elho 10.2 Series User manual

1

Series 10.2-10.4

ELHO

Rake

V-Twin 750

941013

ENGLISH

OY

ELHO

AB

68910 BENNÄS

Finland

www.elho.fi

Email: [email protected]

VTwin - 750

2

EC Declaration of Conformity

Oy ELHO AB

Industrivägen 6

68910 Bennäs

FINLAND

We, the manufacturer of:

ELHO V-TWIN 750 Rakes

Serial number 10.2-10.4

Declare, that these machines fulfill the essential part of the following directives:

2006/42/EC

In the design of the machines the following standards and regulations have been followed for

applicable parts:

EN 292-1

EN 292-2

EN 294

EN 349

EN 811

EN 1152

ISO 5781

ISO 3767/91

Bennäs

2009-04-03

Dan Johan Löfvik

VTwin - 750

3

1

. LIMITED WARRANTY

The agricultural machines produced by Oy El-Ho Ab (hereafter called ELHO) have a limited

warranty for one year or one season, whichever occurs first, from the day of delivery to the

original purchaser-user. The warranty covers defects in materials and workmanship. The

warranty is not valid for spare parts.

Parts not of ELHO's manufacture, i.e. hydraulic or electrical components, universally jointed

shafts, gear boxes, tyres etc. are not subject to this limited ELHO warranty. Such components

rely on the original manufacturers guarantee and conditions.

ELHO´s obligation under this warranty is limited to repairing or replacing free of charge to the

purchaser-user, at a location designated by ELHO, any defect part that in ELHO´s judgment

shows evidence of defect or improper workmanship. Defective parts must be returned through the

selling dealer or distributor, transportation charges prepaid, if requested by ELHO.

The limited warranty does not cover labour or travel costs.

The limited warranty is valid only if the fault is reported to us or our importer within 14 days of

occurrence.

According to normal practice we do not accept any responsibility for damage which, in the

opinion of ELHO, occurs as a result of one or more of the following circumstances:

- Unauthorised modification.

- Non-original parts are fitted.

- The machine is not maintained correctly.

- The machine is operated incorrectly, or overloaded.

- The machine is used for purposes other than for which it has been designed.

This limited warranty and ELHO´s obligation there under is in lieu of all warranties, express or

implied, and all other representations to the original purchaser-user and all other obligations or

liabilities, including liability for loss of crops, losses caused by harvest delays or any expense of

loss of labour, supplies, rental equipment and all incidental or consequential damages.

This limited warranty does not cover damages to the machine or its components caused,

according the judgement of ELHO, by unsuitable hydraulics or electrical connections.

As the use of ELHO products is outside of our control, we can only guarantee quality and do not

accept liability in respect of performance.

No person is authorized to give any other warranties or to assume any other liabilities on ELHO´s

behalf.

This warranty must be registered with ELHO within ten (10) days from the date of original

purchase.

ELHO reserves the right to improve or change the construction to the machine, without liability

in respect of machines previously supplied. ELHO also reserves the right to change or withdraw

this program without notice.

VTwin - 750

4

Identification of machine

The identification of the machine is found from the

plate on the machine frame. This identification

data have to be given by ordering of spare parts, by

warranty claims etc. Write the numbers from your

machine in the field below. This will make spare

part orders more easy for you in the future.

Type

Series

No

Paint

To ensure a long lifetime of the ELHO machines also the paint and painting process used at the

manufacturing fulfil most strict international painting standards.

However also a god paint surface might be damaged or scratched during transport and use.

Paint in correct colour is normally most easily accessible at your local paint shop, As post and

parcel transport of paint is restricted by very strict safety rules.

If you notice the following international colour numbers used for the original painting of the

ELHO machines it will help you to get the right shade. The original paint is a polyurethane based

industrial truck paint but an alkyd based paint of god quality is also suitable for paint repair.

Green RAL 6025

Yellow RAL 1007

VTwin - 750

5

Tractor and machine noise

EC Directive 86-1888-EEC and UK Noise at Work Regulations 1989 place responsibilities on

employers and employees to assess and control noise at the workplace.

Bystander noise level of the ELHO V-TWIN 750 can exceed 87 dB (A) particularly if operated at

full speed in an enclosed space.

We recommend that the machine should not be run at full speed in an enclosed space and that if it

is necessary to approach the machine, that hearing protection is worn.

Noise level during normal field operation will vary depending on the noise of the tractor and how

the tractor is operated. In some instances the tractor, whilst operating under load and normal

engine speed will produce the highest noise level.

The approximate noise at the driving position generated by the ELHO V-TWIN 750 with tractor

cab windows open is in range 80-96 dB (A) and occurs with the machine out of work and raised.

The noise level from the Rake is normally reduced in work.

We recommend that the tractor is operated with the cab windows closed.

Radios are also a source of noise.

The comments on noise level are given for guidance only and each combination of tractor and

machine should be assessed.

Manual handling- Components

EC directives 89/391/EEC and 90/269/EEC and UK Manual Handling Operations Regulations

1992, place responsibilities on employers and employees to operate safe working practices when

manually handling heavy weights.

When assembling or when carrying out repairs the machine all heavy parts must be handled with

a mechanical lifting device.

Depending on working conditions some components may require 2 persons to handle them.

