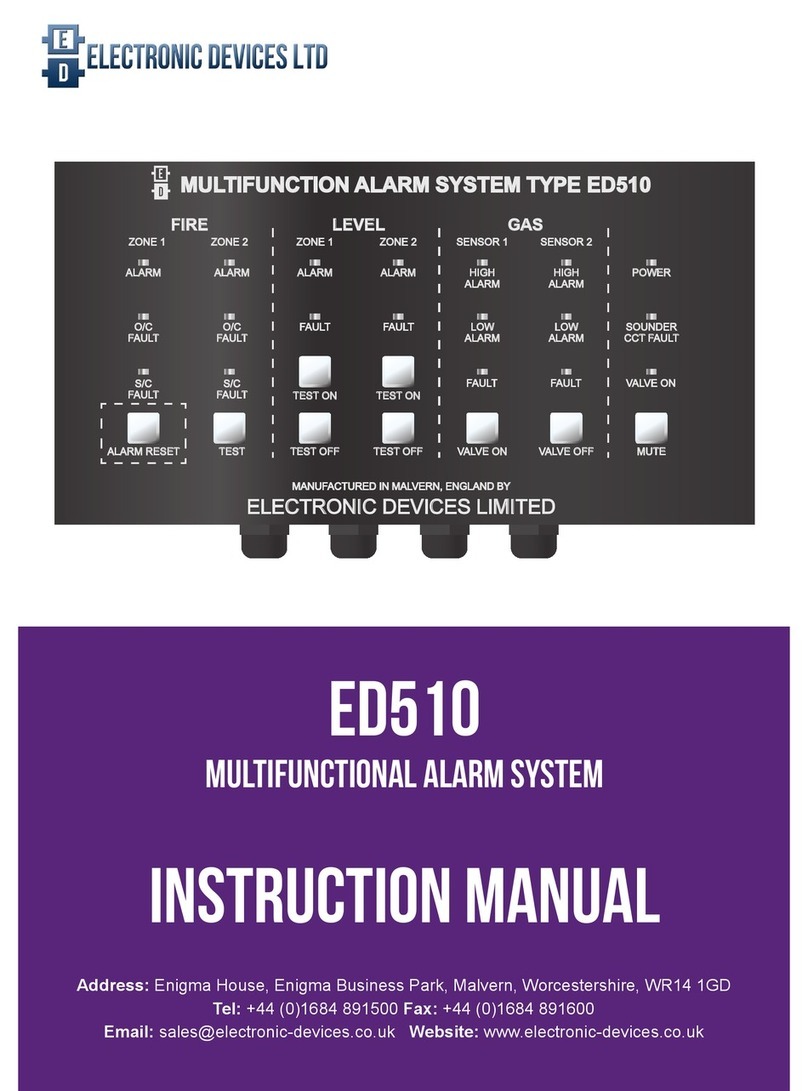

Electronic Devices Limited ED816A User manual

ELECTRONIC

DEVICES

LIMITED TYPE ED 816A

ADDRESSABLE ALARM SYSTEM

E

D

ENIGMA HOUSE, ENIGMA BUSINESS PARK, MALVERN, WORCESTERSHIRE WR14 1GD ENGLAND.

TELEPHONE : +44 (0) 1684 891500 FACSIMILE: +44 (0) 1684 891600 EMAIL: sales@electronicdevice.demon.co.uk

ED816A SYSTEM

INSTRUCTION MANUAL

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

AC MAIN AUX

1 2 3

17 18

DC

POWER IN

DC CHR FLT

BATT

POWER OUT

PRE DEL FLT

FIRE / GAS ALARM

MUTE ISOL DEL TEST

PANEL / DEVICE STATUS

EVAC

4 5 6 7 8 9 10 11 12 13 14 15 16

19 20 21 22 23 24 25 26 27 28 29 30 31 32

+

_

ENT MENU EVAC MUTE RESET LAMP

TEST

FIRE / GAS DETECTOR TYPE ED816A

E

D

COMMSALM

MANUFACTURED BY ELECTRONIC DEVICES LTD., MALVERN, ENGLAND.

ZONES 1 - 32

ALM

POWER - IN LAMPS

POWER - OUT LAMPS

FIRE / GAS LAMPS

-

PANEL / DEVICE STATUS LAMPS

AC - AC SUPPLYINPUT HEALTHY

DC MAIN - MAIN DC INPUT HEALTHY

DC AUX - OPTIONALAUXILIARY DC INPUT

HEALTHY

DC - DC OUTPUT SUPPLY HEALTHY

BATT CHR - BATTERY CHARGING

BATT FLT- BATTERY FAULT / BATTERY

REQUIRES EXTERNAL CHARGING

PRE - PRE-ALARM LEVEL

DEL - DELAYEDALARM OPERATED

FLT - PANEL / LOOP / DEVICE FAULT

EVAC - EVACUATE

MUTE - SOUNDERS HAVE BEEN SILENCED

ISOL - ISOLATED, ONE OR MORE ZONES

HAVE BEEN INHIBITED

DEL - ONE OR MORE DEVICE OUTPUTS

HAVE BEEN DELAYED

TEST - WHILST IN TEST MODE THE

ZONE UNDER TEST WILL NOT INITIATE

ALARMS. REMAINING ZONES WILL

CONTINUE TO FUNCTION NORMALLY

COMMS - COMMUNICATION FAULT

FIRE ALARM, GAS ALARM

- USE TO SCROLL THROUGH CURRENT

EVENTS AND NAVIGATE MENU

- USE TO NAVIGATE MENU

- INCREMENT / DECREMENT

ENT - ENTER / CONFIRM

MENU - MAIN MENU / PREVIOUS MENU

EVAC - EVACUATE OPERATES ALLOUTPUT

DEVICES

MUTE - SILENCE SOUNDERS

RESET - RESET SYSTEM TO NORMAL

CONDITION FOLLOWING ALARM / FAULT

LAMP TEST - PRESSTO TESTALL LAMPS

KEYS

+/-

14:29 27/11/06 ED816 ALARM SYSTEM

NO OF DETECTORS IN ALARM: 1 IN 1 ZONES

DETECTOR 1/ 1:

