Elektronikbau- und Vertriebs Ceta 100 User manual

Operating manual

100

Differential temperature control

Version 0931-10

Art. 0450021000

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 1 Dienstag, 25. August 2009 3:33 15

Scope of delivery ...............................................................................................................1

General ................................................................................................................................1

Intended use .....................................................................................................................1

Safety ..................................................................................................................................1

General key functions ...................................................................................................... 2

Version display (when starting)...................................................................................... 2

Basic display .....................................................................................................................2

Menu level .........................................................................................................................3

Parameter description .....................................................................................................6

Mounting .......................................................................................................................... 10

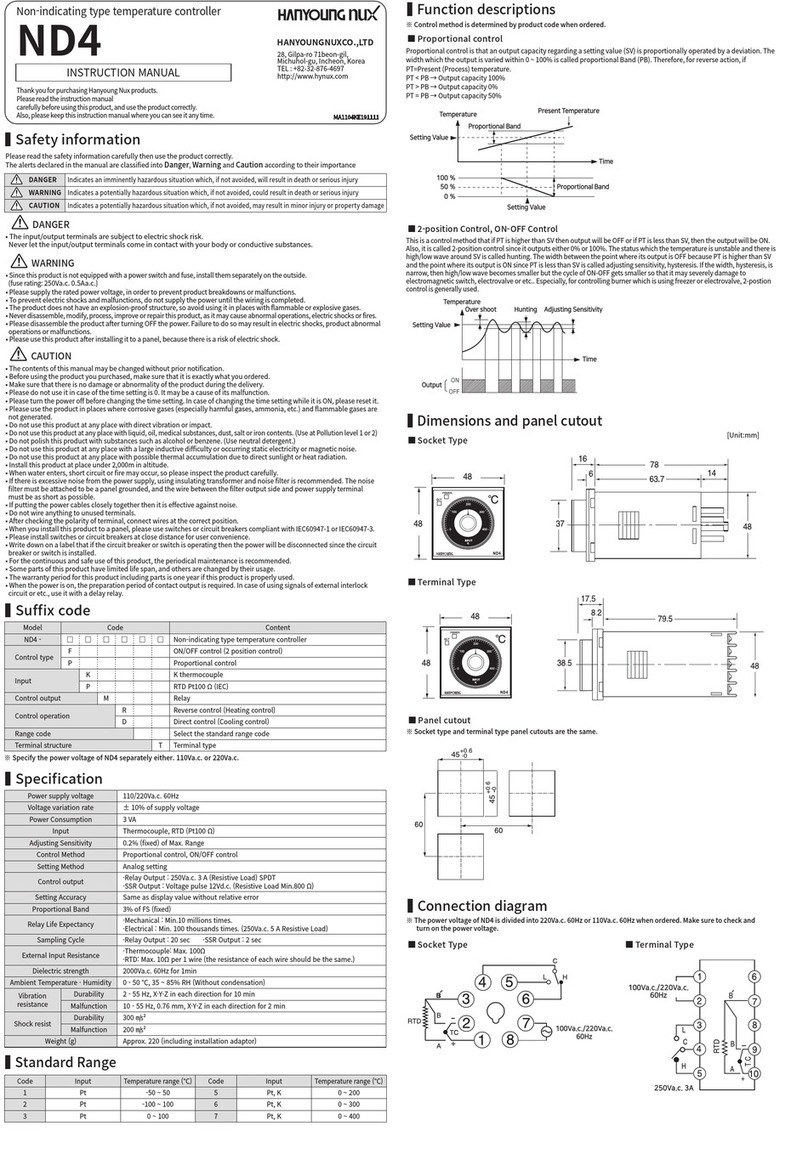

Connection diagram ........................................................................................................ 11

Fault clearance ................................................................................................................. 11

Sensor resistance values .............................................................................................. 12

Declaration of conformity .............................................................................................. 13

Technical Data ................................................................................................................ 14

Liability ............................................................................................................................. 14

Disposal ........................................................................................................................... 14

© Elektronikbau- und Vertriebs GmbH

Heisterner Weg 8 - 12

D-57299 Burbach

This document may not be reproduced nor disclosed to third parties, particularly competitors, in original

or copy form without our prior explicit consent. The document is subject to our proprietary rights and

copyrights.