VTwin - 750

6

E L H O V-Twin 750

1. Technical information

2. Safety instructions

3. Starting up of a new machine

4. Mounting instructions

5. Connection to the tractor

6. Adjustments

7. Use of machine

8. Maintenance

9. Optional equipment

10. Useful hints

11. Storage

Spare parts

This sign is used throughout the manual in cases which particular importance for

• Personal safety

• Particular important advice for use of the machine

1. TECHNICAL INFORMATION

1.1 Intended use

The ELHO V-Twin 750 Rake is designed solely for use in raking agricultural hay or grass or

straw crop into a windrow. The use for other purpose is strongly forbidden.

1. 2 Technical specification

V-TWIN 750

(Main dimensions, see dimensional drawing)

Working width 4,5 -8,0 m

Width of swath 1,2 – 1,7 m

Transport width 2,6 m

Transport height 1,8 m

Length 6,9 m

Number of rake tines 322 pcs

Oil requirement min. 25 l/min

Tyres 11.5/80-15.3

Air pressure in tyres 3 bar

Hydraulic connections 1 double acting, 2 single acting + one free return,

-alternative 2 double acting + one free return

Hydraulic requirement 25 litre/min, pressure min .175bar, max. 210 bar

max. oilflow 50 litre/min

Connection to the tractor 3-P linkage Kat II

Weight approx. 2170 kg

Optional equipment

VT 750 S-kit 114122

Optional wheel sitze 380/55-17 115280

Optional fingers 114129

Hydraulic pump unit for rotor drive 114150

Rake basket holding valve kit 114125

We reserve the right to alter specification details, dimensions, etc., without notice or liability. All data stated above is approximate.

As ELHO rakes are supplied to many countries the detail specification may vary refer to local price list for specification offered and

optional extras.

VTwin - 750

7

Dimensions of V-Twin 750

Lifting of the machine

The lifting points are marked with labels on the machine.

VTwin - 750

8

2.

Safety instructions

Reed carefully the information in the manual and on the machine, before you operate or assemble

the machine

.

In addition to the safety instructions in this list, take care of all general safety rules for machinery

work.

The use of this machine is allowed only for a person familiar with the functions of the

machine and with the manual. The operator must also be mentally and physically capable of

operating the machine safely.

The user shall wear suitable close fitting clothing and avoid wearing other items that could

increase the risk of get stuck in the machine.

The ELHO V-Twin is hydraulic driven. Take therefore particular care before any

work on the machine as there might be full power also behind stopped or blocked

rotors!!!

Before you leave the tractor cab the tractor engine has to be fully stopped and the

parking brake engaged. This to ensure no hydraulic power is applied to the rotor

drive.

Before the baskets are started, make sure that no loose parts or tools are beneath or on the

machine. Keep bystanders, particularly children away.

All maintenance and adjustments is to be carried out with the tractor engine stopped.

Do not work under the machine if it is supported only by the tractor hydraulic controls.

You must not allow people to stand near the machine when it is being used. Danger from

particles thrown by the machine's tines.

Check daily that the joints and arms of the wheel linkage are undamaged and secured, wheel

nuts are tight. If a wheel is lost during transport a serious accident may occur.

Great care must be taken during transport on public roads. Ensure that the mechanical locks

for the basket are closed bout sides. Reduce speed when turning and driving on uneven ground.

Use only original ELHO spare parts. The machine's construction must not be changed and the

machine must only be used for mowing and swath laying grass crops.

VTwin - 750

9

2.1

Tractor and machine noise

EC Directive 86-1888-EEC and UK Noise at Work Regulations 1989 place responsibilities on

employers and employees to assess and control noise at the workplace.

Bystander noise level of the ELHO V-TWIN 750 can exceed 87 dB (A) particularly if operated at

full speed in an enclosed space.

We recommend that the machine should not be run at full speed in an enclosed space and that if it

is necessary to approach the machine, that hearing protection is worn.

Noise level during normal field operation will vary depending on the noise of the tractor and how

the tractor is operated. In some instances the tractor, whilst operating under load and normal

speed will produce the highest noise level.

The approximate noise at the driving position generated by the ELHO V-Twin 750 with tractor

cab windows open is in range 80-96 dB (A) and occurs with the machine out of work and raised.

The noise level from the Rake is normally reduced in work.

Radios are also a source of noise.

The comments on noise level are given for guidance only and each combination of tractor and

machine should be assessed.

Manual handling- Components

EC directives 89/391/EEC and 90/269/EEC and UK Manual Handling Operations Regulations

1992 place responsibilities on employers and employees to operate safe working practices when

manually handling heavy weights.

When assembling the machine heavy components must be handled with a mechanical lifting

device. Some parts might need two persons for the assembly.

When carrying out repairs to the machine the following parts should be lifted with mechanical

equipment; drawbar; main frame; baskets and basket rotor units.

Depending on working conditions other components may require 2 persons to handle them.

