Electromaten TS 959 User manual

en

Installation instructions

Door control

TS 959

51171547_d_03_2014

0000000 0000 51171547 XXXXX

2

GfA - Gesellschaft für Antriebstechnik GmbH

Wiesenstraße 81

D-40549 Düsseldorf

www.gfa-elektromaten.de

info@gfa-elektromaten.de

3

Table of contents

1General safety information ............................................................................................ 5

2Technical data .............................................................................................................. 6

3Mechanical installation .................................................................................................. 7

4Electrical installation ..................................................................................................... 8

Cable connection overview ............................................................................................... 9

Limit switch assignment for screwable version until year of manufacture of 1997 .......... 10

Assignment of individual limit switches ........................................................................... 10

Carrying out the electrical installation .............................................................................. 11

Mains connection ............................................................................................................ 12

Mains connection to control ............................................................................................ 12

Completing the electrical installation ............................................................................... 12

Overview of control panel ................................................................................................ 13

5Initial operation of the control ...................................................................................... 14

DES: Rapid adjustment of final limit positions ................................................................. 14

NES: Rapid adjustment final limit positions ..................................................................... 15

6Advanced electrical installation.................................................................................... 16

External supply X1 .......................................................................................................... 16

Emergency stop X3 ......................................................................................................... 16

Relay contact X20 ........................................................................................................... 16

Control device X5 ............................................................................................................ 1 6

Spiral cable connection ................................................................................................... 16

7Programming the control ............................................................................................. 17

8Table of menus ........................................................................................................... 18

Operating mode .............................................................................................................. 18

Door positions ................................................................................................................. 18

Door functions ................................................................................................................. 19

Safety functions .............................................................................................................. 19

Maintenance cycle counter ............................................................................................. 20

Reading out memory ....................................................................................................... 21

Delete all settings ............................................................................................................ 21

9Safety devices ............................................................................................................ 22

X2: Input, door safety switch ........................................................................................... 22

X3: Input, emergency stop .............................................................................................. 22

4

10Functional description ................................................................................................. 23

X1: Mains supply line for control and external supply ..................................................... 23

X5: Input, control device .................................................................................................. 24

Advanced hold-to-run function ........................................................................................ 24

X20: Floating relay contact .............................................................................................. 25

Force monitoring (DES only) ........................................................................................... 25

Travel time monitoring (NES only)................................................................................... 26

Maintenance cycle counter .............................................................................................. 27

Short-circuit/Overload display ......................................................................................... 27

Standby function ............................................................................................................. 2 7

11Status display ............................................................................................................. 28

12Explanation of symbols ............................................................................................... 32

13Declaration of Incorporation/Declaration of Conformity ................................................ 34

Symbols

Warning - Risk of injury or danger to life!

Warning - Danger to life through electrical current!

Note - Important information!

▶ Request - Required action!

Illustrations show example products. Deviations from the delivered product are possible.

5

1General safety information

Specified normal use

The door control is intended for a power-operated door with a drive unit.

The safe operation is only guaranteed with normal specified use. The drive unit is to be

protected from rain, moisture and aggressive ambient conditions. No liability for damage

caused by other applications or non-observance of the information in the manual.

Modifications are only permitted with the agreement of the manufacturer. Otherwise the

Manufacturer’s Declaration shall be rendered null and void.

Safety information

Installation and initial operation tasks are to be performed by trained, skilled fitters only.

Only trained electrical craftsmen are permitted to work on electrical equipment. They must

assess the tasks assigned to them, recognise potential danger zones and be able to take

appropriate safety measures.

Installation work is only to be carried out with the supply off.

Observe the applicable regulations and standards.

Coverings and safety devices

Do not operate unless corresponding coverings and safety devices are fitted/installed.

Ensure that gaskets are correctly positioned and cable glands are correctly tightened.

Spare parts

Use only original spare parts.

6

2Technical data

Series TS 959

Dimensions W x H x D 155 x 386 x 90 mm

Assembly vertical

Vibration Assembly

free of vibration

Operating frequency 50/60 Hz

Supply voltage (+/- 10%)

1 N~220 V, PE

3 N~220-400 V, PE

3~220-400 V, PE

Output power for drive unit, maximum 3 kW

Backup fuse per phase, on-site 10-16 A

External mains supply: X1/L, X1/N

(backup fuse via F1 micro-fuse)

1 N~230 V

1.6

A

time-

la

g

Control inputs 24 V DC

type 10 mA

Type relay contact

Max. current of 1A at 230VAC, and 0.4A at 24VDC

(The use of LED lamps is recommended.)

floating changeover

contacts

Loading of relay contacts,

ohmic/inductive

230 V AC

1 A

Control power consumption 10 VA

Temperature range Operation: -5..+40

Storage: +0..+50 °C

Humidity up to 93 %

non-condensing

Class of protection of housing IP54

Compatible GfA limit switch NES; DES

7

3Mechanical installation

Control installation!