Contents

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 2 Dienstag, 25. August 2009 3:33 15

1

Scope of delivery

1. 1x Central unit CETA 100

2. 1x Tank immersion sensor KVT 20/2/6

3. 1x Collector sensor PT1000/6

4. 8x Screw, plate 2.9x19 mm

5. 3x Screw assembly 4x35 mm

6. 3x Plug U6

7. 2 x Cable clamp

General

Systems with heat source and hot water tank are controlled via the differential

temperature control. When the heat source temperature exceeds the tank

temperature by the value set on the controller, the circulation pump is activated

by the control and the heat absorbed in the heat source is transported to the hot

water tank.

Intended use

The unit is manufactured in accordance with state of the art technology and

approved safety regulations. Nevertheless, using the unit can cause danger to the

user or third persons, or damage to the unit and other assets. The unit must be

used exclusively as differential temperature controller.

Safety

All electrical connections, safety measures and protections have to be carried out

by an authorised professional electrician according to the valid standards and VDE-

guidelines, as well as the local regulations. The electrical connection must be a

fixed connection according to VDE 0100.

Hazard symbols in this operating manual

Hazard!

This symbol indicates information that warns of possible safety

risks or severe and fatal injuries!

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 1 Dienstag, 25. August 2009 3:33 15

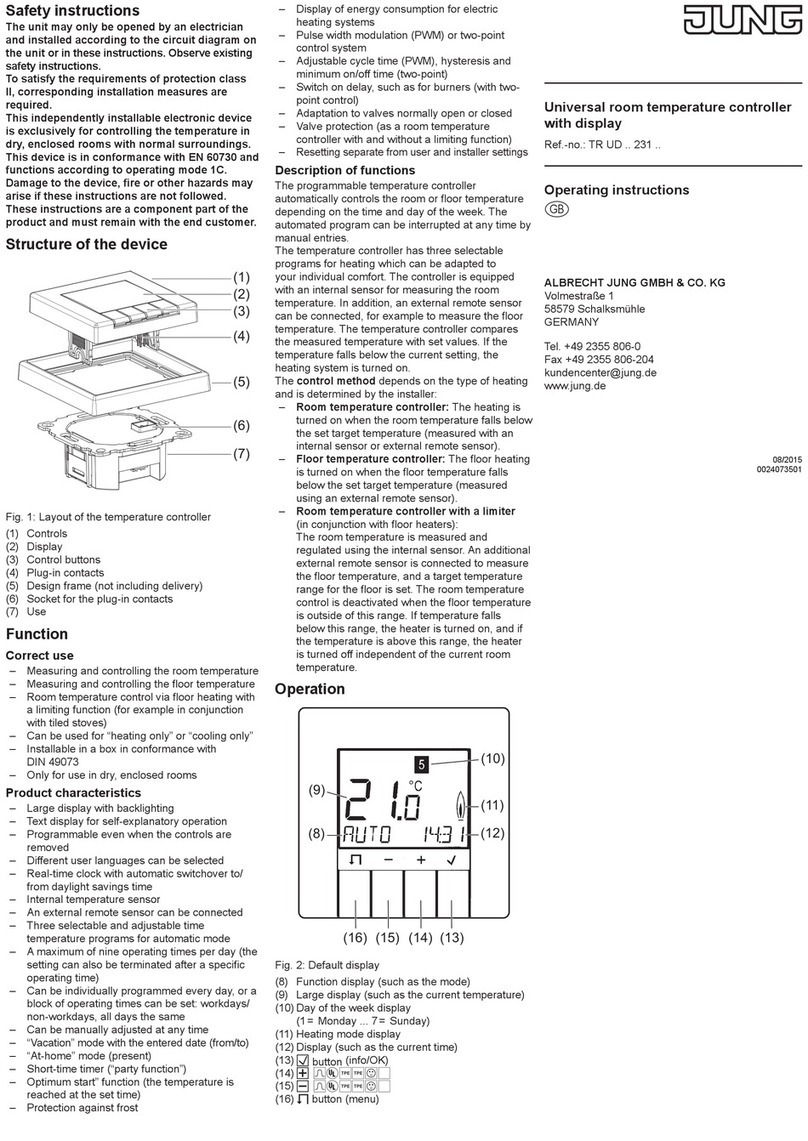

General key functions

2

1. General key functions

Prog

•Change selected submenus

•Change (parameter) setting

•Save value

+ (Plus) or - (Minus)

•Change parameter

•Change menu item

Esc

•Exit setting

•Keep old value

•Select next higher menu level

Esc-Long

•Return to basic display

2. Version display (when starting)

3. Basic display

c 100= Type designation

24.02= Version display (due to update, it can

differ from example shown)

80.5°C= Temperature heat supplier (e.g.

collector or solid fuel boiler)

44.0°C= Temperature heat storage tank

ΔT1= Display pump function

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 2 Dienstag, 25. August 2009 3:33 15

3

Menu level

4. Menu level

General menu structure Ceta series

Basic display

Prog

Esc

01

Menu 01

02

Menu 02

+-

27

Calibration

28

Relay test

02:01

Parameter 01

02:02

Parameter 02

02:nn