VTwin - 750

10

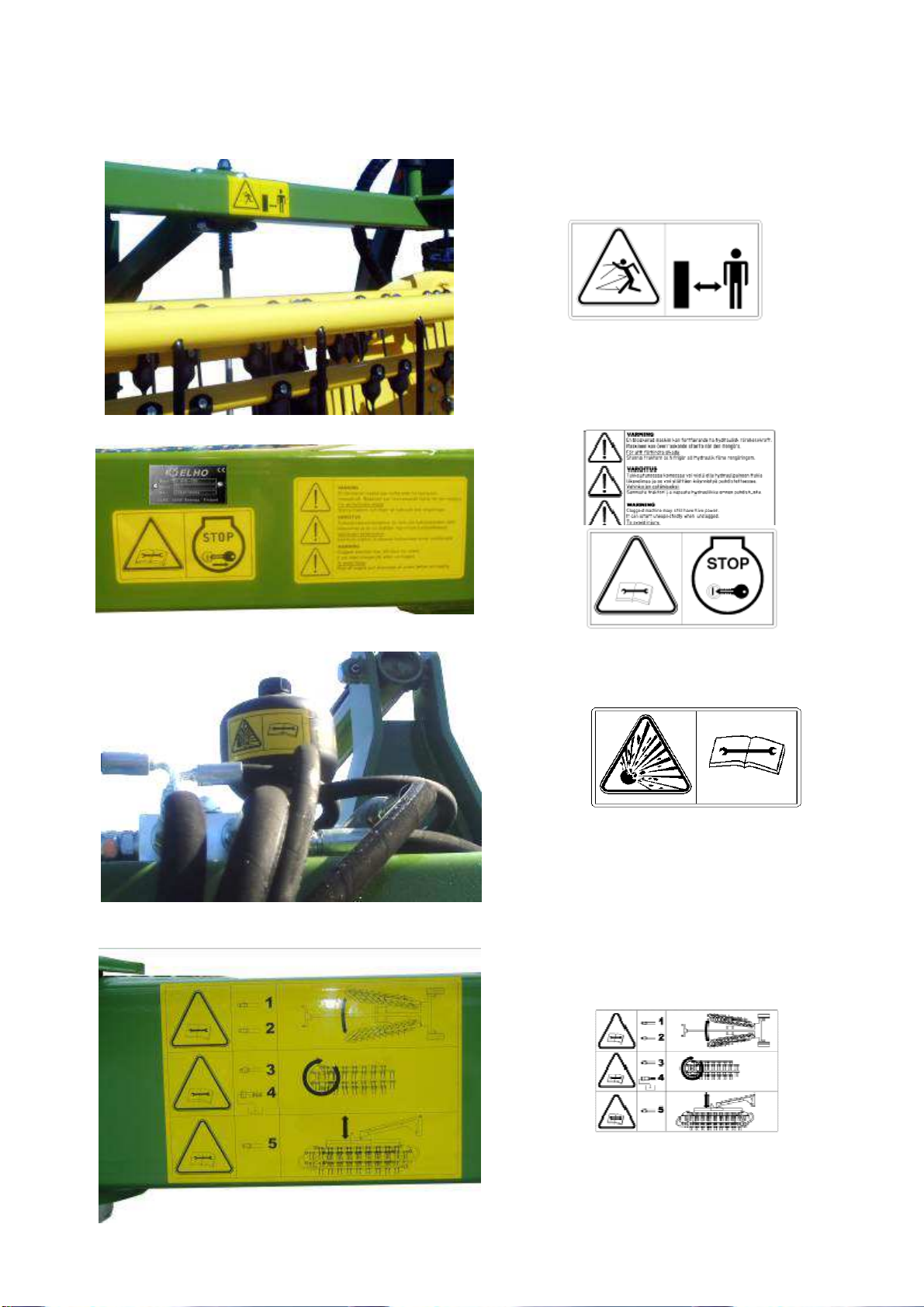

2.2 Safety signs on the machine

On the machine there are some safety signs to make you aware of certain hazards, which have not

been possible to remove by design or by guarding.

1. This sign ask you to stop the engine, switch off the power,

remove the start key and read the instructions before service or

maintenance on the machine.

2. This sign ask remain you t

he ELHO V-Twin are hydraulic driven.

Take therefore particular care before any work on the machine as

there might be full power also behind stopped or blocked rotors

.

3. This sign ask you to stay clear of the danger zone.

4. This sign ask you to stay clear of the danger zone. Risk for

throwing of objects like stones.

5. This sign warn you from thatching driven elements when the

tractor engine is running.

6. This sign warn you from dismantling any part of the hydraulic

unloading system and the nitrogen accumulator circuit before you

have carefully read the instructions.

7. This sign inform you about the correct connection of the

hydraulic hoses.