Only use indoors

Mounting only on a level ground free of vibration

Only vertical mounting position permissible

Door must be visible from the assembly site

Prerequisites

The permissible loads of walls, mountings, connecting and transmission elements must not

be exceeded.

Mounting

The control is mounted via 4 elongated holes

8

4Electrical installation

Warning - Risk of electrocution!

Disconnect the cables and check that they are de-energised

Observe the applicable regulations and standards

Make a proper electrical connection

Use suitable tools

On-site backup fuse and disconnector unit!

Connection to the indoor installation via all-pole disconnector unit ≥ 10 A as per

EN 12453 (e.g. CEE plug connector, main switch)

Read the drive installation instructions!

9

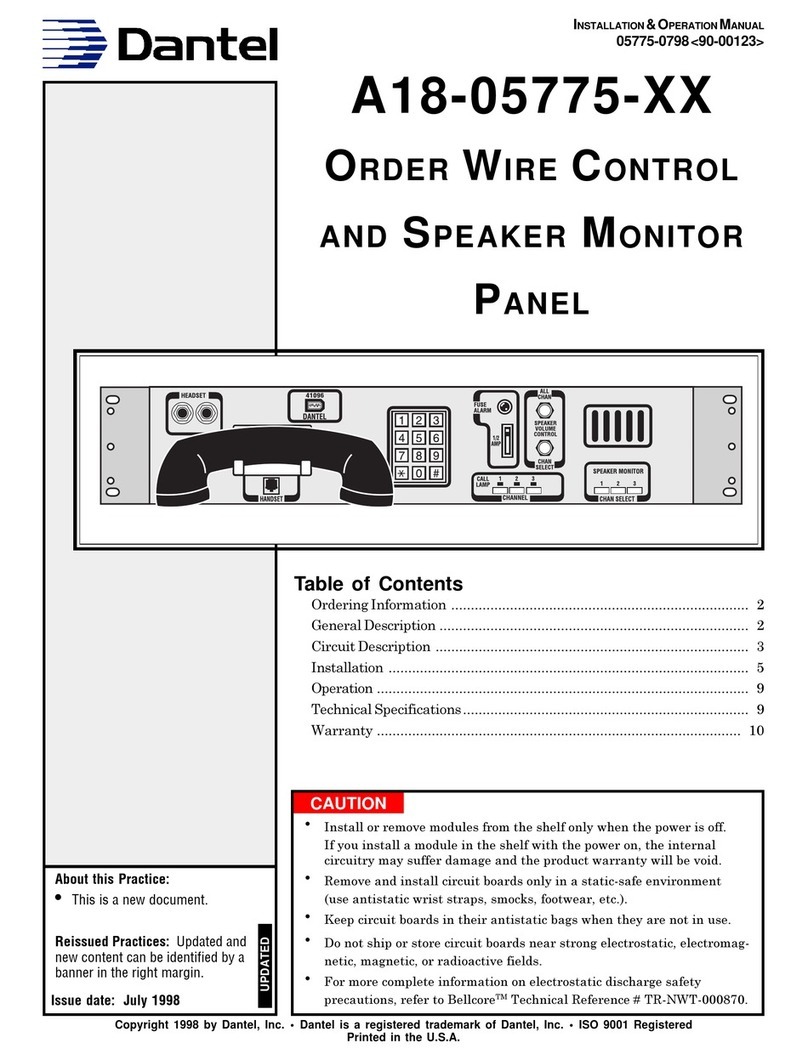

Cable connection overview

DES and NES

motor connection cable DES connection cable for limit switch

MOT X13 Motor plug DES X12 Limit switch plug

Pin Core Term. Pin Core Term.

1 3 W Phase W 15/wh 1+24 V safety circuit

2 2 V Phase V 26/bn 2Channel B (RS485)

3 1 U Phase U 37/gn 3Earth

4 4 N Neutral conductor (N) 48/ye 4Channel A (RS485)

5 PE PE 59/gy 5Safety circuit

610/pk 68-VDC mains supply

Cam-limit connecting cable

NES X12 Limit switch plug

Pin Core Term.

