Eleshop ELE-T12A User manual

ELE-T12A OLED DIGITAL SOLDERING STATION

www.eleshop.eu

Conventional safety

Please use only the power adapter that is dedicated to the product and

is certified by the country / area.

Do not operate in a wet environment.

Do not operate in a flammable and explosive environment.

Please keep the surface of the product clean and dry.

To protect your family and friends for the safety, please

power off after use or leave, beware of fire.

The tip will become very hot, beware of scalds.

℃Do not soak in water and don't touch with wet hands.

.

Operating environment

Operating

environment

Requirements

temperature

Working condition:+0 to +50℃ ℃

Off working state:-20 to +60℃ ℃

humidness

Working condition:high temperature 40 -60 ,

0%-60%RH℃ ℃

Working condition:low temperature 0 -40 ,

10%-90%RH℃ ℃

Off working state:high temperature 40 -60 ,

5%-60%RH℃ ℃

Off working state:low temperature 0 -40 ,

5%-90%RH℃ ℃

Important

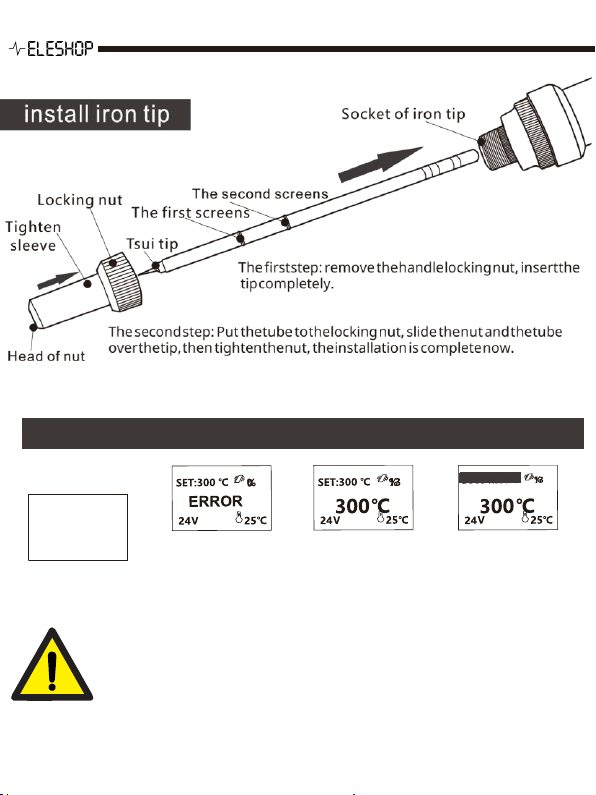

When using the T12 iron tip please tighten the nut to

avoid damage to the tip.

The temperature will reach above 350 of the soldering tip if

station is used for 40 minutes, and the temperature on the end

of the handle will reach 50-60 degrees. When the new T12

soldering iron tip is usedfor the first time, the temperature may

be instable and display ERROR. This is anormal phenomenon

due to the heating of the inner galvanic couple part of the iron

tip. After being used several times, the temperature will

become stable.

