Electus Distribution RAPID BAR 800 User manual

RTE044

RAPID BAR 800

WEIGHT DISTRIBUTION KIT - 365KG BA

2

3

1.Lineupthetowvehicleandtraileronlevelpavement,inthestraight-

aheadposition,uncoupled.

2.Levelthetrailerandmeasureandrecordthedistancefromthegroundto

thetopofthecoupler.(Fig.1).

3.Selectahitchballwithadiameterthatmatchesthetrailercouplersize.

Thethreemostcommonsizesare1-7/8”,2”,and2-5/16”.Selectballwith

1-1/4”or1“threadedshankthatisV-5ratedequaltoorgreaterthanthe

trailer’sgrossvehicleweightrating(GVWR).

1.RefertotheprovidedConsumerInformationtoweighloadedtrailer

tonguetodeterminethepropersystemsize.

2.Chooseasystemwithatongueratingatorabovetheactualtrailertongue

weight.

3.Thetongueratingofthetrailerhitchmustmeetorexceedthemeasured

tongueweightofthetrailer.TheOEMhitchesmaynotberigidenough

fortongueweightandmayneedtobereplaced(toomuchflexandwon’t

carryload).

4.Thetotaltrailergrossweightratingmustneverexceedthetowvehicle’s

ratedgrosstowrating.

Figure1

4

4.Attachhitchtheballtotheballmount(A).Standardheighthitchballs

with1-1/4”shanksaresuppliedwithlockwashersandnuts(Ifyoumust

usea1”shankball,usetheprovided58184bushing(B)toreducethe

holesizeintheballmount(A)to1”).Alwaysusealockwasherplaced

betweentheballmountandthenut.Unlessotherwisespecifiedbytheball

manufacturer,torquetheballnutto450ft/lbsforthe1-1/4”nut,250ft/lbs

forthe1”nut.

5.Someinstallationsmayrequirealongerdrawbar(C).Extendedbumper

guards,pickuptruck“caps”,orrearmountedsparetyrescanlimitturn

anglesunlessalongerbarisused.Individualdrawbars(C)areavailablein

varioussizes.

6.Insertthedrawbar(C)intothehitchboxandinstallapullpin(D)and

springclip(E).Adrawbarmaybeusedineithertheupordownposition

(seeFig.2).Theballheightshouldbegreaterthanthecoupler

heightbyapproximately3/4to1”(measuredinstep2)tocompensatefor

vehiclesquat.Forvehicleswithairsprings,airshocksoranautomatic

levellingsystem,checkthevehicleowner’smanual.Unlessotherwise

specified,levelthetrailerwiththevehicleloadedasitwillbewhentowing

beforesettingballheightandattachingthetrailer.

Fig. 1

Fig. 2

Highest Position Lowest Position

7. Positiontheballmountonthedrawbarsothattheballwillbe

approximately3/4”higherthanthecouplerwheninthecenterofits

tiltadjustment.Insert3/4X41/2”bolt(F)throughthelowerholeinthe

ballmountandinstalla3/4”lockwasher(G)anda3/4”nut(H).Rotatethe

ballmountuptoapproximatelythecenterofthetiltadjustmentandinstall

oneadjustmentwasher(J)ona3/4x51/2“bolt(K)andinsertthebolt

intotheupperslotintheballmount.Theadjustmentwasherhole

isnotcenterandcanberotated180°formaximumheadadjustmentor

halfadjustmentsteps(seebelow).Installthesecondadjustmentwasher

(orientedthesameasthefirst),lockwasher,andthenutontheotherside.

Torquethe3/4nuts(K)to300ft-lbs(Ifalargeenoughtorquewrenchis

notavailable,torquenutsto150ft-lbs,thenturnnutsanadditional1/4turn

-DONOTlubricatethethreads).