1 5/wh 11 Limit switch potential +24 V, jumper on X12 5, 7, 9, 11, 14

2 6/bn 12 S5 additional limit switch, testing or safety edge function

3 7/gn 6 S3, “Open” limit switch

4 8/ye 15 S6 additional limit switch, relay function

5 9/gy 8 S4, “Close” limit switch

6 10/pk 4 Safety circuit

10

Limit switch assignment for screwable version until year of manufacture of 1997

F1 Thermal contact X12 Limit switch board

G1 Rectifier S1 Emergency open limit switch

M1 Motor S2 Emergency close limit switch

S10 Emergency manual operation S3 Open limit switch

W1 Connection cable S4 Close limit switch

Y1 Spring-loaded brake S5

A

uxiliary limit switch

S6

A

uxiliary limit switch

Assignment of individual limit switches

A

1 Terminal box S3 Open limit switch

F1 Thermal contact S4 Close limit switch

M1 Motor S5

A

uxiliary limit switch

S10 Emergency manual operation S6

A

uxiliary limit switch

W1 Connection cable

56710 93214(N)

S6 S5 S3 S1 S2 S4

S10 F1

G1

Y1

1

3

2

4

5

X12

W1

M1

5 671093214PE

M1 S10 F1S4S3 S5 S6

W1

A1

11

Carrying out the electrical installation

▶ Remove coverings. ▶ Open cable entry ① or ②.

▶ Insert and connect control – drive connection cable in the open cable entry ① (from

below) or ② (from above).

▶ Tighten cable gland.

Caution – Damage of components!

Open cable conduit with suitable tool

Install cable entries and/or cable glands

12

Mains connection

3~, N, PE

190 – 440 V

50 -60 Hz

3~, PE

190 – 440 V

50 -60 Hz

1~, N, PE, sym.

190 – 230 V

50 -60 Hz

1~, N, PE, asym.

190 – 230 V

50 -60 Hz

3 x 400V 1 x 230V / 3 x 230V

Mains connection to control

Completing the electrical installation

Connect any other control devices and/or safety equipment.

Install and tighten cable entries and/or cable glands.

For initial operation of the control, leave the coverings open.