14:27

ISOL ZONES 0

27/11/06 ENGINE ROOM

HEAT DETECTOR LOOP 2 ID 035 ZONE 2

PRE ALARMS 0 FAULTS 0

-2-

3

4

INDEX

INTRODUCTION

DESIGN, INSTALLATION & SETUP

SECTION 1

Component overview

ED722 and ED726 Loop Driver Module 4

7

Loop lengths 7

Loop loading 7

Loop cable selection 7

Loop cable resistance 7

Loop cable capacitance 8

Screen continuity 8

Repeater cable selection 8

Power supply 8

9

General 9

ED816A I/O Module PCB connections 10

Detector Base wiring diagrams 11

Sounder wiring diagram 11

Repeater wiring diagram 12

13

PC based setup software (FireConfig.exe) 13

14

Important note 14

Maximum number of entries 14

Adding cause and effect entries 15

Auxiliary relay 16

Sounders 16

Loop device - Sounders and beacons 16

Loop device - Input Output modules 17

Delayed Outputs 17

18

XP95(A) North American models 18

Input Output modules / units 18

Loop powered Sounders and Beacons 18

Discovery Detectors 18

Gas Detection 19

Group Addressed Sounders / Beacons 19

Master / Slave Sounders / Beacons 19

ED816A Display Module 5

ED816A Input / Output Module 6

SECTION 2

System design guidelines

SECTION 3

Control unit installation

SECTION 4

Initial system setup

SECTION 5

Cause and effect matrix

SECTION 6

Device types and configuration

20

Silencing sounders and beacons 20

System reset 20

Evacuate 20

21

Gas Detection 24

Delayed Alarms 25

Reboot system 25

Live values - System Voltages 25

Live values - Head Values 26

View faults 28

View pre-alarms 28

View isolates 28

29

IO to loop cable fault 29

Loop continuity fault 29

No response from sensor 29

Sensor internal fault 29

Short circuit / Open circuit fault 29

Supply voltage fault 29

Communications fault 29

Discovery Conventional Mode /

Hardware Fire Detection 30

OPERATING INSTRUCTIONS

SECTION 7

Operating Instructions - quick guide

SECTION 9

Fault messages

SECTION 10

Dual Redundancy

21

Main Menu 22

History 22

Isolate / De-isolate 22

System setup 23

System setup - Walk through test 23

System setup - Sounder Beacon test 23

System setup - Search for new devices 24

System setup - Set time and date 24

System Menu 24

SECTION 8

Operating instructions 21

Access levels

Switch on / Reboot screen

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

Smoke

Call point

Beacon base

Output module

Damper shutdown

HVAC shutdown

Gas sensor Gas sensor Gas sensor

EOL

Conventional Zone 1

Conventional Zone 2

EOL

Level Detection

Isolating base

Heat

SmokeSmoke

Call point Multi sensor

Integrated

base sounder

Isolating base

CO Fire

detector

EOL

ZONE MONITOR

Conventional Zone

Smoke

Gas detector

interface Gas detector

interface

Gas detector

interface

Isolating base

Switch monitor

Door switches

Heat

Smoke Heat

Remote

indicator

Isolating base

Smoke

Smoke

Isolating base

Zone monitor

EOL

Conventional Zone

LOOP 1

AC MAIN AUX

1 2 3

17 18

DC

POWER IN

DC CHR FLT

BATT

POWER OUT

PRE DEL FLT

FIRE / GASALARM

MUTE ISOL DEL TEST

PANEL/ DEVICE STATUS

EVAC

4 5 6 7 8 9 10 11 12 13 14 15 16

19 20 21 22 23 24 25 26 27 28 29 30 31 32

+

_

ENT MENU EVAC MUTE RESET LAMP

TEST

FIRE / GAS DETECTOR REPEATER

E

D

COMMSALM

MANUFACTURED BY ELECTRONIC DEVICES LTD.,MALVERN, ENGLAND.

ZONES 1 - 32

ALM

POWER- IN LAMPS

POWER- OUT LAMPS

FIRE/ GAS LAMPS

-

PANEL/ DEVICE STATUSLAMPS

AC- AC SUPPLY INPUT HEALTHY

DCMAIN - MAIN DC INPUT HEALTHY

DCAUX - OPTIONAL AUXILIARYDC INPUT

HEALTHY

DC- DC OUTPUT SUPPLY HEALTHY

BATTCHR - BATTERYCHARGING

BATTFLT- BATTERYFAULT/ BATTERY

REQUIRESEXTERNAL CHARGING

PRE- PRE-ALARM LEVEL

DEL- DELAYED ALARM OPERATED

FLT- PANEL/ LOOP / DEVICE FAULT

EVAC- EVACUATE

MUTE- SOUNDERS HAVE BEEN SILENCED

ISOL- ISOLATED, ONE OR MORE ZONES

HAVE BEEN INHIBITED

DEL- ONE OR MORE DEVICE OUTPUTS

HAVEBEEN DELAYED

TEST- WHILST IN TEST MODE THE

ZONEUNDER TEST WILL NOT INITIATE

ALARMS. REMAINING ZONES WILL

CONTINUETO FUNCTION NORMALLY

COMMS- COMMUNICATION FAULT

FIREALARM, GAS ALARM

-USE TO SCROLL THROUGH CURRENT

EVENTSAND NAVIGATEMENU

-USE TO NAVIGATEMENU

-INCREMENT / DECREMENT

ENT- ENTER / CONFIRM

MENU- MAIN MENU / PREVIOUS MENU

EVAC- EVACUATEOPERATES ALL OUTPUT

DEVICES

MUTE- SILENCE SOUNDERS

RESET- RESET SYSTEM TO NORMAL

CONDITIONFOLLOWING ALARM / FAULT

LAMPTEST - PRESS TOTEST ALL LAMPS

KEYS

+/-

14:29 27/11/06 ED816 ALARM SYSTEM

NO OF DETECTORS IN ALARM: 1 IN 1 ZONES

DETECTOR 1/ 1:

14:27

ISOL ZONES 0

27/11/06 ENGINE ROOM

HEAT DETECTOR LOOP 2 ID 035 ZONE 2

PRE ALARMS 0 FAULTS 0

EOL

Fault monitored Flameproof Beacons and Sounders

Conventional Zones 1and 2

can be Safe Area, Hazardous Area,

Fire or level detection.

AC MAIN AUX

1 2 3

17 18

DC

POWER IN

DC CHR FLT

BATT

POWER OUT

PRE DEL FLT

FIRE / GASALARM

MUTE ISOL DEL TEST

PANEL/ DEVICE STATUS

EVAC

4 5 6 7 8 9 10 11 12 13 14 15 16

19 20 21 22 23 24 25 26 27 28 29 30 31 32

+

_

ENT MENU EVAC MUTE RESET LAMP

TEST

FIRE / GAS DETECTOR REPEATER

E

D

COMMSALM

MANUFACTURED BY ELECTRONIC DEVICES LTD.,MALVERN, ENGLAND.

ZONES 1 - 32

ALM

POWER- IN LAMPS

POWER- OUT LAMPS

FIRE/ GAS LAMPS

-

PANEL/ DEVICE STATUSLAMPS

AC- AC SUPPLY INPUT HEALTHY

DCMAIN - MAIN DC INPUT HEALTHY

DCAUX - OPTIONAL AUXILIARYDC INPUT

HEALTHY

DC- DC OUTPUT SUPPLY HEALTHY

BATTCHR - BATTERYCHARGING

BATTFLT- BATTERYFAULT/ BATTERY

REQUIRESEXTERNAL CHARGING

PRE- PRE-ALARM LEVEL

DEL- DELAYED ALARM OPERATED

FLT- PANEL/ LOOP / DEVICE FAULT

EVAC- EVACUATE

MUTE- SOUNDERS HAVE BEEN SILENCED

ISOL- ISOLATED, ONE OR MORE ZONES

HAVE BEEN INHIBITED

DEL- ONE OR MORE DEVICE OUTPUTS

HAVEBEEN DELAYED

TEST- WHILST IN TEST MODE THE

ZONEUNDER TEST WILL NOT INITIATE

ALARMS. REMAINING ZONES WILL

CONTINUETO FUNCTION NORMALLY

COMMS- COMMUNICATION FAULT

FIREALARM, GAS ALARM

-USE TO SCROLL THROUGH CURRENT

EVENTSAND NAVIGATEMENU

-USE TO NAVIGATEMENU

-INCREMENT / DECREMENT

ENT- ENTER / CONFIRM

MENU- MAIN MENU / PREVIOUS MENU

EVAC- EVACUATEOPERATES ALL OUTPUT

DEVICES

MUTE- SILENCE SOUNDERS

RESET- RESET SYSTEM TO NORMAL

CONDITIONFOLLOWING ALARM / FAULT

LAMPTEST - PRESS TOTEST ALL LAMPS

KEYS

+/-

14:29 27/11/06 ED816 ALARM SYSTEM

NO OF DETECTORS IN ALARM: 1 IN 1 ZONES

DETECTOR 1/ 1:

14:27

ISOL ZONES 0

27/11/06 ENGINE ROOM

HEAT DETECTOR LOOP 2 ID 035 ZONE 2

PRE ALARMS 0 FAULTS 0

Up to 8 repeaters

Sounder circuit 1

Sounder circuit 2

Sounder circuit 3

Engineers PC

Alarm relay contacts

Pre - Alarm relay contacts

Delayed Alarm relay contacts

Fault relay contacts

Auxiliary relay contacts

Auxiliary relay contacts

Auxiliary relay contacts

HWFD relay contacts to

additional Fire alarm Panels

INTRODUCTION

The ED816A Analogue Addressable Alarm system is capable of giving

Fire, Gas, Water and/or Engine alarms, operate Fire Fighting

equipment and is approved to Lloyds Register ENV1, 2, and 3.

It is capable of driving up to 252 addressable devices per system in 2

loops of 126 devices per loop.

The ED816A has an enclosure 365 x 340 x 110mm weighing 7.5Kg.