5

Adjustmentwasherholeorientedvehicle

forward:Maxheadtiltrearward

Adjustmentwasherholeorientedvehicle

rearward:Maxheadtiltforward

UsetheshimprovidedwhenneededtofillanygapbetweentheWeight

DistributingHeadshownbelowandthehitchbarusedintheparticular

application.Itiseasiertoinstalltheshimfromthetopdownasshownbelow.

Indoingso,youwillencounteroneofthreescenarios:

1.Theshimwillgoallthewaydowntolineupwiththebottomhole.Ifthis

isthecase,usetheentireshiminthegap.Itisconceivablethatin

somerarecombinations,twoshimscouldbeused.Inthesecases,contact

CustomerServiceforafreeadditionalshimservicekit#58207.

2.Theshimwillnotbegintofit

betweentheheadandthehitch

bar.Ifthisisthecase,discardthe

shimandcontinueinstallation.The

existinggapisacceptable.

3.Theshimwillnotgoinfarenough

toreachthebottomhole.Ifthisis

thecase,cuttheshiminhalfand

useonlythetophalfforthetopbolt.

Discardbottomhalfofshim.

6

StandardSpringBar

1.Pickareferencepointonthefrontwheelwell.

Measureandrecordthedistancetothepavement.

Fromthefrontwheelwelltothepavement.

2.AttachchainstospringbarsusingU-bolts,flat

washers,andlocknuts.Let2-3threadsprotrude

belowltheocknut.Thechainmustnotbind.

3.Lowerthecouplerontotheballwithatonguejackandclosethecouplerlatch.

4.Inserttheroundendofthespringbarintothelowersocketofthe

ballmountandpushupward.Lineupthenotchinthespringbarwiththe

tabintheuppersocket,andpushupuntilseated.Rotatethespringbarso

thatitisinlinewiththetrailerframetolockitintoplace(thespringbars

willfitoneitherside,astheyarenotmaderightorlefthanded).Repeatthe

procedurefortheotherbar.Toreleasethespringbar,liftuponthe

barandrotatesothatthenotchinthespringbarandthetabintheupper

socketareinline,thenallowthebartodropoutoftheballmount.

5.Positionthesnapupbracketsonthetrailer“A”framesothatthechain

attheendofthespringbarisapproximatelyvertical.Turnthe1/2x3-1/2

boltuntilitcontactstheframe.Then,withthewrench,tighten1/4turn.DO

NOTOVERTIGHTEN.

6.Raisethetrailertongueandrearofthevehiclewiththetonguejack.Lower

theyokeofthesnapupbracketuntilitisparallelwiththeground,andslip

theclosestlinkoverthehook.(Iftherearelessthan4linksbetweenthe

hookandtheu-boltadjusttheballmountanglerearward,andrepeatthe

procedure-SeeFig.3&4below).Withthesnapupbrackethandleover

theyoke,raiseuntiltheyokehaspassed“overcenter”.Slidethesafetypin

throughthesmallholetolocktheyokeinplace.Repeatontheotherside.

Fig. 3

SNAP UP HANDLE

PLACE CLOSEST

LINK ON HOOK

Fig. 4

7

7. Lowerjack.Re-measurethefrontwheelwellreferencepoint.The

frontwheelwellheightshouldbeequaltoorlowerthantheoriginal

measurement.Ifthefrontwheelwellheightishigherthanoriginally

measured,reducethenumberoflinksbetweentheyokehookandspring

bar(4linksmin.)andrecheckthewheelwellmeasurement.Ifthefront

wheelwellislowerthanoriginallymeasured,increasethenumberof

chainlinksbetweentheyokehookandspringbarandrecheckthewheel

wellmeasurement.Iftheoriginalwheelwellheightisnotachievable,it

ispreferredthatthewheelwellheightbelowerafterthespringbarsare

loaded.Iftherearenomorechainlinksforadjustment,theheadassembly

mustbetiltedforward.Thetrailermustbeuncoupledandtheupper

boltremovedfromtheheadassembly.Theheadisthenpivotedupas

appropriate.Reassembleandrecheckthewheelwellheight.

