Electro Industries/GaugeTech Shark 100B User manual

Doc# E145752 V.1.05 QS - 1

Shark® 100B Quickstart

Electro Industries/GaugeTech

™

Powered by Innovation™

Shark® 100B Meter Quickstart Guide

CAUTION! Installation of the Shark® 100B meter must be performed only by qualified personnel who follow

standard safety precautions during all procedures. Those personnel should have appropriate training and

experience with high voltage devices. Appropriate safety gloves, safety glasses and protective clothing are

recommended.

During normal operation of the Shark® meter, dangerous voltages flow through many parts of the unit, includ-

ing: Terminals and any connected CTs (Current Transformers) and PTs (Potential Transformers), all I/O Modules

and their circuits. All Primary and Secondary circuits can, at times, produce lethal voltages and currents. Avoid

contact with any current-carrying surfaces.

Do not use the meter or any I/O device for primary protection or in an energy-limiting capacity. The meter can

only be used as secondary protection.

IMPORTANT! Refer to your meter’s Installation and Operation Manual for additional safety warnings before

performing installation, wiring, or maintenance of your meter. See the link to the manual, below.

NOTE: This Quickstart Guide gives basic installation, wiring, and programming instructions.For additional meter operation

and programming information, refer to your meter’s Installation and Operation Manual and the Communicator PQATM,

MeterManagerPQATM, and EnergyPQA.comTM Software User Manual on EIG’s website:

User Manual:

https://www.electroind.com/products/shark-100b-bacnet-ip-communicating-multifunction-meter/

From the webpage, click Technical Documents>User Manual.

Software Manual:

https://www.electroind.com/products/communicatorpqa-software-application-5/

From the webpage, click Technical Documents>User Manual.

CommunicatorPQATM Setup Software:

https://www.electroind.com/products/communicatorpqa-software-application-5/

From the webpage, click Download ComPQA Pro. To get a Professional license for the software, email sales@elec-

troind.com or call 516-334-0870.

All EIG’s metering and software products’ literature can be accessed from:

https://www.electroind.com/all-products/

For software and metering integration, EIG’s Technical Support Engineers are available on an hourly or daily basis to help

with typical commissioning assistance, which includes:

• Verifying meter installation and wiring.

• Verifying proper system integration.

• Working with 3rd parties to ensure cross compatibility.

• Advising users on best practices for optimal implementation.

You can reach Technical Support from 8 a.m. to 8 p.m. EST, Monday-Friday, at 516-334-0870.