VTwin - 750

11

2.2.1 Safety sign positions on the machine

VTwin - 750

12

VTwin - 750

13

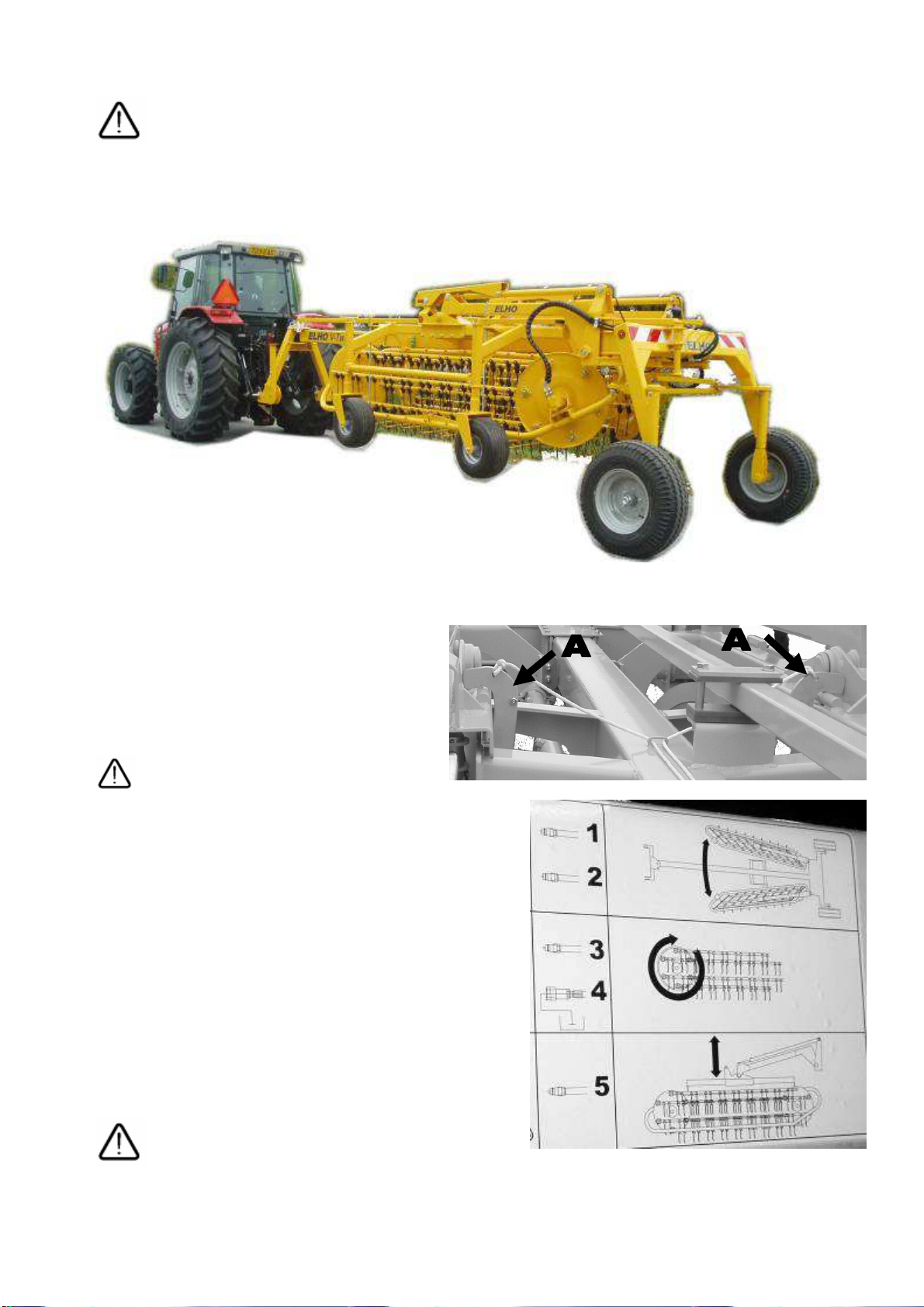

3. Starting up a new machine

It is important that the greatest care is taken when starting up a new machine. Incorrect assembly,

wrong operation etc. may cause damage, which is not covered by the ELHO warranty.

The ELHO V-Twin 750 is connected to the 3-P linkage of the tractor (Kat II ).

See § 5 Connecting to the tractor.

Ensure that the machine is correct assembled

and not damaged.

Check that all greasing points are well

lubricated.

Note particularly that the hydraulic

hoses are correctly connected to the tractor,

in particular the free return. Otherwise

there is a risk of damages to the seals of the

hydraulic motors.