L1L2L3 NPE

L1 L2L3 PE

LNPE

SI 25.15WS, SI 45.7WS

LNPE

SI 25.15WS, SI 45.7WS

20.1

1.5

1.8

1.9

20.2

1.6

20.3

1.7

230V

400V

20.1

1.5

1.8

1.9

20.2

1.6

20.3

1.7

230V

400V

3

13

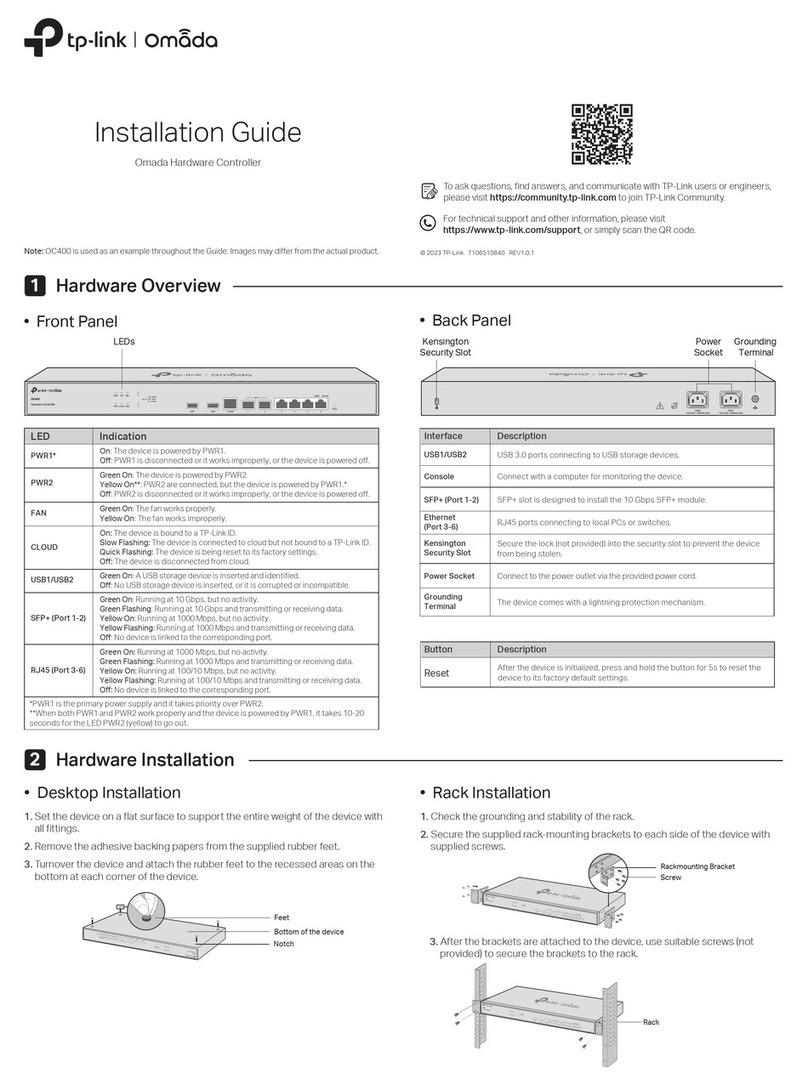

Overview of control panel

DES/

NES DES or NES limit switch socket X1 Mains supply

X2 Door safety switch

F1 1.6-

A

micro-fuse with time delay X3 Emergency stop button

MOT Motor socket X5 Control device, external three push button

S Selector switch X20 Floating relay contact

S11 “Open” button

S12 “Stop” button

S13 “Close” button

V1 Display

20.1

1.5

1.8

1.9

20.2

1.6

20.3

1.7

F1 = 1,6A t

230V

400V

MOT

DES/

NES S11

S12

X20

X3

2.1

2.2

3.1 5.15.25.3 5.43.2

959

X2 X5

S

F1

V1

S13

X1X1

X1

X1

14

5Initial operation of the control

▶ Plug in or switch on mains supply line

DES: Rapid adjustment of final limit positions

1. Check rotating direction

2. Start OPEN final limit position 3. Save OPEN final limit position

4. Start CLOSE final limit position 5. Save CLOSE final limit position

Note!

Rapid adjustment is complete, "Hold-to-run" door operating mode active

Change of OPEN/CLOSE final limit positions under menus "1.1" to "1.4"

15

Read the drive unit mounting manual!