Doc# E145752 V.1.05 QS - 2

Shark® 100B Quickstart

Electro Industries/GaugeTech

™

Powered by Innovation™

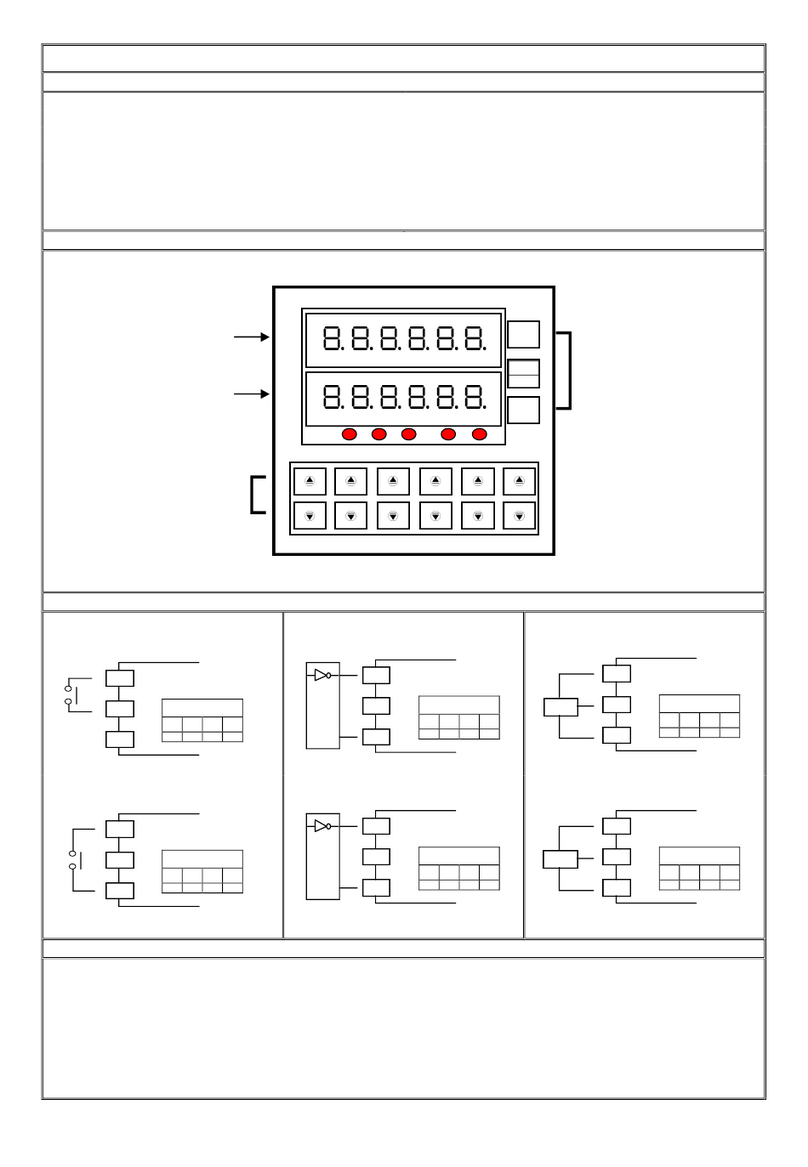

Mechanical Installation

Electrical Installation: Select diagram for your application.

NOTE: Other wiring configurations are available. See the Shark® 100/100B meter User Manual (see

page QS-1 for the download link).

DIN mounting

bracket

Top mounting

bracket groove

Bottom

#8 screw

Remove (unscrew)

ANSI studs for

DIN installation

Meter in

NEMA12

mounting

gasket

DIN Mounting brackets

92mm Square

form

Remove (unscrew) ANSI studs

for DIN installation

DIN Installation

4.0” Round form

ANSI Studs

ANSI Installation

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

3 x 0.1A

FUSE

3A

C

C

B

B

A

A

N

N

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

3 x 0.1A

FUSE

3A

C

C

B

B

A

A

N

N

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

2 x 0.1A

FUSE

3A

C

C

B

B

A

A

WYE direct, 3

phase, 4 wire

Delta direct, 3

phase, 3 wire

lc

HI

LO

lb

HI

LO

la

HI

LO

Earth Ground

L(+)

Power

Supply

Connection

N(-)

L(+)

GND

N(-)

Vref

Va

Vb

Vc

LINE

LOAD

CT

Shorting

Block

FUSES

3 x 0.1A

FUSE

3A

C

C

B

B

A

A

NOTE: Do not overtighten nuts. The maximum installation torque is 0.4 Newton-Meter.

WYE with PTs,

3 phase, 4 wire

Delta with PTs, 3

phase, 3 wire

Doc# E145752 V.1.05 QS - 3

Shark® 100B Quickstart

Electro Industries/GaugeTech

™

Powered by Innovation™

Program Settings Using the Faceplate Buttons:

(MENU, ENTER, DOWN ARROW, RIGHT ARROW)

See the figure on the right for the location of the

faceplate buttons.

Access Configuration Mode:

1.Push the MENU button - you will see

the display on the right; rSt will be

blinking.

2.Press the DOWN ARROW once.

CFG (Configuration) moves to the

top of the display.

3.Press the ENTER button. You will

see the Configuration menu, shown

on the right.

4.Press the DOWN ARROW and then press the ENTER button. You will see the CT

numerator setting screen (Ct-n). The current CT numerator is shown in the second

line. To change the setting, press the DOWN ARROW until the value you want is

displayed. Then press the RIGHT ARROW to move to the next digit. Repeat until

the setting is done.

5.Press the ENTER button to go to the CT denominator screen (CT-d). This setting is

display only - it can’t be changed.

6.Press the ENTER button to go to the CT Scaling setting screen (CT-S). The current

Scaling is shown in the second line. Press the DOWN ARROW to choose another

value. You can choose 1, 10, or 100.