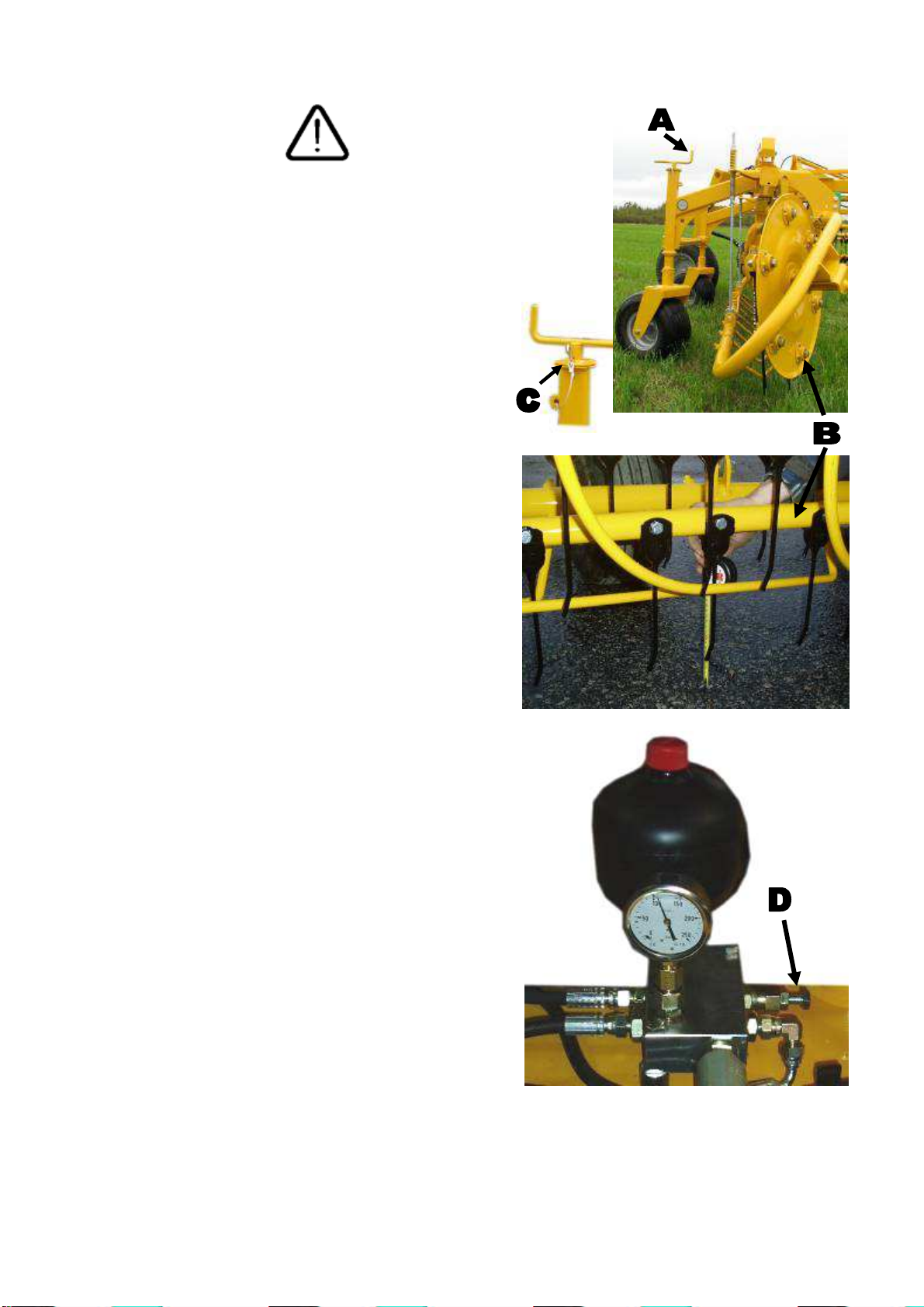

Release the transport hooks A of the baskets

and lift the baskets slowly up (activate

section for hose nr. 5).

Take care nobody is in the danger zone and

swing the baskets out (activate double acting

section for hoses nr. 1 &2) .

Let the baskets down to the ground.

Stop the tractor!

