ELEPHANT LIFTING PRODUCTS Grippa User manual

PUSH & GEARED TROLLEY MANUAL

Elephant Lifting Products Trolley Manual

1 | Page

Contents

1 Personnel Competence .................................................. 2

2 Preface ............................................................................ 2

3 Safety Information .......................................................... 3

3.1 Danger, Warning, Caution and Notice ................... 4

3.2 Safety Summary ..................................................... 4

4 Identification .................................................................. 5

5 Main Components .......................................................... 5

6 Intended Use .................................................................. 5

7 Safe Operating Instructions ............................................ 6

8 Installation ...................................................................... 6

9 Clearances ...................................................................... 7

10 Operating Conditions ..................................................... 7

10.1 Initial Operating Checks ......................................... 7

11 Lubrication ...................................................................... 7

11.1 Geared Trolley Wheels .......................................... 7

12 Safe Transportation ........................................................ 7

13 Storage ........................................................................... 8

14 Inspection ....................................................................... 8

14.1 Frequent Inspection ............................................... 8

14.2 Periodic Inspection ................................................ 8

14.3 Records and Reports .............................................. 9

15 Troubleshooting ............................................................. 9

16 Maintenance .................................................................. 9

16.1 Cleaning and Care ................................................ 10

16.2 Spare Parts ........................................................... 10

17 Hand Chain Adjustment or Replacement ..................... 10

17.1 To Replace Hand Chain ........................................ 10

17.2 To Adjust Chain Length ........................................ 10

18 Technical Data .............................................................. 11

This operation manual edition 05/2017 covers

Elephant

Lifting Products Geared and Push Trolleys:

It must be read carefully and in its entirety before

operating any trolley.

Serial No.

Please enter the Serial No. of your Elephant Lifting

Products trolley here.

2

2 | Page

This operation manual covers the following Elephant

Lifting Products Trolleys:

Manual trolleys

Geared trolleys

THIS MANUAL MUST BE READ CAREFULLY

BEFORE OPERATING OR REPAIRING THESE

PRODUCTS.

This manual contains important safety, operation,

installation, inspection, maintenance and repair

information of Elephant Lifting Products trolleys for

proper and efficient operation. Make this manual

available to all persons responsible for the

operation, installation, inspection, maintenance and

repair of these products. Even if you feel you are

familiar with this or similar equipment, you should

read this manual before operating the product.

•Do not use these trolleys for lifting, supporting, or

transporting people and lifting or supporting loads

over people.

Always operate, install, inspect, maintain, repair and use

these trolleys in accordance with South African Bureau of

Standards Specification number SANS1824:2003 for a

geared or manually driven trolley.

Testing of trolleys must only be carried out by the

competent personnel contemplated in SANS1824:2003

and American Society of Mechanical Engineers (ASME)

standard B30.17-2015.

For Trolleys used outside of South Africa:

It is the responsibility of the owner/user to construct,

operate, install, inspect, test, maintain, repair and use the

trolleys in accordance with ASME B30.17-2015, “Safety

Standard for Cranes and Monorails (with Underhung

Trolleys)” and as well as with Occupational Safety and

Health Administration (OSHA) Regulations.

If the trolley is installed as part of a total lifting system,

such as an overhead crane or monorail, it is also the

responsibility of the owner/user to comply with the

applicable ASME B30 Volume that addresses that type of

equipment.

It is the responsibility of the owner/user to have all

personnel that will construct, operate, install, inspect, test,

maintain, repair and use the trolleys to read the contents

of this manual and applicable portions of ASME B30.17-

2015, “Safety Standard for Cranes and Monorails (with

underhung Trolleys)” and as well as being familiar with

OSHA Regulations.

If the trolley owner/user requires additional information,

or if any information in this manual is not clear, contact

Elephant Lifting Products or the distributor of the

trolley(s). Do not construct, operate, install, inspect, test,

maintain and repair these trolleys unless this information

is fully understood.

A regular schedule of inspection of the trolley(s) in

accordance with the requirements of ASME B30.17-2015,

should be established and records maintained.

The ASME B30 Standard is intended to:

(a) Prevent or minimize injury to workers and

protects property by prescribing safety

requirements.

(b) Guide governments and other regulatory bodies

in the development, promulgation and

enforcement of appropriate safety directives.

1 Personnel Competence

According to ASME B30 Standard, persons performing

construction, operation, installation, inspection, testing,

maintenance, repairing and using Elephant Lifting Products

trolleys shall through education, training, experience,

skills and physical fitness, as necessary, be capable of

performing the functions as determined by the

employer or employer’s representative.

2 Preface

Elephant Lifting Products warrants to the user its trolleys,

and other products to be free from defects in material

and workmanship for a period of one year from the date

of purchase.

Elephant Lifting Products will at its discretion repair

without cost (including parts and labour charges) to the

user for any product found to be defective. Elephant Lifting

Products will replace such product(s) and refund the

purchase price less a reasonable allowance for

handling in exchange for the defective product(s). All

repaired and replaced product(s) are warranted for the

remainder of the original warranty period.

