Emission date: July, 2021 Revision: 2 Pag. : 4/28

1. SAFETY INSTRUCTIONS

This installation and operation manual is

an integral part of the equipment and must

be kept for future consultation.

Unless otherwise stated, this manual is

addressed to operators (staff members

who uses the equipment on a daily basis)

and to servicemen (staff members qualified

to carry out the installation and/or

maintenance). The parts of the manual

addressed only to servicemen are pointed

out accordingly. Please read carefully the

warnings listed here below before

installation and start-up of the equipment.

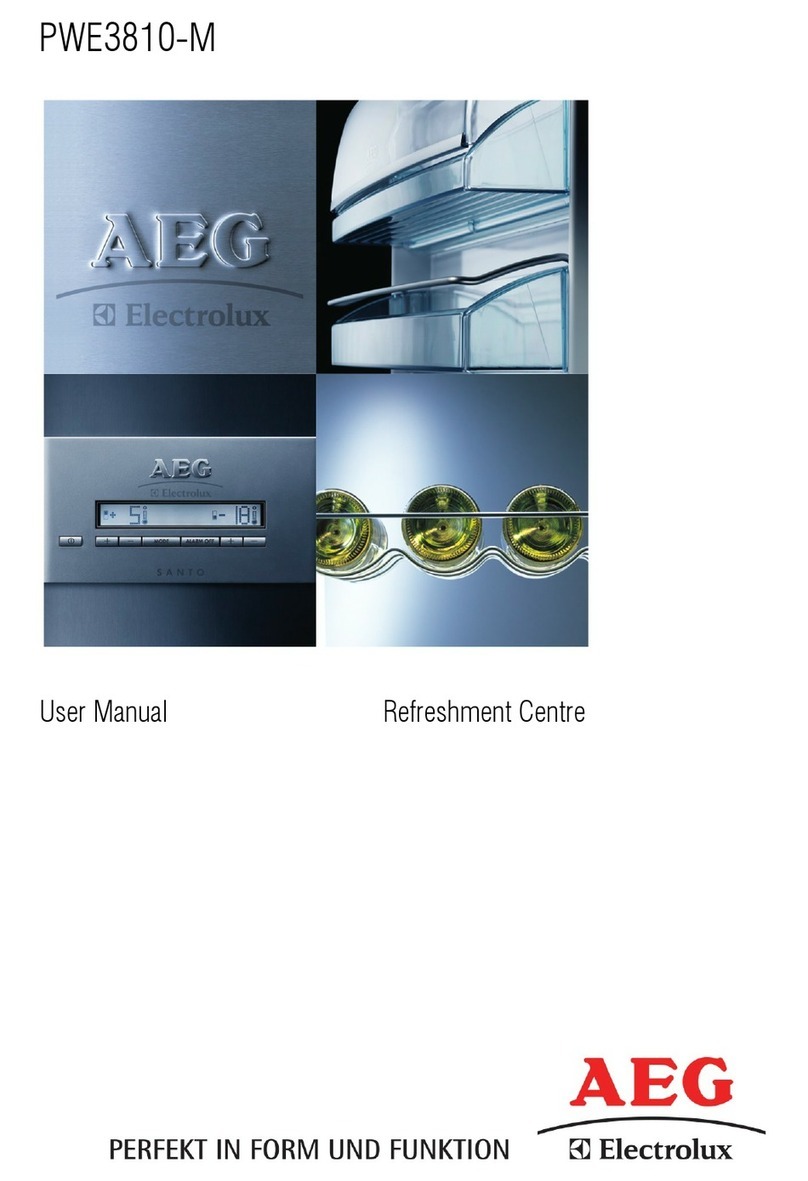

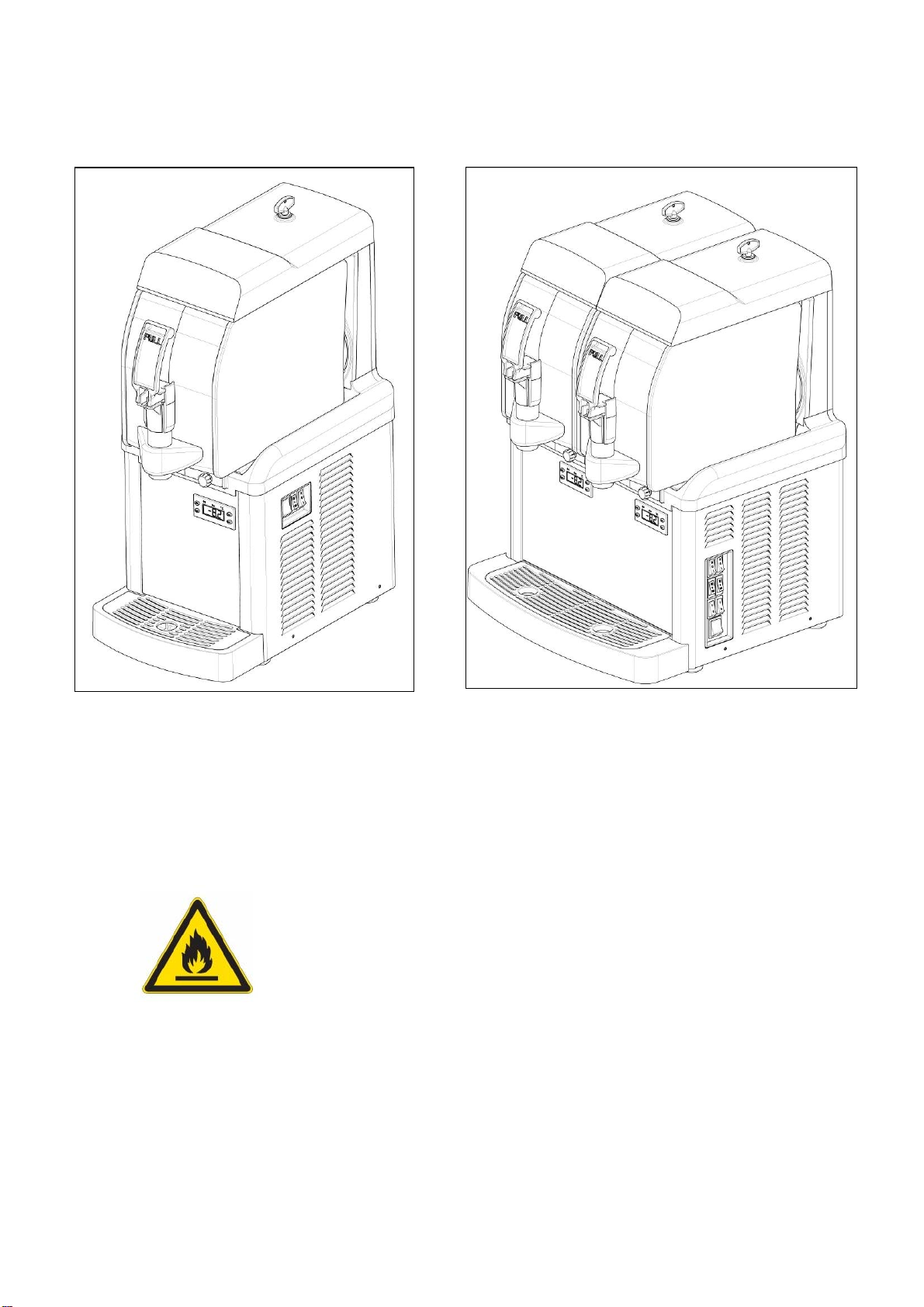

This equipment has been designed to

produce coffee cream, ice cappuccino,

sorbets, slushes and similar frozen dairy

products obtained by blending water or

milk with the powder.

Upon receipt of the equipment, make sure

that its part number matches the one

specified in the order, which can be found

on all the delivery documents.

This equipment is exclusively destined to

the purpose for which it was designed.

The manufacturer cannot be held

responsible for any damage due to

improper use.

This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use

of the appliance in a safe way and

understand the hazards involved. Children

shall not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

This equipment is not suitable for outdoor

use. This machine is not suitable for

installation in locations where water jets

are used and it must not be cleaned by a

water jet.

This appliance is intended for professional

use and must be installed in places where

it can be checked by qualified personnel.

Do not store explosive substances such as

aerosol cans with a flammable propellant

in this appliance.

This appliance is intended to be used in

household and similar applications such as

– staff kitchen areas in shops, offices and

other working environments;

– farm houses and by clients in hotels,

motels and other residential type

environments;

– bed and breakfast type environments;

– catering and similar non-retail

applications.