VTwin - 750

14

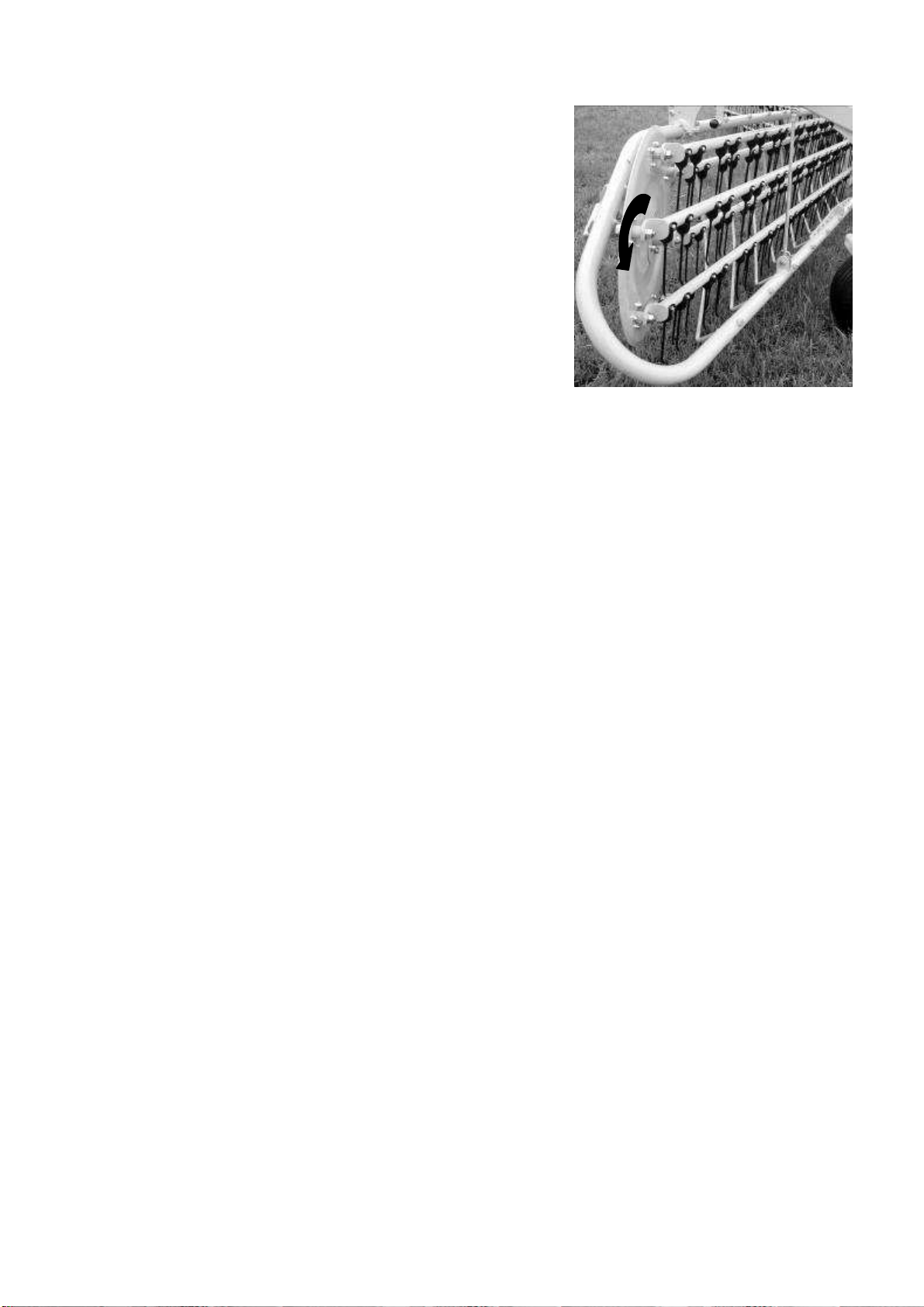

Check that the rake tines are at least 5 cm free from ground.

Check by rotating by hand, that the baskets are free to rotate,

and that no tines, tine bars or tine guides are bent or damaged.

The basket wheel should rotate freely with a minimum of

noise.

Start the tractor and engage slowly oil to the baskets (activate

section for hose nr. 3). The baskets shall rotate smoothly and

with a constant speed.

Check and re-tension if necessary all bolts and nuts after approximately two hours of use.

Particular important this is for the wheel bolts.

4. Assembly

The ELHO V-Twin rakes are generally delivered assembled and tested from the factory.

Therefore no assembly work should be needed. Just check that the machine is delivered without

transport damages.

VTwin - 750

15

5. Connecting and disconnecting to the tractor

The connecting and disconnecting to the tractor should only be

carried out on flat ground. Ensure the surface is has enough

stability to carry the load of the support leg.

Disconnecting

Lower the support by pulling it firmly in the direction of the

arrow and turn it down.

Lower and dismantle the linkage arms. Do not forget to

disconnect the hydraulic hoses and the rope to release the

transport hooks..

Connecting

The connecting to the tractor is done in opposite way. Do not forget the side support stabilisers of

the lift arms!

Connect the hydraulic hoses. Start with ensuring a good connection for

the free return line.

The ELHO V-Twin rake is equipped with hydraulic couplings

according to ISO 5676. It is unfortunately common that hydraulic quick-release couplings on

different brands do not always suit each other to 100% although they are made to the same

nominal size and mechanically fit in each other. Their spring loaded cones may not fully open

and particularly by increased oil flow the return line may suddenly close if matching connectors

is not used.

Required oil flow 25 litre/min, oil pressures 175 Bar, max. 210 Bar. Max oilflow 50 litre/min.

VTwin - 750

16

6. Adjustments

6.1 Raking height adjustment

Normal setting is tine end 5 cm above the ground.

Keep the setting as high as possible while still picking

up crop.

To set the initial raking height:

•Open the rake on a level firm surface.

•Ensure the caster wheels are in trailing position

•Rotate the baskets by hand to bring the tine bar B

in the lowest position.

•Adjust the raking height with the spindle A of the

caster wheels.

•Check both sides & front and rear are at equal

level.

•Secure the spindle A .

6.2 HydroBalance adjustment

During work the weight of the rake baskets are mainly

carried by the HydroBalance pressure stored in the

nitrogen accumulator.

This pressure is factory set to approximately 100 bar.

•If the pressure is too high it will be difficult to get

the baskets down to work position.

•If the pressure is to low the caster wheels are hard

on the ground and the baskets tend to "drag" and

jump.

To adjust the pressure loosen the counter nut of the

screw D and screw it in to increase the pressure and out

to lower the HydroBalance pressure.

Note, that the pressure do not change immediately. You have to lift and lowered the baskets once

before the new pressure level is reached.

VTwin - 750

17

6.3 Swath width.

The swath width is set by crank E.

Adjust left and right hand baskets to

equal width.

Do not mow the baskets more in than

the rubber bumper still is outside the

elbow F. Risk of interference between

the hydraulic motor and the frame.

Note that the swath width

adjustments also influence on the

working width.

6.4

Working width

.

The working width can be infinitely

adjusted by folding the baskets in or out

by the hydraulic cylinder.

6.5 Crop Throw adjustment

The throwing angle of the baskets are set by the adjusting

the length H of the spring bar.

The factory setting is 75 cm.

Generally the length H can be slightly increased in green

crops and decreased in dry light crops.