If any product proves defective within its original one year

warranty period, it must be returned to Elephant Lifting

Products with proof of purchase and the original

test certificate. This warranty does not apply to products

which Elephant Lifting Products has determined to have

been misused, abused and improperly maintained by the

user or where the malfunction or defect was attributed

by the use of non-genuine Elephant Lifting Products parts.

Elephant Lifting Products makes no other warranty and

its maximum liability is limited to the purchase price of the

product and in no event, will Elephant Lifting Products be

liable for any consequential, indirect, incidental or special

damages of any nature arising from the use of the product

whether based on contract or otherwise.

It is Elephant Lifting Products policy to promote safety of

all persons and equipment in the workplace. All equipment

manufactured is thoroughly checked, packed and

inspected before dispatch. Any loss or damage which

3

3 | Page

occurs during shipment while en-route must be reported to

Elephant Lifting Products immediately. Should any item be

delivered to you in apparent good condition, but upon

opening the container, loss or damage has taken place

while in transit; notify Elephant Lifting Products immediately.

Should any items be delivered back to Elephant Lifting

Products all transport costs will be on the account of the

user.

These instructions were prepared by Elephant Lifting

Products to provide agents, fitters, and company

personnel with information required for the purpose of

construction, operation, installation, inspection,

maintenance, repair and the use of its trolleys.

No responsibility for failure of equipment due to

manufacturing procedure will be assumed if these

instructions are not carried out. Only original Elephant

Lifting Products supplied spares are to be used in all repairs.

3 Safety Information

This manual will refer to existing legal requirements and

engineering practices as known when this document was

written. Should any such legislation or practices change or

be “enlarged” upon then due consideration must be

taken. Various standards have been used to assist in

compiling this document and will be listed where

applicable.

According to ASME B30 Standard the use of trolleys is

subject to hazards that cannot be overcome by

mechanical means but only by the exercise of

intelligence, care and common sense.

It is therefore essential that personnel involved in the

construction, operation, installation, inspection, testing,

maintenance, repairing and using Elephant Lifting Products

trolleys must be careful, competent, trained, physically

and mentally qualified in the safe operation of this

equipment and handling of loads.

Serious hazards include but not limited to, overloading,

improper or inadequate maintenance, dropping or

slipping of the load caused by improper hitching or

slinging, obstructing the free passage of the load and

using equipment for a purpose for which it was not

intended or designed.

The above can lead to fatal consequences. Operators of

Elephant Lifting Products trolleys are also under obligation to

ensure safe and hazard-free operation. This can be

achieved through the following measures:

Keep the operation manuals available at the trolley

operating site,

Performing regular training,

Performing regular inspections (at least once

annually),

Implement an inspection log and make regular

entries,

And regularly check personnel for safety and hazard

awareness during work.

Elephant Lifting Products fully realizes the importance

of proper design factors, minimum and maximum sizes

and other limiting dimensions of the trolley and its

fastenings, chains, sprockets and similar parts all of

which are designed with safety in mind.

The various conditions of the equipment or material can

vary depending on the environment they are used in

which may cause corrosion or wear and any other

variables that may arise in each individual application. It

is in the light of this that the trolley(s) must be maintained

and repaired under the supervision of a competent

person:

(a) Who is qualified by virtue of his knowledge, training,

skills and experience to organize the work and its

performance;

(b) Who is familiar with the legal requirements which

apply to the work to be performed;

(c) Who has been trained to recognize any potential or

actual danger to health and safety in the performance

of the work.

The instructions given in this manual must be interpreted

accordingly and sound judgment used in determining their

application. It is intended to help the operator to become

familiar with Elephant Lifting Products trolleys and

how to use them properly. Observance of the

manual helps to avoid hazardous situations, to

reduce repair costs and downtimes and to ensure

the specified service life of the Elephant Lifting Products

trolleys.

•Always keep this manual readily available at the

location where the Elephant Lifting Products trolley(s)

is or are being used.

•All persons charged with constructing, testing,

operating, installing, inspecting, maintaining,

repairing and using Elephant Lifting Products trolleys

must read and follow all the instructions in this

manual.

4

3.1 Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures

which, if not followed, may result in an injury. The

following signal words are used to identify the level of

potential hazard.

Danger is used to indicate the presence of hazard which

will cause severe injury, death or substantial property

damage if the warning is ignored.

Warning is used to indicate the presence of a hazard

which can cause severe injury, death, or substantial

property damage if the warning is ignored.

Caution is used to indicate the presence of a hazard

which will or can cause minor injury or property damage

if the warning is ignored.

Notice is used to notify people performing operation,

installation, inspection and maintenance information

which are important but not hazard-related.

3.2 Safety Summary

1 Do not use these trolleys or any equipment attached

to it for lifting, supporting or transporting people and

lifting or supporting loads over people.

•Elephant Lifting Products trolleys are designed

to provide a MINIMUM of 5 to 1 safety factor. It is

the responsibility of the customer to ensure that the

structure to which a trolley is attached and any load

attaching device(s) used in conjunction with a

trolley(s) can handle the static and dynamic load(s)

when the trolley is lifting

and lowering the rated load. If in doubt, consult a

registered professional structural engineer.

•If a hoist is to be used in conjunction with the

trolley, ensure that a hoist having a rated

capacity equal to or less than the capacity of the

trolley is specified.