Placeseveraldropsofoilatspringbar/ballmountcontactpointseachday

ofuse.Excessoil,dirt,andgritshouldbewipedoutwheneveratraileris

uncoupled.

Somesurgebrakeswillnotworkwithweightdistributinghitches.

Donotuseswaycontrolwithsurgebrakes.

Frontwheeloverloadandlossofrearwheel

tractioncanresult,andcanleadtounstablehandling,reducedbraking

ability,andatendencyto“jackknife”whenturningandbrakingatthesame

time.IFLOADEDBALLHEIGHTISGREATERTHANUNCOUPLEDHEIGHT,

reducethetake-uponthespringbarchainsandre-measureuntilproper

heightisobtained.

8

Goodhabitsfornormaldrivingneedextraemphasiswhen

towing.Theadditionalweightaectsaccelerationandbraking,andextra

timeshouldbeallowedforpassing,stopping,andchanginglanes.Signal

wellinadvanceofamanoeuvretoletotherdriversknowyourintentions.

Severebumpsandbadlyundulatingroadscandamageyourtowing

vehicle,hitch,andtrailer,andshouldbenegotiatedataslowsteadyspeed.

Donotattempttotowanytypeof

trailerbehindanothertrailer.Towingmultipletrailersmaycausesevere

instability,lossofcontroland/orstructuralfailure,andmayresultinvehicle

accidents,propertydamageandpersonalinjury.Towingmultipletrailersis

illegalinmanyjurisdictions.

.Severe

structuraldamagetotowingvehicle,hitch,andtrailermayresult.Atowing

vehicle/trailercombinationcannotbecontrolledadequatelyunlessthe

towingvehicle’srearwheelsarecarryingtheirshareoftheload.

Keepthetrunnionsandsocketsintheheadassemblyfreeofdirtandwell

lubricated.Excessivewearinthisareamayindicateoverloadorinadequate

lubrication.Someelongationofsocketopenings“seatin”isnormal.

Keeptheheadassemblyexteriorclean,especiallythetrunnionsockets.Do

notallowdirtorstonestolodgebetweenthetrunnionsandthehead.

Keepthehitchpaintedtopreventrustandmaintainagoodappearance.(Do

notpaintoverlabels)

•Addadropofoilatthetrunnioncontactareaswithballmount.

•Cleantheballandcouplersocketandcoattheballlightlywithgrease.

•CheckspringbarchainsandU-boltsforwear.Replacethembeforethey

becomewornhalfwaythrough.

•Checktoseethatallboltsareproperlytightenedandthatthehitchpinand

cliparesecurelyinplace.

•Checktoseethatelectricalhookupsareinworkingorder,andthatsafety

chainsareconnected.

9

Periodicallychecktheconditionofallyour

towingequipmentandkeepitintopcondition.

Propertrailerloadingisimportant.Heavyitems

shouldbeplacedclosetothefloornearthetraileraxle.Theloadshould

bebalancedside-to-sideandfirmlysecuredtopreventshifting.Formost

trailers,thetongueweightshouldbearound10–15percentofthegross

trailerweight..Toolowapercentageoftongueweightwilloftenproducea

tendencytosway.Excessweightonthetonguecanalsoleadtoswayand

damagethehitchand/ortowvehicle.

Aswaycontrolcanhelpminimisetheeectsofsudden

maneuvers,windgusts,andbuetingcausedbyothervehicles.Theuseof

aswaycontrolisrecommendedfortrailerswithlargesurfaceareas,suchas

traveltrailers.

Unlessspecifiedotherwisebythetowingvehicle

ortrailermanufacturer,tiresshouldbeinflatedtotheirmaximum

recommendedpressure.

Reviewtheowners’manualsforyourtowing

vehicleandtrailerforspecificrecommendations,capacities,and

requirements.