Last parameter

+-

+-

+

-

+

-

Prog

Select menu level

Select parameters

Esc

Value 1

Prog

Value 2

+-

Value n

+-

Set parameter value

Prog

Return

without

saving

Return

and save

Esc

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 3 Dienstag, 25. August 2009 3:33 15

Menu level

4

Overview of menu level

X1: Only displayed during active heat balancing

X2: Function only in bus connection

X3: Are hidden when activating code 03:09

Basic display

Prog

01

Info

03

System

+-

08

Delta T

27

Calibration

28

Relay test

03:01

Code entry

03:02

Auto set function

08:01

Heat capacity

08:02

Heat balance

08:03

03:03

Bus address

+-

+-

+-

+

-

08:01

Delta-T

Oper.mode

08:02

Switch-on differ.

08:03

Switch-off differ.

08:09

Burner block

heat generator

08:10

Inhibition

heat generator

08:11

Heat balance

On/Off

27:01

Calib.sensor

F1

27:02

Calib.sensor

F2

27:03

Calib.sensor

F3

+

-

28:01

Relay test

output R1

-

+

-

+

Prog

ESC

Prog

ESC

Prog

ESC

Prog

ESC

Prog

ESC

X1X1

ESC

X2X2X3

X3 X3

Pump

On/Off

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 4 Dienstag, 25. August 2009 3:33 15

5

Menu level

08:04

Temperature

heat supplier

08:05

Temp.heat

storage tank

08:06

Temp.return flow

08:07

Pump operating

hours

08:08

Pump starts

03:06

Automatic

exit time

08:04

Min.runtime

pump

08:05

Min.temp.

heat supplier

08:06

Max.temp.

heat supplier

08:07

Fin.switch-off

temp.heat supplier

08:08

Max.temp.

heat stor.tank

08:12

Volume flow

HT-medium

08:13

Density

HT-medium

08:14

Heat capacity

HT-medium

08:15

Reset counter

03:09

Code heating

specialist

03:10

Reset p arameter

03:07

X3 X3 X3

Anti-blocking

prot.pump

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 5 Dienstag, 25. August 2009 3:33 15

Parameter description

6

5. Parameter description

01 Information level

03 Parameter system

Display Designation Description

08:01 Heat capacity Current heat capacity in W X1

08:02 Heat balance Display of cumulative heat energy in kWh X1

08:03 Display pump

function

0: Pump is switched off

1: Pump is switched on

08:04 Temperature

Heat supplier

Sensor temperature of heat supplier (e.g. collector, solid fuel

boiler) at input F3

08:05 Te m p e r a t u re

Heat storage tank

Sensor temperature of heat storage tank at input F1

08:06 Return temperature Sensor temperature of return at input F2, if available.