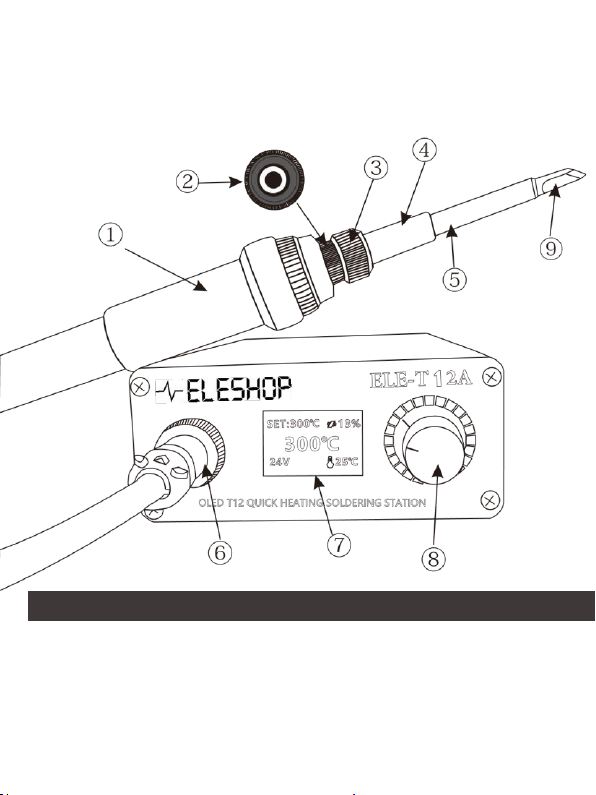

Parts list

1、T12-907 Handle

2、Socket of iron tip

3、Locking nut for iron tip

4、Lock tube for iron tip

5、Head of iron tip

6、Aviation Plug of handle

7、OLED temperature display

8、Encoder

9、Nozzle tip

SET:300

℃

13

%

2

5

℃

2

4

V

300

℃

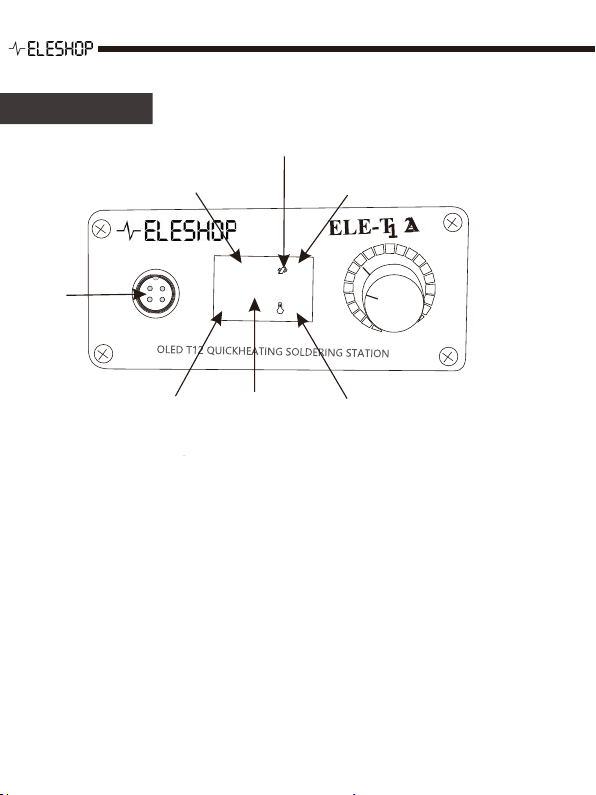

Front

Back

The current set temperature

nside temperature of

the machine

Current working

temperature

Current voltage

Handle

interface

Switch

Power cord connector

Fuse

Power

usage

Vibration

sensor

Overview

Product parameter

Display

OLED

Handle interface

GX12-4pins

Product weight

Dimension of host

Wire length of handle

Model number

ELE-T12A

Standard 510g

88x41x38

mm

1.1

m

Application iron tip

T12 series

Working parameter

Time of melt tin

Max power

Range temperature

Voltage of power

Input voltage

<8

S

W

72

200-480

24

V

24

V

DC

If the display screen shows ERROR, this could indicate tip may not be well installed, please

try to install the iron tip again and press it in completely.

Description for display

T12 SOLDERING

IRON STATION

Initial state of Non plugged Normal One press power off iron tip

working state strong temperature

Note: after confirming the installation of the components is

right, the new iron tip is inserted into the handle and the display

screen will be a flash or ERROR, and the host buzz is wrong. It’s

normal. After heating 5-20 minutes, it will return to normal

gradually. Temperature

control range of the station: 200-480.The common working temperature is 300℃

℃-380 . In order to protect the working life of

the soldering iron tip, it is recommended that the temperature is not

set higher than 380 degrees.