Ifyourtrailerhasastraighttongue(insteadof

anA-frametongue),itwillbenecessarytouseapoletongueadapter.This

adapterattachestothetrailertongue,providingaplacetoattachthesnap

upbrackets.

TrailersshouldNOTbeoccupiedwhilebeing

towed,underanycircumstances.

Always

hookuptrailerlights,turnsignals,electricbrakesandbreak-awayswitch

connection(ifsoequipped)evenforshorttrips.

Removehitchfromtowingvehicle

receiverwhennottowing,topreventcontaminationofheadsockets,reduce

chanceofstrikinghitchondrivewayrampsorotherobjects,andminimize

damageintheeventofarear-endcollision.

10

RoadTechMarinewillreplaceanypartwhichproves

defectiveinmaterialorworkmanshipwhenpresentedtoanyRoadTech

Marinestoreorreturnedtothefactory.

,attheaddressbelow.

Somestatesdonotallowtheexclusionorlimitationofincidentalor

consequentialdamages,sotheabovelimitationorexclusionmaynotapply

toyou.

AnydamagetotheRapidBar800WeightDistributingsystemasaresultof

misuse,abuse,neglect,accident,improperinstallation,oranyuseviolative

ofinstructionsfurnishedbyus,

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveother

rightsthatvaryfromstatetostate.Intheeventofaproblemwithwarranty

serviceorperformance,youmaybeabletogotoasmallclaimscourt,ora

federaldistrictcourt.

11

12

Distributedby:

ElectusDistributionPty.Ltd.