08:07 Pump operating

hours

Number of pump operating hours

08:08 Pump starts Number of pump starts

Display Designation Description

03:01 Code entry Setting range: 0 … 999

Factory setting: 0

Function:

Show parameters marked with X3.

03:02 Automatic set

function

0=OFF, no automatic sensor detection X3

1=ON, automatic sensor detection

03:03 Bus address Setting range: 21…25 X3

Factory setting: 21

Function:

If more than one CETA 100 or 101 has to be connected via data

bus within a system, each unit must be set to a unique address.

03:06 Automatic exit time Setting range: 0.5 … 10 min X3

Factory value: 0.5 min

Function:

When unit is not operated during the set time, the display

returns to basic display.

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 6 Dienstag, 25. August 2009 3:33 15

7

Parameter description

08 Parameter Delta-T

03:07 Anti-blocking

protection

Setting range: 0 = OFF X3

1 = ON

Factory setting: OFF

Function:

Pump is switched on 20 s daily during extended shutdown

(> 24h) as protection against blocking when function is activated.

03:09 Code heating

specialist

Setting range: 0 … 999

Factory setting: 0

Function:

Hide parameters marked with X3.

03:10 To t a l r e s e t Reset to factory settings

Display Designation Description

08:01 Control mode Setting range: 0 = Delta T OFF

1 = Delta-T without return flow sensor

2 = Delta-T with return flow sensor

Factory setting: 1

Function:

The setting determines whether heat balancing is to be

performed by a return flow sensor (additional parameters)

08:02 Switch-on difference Setting range: (Switch-off differential + 3K) … 30K

Factory setting: 10K

Function:

If temperate difference between sensors of heat supplier F3 and

heat storage tank F1 is larger than set value, the pump

switches on.

08:03 Switch-off difference Setting range: 2K … (Switch-on differential - 3K)

Factory setting: 5K

Function:

If temperate difference between sensors of heat supplier F3 and

heat storage tank F1 is smaller than set value, the pump

switches off.

08:04 Minimum running

time of pump

Setting range: OFF (----)

0.5 … 60 min

Factory setting: 3 min

Function:

Minimum switch-on time of pump per start.

Display Designation Description

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 7 Dienstag, 25. August 2009 3:33 15

Parameter description

8

08:05 Minimum

temperature heat

supplier

Setting range: OFF (----)

5…80 °C

Factory setting: OFF

Function:

Irrespective of switching differentials, pump turns on only after

the sensor of heat supplier F3 has exceeded the set value.

08:06 Maximum

temperature heat

supplier

Setting range: OFF (----), 30 … 110 °C

Factory setting: 90 °C

Function:

Irrespective of switching differentials, the pump performs a

forced switch-on after the sensor of heat supplier F3 has

exceeded the set value.

08:07 Final switch-off

temperature heat

supplier

Setting range: OFF (----), 70 … 210 °C

Factory setting: OFF

Function:

Irrespective of switching differentials, the pump performs a

forced switch-off after the sensor of heat supplier F3 has

exceeded the set value.

08:08 Maximum

temperature heat

storage tank

Setting range: OFF (----), 50 … 110 °C

Factory setting: 75 °C

Function:

Irrespective of switching differentials, the pump performs a

forced switch-off after the sensor of heat storage tank F1 has

exceeded the set value. This switch-off takes priority over

functions 08:07 and 08:06.