7.Press the ENTER button to go to the PT numerator setting screen (Pt-n).The current

PT numerator is shown in the second line. To change the setting, press the DOWN

ARROW until the value you want is displayed. Then press the RIGHT ARROW to

move to the next digit. Repeat until the setting is done.

8.Press the ENTER button to go to the PT-denominator screen (Pt-d). The current

PT denominator is shown in the second line. To change the setting, press the DOWN

ARROW until the value you want is displayed. Then press the RIGHT ARROW to

move to the next digit. Repeat until the setting is done.

9.Press the ENTER button to go to the PT Scaling setting screen (PT-S). The current

Scaling is shown in the second line. Press the DOWN ARROW to choose another

value. You can choose 1, 10, 100, or 1000.

NOTE: See example CT and PT Settings beginning on the next page.

0.659

0000

-

-

-

A

B

C

MENU ENTER

MAX

MIN

LM1

LM2

%THD

PRG

VOLTS L-N

VOLTS L-L

AMPS

W/VAR/PF

VA/ H z

lrDA

Wh

VAR h

VAh

120%-

90%-

60%-

30%-

%LOAD

MEGA

KILO

Wh Pulse

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

Doc# E145752 V.1.05 QS - 4

Shark® 100B Quickstart

Electro Industries/GaugeTech

™

Powered by Innovation™

10.Press the ENTER button to go to the Connection setting screen (Cnct). The current

setting is shown in the second line. Press the DOWN ARROW to choose another

value. You can choose 3 EL (element) WYE, 2 Ct del (Delta), or 2.5 EL WYE.

11.Press the ENTER button four times. (You will pass through the Address, Baud Rate,

and Protocol screens. You DO NOT change any of the settings on these

screens.**You will see the Scroll setting screen (SCrL). The current setting is

shown in the second line. Press the DOWN ARROW to choose another setting.

You can choose YES (the meter readings will scroll on the display) or no (the meter

readings will not scroll on the display).

12.Press the MENU button twice. You will see the Store Settings screen (Stor ALL?).

The default setting is YES. To save the settings you’ve made, press the ENTER

button. You will see the confirmation screen (Stor ALL done) and then the meter

resets.

NOTE: If you do not want to save your settings, press the RIGHT ARROW. YES

changes to no. Press the ENTER button.

Example CT Settings:

200/5 Amps: set the Ct-n value as 200, Ct-S value as 1.

800/5Amps: set the Ct-n value as 800, Ct-S value as 1.

2000/5 Amps: set the Ct-n value as 2000, Ct-S value as 1

10,000/5 Amps: set the Ct-n value as 1000, Ct-S value as 10.

Example PT Settings:

14400/120 Volts: set the Pt-n value as 1440, Pt-d value as 120, Pt-S value as 10.

138000/69 Volts: set the Pt-n value as 1380, Pt-d value as 69, Pt-S value as 100.

345000/115 Volts: set the Pt-n value as 3450, Pt-d value as 115, Pt-S value as 100.

345000/69 Volts: set the Pt-n value as 345, Pt-d value as 69, Pt-S value as 1000.

**The default communication settings are Address 001, Baud Rate 57.6, and Protocol Mod rtU

(Modbus RTU). In the event that the communication settings are accidentally changed, change them

back to these default values.

NOTE: For additional wiring options, meter configuration screens, and instructions on using the

Shark® 100B’s BACnet®*, refer to the Shark® 100/100T/100B Meter Installation and Operation Man-

ual and the CommunicatorPQATM, MeterManagerPQATM, and EnergyPQA.comTM Software User Manual

(see page QS-1 for the download links).

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

A

B

C

-

-

-

MENU ENTER

Shark® is a registered trademark of Electro Industries/GaugeTech. CommunicatorPQATM, MeterManagerPQATM, and EnergyPQA.comTM are trade-

marks of Electro Industries/GaugeTech.

*BACnet is a registered trademark of ASHRAE.

https://electroind.com/

Popular Cash Counter manuals by other brands

Parametric

Parametric LoRaWAN TCR-LSA quick start guide

Agilent Technologies

Agilent Technologies 53181A operating guide

Ludlum Measurements

Ludlum Measurements 182 manual

Eaton

Eaton MN05401014E operating instructions

Veeder-Root

Veeder-Root A103-007 Technical manual

Parametric

Parametric LoRaWAN Radar People Flow Sensor user manual