320VictoriaRd,Rydalmere

NSW2116Australia

www.electusdistribution.com.au

MadeinChina

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

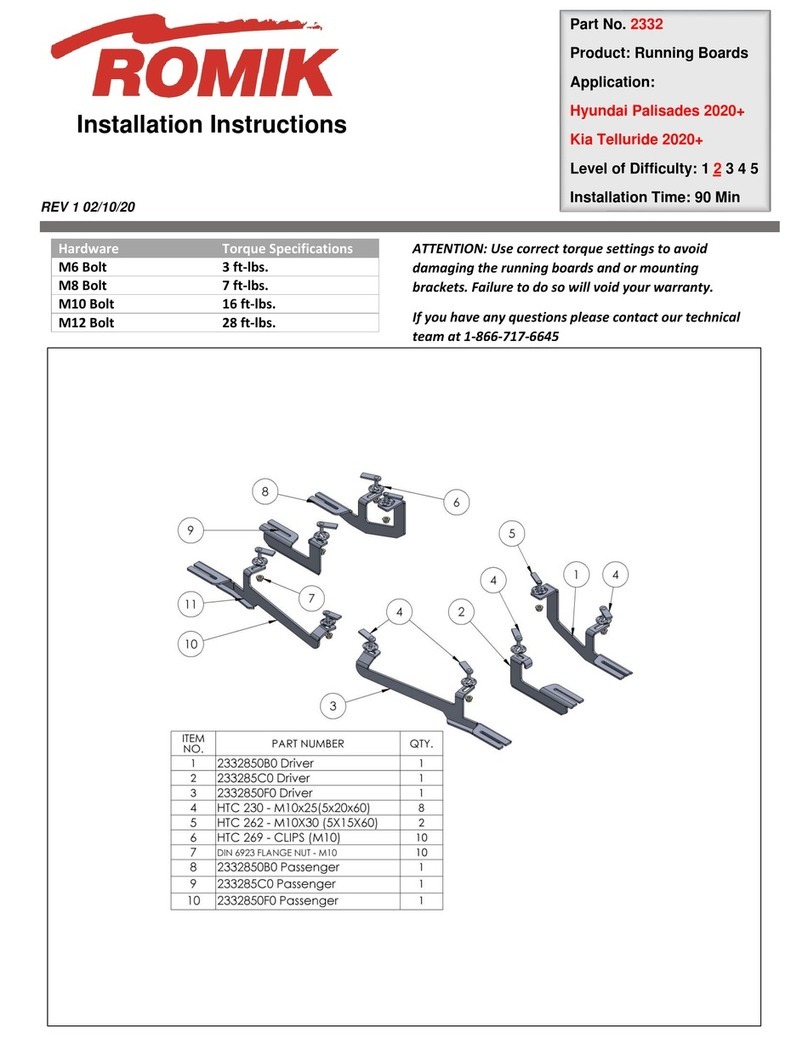

Romik

Romik 2332 installation instructions

