ELECRAFT 9

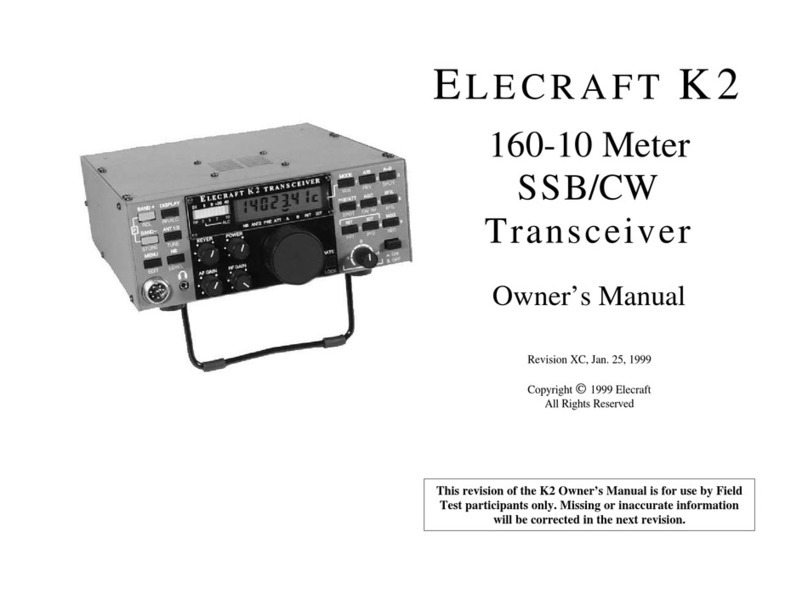

There are six steps in the K2 assembly process:

1. Control Board assembly

2. Front Panel Board assembly

3. RF Board assembly and test, part I (control circuits

4. RF Board assembly and test, part II (receiver and synthesizer

5. RF Board assembly and test, part III (transmitter

6. Final assembly

This assembly sequence is important because later steps build on the

previous ones. For example, in step 3 you’ll put the modules

together for the first time, allowing you to try out the K2’s built-in

frequency counter. The counter will then be used in step 4 to align

and test the receiver and synthesizer on 40 meters. In step 5 all the

pieces will come together when you complete the transmitter and

filters, then align the K2 on all bands. The last few

details—speaker, tilt stand, etc.—will be wrapped up in step 6.

Unpacking and Inventory

When you open the kit you should find the following items:

six chassis pieces (Figure 3-1

three printed circuit boards (Figure 3-2

FR NT PANEL board components bag

C NTR L board components bag

RF board components in two bags

MISCELLANE US components bag (includes hardware

WIRE bag

4-ohm Speaker, 5 small knobs, and large tuning knob

plastic tube containing the latching relays

an envelope containing the LCD bezel, green LED bargraph

filter, serial number label, thermal insulators, and other items

Inventory

We strongly recommend that you do an inventory of parts before

beginning to assemble the kit. It is not necessary to inventory the

resistors, which are supplied attached to tape in assembly order.

Even if you don’t do an inventory, it is helpful to familiarize

yourself with the parts list, Appendix A. Additional information on

identifying capacitor, chokes, and resistors is provided below.

Identifying Capacitors

Small-value fixed capacitors are usually marked with one, two, or

three digits and no decimal point. If one or two digits are used, that

is always the value in picofarads (pF . If there are three digits, the

third digit is a multiplier. For example, a capacitor marked "151"

would be 150 pF (15 with a multiplier of 101. Similarly, "330"

would be 33 pF, and "102" would be 1000 pF (or .001 µF . In rare

cases a capacitor manufacturer may use "0" as a decimal

placeholder. For example, "820" might mean 820 pF rather than

the usual 82 pF. Such exceptions are usually covered in the parts

lists. To be safe, measure the values of all capacitors below 1000 pF

(most DMMs include capacitance measurement capability .

Fixed capacitors with values of 1000 pF or higher generally use a

decimal point in the value, such as .001 or .02. This is the value in

microfarads (µF . Capacitors also may have a suffix after the value,

such as ".001J." In some cases the suffixes or other supplemental

markings may be useful in identifying capacitors.

Hard-to-identify capacitor values:

3.3 pF: These capacitors may have pillow-shaped, dark-green

bodies about 1/8" (3 mm square, with a black mark on the top. The

"3.3" label may be difficult to read without a magnifying glass.

150 pF: These are correctly marked "151" on one side, but the

other side may be marked #21 ASD, where "#21" looks like "821."