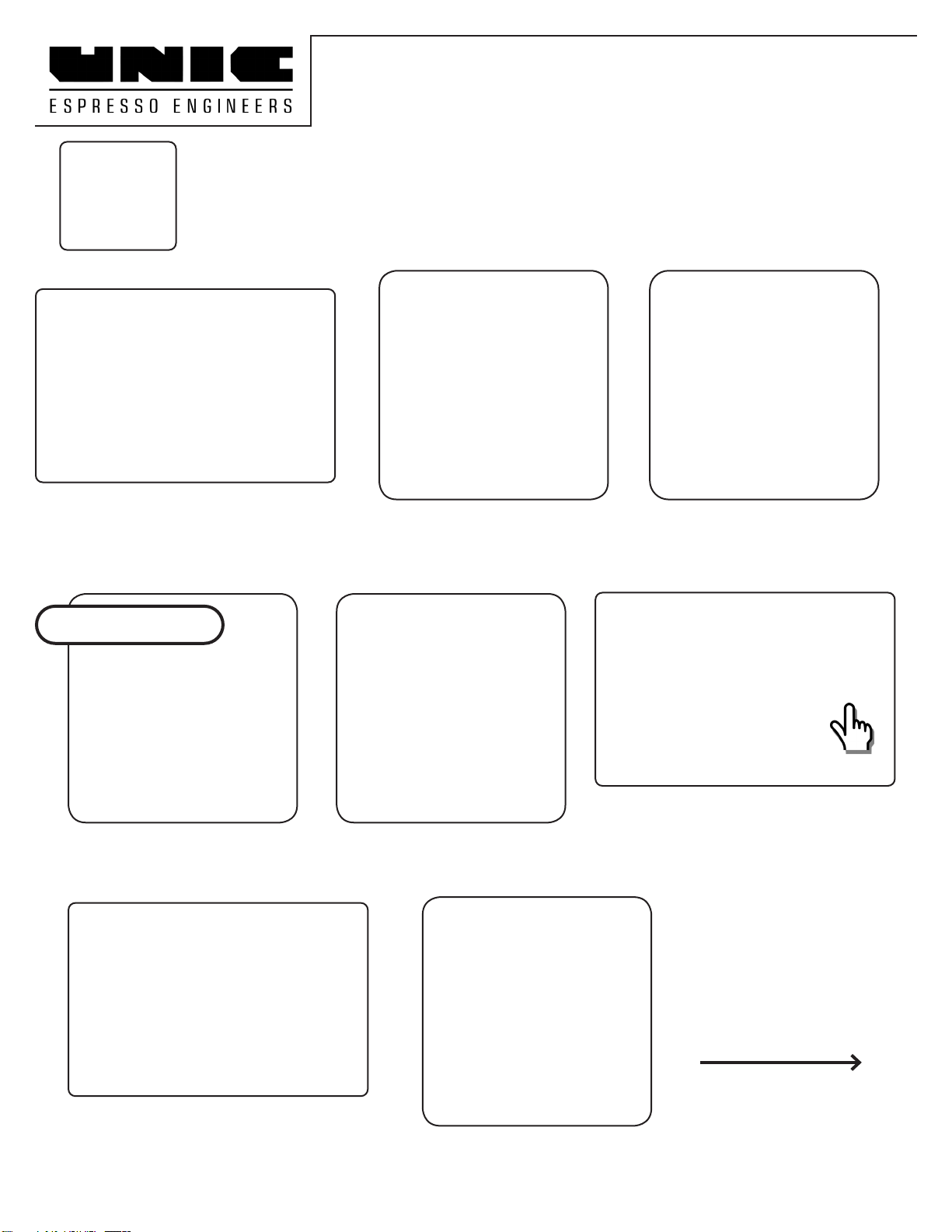

Tango ACE-ST PM

Unic Parts listing Description from

ACE Parts Manual TG9060 Part # Parts

Manual Page

Quantity

Odd

Years

Even

Years

6-Year

Rebuild

SteamAir Autosteam Service

12 Hole Steam Tip 12 HOLES END PIPE 25909 241 1

O-ring - 2x9.5mm GASKET 2 X 9.5 28134 241 2

O-ring - 8.73x1.78mm GASKET 8.73 X 1.78 CN-436 241 1

O-ring - 9.13x2.62mm O RING - 9.13 X 2.62 PH-78 241 1

Set-screw - M5x8mm POINT END SCREW PC-38 241 1

Spring Inserts THRUST BALL BEARING RO-58 241 2

Other PM Parts

Drip Tray O-ring O RING - 2.62 X 17.13 27845 361 1

Cleaning Cap O-ring GASKET 3.53 X 34.52 EPDM 27907 361 1

Cleaning Cap Flat Seal GASKET 28700 361 1

Vacuum Break Plunger O-ring GASKET 6.07 X 1.78 CN-198 201 1

