ii

Contents

Introduction...............................................................................................................................................1

Customer Service and Support............................................................................................................................1

Technical Assistance.......................................................................................................................................1

Preventing Electrostatic Discharge Damage ............................................................................................3

How ESD Damage Occurs..................................................................................................................................3

Preventing ESD Damage..................................................................................................................................... 3

Preparing for Assembly............................................................................................................................4

Overview of the Kit.............................................................................................................................................4

Tools and Test Equipment Required...................................................................................................................6

Unpacking and Inventory....................................................................................................................................7

Screws.............................................................................................................................................................7

Standoffs .........................................................................................................................................................8

Lock Washers.................................................................................................................................................. 8

Assembly ..................................................................................................................................................9

RF Board and Chassis.........................................................................................................................................9

Circuit Description..........................................................................................................................................9

RF Board and Chassis Assembly Procedure................................................................................................. 11

KANT3 or KAT3 and Rear Panel.....................................................................................................................19

Circuit Description........................................................................................................................................19

KANT3 or KAT3 and Rear Panel Installation Procedure.............................................................................19

KIO3 Interface .................................................................................................................................................. 22

KIO3 Circuit Description..............................................................................................................................22

KIO3 Interface Installation Procedure .......................................................................................................... 23

Front Panel and DSP.........................................................................................................................................25

Circuit Description........................................................................................................................................25

Front Panel Assembly Procedure..................................................................................................................26

Resistance Checks......................................................................................................................................... 34

Initial Power On Check.................................................................................................................................35

KREF3 ..............................................................................................................................................................36

Circuit Description........................................................................................................................................36

KREF3 Installation Procedure ......................................................................................................................36

KSYN3..............................................................................................................................................................37

Circuit Description........................................................................................................................................37

KSYN3 Installation Procedure......................................................................................................................38

KPA3 Installation..............................................................................................................................................39

Bottom Cover....................................................................................................................................................39

Bottom Cover Installation.............................................................................................................................40

Battery BT1.......................................................................................................................................................41

Battery BT1 Function....................................................................................................................................41

Battery BT1 Installation Procedure............................................................................................................... 42

Top Cover and Speaker..................................................................................................................................... 42

Test and Calibration................................................................................................................................44

Initial Power Checks ......................................................................................................................................... 44

Synthesizer Calibration..................................................................................................................................... 45

Filter Setup........................................................................................................................................................45

Option Modules.................................................................................................................................................45

Transmitter Test................................................................................................................................................45

Wattmeter Calibration (Optional) ..................................................................................................................... 45

Reference Oscillator Frequency (Optional) ...................................................................................................... 45

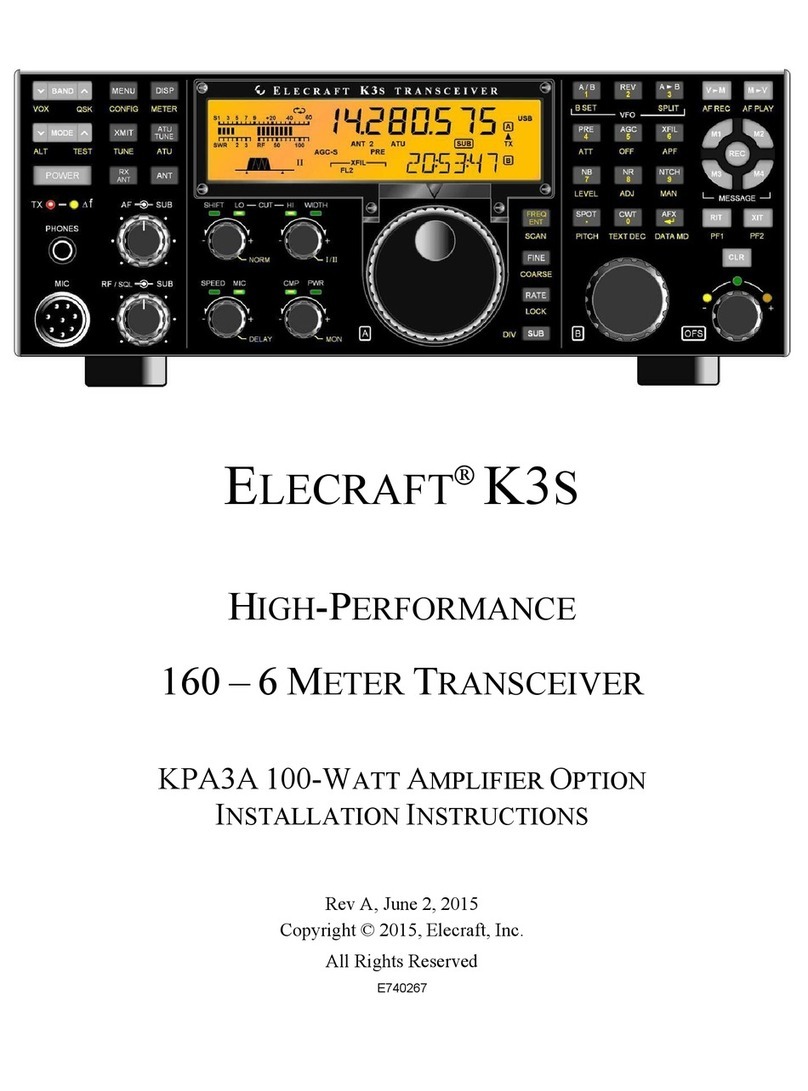

KPA3 100-Watt Module Installation......................................................................................................46