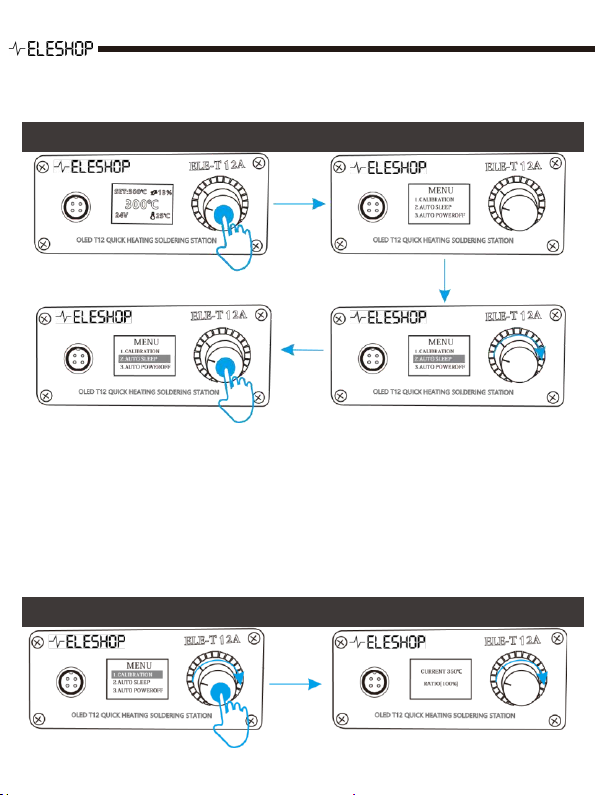

Menu use

Enter the menu setting interface: under the normal working temperature interface, long

press the encoder button (about 3s). Enter the host setup mode! Exit menu settings

interface: at the menu setting interface, long press the encoder button (about 3s), exit the

host setup mode!

Setting menu:

Enter the function item: rotate the encoder to the corresponding function, and short

press the button to enter the function item.

Exit setting function item: after setting the corresponding parameters with the encoder

rotary knob, short press the button to confirm exit the function item.

Temperature calibration

After selecting the temperature calibration function, short press the encoder to enter the

temperature calibration setting, the adjustable temperature ratio: 70%-130%, if there is no

professional measurement instrument, please set the ratio value to 100%.

Choosing sleeping time feature, short press encoder, into the sleeping time setting, the

time setting range: 0-99 minutes, if you don't need the sleeping time function, the dormancy

feature can be set to OFF.

Default sleeping time for 1 minute, means after 1 minute the host and handle is stand

still, the soldering station will entry to dormant state, the temperature of soldering iron tip will

drop to 150℃, at this time when move handle or rotary encoder, the soldering station will

rapidly heat up the working temperature before Sleeping.

You can set the sleeping time according as the usage scenario and working habit, it can

be extended the working life of the iron tip and protect your family and friends safe!

Power off time

Choosing power off time feature, short press encoder, into the power off time setting, the

time setting range: 0-99 minutes, if you don't need the power off time function, the power

off function can be set to OFF.

Default power off time for 1 minute, means after 1 minute the host and handle is stand

still, the soldering station will entry to power off time state, the temperature of soldering

iron tip will drop to indoor temperature (note: The temperature control range of the host is

200480℃, it will appear larger deviation when the temperature less than 100℃. Please

ignore it.). At this time when move handle or rotary encoder, the soldering station will

rapidly heat up the working temperature before power off.

You can set the power off time according as the

usage scenario and working habit, it can be extended the working life of the soldering iron

tip!

Boost duration

boost duration. The time setting range: 0-99 minutes.

The default time is 30 seconds, it can be set according as the actual needs, after setting,

short press the encoder to confirm and exit. When working normally, it takes a short time

to increase temperature welding the larger welding spot, it can be heated to the set

temperature rapidly after pressing

the encoder. After 30 seconds, the

host will automatically return to

original temperature. This can avoid soldering iron tip oxidation when with high

temperature to use! Boost degree

To control the boost temperature increase, short press the encoder, enter boost

degree, the temperature setting range: 10-80 degrees.