08:09 Burner block

Heat generator

Setting range: 0 ... 2 X2

Factory setting: 1

Function: 0 = OFF

1 = Burner block when pump is active

2 = Burner block only for DHW when pump

is active

08:10 Inhibition heat

generator

Setting range: OFF (----) ... 24h X2

Factory setting: OFF

Function:

After burner block is active, the heat generator is also blocked for

the duration of the set time.

08:11 Activation of heat

balance

Setting range: OFF (----) X3

1 = Heat balancing via sensor on F2

Factory setting: OFF

Function:

The settings of parameters 08:12 to 08:14 are only active if the

heat balance function has been switched on via this parameter.

Display Designation Description

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 8 Dienstag, 25. August 2009 3:33 15

9

Parameter description

27 Sensor calibration

28 Relay test

08:12 Volume flow HT-

medium

Setting range: 0.0 … 30 l/min

Factory value: 0.0 l/min

Function:

Here the volume flow is set in litre/minute when calculating flow

rate, according to respective pump capacity.

08:13 Density HT-medium Setting range: 0.8 … 1.2 kg/l

Factory setting: 1.05 kg/l

Function:

Using this parameter, the density of the heat transfer medium is

entered in kilogramme per litre, according to manufacturer's data.

08:14 Heat capacity HT-

medium

Setting range: 2.0 … 5.0 kJ/kgK

Factory value: 3.6 kJ/kgK

Function:

This setting value is used to enter the specific heat capacity of

the heat transfer medium according to manufacturer's

information.

08:15 Reset counter Setting range: 0 = no reset, 1 = reset counter

Factory setting: 0

Function:

When value is changed to 1 and confirmed, all counters (heat

balance, operating hours and starts) are reset.

Display Designation Description

27:01 Calibration F1 Setting range: -5K … +5K

Factory value: 0K

Function: Correction of measured sensor value on

Input heat storage tank F1

27:02 Calibration F2 See 27:01 on input return F2

27:03 Calibration F3 See 27:01 on input heat supplier F3

Display Designation Description

28:01 Test pump output Setting range: -0 = OFF

1 = ON

Factory value: 0

Function:

By changing the value, the output switches on and off (test

function), independent of function.

Display Designation Description

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 9 Dienstag, 25. August 2009 3:33 15

Mounting

10

6. Mounting

Drilling pattern for wall fastening

Rail mount

Hazard!

Mounting must be performed by an authorised professional electrician!

Ensure that unit is de-energised before opening it!

1. Remove terminal area cover from

casing.

2. For mounting, first put a screw

into the wall.

3. Hang controller into the opening.

4. Use controller as template for the

other screw holes.

1. Insert mounting feet into rail

mount opening.

2. Lock hook in place by pushing

down.

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 10 Dienstag, 25. August 2009 3:33 15

11

Connection diagram

7. Connection diagram

8. Fault clearance

To allow an accurate diagnosis in case of malfunction, the unit is equipped with

a fault display system. The faults are shown on the basic display of the unit in

form of an error code:

Hazard!

Connection must be performed by an authorised professional

electrician! Ensure that unit is de-energised before opening it!

0---°C = Sensor heat supplier (e.g. collector or

solid fuel boiler) has interruption

1---°C = Sensor heat storage tank has short

circuit

230V connections Low voltage connections

L=Phase 230V mains

1=L1 (230V) pump connection

Connections without function

Connections without function

N=Neutral 230V mains, pump

Connections without function

=Earthing

Bus connections for networking

(see parameter 03:03)

Connections without function

Connections without function

F1=Sensor heat storage tank Delta-T (KVT20)

F2=Sensor return flow Delta-T (KVT20), (option)

F3=Sensor heat supplier Delta-T (PT1000)

Connections without function

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 11 Dienstag, 25. August 2009 3:33 15

Sensor resistance values

12

Fault overview:

9. Sensor resistance values

Depending on temperature:

PT1000 KVT 20

Fault code Cause Repair

0--- Tank sensor interruption Check cable and plug connection;

repair if necessary

1--- Short circuit on tank sensor Replace tank sensor

Fault Cause Repair

Display text not visible No power, defective fuse in unit Check cable and plug connection;

repair if necessary; replace fuse

T (°C) R (kOhm) T (°C) R (kOhm)

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

1.155

1.194

1.232

1.271

1.309

1.347

1.385

1.423

1.461

1.498

1.536

1.573

1.611

1.648

1.685

1.722

1.758

1.795

1.832

1.868

1.905

1.941

10

12

14

16

18

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

1.783

1.812

1.840

1.869

1.898

1.928

2.002

2.078

2.155

2.234

2.314

2.395

2.478

2.563

2.648

2.735

2.824

2.914

3.005

3.098

3.192

3.287

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 12 Dienstag, 25. August 2009 3:33 15

13

Declaration of conformity

10. Declaration of conformity

Elektronikbau- und Vertriebs- GmbH

Heisternerweg 8-12, 57299 Burbach

EC Declaration of Conformity

Product identification: Heating controller

Type designation: CETA 100

Manufacturer:

EbV Elektronikbau- und Vertriebs-GmbH

Heisternerweg 8-12

57299 Burbach

The product described is in full compliance with the following European directives:

89/336/EEC

„Council directive on the approximation of the laws of the member states

relating to Electromagnetic Compatibility“

73/23/EEC

„Council directive on the approximation of the laws of the member states

relating to electrical equipment designed for use within certain voltage

limits" (low voltage directive)

Compliance of the designated product with the rules of the directive is proven by complete

adherence to the following standards:

EMV: Requirements for household appliances, electric tools and similar devices

DIN EN 55014-1:2003 Part1: Transient emission

DIN EN 55014-2:2002 Part 2: Immunity

EMV: Limit values

DIN EN 61000-3-2:2002 Part 3-2: Limit values for harmonic current emissions

DIN EN 61000-3-3:2002 Part 3-3: Limitation of voltage fluctuations and flicker

Automatic electrical controls for household use and similar applications

DIN EN 60730-1:2002 Part 1: General requirements

DIN EN 60730-2-9:2004 Part 2: Particular requirements for temperature sensing controls

We declare that the described product - as independent device - is in conformity with the standards,

directives and/or technical specifications listed above.

EbV Elektronikbau- und

Vertriebs-GmbH

Burbach, 20.02.2009 _________________________________

Wolfgang Höse

Managing Director

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 13 Dienstag, 25. August 2009 3:33 15

Technical Data

14

11. Technical Data

12. Liability

Our general terms and conditions of business are generally applicable. Any liability

claims based on failure to observe operating manual as well as safety instructions

contained therein, are excluded. Subject to technical modifications.

13. Disposal

Dispose of all replaced parts, and eventually the controller itself, in an

environmentally sound manner in compliance with applicable statutory

regulations of the corresponding country.

Mains voltage: 230V +6%/ -10%

Rated frequency: 50...60Hz

Power input: max. 2.1VA

Fuse: 6.3A

Output relay contact load: 2 (2) A

Ambient temperature: -10...+50 °C

Storage temperature: -25...+80 °C

Degree of protection: IP 30

Protection class according to EN 60730: II

CE compliance: 89/336/EEC

Casing dimensions: 145.5 x 161 x 48 mm (W x H x D)

Casing material: ABS V0

Weight: 420g

Mains connection technology: Screw terminals 1.5 mm2

Sensor connection technology: Screw terminals 1.0 mm2

Company stamp:

BA_CETA100_EbV_EN_0450021000_0931-10.book Seite 14 Dienstag, 25. August 2009 3:33 15

Table of contents

Other Elektronikbau- und Vertriebs Temperature Controllers manuals