC board includes two

conservatively-rated RF power transistors, low-pass filters, SWR bridge,

monitoring circuits, speaker, and an RS-232 interface. Filter switching, T-

R sequencing, and other configuration is handled by the K2/100's main

microcontroller.

KPA100 assembly and installation should be done only after the

transceiver has been aligned and tested at the 10-watt level.

Upgrades Recommended for Older K2s

All K2 owners are encouraged to keep their transceivers up to date by

making recommended changes. These changes should be installed and

tested before the KPA100 is installed.

K2 s/n 4059 or lower: K2 keying bandwidth modification (order

#K2KEYMODKT). This modification is strongly recommended for CW

operators, especially if you use high power. Note: Requires upgrade to

revision 2.04 or later K2 firmware (order #FWK2MCIO).

K2 s/n 3445 or lower: PLL Upgrade (order #E850138). This ensures

excellent VFO temperature stability during high-power operation.

K2 s/n 2999 or lower: (1) 10 meter band-pass filter and VFO ALC

modification (#E850093, supplied with your KPA100 kit). (2) BFO

modification (order #BFOMDKT). You should also make all applicable

changes described in this document:

http://www.elecraft.com/manual/k2a2binstr.pdf

Pre-Wound Toroids Available

The toroids used in the KPA100 are not difficult to wind, and full

instructions are provided. If you prefer not to wind them yourself, you

can obtain a full set of pre-wound toroids from an Elecraft-qualified

source. Ordering information can be found on our web site,

www.elecraft.com. You do not need to send your cores or wire to the

winding service.

Preparation for Assembly

With all equipment that operates at high power levels, proper assembly

and alignment are critical for safe and reliable operation. Follow the

instructions carefully and make all of the recommended measurements.

Do not substitute components or perform any assembly steps out of order.

Please read the following information regarding tools before

proceeding.