Contact Electronic devices limited on:

Tel: +44 (0)1684 891500

Fax: +44 (0)1684 891600

Email: [email protected]

LOOP 2

-3-

AC MAIN AUX

1 2 3

17 18

DC

POWER IN

DC CHR FLT

BATT

POWER OUT

PRE DEL FLT

FIRE / GAS ALARM

MUTE ISOL DEL TEST

PANEL/ DEVICE STATUS

EVAC

4 5 6 7 8 9 10 11 12 13 14 15 16

19 20 21 22 23 24 25 26 27 28 29 30 31 32

+

_

ENT MENU EVAC MUTE RESET LAMP

TEST

FIRE / GAS DETECTOR TYPE ED816A

E

D

COMMS

ALM

MANUFACTURED BY ELECTRONIC DEVICES LTD.,MALVERN, ENGLAND.

ZONES 1 - 32

ALM

POWER- IN LAMPS

POWER- OUT LAMPS

FIRE/ GAS LAMPS

-

PANEL/ DEVICE STATUSLAMPS

AC- AC SUPPLY INPUT HEALTHY

DCMAIN - MAIN DC INPUT HEALTHY

DCAUX - OPTIONAL AUXILIARY DC INPUT

HEALTHY

DC- DC OUTPUT SUPPLY HEALTHY

BATTCHR - BATTERY CHARGING

BATTFLT - BATTERYFAULT / BATTERY

REQUIRESEXTERNAL CHARGING

PRE- PRE-ALARM LEVEL

DEL- DELAYED ALARM OPERATED

FLT- PANEL / LOOP / DEVICE FAULT

EVAC- EVACUATE

MUTE- SOUNDERS HAVE BEEN SILENCED

ISOL- ISOLATED, ONE OR MORE ZONES

HAVE BEEN INHIBITED

DEL- ONE OR MORE DEVICE OUTPUTS

HAVEBEEN DELAYED

TEST- WHILST IN TEST MODE THE

ZONEUNDER TEST WILL NOT INITIATE

ALARMS. REMAINING ZONES WILL

CONTINUETO FUNCTION NORMALLY

COMMS- COMMUNICATION FAULT

FIREALARM, GAS ALARM

-USE TO SCROLL THROUGH CURRENT

EVENTSAND NAVIGATE MENU

-USE TO NAVIGATE MENU

-INCREMENT / DECREMENT

ENT- ENTER / CONFIRM

MENU- MAIN MENU / PREVIOUS MENU

EVAC- EVACUATE OPERATESALL OUTPUT

DEVICES

MUTE- SILENCE SOUNDERS

RESET- RESET SYSTEM TO NORMAL

CONDITIONFOLLOWING ALARM / FAULT

LAMPTEST - PRESSTO TEST ALL LAMPS

KEYS

+/-

14:29 27/11/06 ED816 ALARM SYSTEM

NO OF DETECTORS IN ALARM: 1 IN 1 ZONES

DETECTOR 1/ 1:

14:27

ISOL ZONES 0

27/11/06 ENGINE ROOM

HEAT DETECTOR LOOP 2 ID 035 ZONE 2

PRE ALARMS 0 FAULTS 0

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

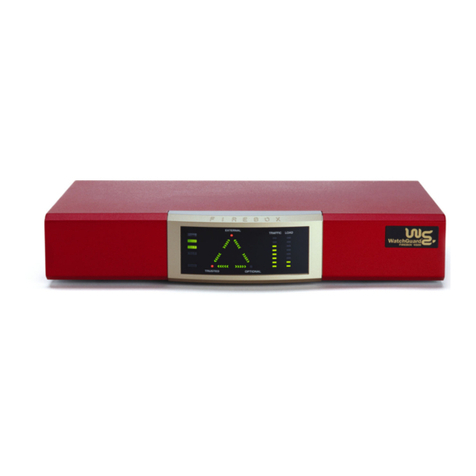

The ED722 and ED726 loop driver can provide 300mA of continuous loop current, driving up to

126 devices using Apollo S90, XP95 or Discovery protocol.

Each loop is fully isolated electrically from the input power supply, giving continued operation

in the event of earth faults on the dc input, greatly increasing immunity to electrical noise and

eliminating false alarms due to crosstalk.

The ED722 and ED726 are similar but the ED726 can also accept up to 10 EDL addressable

gas detection interface modules. Both models are available with front panels, as used in the

ED700A 8 Loop Control Panel, or without front panels for use in the ED816A. For the full

failsafe features to be available on the ED816A the ED722 / ED726 front panel lamps and

switches are relocated on the ED816A I/O motherboard.

FAIL SAFE OPERATION

Each module within the system (ED722/6 loop modules, ED816A Display module and ED816

I/O module) communicate with each other using an industry standard I2C bus. In the event of

a communications failure, or a fault developing on any of the modules, creating a

communications failure, the loop cards continue to operate autonomously.

The loop modules are directly connected to the following normally energised relays mounted

on the IO module.

HWFD = normally open contact closing to 470 ohms in the alarm condition.

PRE = Pre-alarm.

IMM = Immediate Fire or Gas Alarm.

DEL = Operates 2 minutes after an alarm if mute or reset has not been pressed.

FLT = Fault.

Sounder 1 is directly connected to the alarm relay.

DISCOVERY CONVENTIONAL MODE (Hardware Fire Detection HWFD)

Not to be confused with conventional fire zones, conventional mode, built into the Discovery

detectors and Electronic Devices gas detector interface, provides continued alarm detection in

the event of limited circuit failure. E.g. Microprocessor failure on the loop module resulting in

panel to detector communications failure. Conventional mode becomes operational

approximately 2 minutes after loop to detector communications has failed. Electronic Devices

recommend using Discovery detectors to take advantage of this feature.

PUSH BUTTON OPERATION

If pressed under normal operating conditions the three push buttons operate as lamp test

buttons only. However in the event of a communications error or fault on the Addressable

display module, the loop cards continue to operate autonomously and the push buttons will

function as labelled. See page 29 for details.

These should be used for all safety critical operations as they are operated

in the fail safe mode.

Section 1 - Component overview.

ED722 and ED726 Loop Driver Module (ED816A Variation)

-4-

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

Back up alarm / indicator lamps

EVACUATE MUTE RESET

POWER

ALARM

PRE-ALM

DELAYED

FAULT

SILENCED

ISOLATED

LOOP 1 STATUS

EVACUATE MUTE RESET

POWER

ALARM

PRE-ALM

DELAYED

FAULT

SILENCED

ISOLATED

LOOP 2 STATUS

Lamp Test button and backup Reset

button.

(See below for usage)

Lamp Test button and backup Evacuate

Lamp Test button and backup Mute

button.