Remember to set all spring bars to the same length and

secure by tightening the counter nuts firmly.

a

VTwin - 750

18

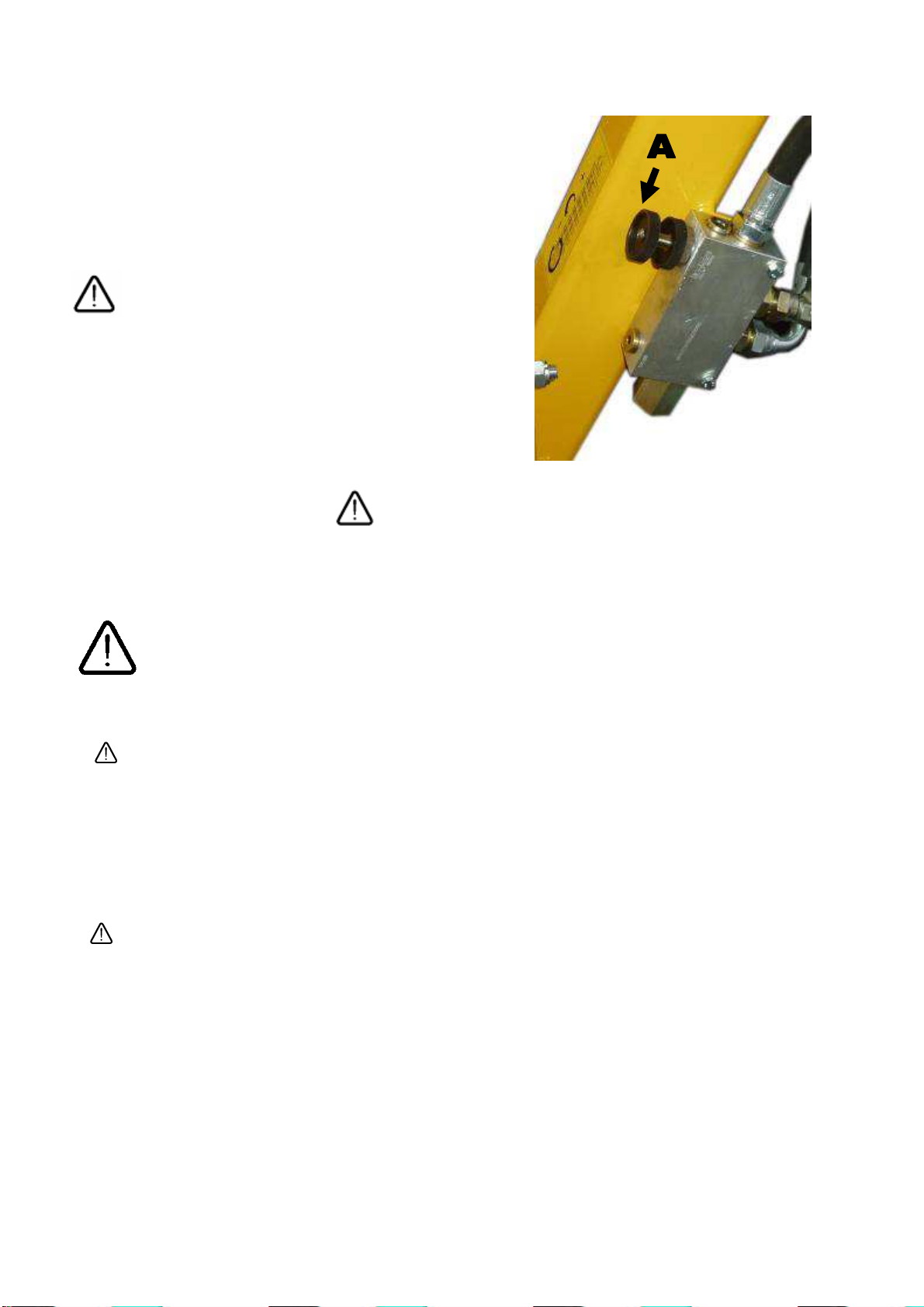

6.6 Basket speed

The basket speed is adjusted with the oil flow divider A.

Normal basket speed is 80 - 100rpm.

The slower the speed, the more gentle raking.

Do not increase the basket speed over 110 rpm.

Risk for major damage to the tine bars.

7. Use of the machine

7.1 General guidelines for working with the machine

All work in the immediate area of the baskets may be carried out only with the tractor

engine stopped.

The rotors are hydraulic driven. Take therefore particular care before any work on the

machine as there might be full power also behind stopped or blocked rotors.

Choose the speed of travel so that all crops are picked up thoroughly.

- In cases of overloading, shift down one gear.

After the baskets are lowered for a new swath, check that the caster wheels of the basket take

their trailing position.

If joining swats, adjust the working width to avoid splitting up a swath.

If the baskets tend to block:

-Ensure the rake tines rotate clear of ground.

-Reduce the speed of travel

-Reduce the working width

-Adjust the length of the basket spring bar. Se § 6.5 Crop Throw adjustment.

-If the problem continue, check that the tractor hydraulics is working properly. Measure the oil

flow also under load at your tractor service.

VTwin - 750

19

7.2 Transport

For transport:

•lift the baskets to max. lift height.

•Fold the baskets fully in.

•Let the baskets down in the transport supports.

•Ensure bout transport locks A hooks in fully.

•Lock the support wheels in the travel direction by use of

the ring pin B.

Reduce the speed when turning and driving on uneven roads. Too high speed can create big

chock loads to the construction, which might result in damages to the wheel arms and frame (not

covered by the warranty). The maximum road speed for the ELHO V-Twin rake is 30 km/h.

Observe the local legislation for transport on roads. In certain countries it may be necessary

to equip the machine with a SMV triangle or rear lights and reflectors when driving on public

roads.