2 Lifting equipment is subject to different regulations in

each country. These regulations may not be

specified in this manual. Whenever a conflict arises

between the contents of this manual and any other

applicable legislation, standard or procedure, the

more stringent of the two must be applied.

The Occupational Health and Safety Act and Mine Health

and Safety Act and other recognized safety sources make

a common point: Employees who work near cranes or

assist in hooking on and arranging a load(s) should be

instructed to keep out from under the load.

From a safety standpoint, one factor is paramount,

conduct all lifting operations in such a manner that if there

were an equipment failure, no personnel would be injured.

This means keep out from under a raised load and keep

out of the intended path of any load.

Elephant Lifting Products Trolleys are manufactured in

accordance with the latest ISO9001 standards. The

Occupational Safety and Health Act of 1993, section 10

states:

1. Any person who designs, manufactures, imports,

sells or supplies any article for use at work shall

ensure, as far as is reasonably practicable, that the

article is safe and without risks to health when

properly used. It must comply with all prescribed

requirements.

2. Any person who erects or installs any article for use

at work on or in any premises shall ensure, as far as

is reasonably practicable, that nothing about the way

it is erected or installed makes it unsafe or creates a

risk to health when properly used.

3. Any person who manufactures, imports, sells or

supplies any substance for use at work shall:

(a) Ensure, as far as is reasonably practicable, that

the substance is safe and without risks to health

when properly used; and

(b) Take necessary steps to ensure that information

is available about the use of the substance, the

associated risks to health and safety and the

procedures to be followed in the case of an

accident involving such substance.

4. Where a person designs, manufactures, imports,

sells, or supplies an article or substance for or to

another person, and that other person, and that other

person undertakes in writing to take specified steps

WARNING

NOTICE

CAUTION

WARNING

NOTICE

DANGER

5

5 | Page

sufficient to ensure, as far as is reasonable

practicable, that the article or substance will comply

with all prescribed requirements and will be safe and

without risks to health when properly used. The

undertaking shall have the effect of relieving the first

mentioned person from the duty imposed upon him

by this section to such an extent as may be

reasonable having regard to the terms of the

undertaking.

It is the owner’s and user’s responsibility to determine the

suitability of a product for any particular use. It is

recommended that all applicable industry, trade

association and legislation are checked. Read all

operation instructions and warnings before operation.

It is extremely important that fitters and operators are

familiar with the servicing procedures of these products,

or similar products and are physically capable of

conducting the procedures. These personnel shall have a

general working knowledge that includes:

(a) Safe use and application of fitter’s common hand

tools as well as special or recommended tools.

(b) Safety procedures, precautions and work habits

established by accepted industry standards.

Elephant Lifting Products cannot know of, nor provide

all the procedures by which product operations or repairs

may be conducted and the hazards and/or results of

each method. If operation or maintenance

procedures not specifically recommended by the

manufacturer are conducted, it must be ensured that

product safety is not endangered by the actions

taken. If unsure of an operation or maintenance

procedure, personnel should place the product in a

safe condition and contact supervisors and/or the factory

for technical assistance.

4 Identification

The nameplate mounted on the side plate identifies the

type of Elephant Lifting Products trolley, rated load,

manufacturer’s name (Elephant Lifting Products) and the

model or serial number.

If you have any questions concerning the operation of

Elephant Lifting Products trolleys which are not

addressed in this operation manual, please contact

us at the following address:

Elephant Lifting Products

38381 N Robert Wilson Rd

Gonzales, Louisiana, 70737

Phone (888) 844-6113

Fax (225) 644-6695

e-mail: [email protected]

5 Main Components

Elephant Lifting Products trolleys consist of the

following main components:

1 Side plates

2 Rolling wheels

3 Distance spacers

4 Crosshead

5 Reel chain drive (for running geared wheels)

Exception: no drive with push trolleys.

6 Intended Use

Elephant Lifting Products trolleys are intended to be

used exclusively for lifting, lowering loads and for their

horizontal movement of the load above floor.

Elephant Lifting Products air hoists can be suspended

or built into trolleys.

Any other use outside these stipulations is deemed to be

impermissible. For applications requiring this type of use

please consider the Elephant Lifting Products range of

winches and the Elephant Lifting Products range of

hoists. Elephant Lifting Products cannot be held liable

for any damage resulting from incorrect usage. The

entire risk is borne by the operator.

The following situations, among others, are regarded as

improper use:

•Exceeding the permitted load-carrying capacity

•Oblique pulling of loads

•Sliding loading

•Dropping a trolley

•Detaching, dragging or pulling of loads

•Catching of falling loads

•Carrying people

•Switching to the opposite direction with load in motion

•Operation reaching of the end stop

Intended use also includes observance of the operation

manual and compliance with the inspection and

maintenance conditions according to ASME B30

Standards.

6

6 | Page

7 Safe Operating Instructions

1. Before each use or shift, the operator should inspect

the trolley for distortion, wear and damage.

2. If inspection indicates that a trolley is damaged, it

should never be used. Replace any item indicating

damage, distortion and/or excessive wear.