Complete Vacuum Break Kit VACUUM VALVE KIT 27224 201 1

Steam Boiler Safety Valve LP VALVE 3.5 BARS 27200 340 1

Water Inlet Filter 80 Microns FILTER CARTRIDGE 80 MICRONS CN-96B 620 1

Water Inlet filter Cap O-ring GASKET 3.53 X 29.75 83501 620 1

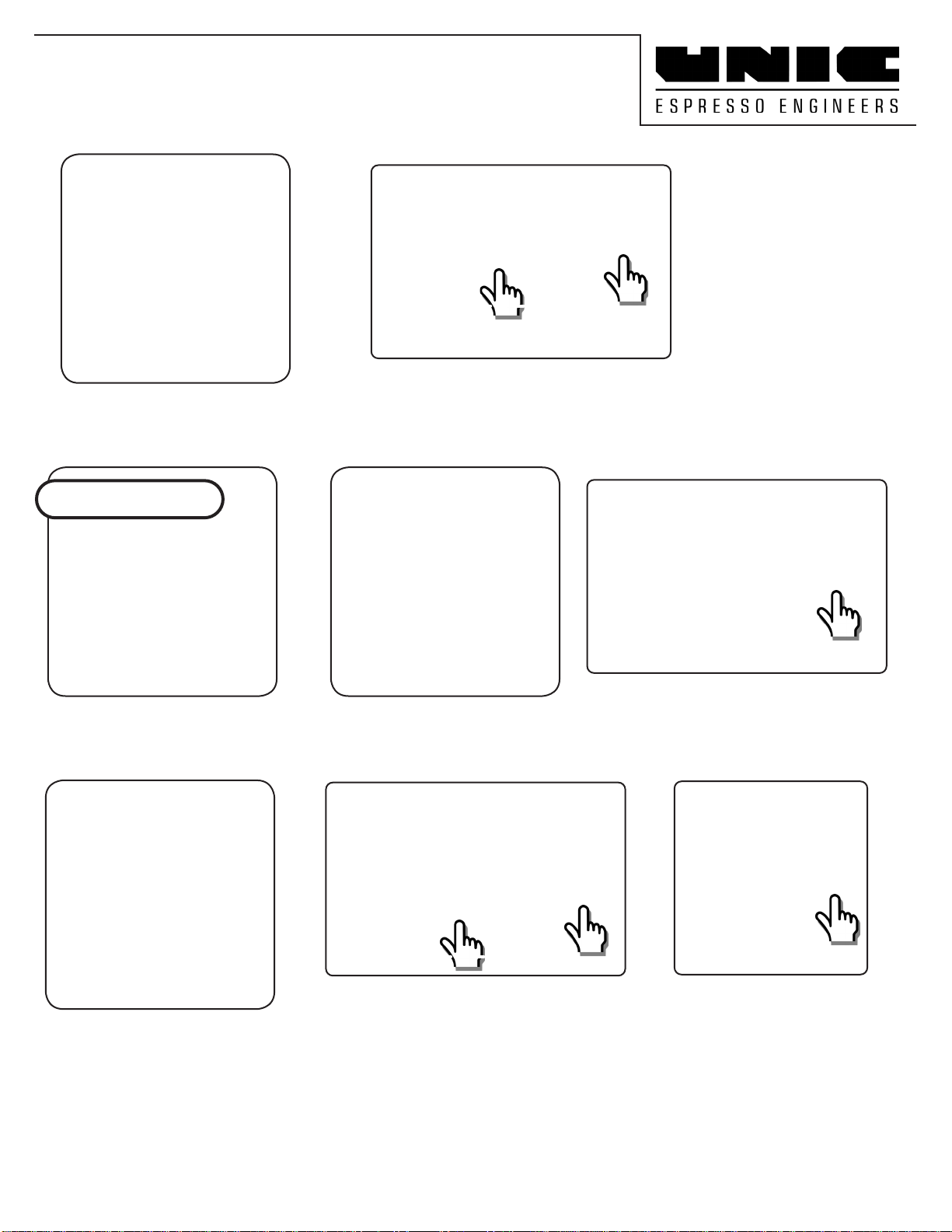

General Service Parts

Hot Water/Coffee Flow Meter Impeller TURBINE CN-829 251;330 2

Hot Water/Coffee Flow Meter O-ring GASKET - DOSING DEVICE CN-828 251;330 2

High-Level Probe Assembly HIGH LEVEL PROBE 26526 340 1

Low-Level Probe Assembly LOW LEVEL PROBE 26527 340 1

Americano Valve

ELECTROVALVE 2 WAYS 24V D2.3

35500 345 1

Americano Valve O-ring - 2x9.5mm GASKET 2 X 9.5 28134 345 2

Grinder Burrs 64mm GRINDING WHEEL SET 37516 401 2