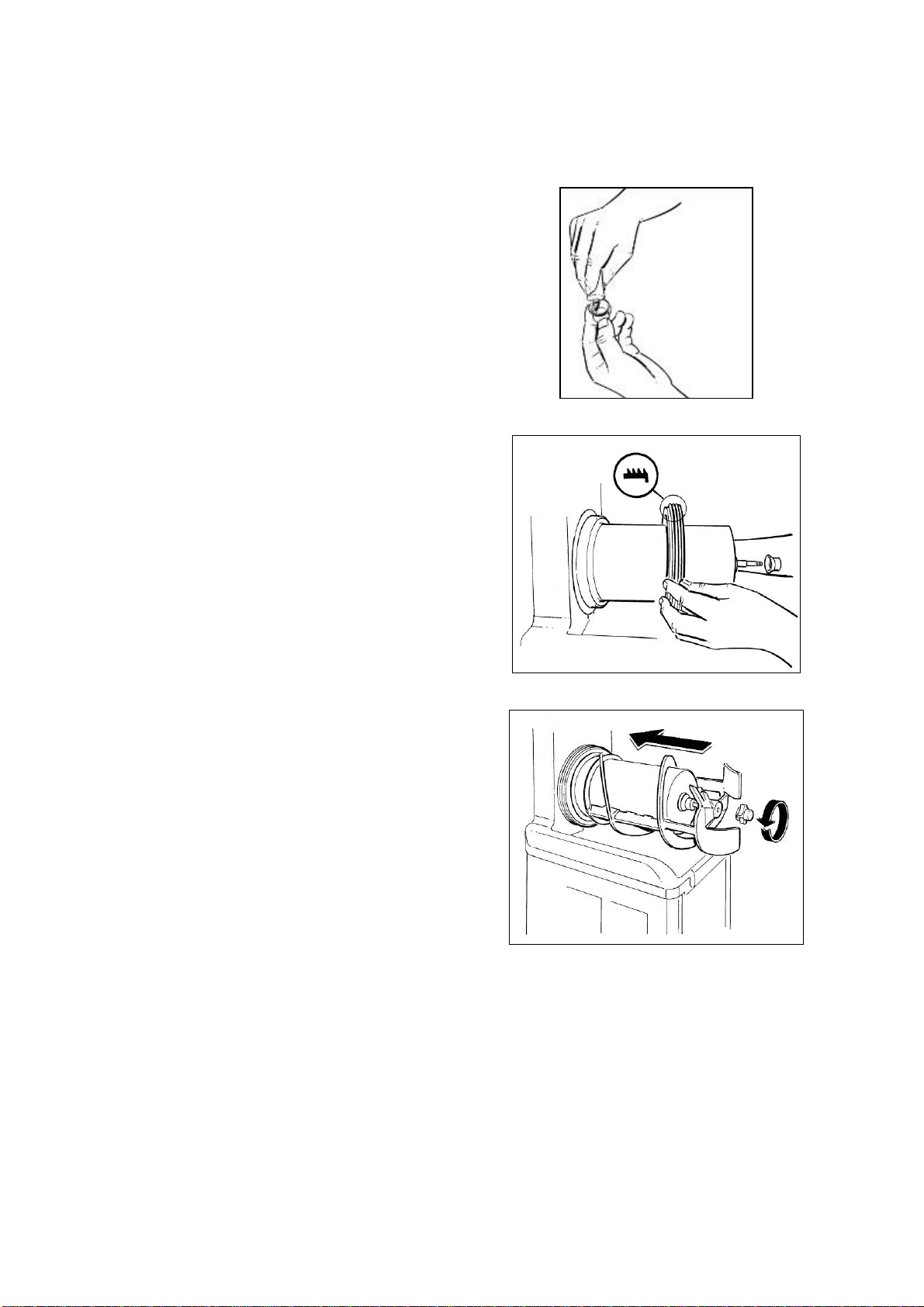

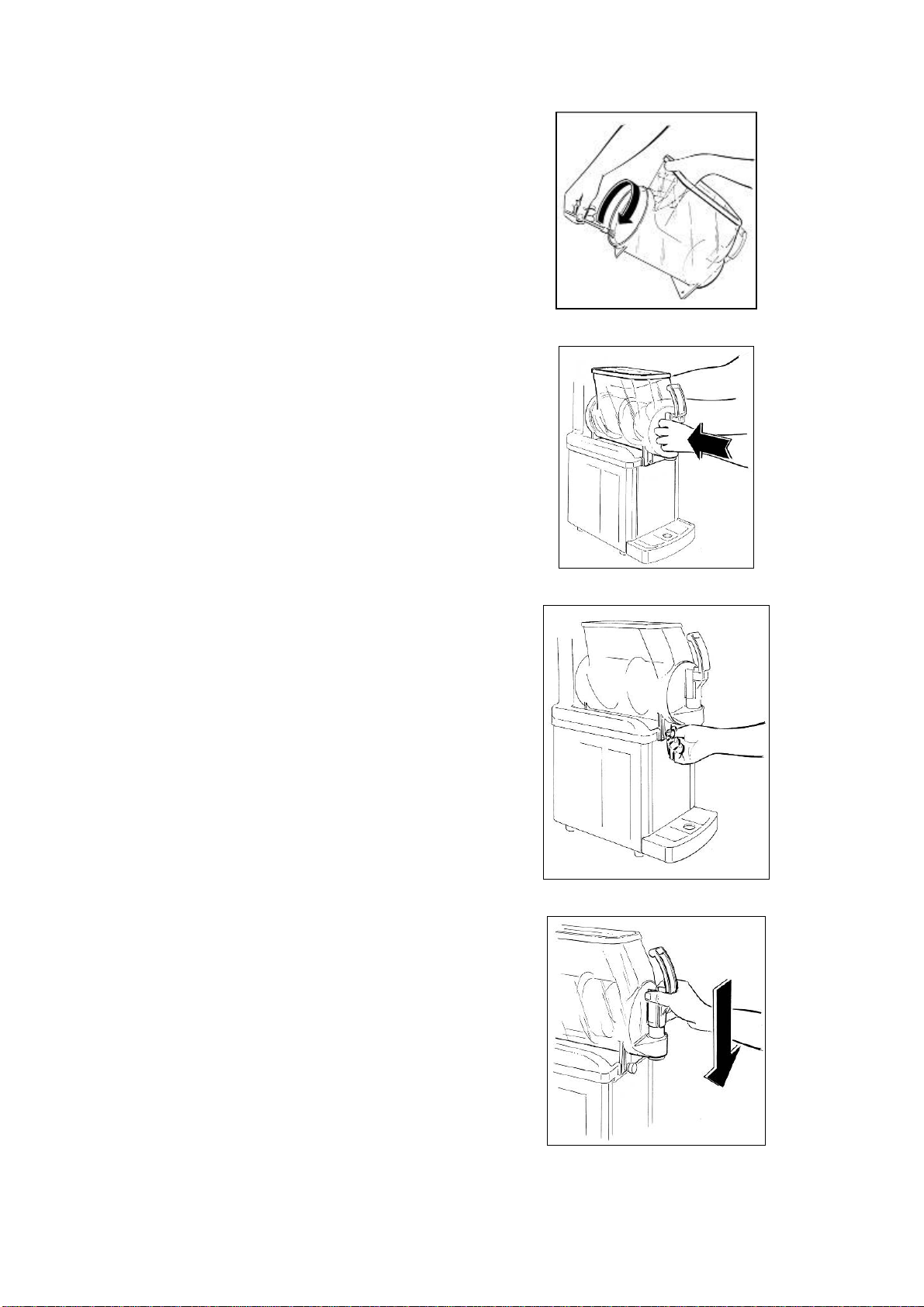

The installation and subsequent servicing

operations must be carried out by skilled

members who have been trained to use the

device and in compliance with the

regulations in force.

The machine has to be placed on a sturdy,

horizontal surface making sure it is well

ventilated by leaving a gap of 20 cm around it

and do not install it near heat sources (fig.1);

we recommend you to maintain a room

temperature between 24 and 32°C.

For a safe and correct installation, it is

essential to provide a suitable socket controlled

by a thermal cut-out switch whose contacts are

at least 3 mm apart, in accordance with the

current national safety regulations.

If the power cable is damaged, it must be

replaced by the manufacturer, its after sale

service or by qualified personnel, to prevent any

possible risk.