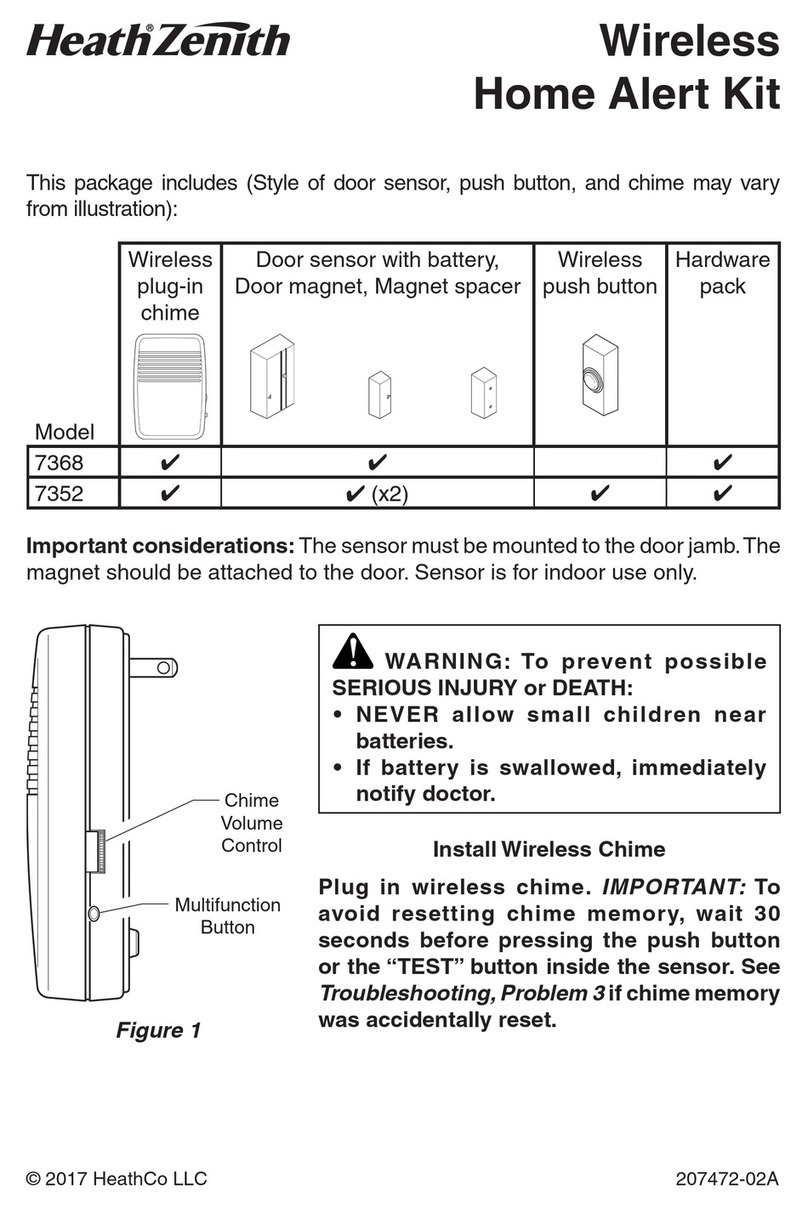

The ED816A Display module provides all system information during normal operation. Detailed information

about each device connected to the system, system voltages, Isolated zones, delay times and function are all

available.

Also available is a Marine approved Repeater unit, with identical functionality, connected to the main panel via

RS485 full duplex. Up to 8 repeaters can be connected to the main system.

LED FUNCTION (left to right)

AC AC mains connected.

MAIN Main DC input connected.

AUX Aux DC input connected.

DC Fused DC output okay.

CHR Battery being charged.

FLT Battery fault.

FIRE Main Fire or Gas Alarm.

PRE Pre alarm early warning of Fire or Gas Alarm.

DEL Delayed Alarm, Fire or Gas Alarm has been present for 2 minutes without being acknowledged.

FLT Fault on System, wiring or loop device.

EVAC Evacuate condition has been implemented.

MUTE Sounders / Beacons have been silenced.

ISOL 1 or more zones have been isolated.

DEL Delayed output, one of the 8 delayed outputs will action after preset time.

TEST System is currently in test mode.

COMMS Communications failure has occurred.

1 - 32 Zone LEDs, indicating a Fire / Gas alarm.

PUSH BUTTON FUNCTION(left to right)

Use to scroll through current events and navigate menu.

Use to navigate menu.

+/- Increment / decrement.

ENT Enter confirm.

MENU Previous menu / main menu.

EVAC Evacuate, operates all output devices.

MUTE Turn off Sounders and Beacons.

RESET Reset to normal condition following alarm or fault.

LAMP TEST Test all Display Module lamps. -5-

ED816A Display Module

AC MAIN AUX

1 2 3

17 18

DC

POWER IN

DC CHR FLT

BATT

POWER OUT

PRE DEL FLT

FIRE / GAS ALARM

MUTE ISOL DEL TEST

PANEL / DEVICE STATUS

EVAC

4 5 6 7 8 9 10 11 12 13 14 15 16

19 20 21 22 23 24 25 26 27 28 29 30 31 32

+

_

ENT MENU EVAC MUTE RESET LAMP

TEST

FIRE / GAS DETECTOR TYPE ED816A

E

D

COMMS

ALM

MANUFACTURED BY ELECTRONIC DEVICES LTD., MALVERN, ENGLAND.

ZONES 1 - 32

ALM

POWER - IN LAMPS

POWER - OUT LAMPS

FIRE / GAS LAMPS

-

PANEL / DEVICE STATUS LAMPS

AC - AC SUPPLY INPUT HEALTHY

DC MAIN - MAIN DC INPUT HEALTHY

DC AUX - OPTIONAL AUXILIARY DC INPUT

HEALTHY

DC - DC OUTPUT SUPPLY HEALTHY

BATT CHR - BATTERY CHARGING

BATT FLT - BATTERY FAULT / BATTERY

REQUIRES EXTERNAL CHARGING

PRE - PRE-ALARM LEVEL

DEL - DELAYED ALARM OPERATED

FLT - PANEL / LOOP / DEVICE FAULT

EVAC - EVACUATE

MUTE - SOUNDERS HAVE BEEN SILENCED

ISOL - ISOLATED, ONE OR MORE ZONES

HAVE BEEN INHIBITED

DEL - ONE OR MORE DEVICE OUTPUTS

HAVE BEEN DELAYED

TEST - WHILST IN TEST MODE THE

ZONE UNDER TEST WILL NOT INITIATE

ALARMS. REMAINING ZONES WILL

CONTINUE TO FUNCTION NORMALLY

COMMS - COMMUNICATION FAULT

FIRE ALARM, GAS ALARM

- USE TO SCROLL THROUGH CURRENT

EVENTS AND NAVIGATE MENU

- USE TO NAVIGATE MENU

- INCREMENT / DECREMENT

ENT - ENTER / CONFIRM

MENU - MAIN MENU / PREVIOUS MENU

EVAC - EVACUATE OPERATES ALL OUTPUT

DEVICES

MUTE - SILENCE SOUNDERS

RESET - RESET SYSTEM TO NORMAL

CONDITION FOLLOWING ALARM / FAULT

LAMP TEST - PRESS TO TEST ALL LAMPS

KEYS

+/-

14:29 27/11/06 ED700 ALARM SYSTEM

NO OF DETECTORS IN ALARM: 1 IN 1 ZONES

DETECTOR 1/ 1:

14:27

ISOL ZONES 0

27/11/06 ENGINE ROOM

HEAT DETECTOR LOOP 2 ID 035 ZONE 2

PRE ALARMS 0 FAULTS 0

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

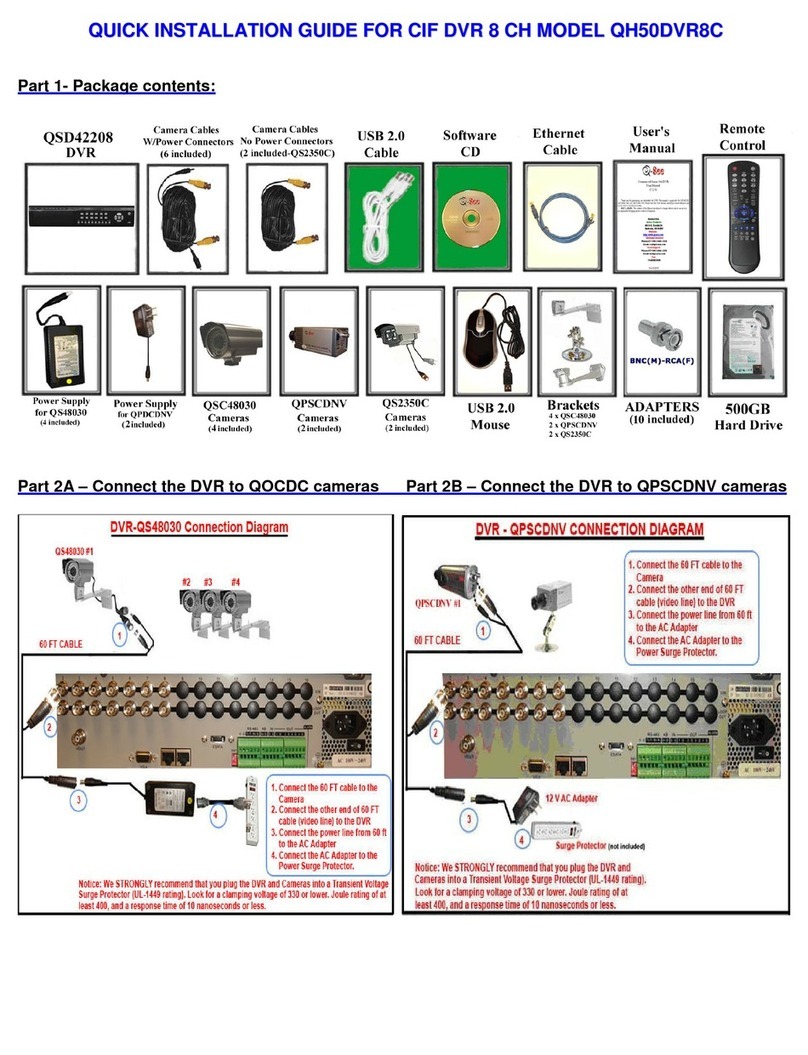

ED816A Input / Output Module

-6-

The Input / Output module provides all of the facilities required for most applications, eliminating the need to

purchase additional add-on modules or interface units.