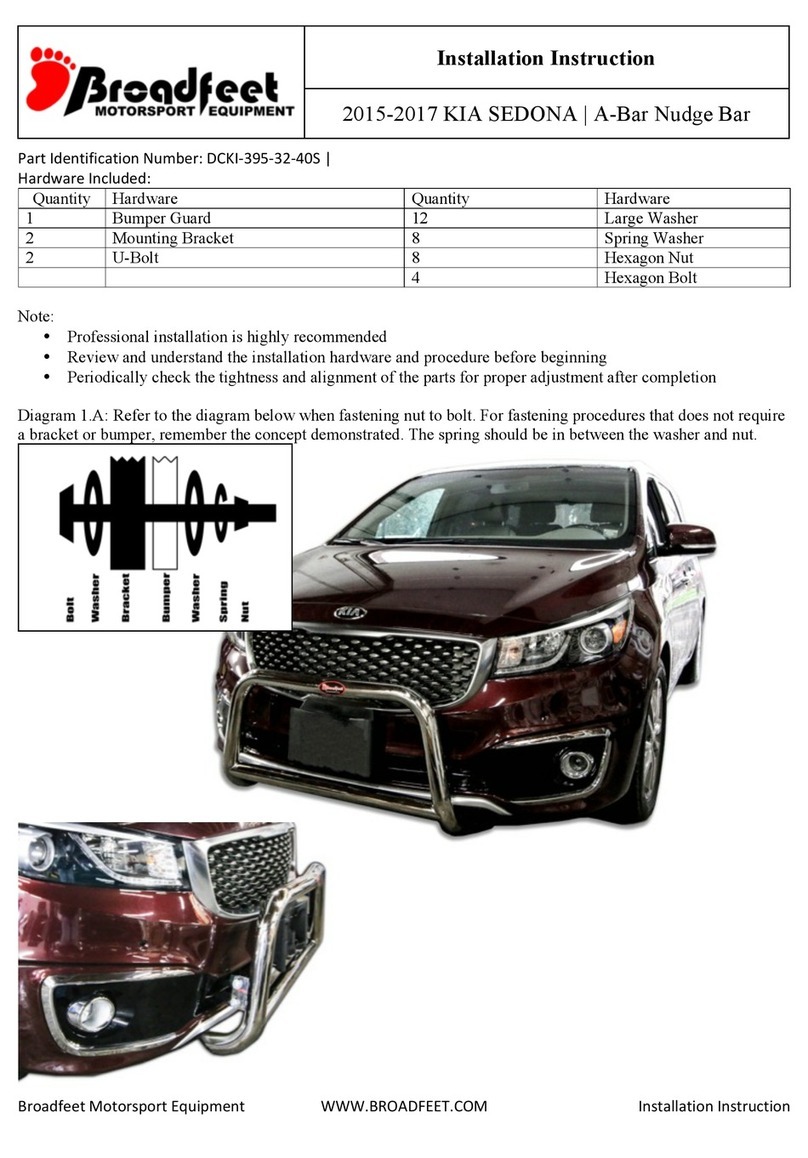

Broadfeet

Broadfeet DCKI-395-32-40S installation instructions

DC Power Solutions

DC Power Solutions B-COOL RV Series installation manual

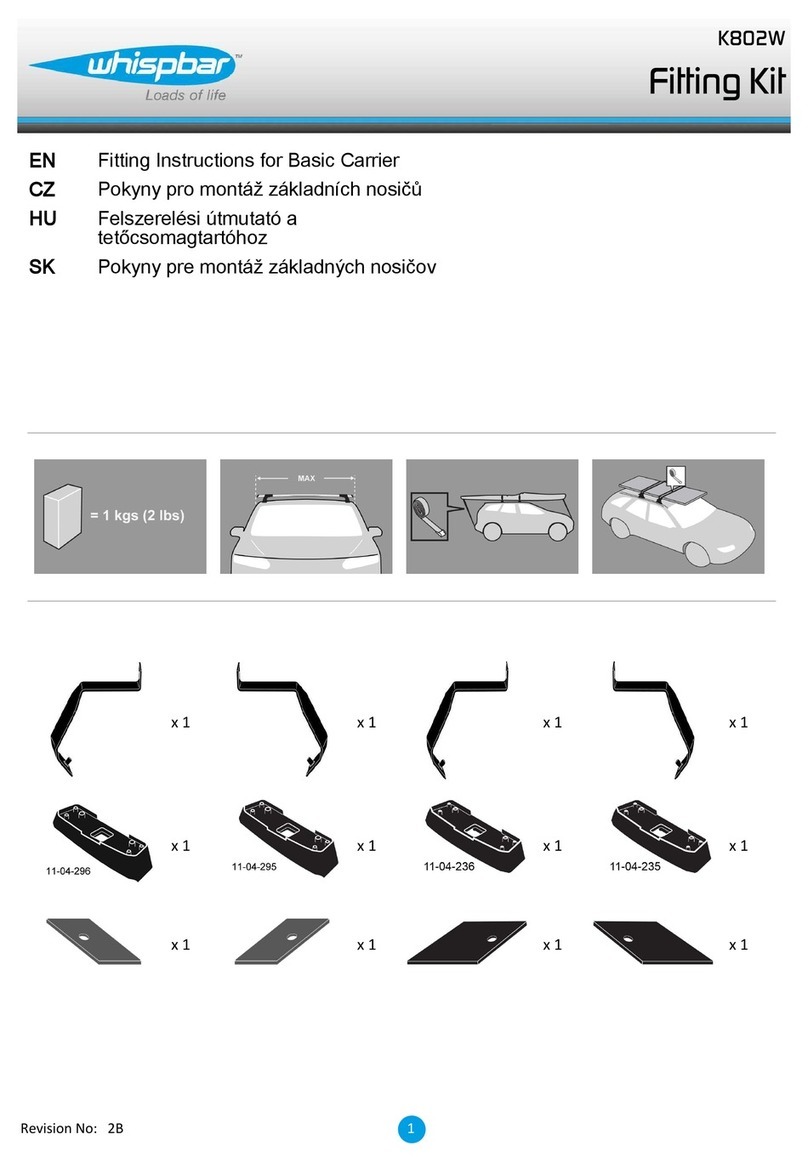

Whispbar