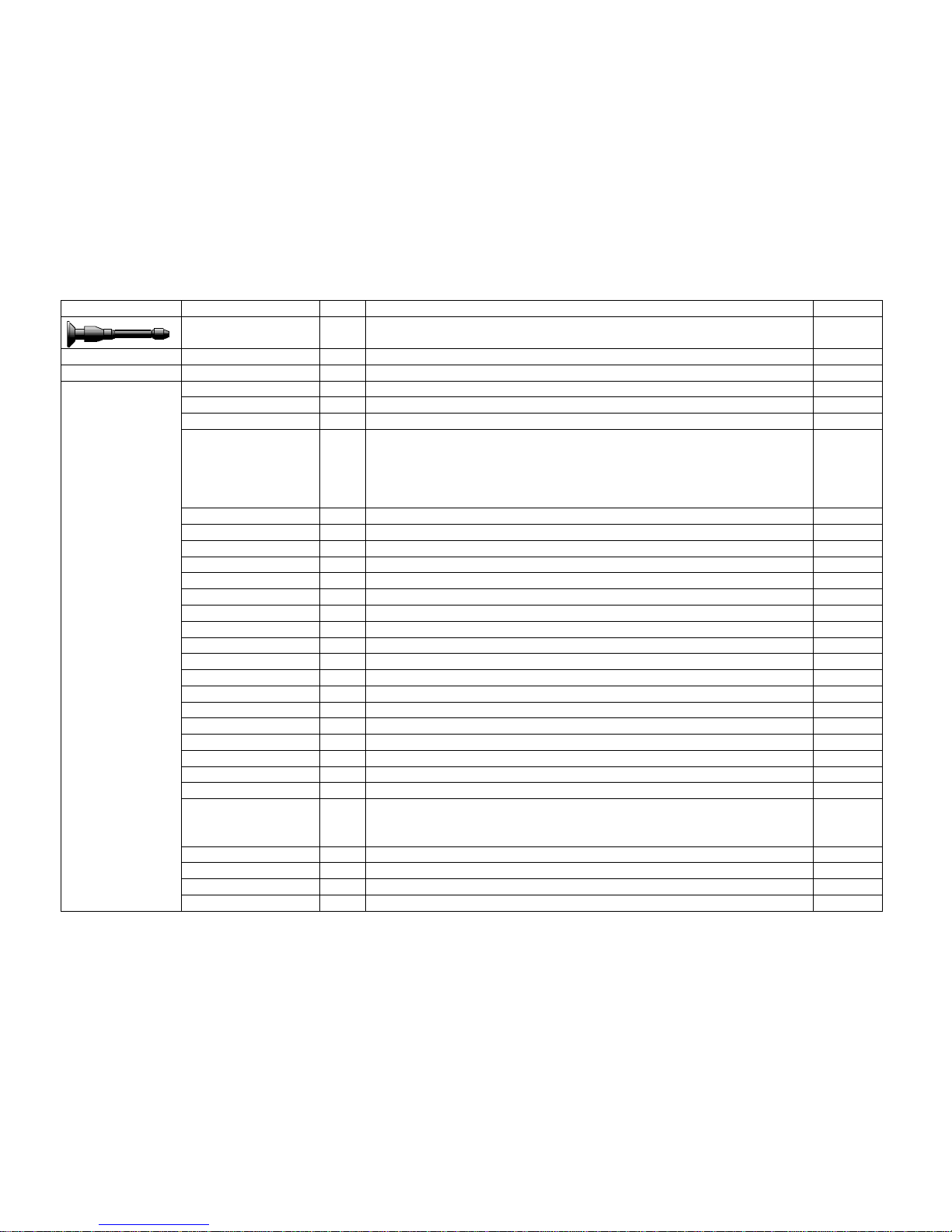

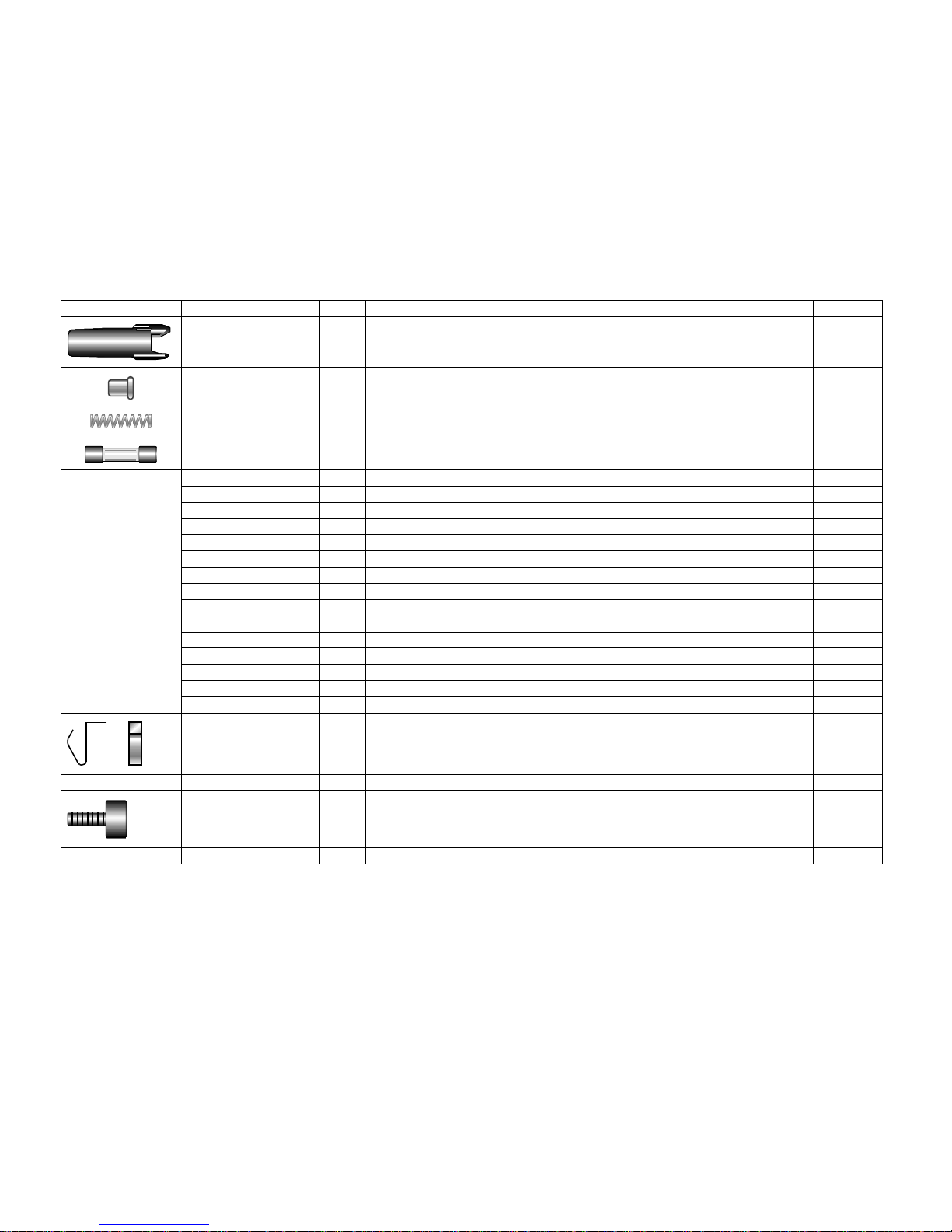

Tools Required

The following tools are required to build this kit:

Flush-cutters (Hakko CHP-170, Xcelite 170, etc.). Ordinary

diagonal cutters are not suitable for flush-cutting (trimming leads

very close to the board).

Temperature-controlled soldering station with a fine-point, 700

to 800-degree (F) tip. Do not use a high-wattage iron or gun with

small components, since this can damage pads, traces, or the parts

themselves.

Larger iron or soldering gun. This will be used only for installation

of power transistors, output transformer, and DC power wiring. A

low-wattage iron cannot be used for these steps.

Digital Multimeter (DMM). A DMM with diode-checking

capability. Capacitance measurement capability is desirable, though

not required.