http://www.nexbill.co.kr

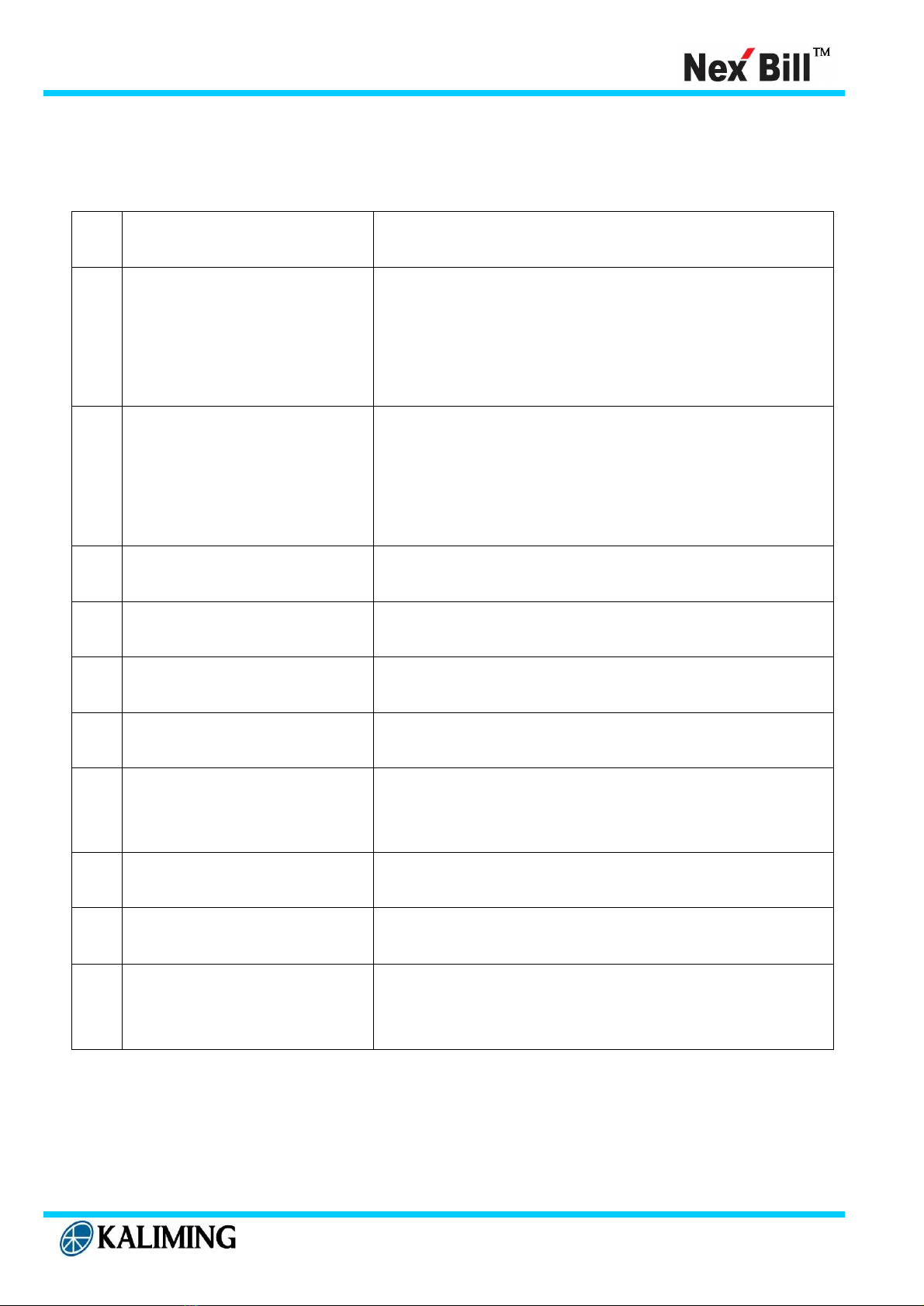

Jam

(E.JA)

Jamming of note.

Count Sensors are

Covered designate

time.

1. Check and remove the bad notes(s) at stacker.

2. Check the gaps between Feed Rollers and Reversing Rollers.

3. Check or adjust the value of Counter Sensor. (VR 9,10)

4. Check and clean Counter Sensor

5. Check reverse delay time (VID 446,456,466,476,486/SP1,2,3,4,5)

6. Malfunction of Main PCB

Over

count

(E.OC)

After complete of

counting, count is

increased by

Counter Sensor

1. Check the gaps between Feed Rollers and Reversing Rollers.

2. Check reverse delay time (VID 446,456,466,476,486/SP1,2,3,4,5)

3. Malfunction of Main PCB

Unknown

(E.UN)

Unknown notes

are fed.

1. Check and remove the bad notes(s)

2. Check the gaps between Feed Rollers and Reversing Rollers.

3. Clean Count Sensor, CIS Sensor, RGB Sensor

4. Check or adjust value of Count Sensor’s level. (VR 9,10)

5. Check or adjust value of CIS Sensor’s level. (VID 1308)

6. Check or adjust RGB sensor’s level. (VR 123456)

7. Malfunction of Main PCB

Balance

(E.bA)

Tilted notes are

fed.

1. Check and remove the bad notes(s)

2. Check the gaps between Feed Rollers and Reversing Rollers.

3. Check if there is no slip between notes and Feed Rollers. Clean

the rollers if necessary.

4. Clean Count Sensor.

5. Check or adjust value of Count Sensor’s level. (VR 9,10)

6. Malfunction of Main PCB

Thin

(E.th)

Thin notes are

fed.

1. Check and remove the bad notes(s)

2. Check the gaps between Feed Rollers and Reversing Rollers.

3. Check if there is no slip between notes and Feed Rollers. Clean

the rollers if necessary.

4. Clean Count Sensors

5. Check density level

6. Check or adjust value of Count Sensor’s level. (VR 9,10)

7. Malfunction of Main PCB

E.CF

(M=MG)

(X=UV P)

(U=UV R

Counterfeit notes

are fed.

1. Check the condition of counted notes.

2. Check of it is a counterfeit note.

3. If necessary check the value of UV LEVEL(VR 7,8,12).

4. If necessary the UV level can be flexibly adjusted to be suitable for

the targeted notes(VR 7,8,12):VR7:Left UV penetration. VR8:Right

UV penetration. VR12: UV reflection).

5. If necessary, check the value of MG LEVEL(VID 1311)

6. If necessary, the MG level can be flexibly adjusted to be suitable

for the targeted notes(VID 1311).

Over

load

(E.OL)

Over load on the

motor 1. Check over load value of each speed (VID 1302)

L uv err

(E.LU)

Left UV sensor is

on problem.

(Penetrative UV)

1. Check the level of left UV sensor.(VID 1303)

2. Check if the connectors of left UV sensor are well fixed.

3. Check if the left UV sensor is OK.

4. Check if the left UV sensor is covered with notes.

5. If the left UV sensor is covered with dust or dirt, clean the sensor

with

brush.