Designed with ease of installation in mind the I/O Module is fitted with large terminals capable of easily

accepting 4mm square conductors.

The I/O module provides the following:

Loop input / output terminals for up to 2 loops.

2 x Conventional Fire Detection Zones, ideal for utilising existing conventional detectors when retro fitting.

Suitable detectors are Apollo S60 / S65, Apollo Orbis, Tyco M600 and the Hochiki CDX range.

1 x RS232 Comms port for connection to a PC or a laptop running Electronic Devices FireConfig.exe Windows

software Application. Use a straight through (not null modem) serial cable with a 9 pin D type male

connector on one end and female on the other. If using a laptop which does not have a suitable serial port

you will also need a USB to Serial port converter.

1 x RS485 Full Duplex Comms port for connection to up to 8 Repeater modules.

1 x HWFD Relay Output, (Hardware Fire Detection). Normally energised relay output for connection to

additional control panels or third party conventional / addressable fire panel. The HWFD contacts are

normally open and close to 470 Ohms in the event of an alarm condition. Importantly this relay will

continue to operate correctly in the event of internal panel communications failure and also loop

communications failure (discovery detectors and EDL gas detectors only).

All relays are Voltage free change over contacts. All are rated at 2.5A @ 30V d.c. non inductive.

1 x Fire Alarm Relay, fail safe hardware driven.

1 x Delayed Fire Alarm Relay.

1 x Pre Alarm Relay.

1 x Fault Alarm Relay contacts.

3 x Auxiliary Alarm Relay contacts, 3 Relays each with 2 sets of

Contacts. Configurable using PC application.

3 x Monitored Sounder Circuits rated 1A ; 24V dc. Sounder circuit 1 is fail safe, hardware driven.

Sounder circuits 2 and 3 are software driven and configurable.

2 x 24V DC Monitored Fused Outputs.

1 x Auxiliary DC Monitored Input, 24V dc +/- 25%..

1 x Battery Input with automatic charging and disconnection before battery damage can occur.

1 x Main DC Monitored Input, normally used with the internal Power Supply, 24V dc +/- 25%..

1 x Main AC Monitored Input.

1 x Internal Buzzer (comms failure).

MAINS

AC

MAIN

DC

AUX

DC

PC

SETUP

1 - 8 FIRE / GAS

LOOPS

2

CONVENTIONAL

ZONES

3 AUX

RELAY

VFC

3 SOUNDER CCTS

REPEATERS

HARDWARE FIRE / GAS

DETECTION (HWFD)

TO ADDITIONAL

FIRE / GAS PANELS

DC

OUT

PRE

ALARM

VFC

ALARM

VFC

DELAY

ALARM

VFC

FAULT

VFC

I/O MODULE

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-7-

Section 2 - System design guidelines

LOOP LENGTHS

LOOP LOADING - Maximum number of addresses

LOOP LOADING - Short circuit isolators

LOOP CABLE SELECTION

LOOP CABLE RESISTANCE

The maximum permitted loop length can be determined using Apollo’s loop calculator, available free from EDL.

Remember to include the vertical distances when looking at plan drawings and also ensure cable capacitance is

within the panels specification.

The maximum number of addresses is 126 per loop. System designers should avoid fully loading loops. The

optimum number of addresses per loop is approximately 90 to 100, this ensures the system is operating well

within its capacity and allows the customer flexibility in the future to add additional devices.

Short circuit isolators should be fitted with no more than 20 detectors between isolators. No more than 10

detectors (or equivalent load) between the panel and the first isolator and no more than 10 detectors (or

equivalent load) between the panel and last isolator. Ideally the first and last items fitted to a loop should be

isolators.

Isolators should always be fitted at zone boundaries and it is good practice to reduce the number of times loop

wiring enters and leaves the same zone. A single fault on a loop should not remove protection from an area

greater than a single zone.

Two simultaneous faults on a loop should not remove protection from an area greater than 10,000 sq m . This

requirement limits the total floor area covered by one loop to 10,000 sq m regardless of the number of

detectors.

Isolators are available as standalone or built in to detector bases and integrated in to Apollo interface modules .

The additional cost of the built in isolators is small compared to the non isolated bases or interface units

therefore as many isolators should be fitted as possible.

Short circuit isolators do not use up addresses and there is no limit to the number of isolators fitted.

Each loop card is fitted with two onboard short circuit isolators, one for loop out and one for loop return,

protecting the wiring between the panel and first and last isolator.

The cable must be a suitable type e.g. FireTuf, FP200 or equivalent and must have the following characteristics:

1. The cable must be 2 core with screen + drain core.

2. Loop out and loop in should never be run within the same cable.

3. Multicore cable should never be used.

The maximum permissible resistance per core is 12.8 Ohms at maximum load (300mA). Loops with lower

loads can accept higher cable resistance, however it is good practice to consider the maximum load at the

design stage thus allowing for future expansion.

Core diameter Typical resistance (FP200 / FireTuf)

1.0mm 18.1 Ohms/Km/Core

1.5mm 12.1 Ohms/Km/Core

2.5mm 7.4 Ohms/Km/Core

4.0mm 4.6 Ohms/Km/Core

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

System design guidelines - continued

LOOP CABLE CAPACITANCE

SCREEN CONTINUITY

REPEATER CABLE SELECTION

POWER SUPPLY

Cable capacitance is an important consideration when choosing loop cable.

The maximum permissible capacitance is 0.5uF (500nF) between loop + and loop -.

As each loop is electrically isolated therefore high loop to screen capacitance does not normally cause a

problem and should not be the limiting factor for loop lengths.

Typical capacitance per 100m (FP200 / FireTuf)

Core diameter core to core core to screen

1.0mm 10nF 17.5nF

1.5mm 12nF 20.5nF

2.5mm 13nF 24.0nF

It is vital, for correct and trouble free operation, that the screen is continuous along the full loop length. Ensure

that the screen connection is continued at each loop device. The screen should be earthed at one end only, via

the control panel, and never at loop devices.

All cables entering the control unit should be screened and ferrite sleeves, supplied with the control unit, must

be used. All screens should be terminated at the control panel only thereby avoiding earth loops.

See page 9 for connection diagram.

Note the repeater data cable screens must NOT be connected to the enclosure (earth) and instead connected

to the terminals marked SCRN inside the control unit and repeater units.

The repeater communicates with the control panel using the industry standard RS485 full duplex.

The data cable used should be 2 conductor (twisted) 124 Ohm twinixial 25 AWG (0.16 sq mm) with foil screen

and drain wire. E.g. Beldon 9271 006 (BLULT).

Repeaters can be powered locally to avoid running additional power cables or they can be powered from the

control unit using the fused output terminals. Up to 8 repeaters can be connected to each system, however if

powered from the control panel the repeater current consumption should be included in power supply and

battery calculations.

Each repeater can operate from 18 - 30Vdc with a worst case current consumption of 350mA.

See page 10 for connection diagram.

The control unit requires a nominal 24V dc supply and must always have batteries connected. Normally the AC

mains is connected to the AC mains input terminals and the AC mains output terminals are wired to the external

power supply. The power supplies DC output is connected to the systems main DC input terminals.