Adjust the cam limit switch, see drive unit mounting manual

NES: Rapid adjustment final limit positions

1. Check rotating direction

2. Move to OPEN final limit position and adjust S3 OPEN limit switch

3. Move to 5 cm in front of the CLOSED final limit position and set S5 pre-limit

4. Move to CLOSED final limit position and set S4 CLOSED limit switch

16

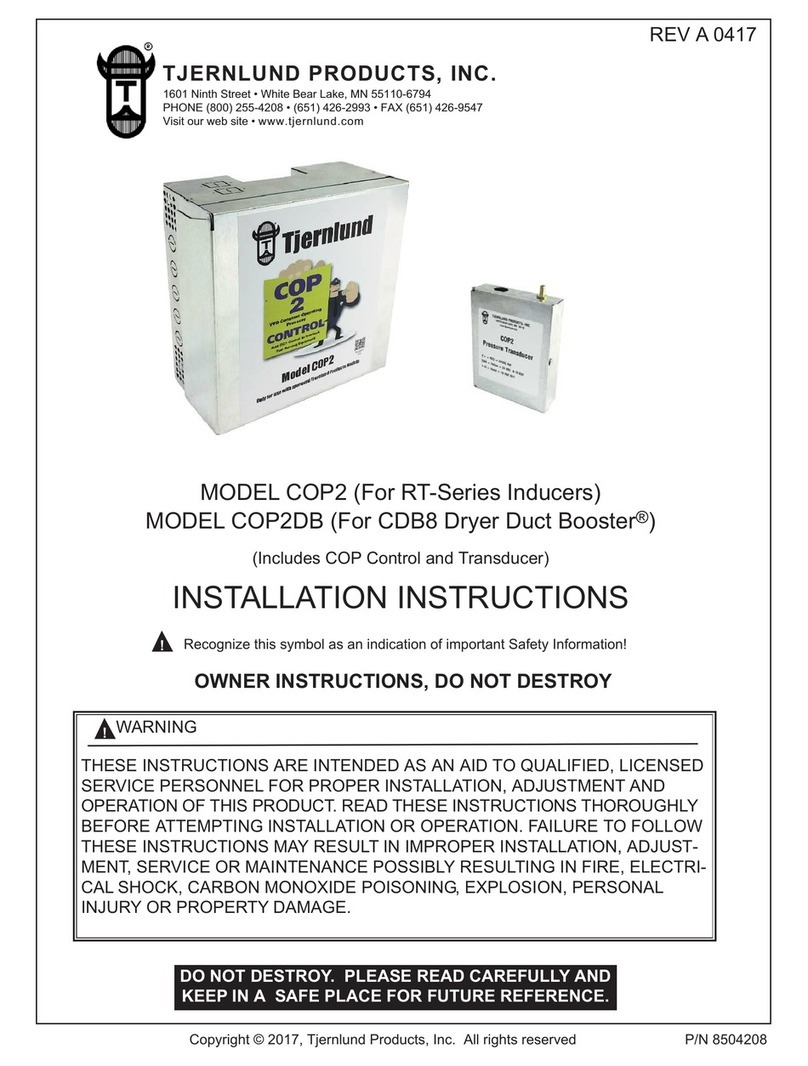

6Advanced electrical installation

Exter nal s uppl y X 1

Emer genc y stop X 3

Relay contact X20

External supply X1 Emergency stop X3 Relay contact X20

A

1 External device

A

2 Control device

A

16 Relay

Emergency stop

Control device X5

Control device X5

A

4 Key-switch

A

6Three push button

Open/Close locked

Spiral cabl e connection

Spiral cable connection

Door safety switch

A20 Junction box switch

S30 Pass door switch (NC)

S31 Slack-rope switch (NC)

X1

A1

X3

A2

2

1

S15

X20

20.1

20.2

20.3

A16

X5

P

1

S17

2

A4

X5

4

3

2

1

S14

4

3

2

1

S16

2

1

S15

A6

X5

ST+

ST

A20

2

1

S30/

S31

12

2.1

2.2

X2

1

2

17

7Programming the control

1. Only program after rapid adjustment of final limit positions!

2. Select and confirm the menu

3.a) Set and store functions

3.b) Set and save (DES) positions

4. Exit programming

18

8Table of menus

Operat in g mod e

Operating mode

Door operating mode

OPEN

CLOSE

Hold-to-run

Hold-to-run

OPEN

CLOSE

Self-hold

Hold-to-run

Extended hold-to-run

For NES: Set the S5 limit switch right before the Close position

Output direction of rotation

Maintain the output direction of rotation

Change output direction of rotation

Door positions

Door positions

OPEN final limit position, coarse correction (DES)

OPEN/CLOSE door movement

CLOSE final limit position, coarse correction (DES)

OPEN/CLOSE door movement

OPEN final limit position, fine correction (DES)

Without door movement,

[ + ] correct in OPEN

[

–

] correct in CLOSE

CLOSE final limit position, fine correction (DES)

Without door movement,

[ + ] correct in OPEN

[ – ] correct in CLOSE

Setting for position of relay switching point

Select relay function via menu 2.7

OPEN/CLOSE door movement

For NES: Set S6 auxiliary limit switch

19

Door func ti ons

Door functions

Relay function on X20

Teach in door position via menu 1.7 (DES only)

Off

Pulse signal

for 1 second

Permanent signal

Red lamp, permanent light during door movement

OPEN final limit position 3 seconds permanent light

CLOSE final limit position 3 seconds permanent light

Red lamp, permanent light during door movement

OPEN final limit position 3 seconds permanent light

CLOSE final limit position Off

Clearance dock leveller

Active at OPEN final limit position only

Safety f unctio ns

Safety functions

Force monitoring (DES)

0 = Off

Adjustable from 2 % to 10 % overload

Travel time monitoring (NES) only

0 = Off

0 to 90 seconds

20

Maintenance cycle counter

Maintenance cycle counter

Maintenance cycle preselection

01-99 corresponds to 1,000 to 99,000 cycles

Cycles are counted down

Reaction on reaching zero

"CS" display with set value of maintenance cycle

Changeover to hold-to-run mode in OPEN direction, if door operating

mode .2 has been set and "CS" is displayed

Changeover to hold-to-run mode in OPEN direction and "CS" display with

set value of maintenance cycle. Press the STOP button for 3 seconds to

reactivate 500 cycles in OPEN self-hold mode

“CS” display with set value of maintenance cycle and switching of relay

contact X20

Table of contents

Popular Controllers manuals by other brands

Daikin

Daikin MicroTech III Installation and operation manual

LOVATO ELECTRIC

LOVATO ELECTRIC DCRG8 installation manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO-J5 MR-J5-G Series user manual

MDT Technologies

MDT Technologies AKS Series operating instructions

Kondo

Kondo KRS Series instruction manual

ROSSMONT

ROSSMONT Waver Master WR-2CH quick guide