VTwin - 750

20

8. Maintenance

To ensure a long and trouble free use of the machine, keep the machine

clean and follow the maintenance instructions below.

It is particular important to keep the hydraulic oil of the

tractor clean and in god condition. Change the oil and the oil

filter according the tractor manufacturers instruction .

Check regularly all bolts and nuts and re-tighten when necessary.

Tightening moments (in Nm) if not especially mentioned are according to

the following list.

Remove possible grass remaining from the area around the basket

tine bar bearings. Dried dirt can damage the bearing seals. Avoid

the use of high pressure cleaner, since the high-pressure water jet

can penetrate into the labyrinth sealing of the bearing house.

Check the bearings straight after the season. Change if doubt, it will

save you problems during the season. The bearings are available

in kits of 14 Pcs. Order number: 418125.

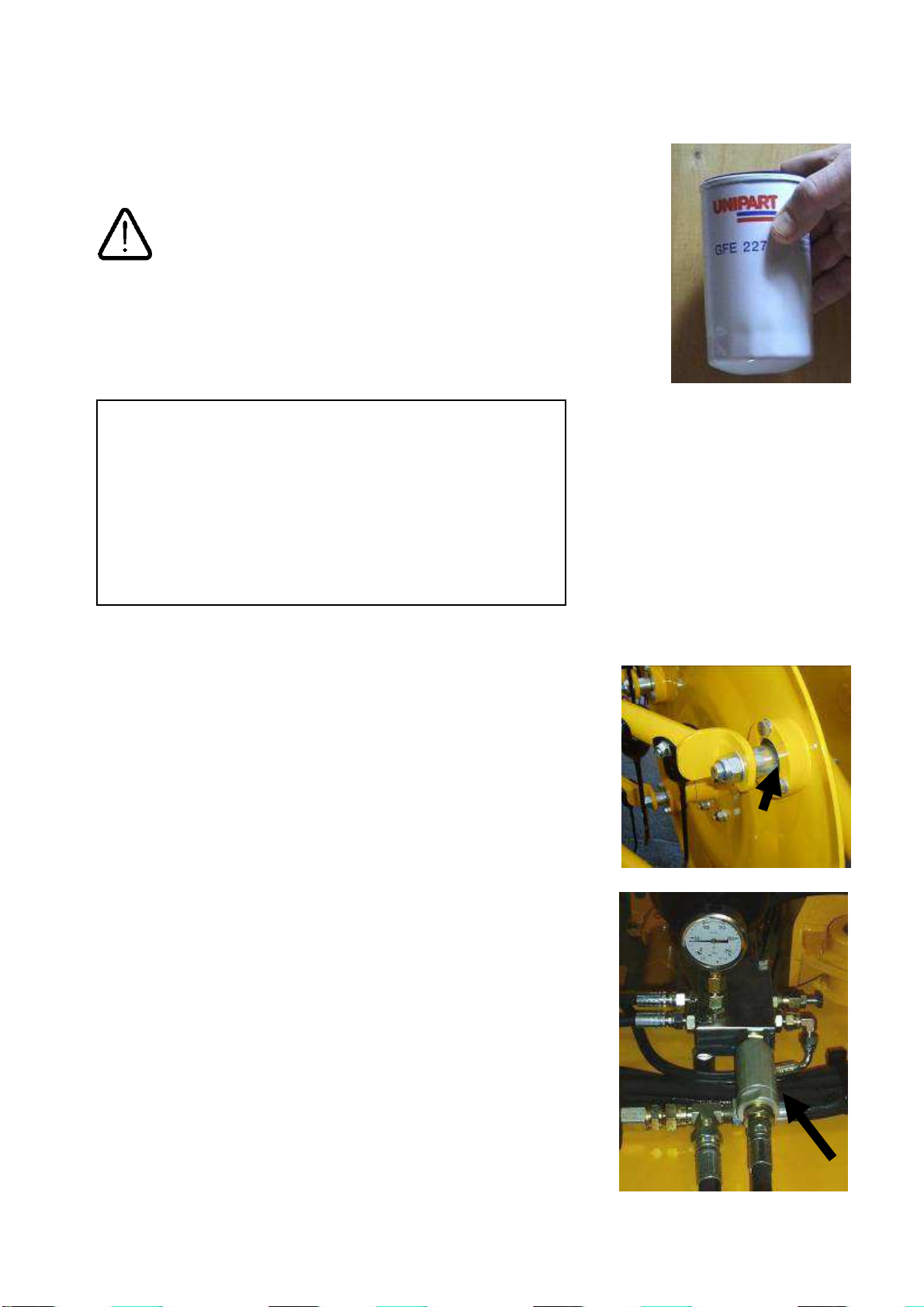

On the inlet hose to the HydroBalance valve there is a small high

pressure filter to prevent dirt from the quick release couplings from

entering the sensitive regulator valve.

Normally this high pressure filter do not need any maintenance,

because the return oil from the cylinders normally clean away the

dirt.

If however the oil in the tractor is dirty, this filter might be blocked

and has to be replaced.

Bolt size M Bolt class 8.8 Bolt class 10.9

6(mm) 11 (Nm) 17 (Nm)

8 28 40

10 55 80

12 95 140

16 235 350

20 475 675

24 825 1170

This manual suits for next models

2

Table of contents

Other elho Farm Equipment manuals