Auxiliary DC input terminals are provided as an additional option. The DC input and Auxiliary (if used) must be

suitably rated to charge the internal batteries.

All power supply cables must be screened and ferrite rings used and cables should not be routed near EMC

generating equipment, radio transmitters, paging systems etc., See page 9.

-8-

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

Section 3 - Control unit installation

GENERAL

WARNING: Please read this section completely before commencing installation.

The panel must be located in a clean, dry position at least 2 metres away from any radio transmitting equipment

e.g Pager systems.

NOTE

When changing any plug-in cards or loop devices, observe anti-static precautions. Ensure that all power is

removed and the system is switched off. Failure to do so may result in damage to the cards or panel.

The panel be switched off before removing or replacing any card or module. Failure to observe this may

cause damage to the printed circuit boards.

Each loop card has an ID, set via the dip switches mounted on each loop card. No two loop card should have

the same ID.

FireConfig.exe must be used for initial system setup.

The Mains supply should be installed in accordance with the current edition of the IEE wiring regulations.

Connection to the mains supply must be via an isolating protective device (e.g. an isolating fuse) reserved

solely for the fire alarm system. It should be insured that all isolating switches, circuit breakers etc., connected

to the system should be labelled “FIRE ALARM DO NOT SWITCH OFF”.

Correct earthing is vital for trouble free operation. The earth connection should be as short as possible, using

4mm square conductors, connected directly to a good quality earth. The earth should not be routed via radio

transmitting devices or other electrical equipment.

All cables entering the control unit should be screened and ferrite sleeves, supplied with the control unit, should

be used. All screens should be terminated at the cable gland. Only metal, EMC shielding cable glands should

be used. Screens should be continuous and have continuity along the entire length of the cable. Only connect

the screen to earth at one end thus avoiding earth loops. All unscreened conductors should be kept as short as

possible and the ferrite ring should be as close to the cable gland as possible. Wrap each conductor around the

ferrite at least twice. Any communication faults experienced are likely to be caused by poor EMC shielding

practices. Repeater cable screens should never be connected to earth, always use the terminals provided.

MUST

LOOP OUT LOOP IN

SCREEN CONNECTED

TO METAL CABLE GLAND

ENSURE GOOD

CONNECTION BETWEEN

GLAND AND ENCLOSURE

SHORT CIRCUIT ISOLATORS ARE

ALWAYS THE FIRST AND LAST

DEVICE ON A LOOP AND SHOULD

ALWAYS BE USED AT ZONE

BOUNDARIES.

ISOLATOR ISOLATOR

ISOLATOR

CONDUCTORS WRAPPED

AROUND FERRITE CORE

ISOLATOR

ZONE 1 ZONE 32

ZONE 2 SCREEN NOT EARTHED

AT THIS END

-9-

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

ED816A I/O BOARD CONNECTIONS

EVACUATE MUTE RESET

POWER

ALARM

PRE-ALM

DELAYED

FAULT

SILENCED

ISOLATED

LOOP 1 STATUS

EVACUATE MUTE RESET

POWER

ALARM

PRE-ALM

DELAYED

FAULT

SILENCED

ISOLATED

LOOP 2 STATUS

SCRN

B

A

SCRN

Y

Z

+ - + -

+ - + -

+ - + -

SCRN

Z1 Z2

CONVENTIONAL

IN OUT

LOOP 2

IN OUT

LOOP 1

LOOP 2

CONNECTIONS

PC CONNECTION

LOOP 2

CONNECTIONS

CONVENTIONAL

CONNECTIONS

REPEATER

CONNECTIONS

- +

+ - + - + -+ -+ -+ -

MAIN

24VDC

INPUT

AUX

24VDC

INPUT

24V

BATTERY

INPUT

FUSED 24VDC

OUTPUT

SOUNDER

OUTPUT

NO. 3

SOUNDER

OUTPUT

NO. 1

SOUNDER

OUTPUT

NO. 2

L N E

MAIN

AC

OUTPUT

L N E

MAIN

AC

INPUT

AUX # 5

RELAY CONTACTS

C NO NC

AUX # 3

C NO NC

AUX # 1

C NO NC

FAULT

C NO NC

DELAYED

ALARM

C NO NC

PRE-

ALARM

C NO NC

ALARM

C NO NC

HWFD

-10-

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

XP95 / DISCOVERY MOUNTING BASE WIRING DIAGRAM

-11-

L2

EARTH

L1

-R +R

SCREEN

LOOP -VE

LOOP +VE

SCREEN

LOOP -VE

LOOP +VE

4K7

EOL

APOLLO

ORBIS

LED -

COM -

OUT +

IN +

4

REMOTE

INDICATOR

APOLLO

ORBIS

LED -

COM -

OUT +

IN +

4

APOLLO

ORBIS

LED -

COM -

OUT +

IN +

4

REMOTE

INDICATOR

REMOTE

INDICATOR

1. Connect detector earth connection to cable screen

2. Always fit call points at the beginning of a zone or on a separate zone. Removal of detectors fitted between

the control unit and call points would disable the call points.

3. Never use looped wire for connection into and out from the same terminal, always break wire.

Any single wire coming loose from a terminal should open circuit the end of line resistor to enable a fault

to be indicated.

C O N V E N T I O N A L Z O N E S W I R I N G D I A G R A M

+VE

-VE

CONVENTIONAL

ZONE

XP95 / DISCOVERY ISOLATING BASE WIRING DIAGRAM

L2

EARTH

L1

-R +R

SCREEN

LOOP -VE

LOOP +VE

SCREEN

LOOP -VE

LOOP +VE

IN OUT

SCREEN

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

+

SOUNDER WIRING

The fault monitored sounder circuits can be used to operate several sounders and beacons up to a

maximum load of 1A. A 4K7 Ohm end of line resistor should be fitted across the last device to facilitate

fault monitoring. Note: SNDR1 is fail safe and should always be used first, with sounders / beacons in

a manned location.

-

+

-

-

-

SND 1

SND 2

+

-

+

-

-

-

SND 1

SND 2

+

-

+

-

4K7

EOL

+VE

-VE

SOUNDER CCT

1,2 OR 3

ED6 SOUNDER ED6 SOUNDER /

BEACON COMBINATION

ED6 BEACON

Never use looped wire always use separate conductors for input and outputs thus enabling fault

monitoring. If Sounders and Beacons are not supplied by EDL, ensure they have a series polarity

protection diode fitted. Please contact EDL for further information.

REPEATER WIRING

Up to eight repeaters can be connected to each system. The last repeater on the line must be a type A.

Type A and B repeaters differ only in that type A repeaters have terminating resistors, R2 and R39,

fitted.

Repeaters can be powered by a local, battery backed, 24Vdc supply or driven off the fused output

terminals provided in the ED816A. Each repeater draws a maximum of 350mA.

The data cable used should be 2 conductor (twisted) 124 Ohm twinixial 25 AWG (0.16 sq mm) with foil

screen and drain wire. E.g. Beldon 9271 006 (BLULT).

With full duplex wiring each repeater has exactly the same functionality as the main control panel, giving the

designer the option of using the repeater as the main interface. This allows the control panel to be situated in a

more central location.

It is possible to operate repeaters without their full functionality by omitting the repeater transmit wiring; i.e.

Wiring between Z, Y (repeater) and A, B (control panel).Thus the repeater can only receive information, no

information can be transmitted to the control panel including setup information etc.. Electronic Devices Limited

do not recommend this method because the EVAC button on the repeater will not function. However a solution

is to have a call point located next to the repeater set to “no zone”. Call points set to no zone automatically

operate the evacuate command when operated. It is for this reason all repeaters installed should be checked

they both transmit data as well as receive it from the control panel.

SCRN

B

A

SCRN

Z

Y

SCRN

Z

Y

SCRN

B

A

SCRN

Z

Y

SCRN

B

A

SCRN

Z

Y

SCRN

B

A

24V FUSED

OUTPUT

+

-

RS485 FULL DUPLEX

+

-

+

-

+

-

CONTROL PANEL

REPEATER

TYPE B

REPEATER

TYPE B

REPEATER

TYPE A

RX

TX

TX

RX

TX

RX

TX

RX

-12-

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-13-

Section 4 - Initial system setup

FIRECONFIG

MUSTFireconfig.exe is a windows based application program which be used for initial system setup.