3. To avoid an unbalanced load which may damage the

trolley, operate the trolley when the load or hoist (if a

hoist is used in conjunction with the trolley) is

centered under the trolley. Position the hanger shaft

at the centerline of the trolley and beam using

properly installed spacer washers. Do not “side pull”.

4. If a hoist is to be used in conjunction with the trolley,

ensure that a hoist having a rated capacity equal or

less than the capacity of the trolley is specified.

5. Do not use these trolleys for lifting, transporting

people or supporting loads over people. Make sure

people or any obstruction are clear of the load path

before traversing the load and trolley.

6. If multiple trolleys are used together at the same time,

avoid collision or bumping of trolleys and do not ram

trolleys into the end stops. Improper and careless

operation can result in a hazardous condition for

operator and load.

7. Ensure stops are securely installed at both ends of

the beam prior to using trolley.

8. Ensure that stops are installed to prevent the trolley

from running off either of the open ends of the beam

track when the trolley is being installed over the open

end of the beam.

9. On a hand-operated trolley, the stops should engage

parts of the trolley other than a wheel. If a stop

engages the tread of the wheel, its height shall be no

less than the radius of the wheel.

10. Do not join a hand chain by inserting a bolt between

links as this may cause jamming of a hand chain with

the hand wheel sprocket.

11. Do not swing a suspended load.

12. Ensure that trolley wheels’ ride on the top surface of

the lower flange of the beam.

13. Install manual chain hoists so that hoist hand chain is

on opposite side of trolley hand chain.

14. When operating the trolley, keep the load as close to

the floor as practical to make people aware and keep

clear of any load the trolley is supporting.

8 Installation

The installation of the Elephant Lifting Products

trolleys shall be in accordance with the qualified

persons recommendations described above “Personnel

Competence” on page 2.

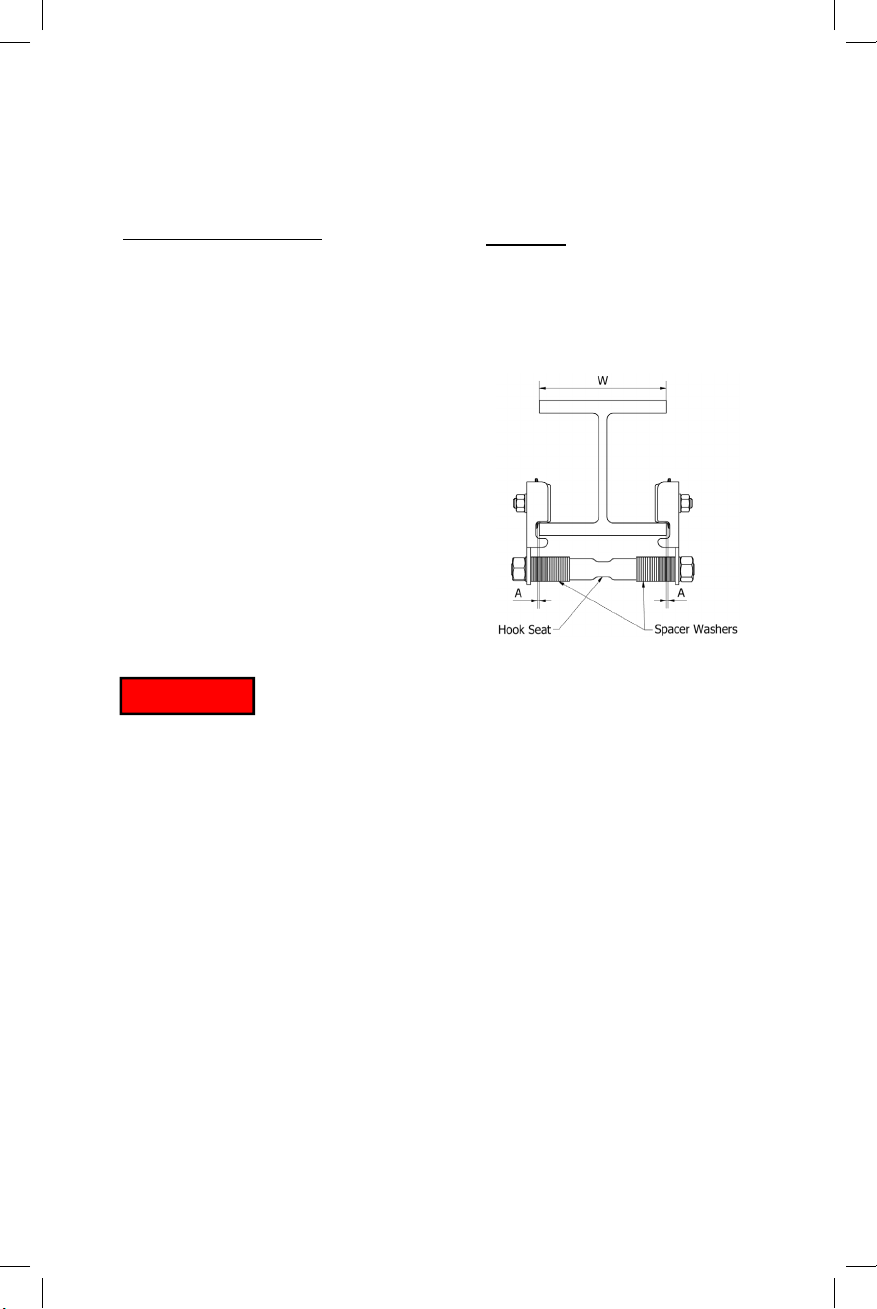

Adjust trolley width before installation. Refer to Figure 1

below along with instructions to position spacer washers

for measured beam flange width (W).