Heat Exchanger Service Parts

Heat Exchanger O-ring - 1.78x17.17mm O RING 1.78 X 17.17 27716 345 1

Heat Exchanger Teflon Seals PTFE FLAT GASKET 28720T 345 2

Brew Valve Pipe O-ring - 1.78x12.42mm O RING - 1.78 X 12.42 27796 345 2

Americano Valve Banjo O-ring - 2x9.5mm GASKET 2 X 9.5 28134 345 2

Copper Crush Washer 1/2 JOINT CUIVRE RECUIT 1/2 CH-17 345 2

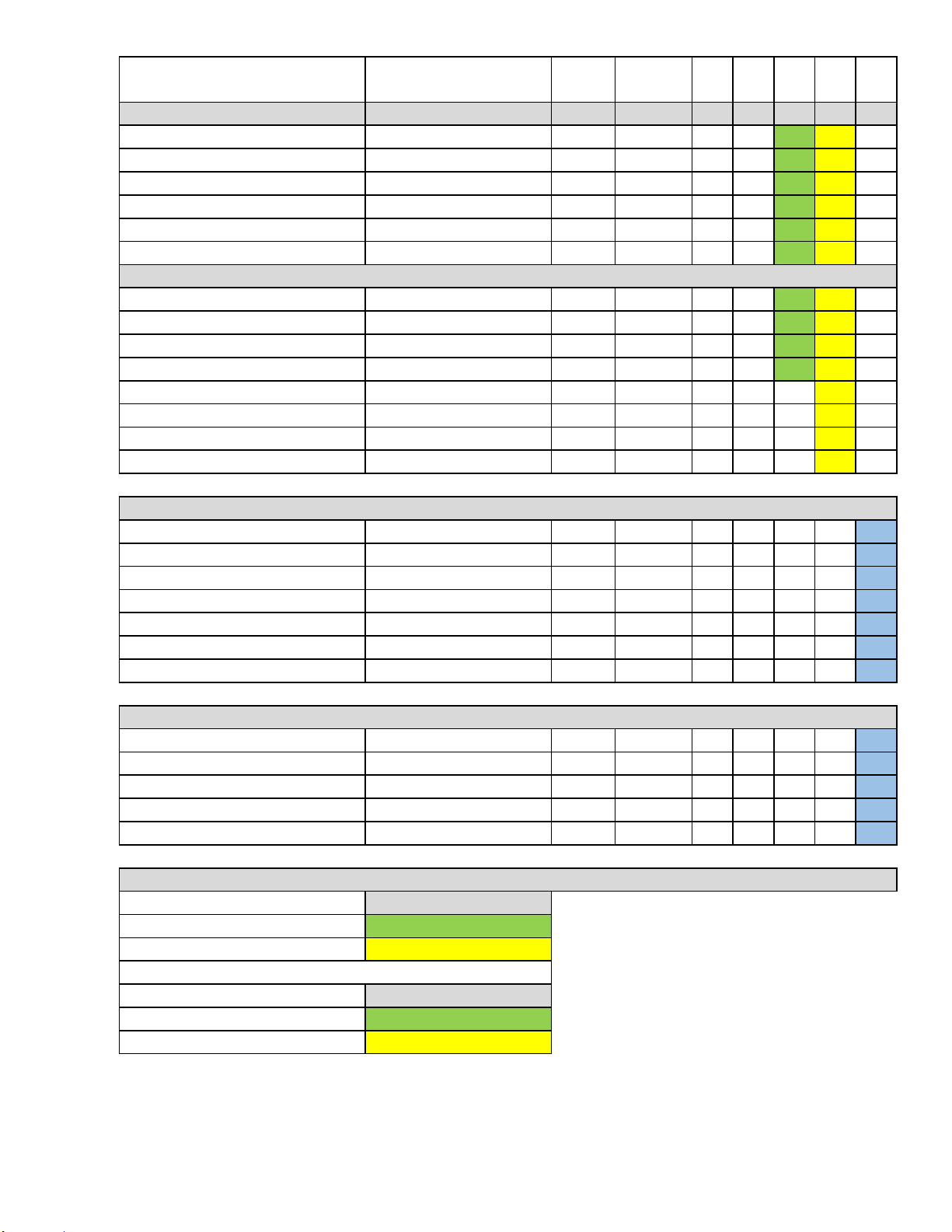

Complete PM Kits

Tango Ace/ST 2 Step 6 Month 250-00365

Tango Ace/ST 2 Step Years 1-3-5 250-00367

Tango Ace/ST 2 Step Years 2 & 4 250-00366

www.unic-usa.com

Tango Ace/ST 1 Step 4 Month 250-00362 www.grindmaster.com

Tango Ace/ST 1 Step Years 1-3-5 250-00364 www.electroluxprofessional.com

Tango Ace/ST 1 Step Years 2 & 4 250-00363