Install FireConfig.exe on to your Windows XP / Vista PC hard drive or run directly from a data stick if required.

Use a straight through (not null modem) serial cable with a 9 pin D type male connector on one end and female

on the other. If using a laptop which does not have a suitable serial port you will also need a USB to Serial port

converter.

1. Check the loop fitted boxes for all loops fitted. (For the ED816A only loop 1 and 2 are applicable.)

2. Click “Configure” for loop 1.

3. Click “Add Head” and then fill in the details for the first addressable device on the loop.

4. Choose the address, which can be 1 to 126.

5. Choose the name, which can be a maximum of 12 characters.

6. Choose the zone, which can be 1 to 32. Additionally No Zone can be specified. Any device going in to alarm,

which has not had a zone assigned, will operate the evacuate command and all sounders and beacons will

operate. Additionally no delays or zone isolates are allowed.

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-14-

Initial setup - continued

When choosing some devices additional check boxes / drop down menus may appear, eg. Discovery

sensitivity. See DEVICE TYPES AND CONFIGURATION (page 14) for further details.

7. Repeat steps 2 - 6 until all loops are configured.

9. Click “ ” and choose the text that appears in the top right hand side of the display for both

main panel and repeaters.

10. Click “ ” and check the appropriate boxes. If not checked the system will not give fault

warnings for that particular supply.

11. Click “ ”, if used, and choose whether the zone is to be used for Hazardous or safe

Areas. If “Intrinsically Safe Devices” are chosen the zone wiring must be connected through an

Electronic Devices zener barrier type ZBD7+ located in the Safe Area. See connection diagram and

also ensure ATEX regulations are met fully.

12. Click “ ” to save the configuration to you computers hard drive or data stick.

13. Click “ ” to save the configuration to .csv format which can be read and printed using most spread

sheet programs e.g. Microsoft excel or openoffice (freeware available from www.openoffice.org).

14. Click “ ” to select which comms port your serial cable is attached to. Click test to check both the

port and system are working correctly.

15. Click “ ” if the system has previously been configured and now requires

changing. This will take several minutes and will information held in memory.

16. Click “ ” to clear the history stored in the systems memory.

17. Click “ ” to send the data in to the system. This can take several minutes. Once complete turn

the system off for one or two seconds before turning back on. Monitor the system closely for the next

several minutes, checking for any faults to be reported. Most faults will be reported within 2 minutes,

however internal memory and program errors can take up to 1 hour to be reported.

If downloading is interrupted (power failure, pc failure etc.) turn off the systems power and then after a

few seconds, re-power the system and, when ready, start the download again.

The Cause and Effect matrix does not have to be used for simple applications. However for the needs of larger

and more complicated systems a powerful cause and effect matrix is provided.

It is important to note that in the event of panel failure or communications failure the cause and effect matrix will

not function. SNDR1 is the dedicated fire/gas alarm which is operated in failsafe mode and also via the

HardWare Fire Detection circuit. The HWFD circuit will continue to give alarms from Discovery detectors and

EDL gas detectors in the event of communication failure between panel and loop devices, provided the loop

voltage is still correct. Therefore SNDR1 should be the first choice and should always be used with at least

one sounder located in a manned area. See page 30.

No more than 50 cause and effects should be used. To help reduce the number of cause and effects the

following methods should be used:

1. All sounders, beacons, sounder control units etc., that are to operate from the main fire/gas Alarm

should have the “always operate in the event of alarm” check box ticked on the loop configuration page.

If this is done no cause and effect entries are necessary.

2. All I/O controllers and Switch monitor I/O modules with inputs only being used to operate the main

fire/gas Alarm, should have the appropriate “alarm on bit 0,1 or 2” boxes checked on the loop

configuration page. If this is done no cause and effect entries are necessary.

3. If large numbers of loop powered sounders / beacons are to operate from any cause other than the

main fire/gas alarm (e.g. Pre-alarm), group addressing and / or master - slave sounders / beacons

should be used so that only minimal cause and effect entries are required.

Display Names

Power Supplies

Conventional Zones

Save

Export

Options

Clear configuration

Erase History

Download

IMPORTANT NOTE

MAXIMUM NUMBER OF ENTRIES

CLEAR ALL

Section 5 - Cause and Effect Matrix

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-15-

Cause and Effect Matrix - continued

Adding Cause and Effects entries

“Cause and Effect” “add Entry”

“input type”

“Device”

“Zone”

“Loop”

“Cause”

“Coincidence”

I/O unit Latching I/O unit Non-Latching.

1. Click and then .

2. Choose a name for the entry.

3. Select the .

is any detector, input module, zone

monitor or switch monitor on any loop.

is any of the 32 zones and also either of the

2 built in conventional zones.

is any of the loops attached to the system

only loop 1 and 2 apply for the ED816A.

4. Select . Cause can be pre-alarm, alarm

or fault.

If Zone was chosen for input type an extra cause

choice becomes available.

detection is available between any 2 zones.

In the event of the 2 zones chosen both being in

the alarm condition then the effect will be actioned.

If Device was chosen for input type and the device is an I/O module, 2 extra cause choices become

available. and

Apollo manufacture 3 main I/O modules with the following inputs:

Mains switching I/O 0 1 status of monitored switch

1 2 not used

2 3 not used

Input Output Unit 0 1 status of monitored switch

1 2 status of opto input

2 3 not used

3 Channel Input Output Unit 0 1 status of monitored switch 1

1 2 status of monitored switch 2

2 3 status of monitored switch 3

Whilst the monitored switch is open no effect will occur, once the switch closes the chosen effect takes

place.

When choosing “I/O unit Latching” the effect will remain until RESET has been pressed, any

effect can be chosen from the drop down box.

When Choosing “I/O unit Non-Latching” the effect will remain for only as long as the input is set. Only

Loop Devices can be chosen in the “Effect” drop down box. When operating a loop output device only

one non-latching cause can be assigned to it.

5. Select Output type in the “effect” dialogue box, which can be Aux Relay, Sounder, Loop Device or

Delayed Output.

I/O module input bits FireConfig input use

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-16-

Cause and Effect Matrix - continued

There are 3 Auxiliary relays located on the ED816A Input / Output module, each with 2 sets of voltage free

contacts. (Note the ED816A has 1 set of voltage free contacts per aux relay.)

There are 3 monitored sounders on the ED816A Input / Output module. SNDR1 is the dedicated fire/gas alarm

which is operated in failsafe mode and also via the HardWare Fire Detection circuit. The HWFD circuit will

continue to give alarms, from Discovery detectors and EDL gas detectors, in the event of communication failure

between panel and loop devices, provided the loop voltage is still correct. Therefore SNDR1 should be the first

choice and should always be used with at least one sounder located in a manned area.

Sounders 2 and 3 are configurable via FireConfig.

When choosing loop device in the “effect” dialogue box it is possible to select any addressable device.

However care should be taken to only select suitable devices e.g. Sounders, beacons and output

modules. The following guidelines should be observed:

When choosing loop powered sounders / beacons as

output devices the set tone drop down box appears.

Allowing the commissioning engineer to choose which

output bits are set and hence the tone to be used.

Refer to the Apollo data sheets for individual sounder /

beacon types, below are the most common examples:

100dB loop powered sounder

0 continuous tone

1 pulsed tone

0+1 continuous tone

Intelligent base sounder

0 alternates 510hz / 610hz

1 intermittent 510hz

0+1 alternates 510hz / 610hz

Ancillary base sounder

0 continuous tone

1 not used

0+1 not used

To avoid confusion it is important to ensure all sounders use the same tones (or as similar as possible) to signal

the same condition.

Aux Relay

Sounders

Loop Device

Sounders and beacons

Output bit Action

Output bit Action

Output bit Action

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-17-

Cause and Effect Matrix - continued

When choosing Input / Output and Output modules as

output devices the output bit drop down box appears,

allowing the commissioning engineer to choose which

output bits are set and hence the Relay to be switched.