Figure 1: Push Trolley

Instructions:

1. Measure the beam width (W) and add 2-4mm to this

amount for clearance between the wheel flanges to

allow 1 to 2 mm of clearance per side (“A” in the

figure);

2. Remove the locknuts from the crosshead and adjust

the width of the trolley by shifting the spacers

accordingly. There are two different thicknesses of

spacers that allow for adjustment in 1mm increments.

Ensure that the amount of spacers on either side of

the crosshead are the same. Spacers not used

between the side plates should be fitted to the shaft

between the side plate and the lock nut. Ensure that

the suspension plate (if fitted) or the groove in the

crosshead is central to the side plates;

3. Fully tighten the locknuts and re-check the clearance

between the wheel flange and the beam.

Upon completion of installation, perform initial operating

checks, Section 10.1 and ensure familiarity with “Safe

Operating Instructions”, Section 7.

NOTE: Rounded wheel tread is suitable for taper and

parallel flanged beams.

DANGER

7

7 | Page

9 Clearances

Under all operating conditions, clearances between

beams, trolleys operating at various levels and potential

obstructions, shall be maintained.

Where passageways or walkaways are provided on

the structure supporting the trolleys, obstructions

shall not be placed so that personnel will be

jeopardized by movements of the trolleys.

Clearances shall be provided at the curves of the beam

to allow for the swing of the load when the trolley is

negotiating the curve. The amount of clearance shall be

determined by considering the size, weight and speed of

the trolley and track curve radius.

10 Operating Conditions

The four most important aspects of trolley operation

are:

1. Follow all safety instructions when operating the

trolley.

2. Ensure that only people instructed in safety and

operation of these products operate the trolley.

3. Inspect each trolley on a regular basis and scheduled

a maintenance program.

4. Always ensure that the weight of the load and rated

capacity of a hoist (if it is to be used in conjunction

with the trolley) are equal or less than the capacity of

the trolley assembly. Do not overload.

10.1 Initial Operating Checks

1. Upon completion of trolley installation, ensure the

side plates are parallel to the beam.

2. If a hoist is used in conjunction with the trolley ensure

that the hoist and load are centered below the trolley

and beam.

3. Lift a load equal to or less than the rated capacities of

either the trolley or hoist a few centimeters or inches

off the floor. This is to ensure that all parts of the

trolley are in working order. If parts of the trolley are

dropped, they can cause severe injury or damage.

4. Ensure that the rail stops are securely installed.

5. Operate the trolley along the entire length of the

beam.

6. Inspect trolley performance when raising, moving and

lowering test load(s). Trolley must operate smoothly

prior to being placed in service.

11 Lubrication

Trolley wheels are equipped with sealed bearing which

require no lubrication.

11.1 Geared Trolley Wheels

Trolleys shall be stationary while lubricants are being

applied. Lubricate exposed trolley drive pinion and wheels

teeth with grease as often as necessary to keep the teeth

liberally covered.

If the grease becomes contaminated with dirt or other

abrasive material, clean off old grease and apply new

grease. For temperature -29o to 10o C (-20o to 50o F) use

M2 EP 1 grease or equivalent grease. For temperature -

1o to 49

o C (-30o to 120o F) use M2 EP 2 grease or

equivalent grease.

•When greasing pinion and geared wheels make

sure excess grease is removed from trolley

wheels riding surface and track of the beam.

•Failure to keep beam track and wheel contact

surface clean affect the safe operation of the

trolley.

12 Safe Transportation

If you wish to transport your Elephant Lifting Products

trolleys to another site or for inspection, please observe

the following points:

1. Dismounting:

a) Make sure there is no load attached to the

trolley;

b) Attach the trolley load hook or suspension

plate to the chain hoist or other means of

lifting;

c) Remove beam or rail stops and slide the

trolley over the edge of the beam;

d) Set the entire trolley down carefully, do not

allow it to drop.

2. Disassembly:

a) Remove the crosshead from the side plates;

Note: Only necessary for geared trolleys.

b) Remove the chain from the hand wheel;

c) Remove the hand wheel assembly from the

geared side plate assembly.

CAUTION

WARNING

DANGER

8

8 | Page

Disassembling a trolley from the beam by separating the

slide plate is extremely dangerous and this operation

should be carried out by the trained or competent

personnel contemplated in SANS1824:2003 and

American Society of Mechanical Engineers (ASME)

standard B30.17-2015.

13 Storage

Store the trolley in a clean, dry place indoors. If lengthy

storage is required, lubricate wheels and place entire

unit in a suitable storage container. Store the product

away from heat and steam. Never allow it to rest for

lengthy periods of time on concrete or ash floors as the

lime sulfur and ash can cause corrosion.

14 Inspection

All inspections shall be performed by designated

personnel in accordance with the Elephant

Lifting Products recommendations and with the

requirements of ASME B30 Volume.