The default strengthen temperature is 30 ℃, it can be set according as actual needs, after

setting, short press the encoder to confirm and exit. When working normally, it takes a short

time to increase temperature welding the larger soldering spot, it can be heated to the set

temperature rapidly after pressing the encoder. After 30 seconds, the host will automatically

return to original temperature. This can avoid soldering iron tip oxidation when with high

temperature to use!

After selecting the wake-up function, short press the encoder, enter setting of wake-up

type, the system provides two kinds of wake-up type: encoder together with handle or just

encoder. When choosing encoder + handle, the soldering station is automatic power off,

shaking handle or short press or rotary encoder, all can wake-up the host!

When choosing the encoder, the automatic shutdown state, short press or rotary encoder

can wake-up the host, but shaking handle cannot wake-up the host!

The default setting is: encoder + handle, which can be set according to actual needs.

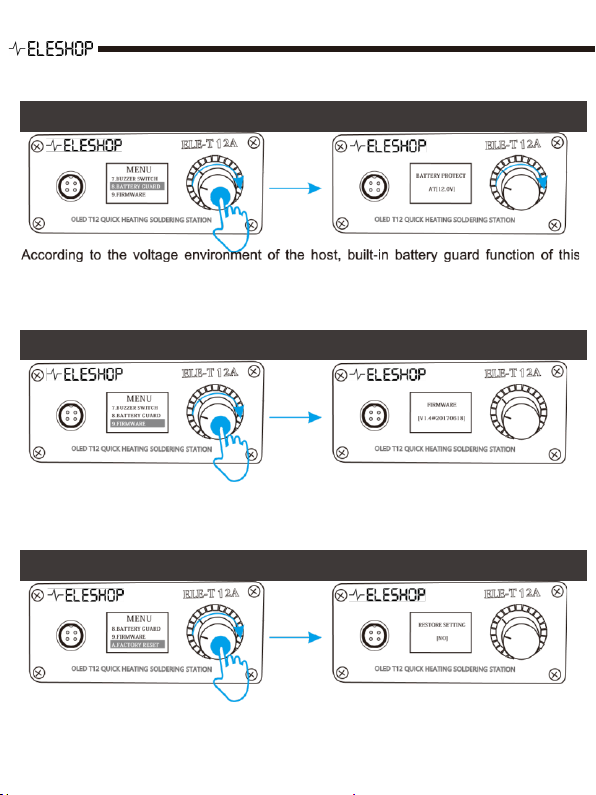

Buzzer switch

This version OLED controller integrates with a buzzer, and the sound prompts the host

state. The buzzer will beep when the host encounters an error or sets the appropriate

function.

Battery guard

soldering station, and the default voltage is 12V. When the voltage is not stable, the power

supply will be supercharged according to the setting. Usually don't need to set it. The setting

range is 12V-24V.

Version information

It shows the information of this version controller.

Restore default

Restore the parameters of the soldering station to the factory default. Note: please back-up

your usual important parameters before you restore factory Settings to prevent data loss.

For example: temperature calibration value, strengthening time and temperature, etc.