Whispbar K802W Fitting Instructions for Basic Carrier

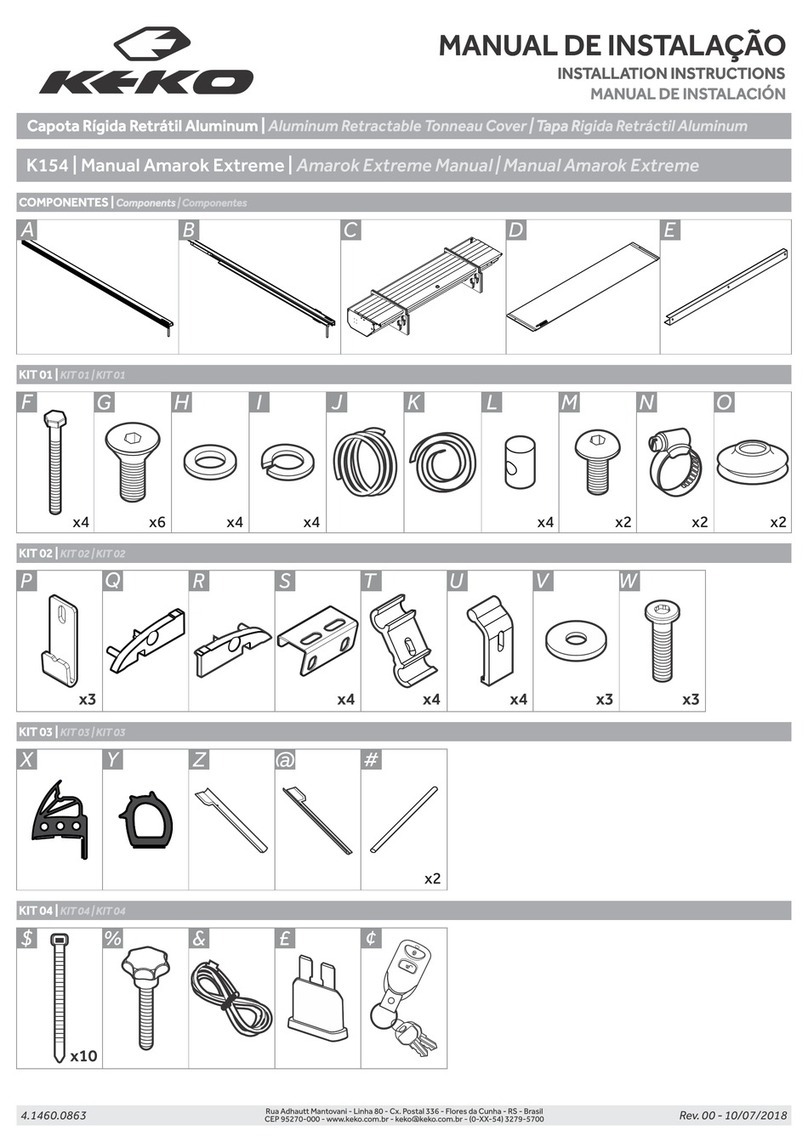

KEKO

KEKO K154 installation instructions

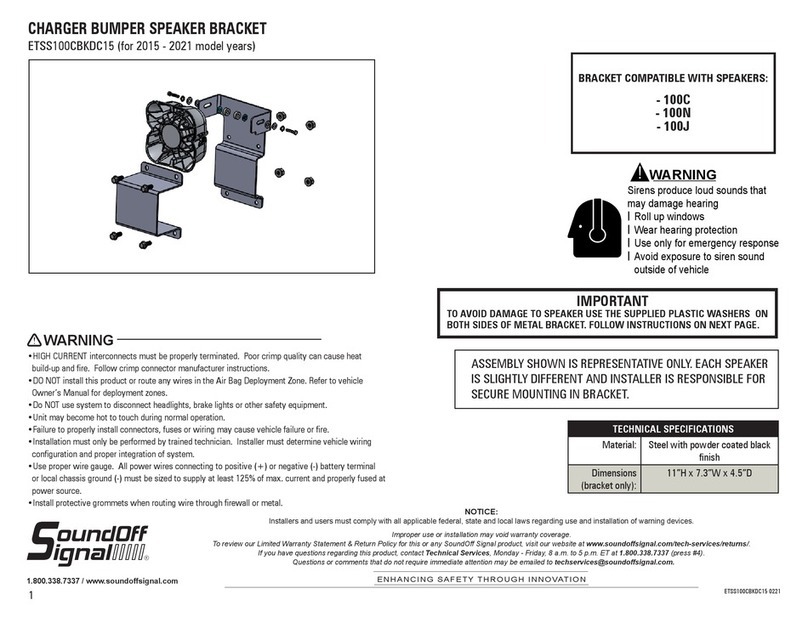

Soundoff Signal

Soundoff Signal ETSS100CBKDC15 quick start guide