Any deficiency revealed through inspection must be

reported to an appointed or qualified person. A

determination must be made as to whether a more

detailed inspection is required or a deficiency constitutes

a safety hazard to continued operation. Such deficiency

shall be corrected before resuming operation of the

trolley. The results of the inspection must be recorded in

the inspection log.

Careful inspection on a regular basis will reveal potentially

dangerous conditions or evidence of malfunction while

still in the preliminary stages, allowing corrective actions

to be taken before the condition becomes dangerous.

Elephant Lifting Products recommends two types of

inspection:

a) The frequent inspection performed by the operator as

pre-work inspection.

b) The periodic inspections performed by personnel

trained in the operation and repair of these trolleys.

14.1 Frequent Inspection

Trolleys that are in continuous service, inspection should

be made at the beginning of each shift or before the trolley

is first used during each shift.

Elephant Lifting Products trolleys shall be

inspected at intervals depending on severity of

usage, as follows:

NORMAL HEAVY SERVERE

Monthly Weakly to Monthly Daily to Weekly

The following items shall be inspected:

1. Operating mechanisms of the trolley and hand chain

drive wheel for proper operation and adjustment.

Operate the trolley so that it travels 1 metre (3 feet)

along the beam. Inspect for visual signs or abnormal

noises such as but not limited to, squeaking, grinding

and grating which could indicate a problem. Do not

operate the trolley until all problems have been fixed.

2. Inspect trolley load hooks if used in accordance with

ASME B30.10 - 2015 Standard.

Trolleys that have been idle for a period of 1 month or

more but less than 1 year shall be inspected in

accordance with frequent inspection before being placed

into service.

14.2 Periodic Inspection

Frequency of periodic inspection depends on the severity

of trolley usage, as follows:

NORMAL HEAVY SERVERE

Yearly Biannually Quarterly

•Please note the requirements of the Occupational

Health and Safety Act of South Africa (Act 85 of

1993), Driven Machinery (Regulation 18), Lifting

Machines and Lifting Tackle regarding the

examination and testing of lifting machines and lifting

tackle.

Disassembly may be required for HEAVY or SEVERE

usage. Keep accumulative written test records of dated

and signed periodic inspections to provide a basis for

continuing evaluation. Records should be kept available.

Inspection of all the items in “Frequent Inspection” must

be conducted and also the following items shall be

inspected:

1. Fasteners

Check cap screws, retainer rings, pins and nuts. Replace

if missing or damaged and tighten if loose.

2. All Components

Inspect for wear, damage, distortion, deformation and

cleanliness.

If external evidence indicates the need, disassemble.

Check gears, shafts, bearings, wheels, load sheaves and

side plates. Replace worn or damaged parts. Clean,

lubricate and reassemble.

3. Drive Chain Hand Wheel

Check for damage or excessive wear of chain drive

sprockets and excessive chain stretch or distortion.

Replace if necessary. Observe the action of the hand

chain feeding through the hand chain drive.

Do not operate a trolley unless the hand chain feeds

through the hand chain drive smoothly and without

NOTICE

9

9 | Page

irregular sounds or other evidence of jamming, wedging

or malfunctioning.

4. Supporting Structure.

Check the supporting structure for distortion, excessive

wear and continued ability to support the load.

5. Trolley

Check that the trolley wheels run and track the beam

properly and that the clearance between the beam and

trolley wheel flanges is 1 to 2 mm maximum per side.

Check that wheels, bearings shafts, gears or rollers are

not excessively worn, cracked or distorted and inspect the

side plates for opening due to bending. Do not operate

the trolley until any problems have been identified and

fixed.

6. Nameplate.

Check for presence and legibility. Replace if necessary.

Trolleys that has been idle for a period of 1 year or more

shall be inspected in accordance with periodic inspection

before being placed into service.

14.3 Records and Reports

An inspection record should be maintained for each

trolley, listing all points requiring periodic inspection. A

written report should be made monthly on the condition of

the critical parts (e.g. wheels, bearings, side plates and

hanger shaft) of each trolley. These reports should be

dated, signed by each person who performed the

inspection, and kept on file where they are readily

available to the authorized personnel.

15 Troubleshooting

This section provides the information necessary for

troubleshooting the Elephant Lifting Products

Trolleys. The troubleshooting guide provides a

general outline of problems which could be

experienced with normal use of the trolley. Table 1 lists

the symptom, the possible cause, and the possible

remedy for the trouble being experienced.

Table 1: Troubleshooting

16 Maintenance

General maintenance should be performed in accordance

with the requirements of ASME B30 Volume and the

conditions and practices of a particular workplace.

Elephant Lifting Products trolleys are extremely robust

and require little maintenance. They are suitable for

use in explosion-hazardous areas as well as in

areas with increased concentrations of soot and dust,

high humidity and at ambient temperatures of – 20° C

up to approx. + 70° C if they are not heated above

this level due to external influences. The thermal

endurance of chains and hooks is up to + 150° C.

In order for the trolleys to operate safely and reliably over

a period of many years, compliance with maintenance

and inspection intervals is of immense importance. If the

trolley is being operated in a harsh environment that leads

to accelerated wear, then the maintenance intervals

should be reduced.