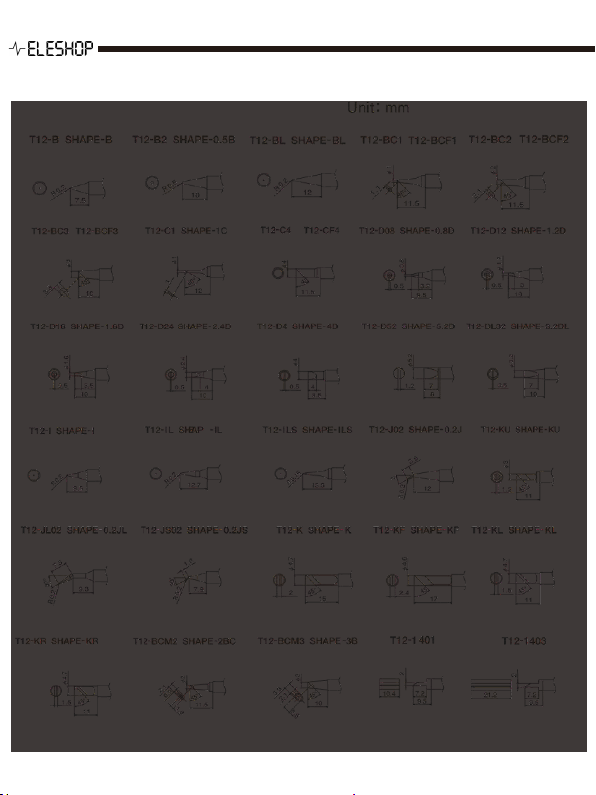

How to choose the iron tip

Note: Choosing the right iron tip can make the work more efficient.

Iron tips maintenance

1.Please put appropriate tin on the adhering head of iron tip before powering off ,and please

clean it before soldering.

2.Do not allow the iron tip to stay at high temperature for a long time to avoid dry burning.

3.In welding, do not rub the soldering tip with too much pressure to friction the solder,

which will damage the iron head.

54.Never clean iron head with a rough material or file..If the surface is oxided and does not

absorb tin, you can use fine sanding paper (600-800).

Sand it carefully and use isopropyl alcohol or equivalent solution to clean, heat to

200℃immediately adhering tin to prevent sticking tin and then oxidation.

6.Do not use chlorine or high acid soldering flux. Only use of synthetic resin or activated

resin flux.

7.The working temperature of the soldering iron tip is about 300℃ ℃ to 380 , and the

working temperature should not exceed 450℃in a short time. Otherwise it will affect the

working life of the soldering iron tip!

8.Different welding scenes should be selected with different soldering iron tip. Large

welding spot or aluminum base plates will need to be touched to large soldering iron tip

(such as C4). Small welding spot can be usedC1, JL02, ILS, etc.

9.The new soldering tip is used for the first time, the heat up may be slightly slower, and

it can melt tin 7 seconds after the normal use of 1-3 hours.

After-sales service 保修服务

This station comes with one year of warranty. Soldering tips are not covered by warranty

because these are subjective to wear. Proper care will significantly extend the lifetime of

the soldering tips.

About Discarding

Do not discard in family garbage!

Handling and recycling: you have to deal with the iron correctly

according to local laws and regulations.

FAQ

FAQ:

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high

temperature, so the first time to use will be a bit of temperature, generally without special

treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to

immediately effective, the general proposal to adjust the temperature to 380℃ ℃ -400

, side of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown,

until the solder tip of the cooling and then re-boot! ( if 1 times no effect, then can be

repeated 2-3 times). T12 is pulsating temperature warming, even if the display temperature

is flashing, the tip of the real temperature is completely stable.

T12 jump temperature also are connected with the temperature control board

of procedures, power of electrostatic and if it connect the ground. 2. What the

problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it

must be tinput immediately to the solder tip, for protection, due to heating up fast, just

need 6-10 seconds, no have more time to you for preparetion. so the important is

prepare the items which will be welded, and finally boot power, and each welding gap or

the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the

new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL

/ T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature

control, the general recommended working temperature control between 300℃ ℃ ~ 380

, higher than 380℃damage the coating of solder tip and cut down the PTC

life!

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of

tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the

tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the

hard objects, but can not be used to hot plastic and other materials, specifically reminded

that friends like tin should avoid the iron and other hard metal knock tin, the heating core of

T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as

possible! When scaling powder help make beautiful and reliable welding at the same time,

but also greatly speed up the consumption the coating of the solder tip, T12 heating core

high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in

the fear of threat to T12 head pressing parts.

4.How to do when T12 tip does not absorb tin?

T12 iron head does not absorb tin, generally there are two reasons:

A. The head of solder tip is severe oxidation can not absorb tin.

B.Temperature can not rise up then can not tin.

C.The head is oxidized and can not the tin, you can use the soldering iron to clean the ball

gently, then use the wet sponge rub and then heat the tin.

Your feedback will make us better!

Made in China

Other manuals for ELE-T12A

1

Table of contents

Other Eleshop Soldering Gun manuals