Please note output bits are referred to as output 1,2 and 3

in FireConfig but as output bits 0,1 and 2 in Apollo’s literature.

Refer to the Apollo data sheets for individual module

types, below are the most common examples:

Mains Switching Input Output unit

0 relay drive 1

1 not used 2

2 not used 3

3 channel Input Output unit

0 channel 1 relay 1

1 channel 2 relay 2

2 channel 3 relay 3

When choosing delayed output in the “effect”

drop down box it is possible to setup up to 8

delayed effects. The 8 delayed effects can be

called as many times as required by different

cause and effect entries, remembering 50

entries is the maximum number of cause and

effects allowed.

The “configure delayed outputs” button is at

the bottom of the main cause and effects

page and brings up the dialogue box shown.

Delays can be set anywhere between 1 and

600 seconds.

It is important to ensure all fire / gas

detection standards are not infringed when

adding delays. E.g. EN54-2 stipulates what

can and cannot be delayed when outputs are

connected to “fire alarm routing equipment”.

It is possible to override delays at any stage during normal operation by choosing item 6 (delayed outputs) from

the main system menu. It should also be remembered that, from within the cause and effect matrix, a dedicated

and suitably labelled call point could be assigned the same 8 outputs but without delays thereby giving an easy

method to override the delays. Additionally pressing the “EVAC” button or any call point not assigned a zone

will operate the evacuate command and all loop powered sounders, beacons, sounders circuits and Immediate

Alarm, Pre-Alarm and Delayed output relays will operate.

Apollo Input Output modules and Output modules

Output bit Action FireConfig Output

Output bit Action FireConfig Output

Delayed Output

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-18-

Section 6 - Device types and configuration

The ED722 and ED726 Loop drivers communicate with loop devices using Apollo Fire Detectors Ltd., protocol

S90, XP95 and Discovery.

For most devices it is obvious what selection to

make when adding to FireConfig. However it

may not be immediately obvious for some devices

which is why the device type code is shown in

brackets. e.g. Discovery optical smoke detectors

are type code 160. All Apollo devices have a type

code telling the control panel what the device is and

how it operates. If you cannot find a

particular device in FireConfig contact EDL

or Apollo and obtain the device code.

Additional drop down boxes appear when

selecting some devices and fall in to four

Categories. Input Output units, Sounder / Beacons,

Discovery detectors and Gas Detection.

XP95(A) the protocol used in North America, is also supported, allowing Apollo devices to be purchased directly

from the USA.

When adding Input Output units three check boxes

will appear. “Alarm on bit 0,1 or 2”. Consult the

data sheet and choose which bits, if any, you

require to operate the main Fire / Gas alarm. Cause

and effect entries are not required if these boxes

are ticked.

Check the “never generate alarm” box if the main

Fire / Gas alarm is not required and cause and

effect entries are to be used instead.

By adding suitable cause and effect entries it is

possible for an input module (e.g. Monitoring an

Emergency Exit switch) to operate an output module on any loop silently without any front panel indication,

buzzers etc., operating.

When adding Sounders and Beacons the “Always operate sounder in event of alarm” check box appears.

Always check this box for operation from the main Fire / Gas alarm and no cause and effect entries will be

required. If left unchecked the device will only operate if a suitable cause and effect entry has been made.

All Discovery detectors have 5 modes of operation to choose from, changing sensitivity, time to respond and for

the multi-sensor whether it reacts to heat or smoke only or both.

XP95(A) North American Models

Apollo Input Output modules / units

Loop powered Sounder and Beacons

Discovery Detectors

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-19-

Device types and configuration - continued

Gas Detection

When adding EDL Gas Detection three dialogue

boxes will appear. Sensor range, Pre-Alarm limit

and Alarm limit. When choosing the sensor range

ensure the sensor is capable of operating correctly

within that range. Pre-Alarm and Alarm limits are

the value that the gas sensor has to reach before

the alarm is given. Both alarm and pre-alarm can

be set between 10% and 80% of the sensors range

(full scale value) in 10% steps.

Group Addressed Sounders and Beacons

Some Apollo Sounders and Beacons are available with a second set of dip switches used for group

addressing., the address must be in the range of 112 - 126. This feature is useful when operating several

sounders from a single cause and effect or when adding to an existing system without the need to connect to a

PC. Group addressing should be setup as follows:

1. Add a Sounder or Beacon with its individual address in the range 112 - 126 using FireConfig

setup software. Ensure this device is NOT group address enabled by setting the group address dip

switches to “0000”.

2. Add a cause and effect entry to operate the device and / or tick the “always operate in the event of

alarm” check box.

3. All additional Sounders / Beacons to be included in this group should be added with their individual

addresses in the range 1 - 126 and the group address dip switch should be set to the address

chosen in 1 above. Additional sounders / beacons can be added either by using the FireConfig software

or using the “search for new devices” function from the main panel or any repeater.

4. Group addressing can only operate on the same loop.

5. Please see Apollo data sheets for more information.

Master / Slave Sounders and Beacons

Some Apollo Sounders and Beacons are available with an additional dip switch for selecting “Master” or “Slave”

mode. The feature is has similar benefits to using group addressing but should not be confused with group

addressing as the setup is different. Master / Slave sounders should be setup as follows:

1. Add a Sounder or Beacon with its individual address in the range 1 - 126 using FireConfig

setup software. Ensure this device is set as “master” using the appropriate dip switch.

2. Add a cause and effect entry to operate the device and / or tick the “always operate in the event of

alarm” check box.

3. Additional Sounders or Beacons can be added using the same individual address as above but the

units should all be set as “Slave” on the appropriate dip switch.

4. Group addressing can only operate on the same loop.

5. Please see Apollo data sheets for more information.

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

-20-

Section 7 - Operating Instructions - quick guide

Please read the full operating instructions before starting, however below is a quick overview of the most

commonly used functions.

During an alarm or fault condition all sounders, beacons and internal buzzers can be turned off by pressing the

button. You will be asked to enter a password which is factory set at “AAAAAA”. As this is the default

password just pressing enter is sufficient. Once the password has been entered press the button once

more.

Pressing mute does not stop any customer configured delayed outputs from operating. If the right hand DEL

lamp under the panel / device status heading is illuminated one or more (maximum of 8) of the customer

configured delayed outputs are due to operate. Pressing the button will stop the delayed outputs

from operating, however if the fire or gas alarm condition returns the count down for the delayed output will start

again. If the alarm cannot be rectified before the delayed output operates, once operated it can be turned off by

pressing the button.

If the right hand DEL lamp under the panel / device status heading is illuminated one or more (maximum of 8) of

the customer configured delayed outputs are due to operate. Pressing the button will stop the

delayed outputs from operating, however if the fire or gas alarm condition returns the count down for the

delayed output will start again. If the alarm cannot be rectified quickly enough the delayed output, once

operated, can be turned off by pressing the button. One or all of the delay times can be reduced to

zero from menu item number 6 in the systems main menu. Use the +/- keys to toggle between “normal” and “no

delay”. Use the arrow keys to choose which delay to change or choose global to change all.

After an alarm or fault condition has been rectified the system should be reset. Pressing the button

will return the system to the normal state. You will be asked to enter a password which is factory set at

“AAAAAA”. As this is the default password just pressing enter is sufficient. Once the password has been

entered press the button once more.

To operate all sounders, beacons, alarm relay and pre-alarm relay press the button. You will be asked

to enter a password which is factory set at “AAAAAA”. As this is the default password just pressing enter is

sufficient. Once the password has been entered press the button once more.

Silencing sounders, beacons and internal buzzers (MUTE)

Delayed outputs

System Reset

Evacuate

“MUTE”

“MUTE”

“RESET”

“MUTE”

“RESET”

“MUTE”

“RESET”

“RESET”

“EVAC”

“EVAC”

ED816A Addressable Fire and gas detection Installation manual 8-9-08 Rev-a

Table of contents

Other Electronic Devices Limited Security System manuals