•Never perform maintenance on the trolley while it is

supporting a load.

•After performing any maintenance on the trolley, test

trolley as described in the “Safe Operating

Instructions”, Section 7, before returning trolley to

service.

SYMPTOM CAUSE REMEDY

Geared

Trolley

cannot be

moved

Hand chain

drive is

stuck or

pinion is

stuck

Repair the chain drive

or renew grease

lubrication

Trolley can

only be

moved slowly

or not at all

Track of

trolley too

narrow

Adjust the clearance

between the wheel

flange and the outside

edge of the bottom

flange of the trolley

beam

Trolley is

repeatedly

blocked at

the same

place

Tracks are

uneven or

rail joint

displaced

Rectify track faults

WARNING

10

10 | Page

•Maintenance work on Elephant Lifting Products

trolleys must only be performed by trained and

qualified personnel.

•In the case of maintenance work exceeding normal

service and maintenance, please contact Elephant

Lifting Products.

•For stationary outdoor operation, trolleys must be

protected against weathering and the maintenance

intervals must be shortened.

16.1 Cleaning and Care

If your Elephant Lifting Products trolley has to work in

dirty surroundings, remove coarse dirt from the trolley.

Trolley wheel bearings are sealed and require no

lubrication. If trolley wheel rotation is rough or noisy,

replace trolley wheel bearing.

Threaded components of Elephant Lifting Products

Trolleys are metric. Verify and match thread sizes

before assembly.

16.2 Spare Parts

If during repair work, the replacement of components is

necessary, only original Elephant Lifting Products

spare parts may be installed.

17 Hand Chain Adjustment or Replacement

•When cutting the weld side of a hand chain link,

do not cut or nick the opposite side. A damaged

link must be replaced to prevent premature

failure. A falling hand chain can injure personnel.

•Proper use, inspections and maintenance will

increase the life and usefulness of your Elephant

Lifting Products equipment. During assembly

lubricate gears, threaded areas of nuts, bolts,

caps crew and all machined threads with applicable

thread lubricants or antiseize compound to prevent

corrosion and allows for ease of disassembly of

components.

17.1 To Replace Hand Chain

1. Cut a length of chain twice the required hand chain

drop plus 30 cm (1 foot)

2. Run the new hand chain around the hand wheel,

making sure that it is seated correctly in the hand

wheel sprockets.

3. To create a “C” link, cut the welded side of the chain

link and bend it open to grip the exposed part of the

link.

4. Connect the hand chain ends with the “C” link(s),

make the total number of links even and bend the “C”

link(s) shut.

5. If replacing the hand chain, disconnect it at the “C”

link and carefully remove the hand chain.

6. Make sure the hand chain is not twisted. To untwist a

hand chain, open a “C” link and remove one chain

link.

17.2 To Adjust Chain Length

Add or remove a length of chain twice the desired

amount of chain adjustment.

CAUTION

CAUTION

11

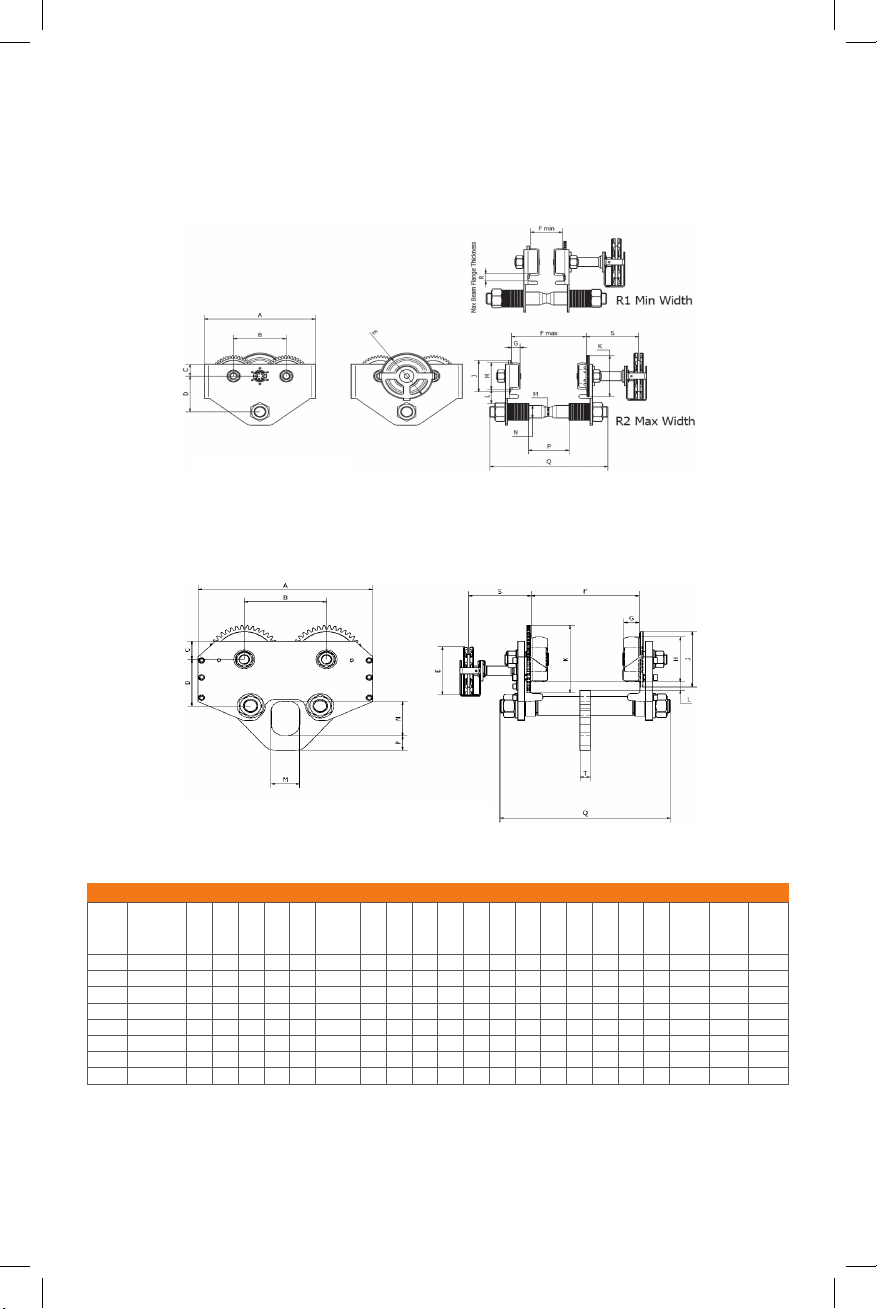

SPECIFICATIONS & DIMENSIONS - GRIPPA BEAM CRAWLS

Model Headroom

(in) A B C D E

Beam

Width

Range

(F)

G H J K L M N P Q R S T

Min

Beam

Radius

(in)

Unit

Weight,

P u s h

(lbs)

Unit

Weight,

G e a r e d

(lbs)

0.5t 1.73 7.4 3.7 1.1 3.3 N /A 1.9 - 5.6 0.6 2.2 3.0 NA 1.6 1.0 1.2 2.9 9.1 0.8 N /A N /A 29.5 12.1 N /A

1t 2.5 9.6 4.5 1.4 4.3 6.1 2.9 - 8.3 0.7 2.6 3.3 3.8 2.2 1.0 1.4 4.3 11.8 1.0 6.2 N /A 35.4 22.25 30

2t 1.8 13.0 6.2 1.6 4.7 6.1 3.5 - 8.6 1.0 3.5 4.2 5.4 1.9 1.2 1.6 4.7 13.8 1.0 6.2 N /A 43.3 42 50

3t 2.1 13.0 6.2 1.6 5.3 6.1 3.9 - 8.2 1.0 3.5 4.2 5.4 2.4 1.4 1.9 4.9 12.8 1.1 6.2 N /A 43.3 53 62

5t 3 14.4 6.9 1.6 6.5 6.1 4.4 - 8.3 1.4 4.3 5.5 5.9 2.9 1.6 2.4 5.9 14.6 1.4 6.6 N /A 59 92 101

10t 6.85 19.8 9.3 2.3 5.9 6.1 6.8 - 12.0 1.7 5.7 7.0 8.5 1.1 3.2 4.3 1.8 19.3 1.1 7.1 1.2 82.6 232 250

20t 10.25 24.0 11.4 4.7 10.4 8.1 6.8 - 12.0 2.6 7. 9 9.6 10.8 3.3 4.3 5.9 2.8 21.7 1.6 8.6 1.6 137 618 630

40t 11.61 52.0 * 5.3 9.3 7. 9 6.8 - 12.0 2.5 7.9 9.6 10.8 3.3 4.9 5.9 3.3 23.6 2.0 8.2 2.4 NA 1510 1542

0.5-5t Trolleys

10-40t Trolleys

Note: 40t trolley is a tandem design,

request drawing from factory

12

Due to continued innovation and improvement of our products, specications and dimensions

are subject to change without notice. Please consult Elephant Lifting with any questions.

NOTES

Elephant Lifting Products, LLC

38381 N. Robert Wilson Rd. | Gonzales, Louisiana 70737 • USA

Toll Free: 1.888.844.6113 • Phone: 1.225.644.6113 • Fax: 1.225.644.6695

www.elephantlifting.com • sales@elephantlifting.com

Table of contents

Popular Lifting System manuals by other brands

TECNA

TECNA 9300NY instruction manual

Nussbaum

Nussbaum TSK 8000 Operating manual, Inspection book

Ranger

Ranger RML-1500XL Installation and operation manual

AUSLIFT

AUSLIFT DHE-LG800 instruction manual

TRIUMPH BOARD

TRIUMPH BOARD LiftBox 650 installation manual

Sicor

Sicor MR14 Operation and maintenance manual

GÜDE

GÜDE GWK 1000 Translation of original operating instructions

Proactive

Proactive Protekt Take-A-Long 33400P owner's manual

Powerlift Dumbwaiters Corporation

Powerlift Dumbwaiters Corporation P-100 owner's manual

HESHBON

HESHBON HL-26K Installation, operation and maintenance manual

AMGO

AMGO SPL-6 Installation and service manual

Celexon

Celexon PL300 installation manual