2. - Contents

GA4121GM

3

KN129DGB D

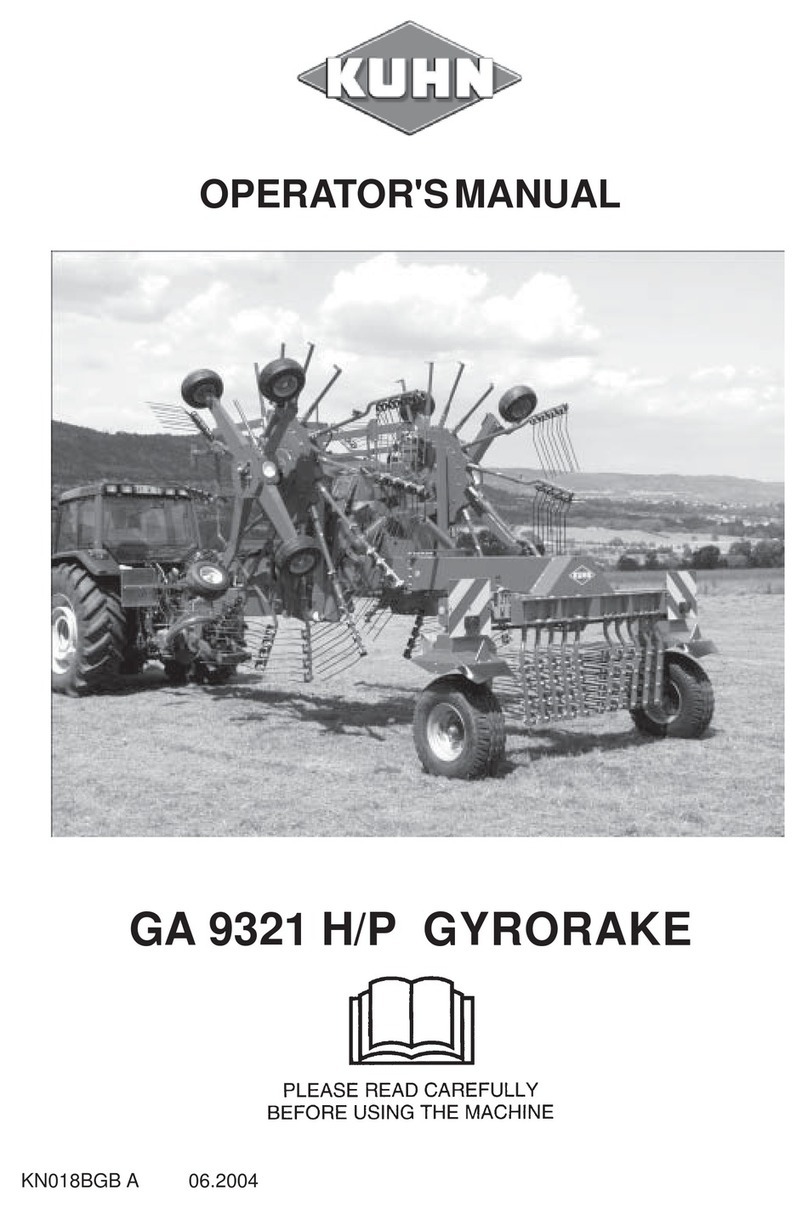

Gyrorake

-

6. Putting into service...................................................................................................... 26

6.1 Coupling and uncoupling............................................................................................................... 26

6.1.1 Description of coupling elements ..................................................................................... 26

6.1.2 Preparing the tractor......................................................................................................... 26

6.1.3 Coupling the machine.......................................................................................................28

6.1.4 Primary PTO shaft............................................................................................................ 30

6.1.5 Hydraulic connections......................................................................................................31

6.1.6 Electrical connections....................................................................................................... 32

6.1.7 Uncoupling the machine................................................................................................... 32

7. Instructions for transport............................................................................................ 34

7.1 Putting the machine into transport position ................................................................................... 34

7.2 Conformity with the road regulations............................................................................................. 38

8. Instructions for work................................................................................................... 39

8.1 Putting the machine into work position.......................................................................................... 39

8.2 Adjustments in working position .................................................................................................... 41

8.2.1 Wheel height adjustment.................................................................................................. 41

8.2.2 Swath screen adjustment................................................................................................. 43

8.3 Machine use .................................................................................................................................. 46

8.3.1 Drive speed...................................................................................................................... 46

9. Optional equipment..................................................................................................... 47

9.1 1 3/8 - 6 spline pto shaft ................................................................................................................ 47

9.2 1 3/8 - 6 spline wide angle u-joint drive ......................................................................................... 47

9.3 Front support wheel....................................................................................................................... 47

9.3.1 Fitting................................................................................................................................ 48

9.3.2 Adjustments...................................................................................................................... 48

9.4 Bogie axles.................................................................................................................................... 50

9.4.1 Fitting................................................................................................................................ 50

9.4.2 Machine use..................................................................................................................... 51

9.4.3 Lubrication........................................................................................................................ 52

9.5 Three point frame damper............................................................................................................. 52

9.5.1 Fitting................................................................................................................................ 52

9.6 Hydraulic windrow curtain.............................................................................................................. 53

9.6.1 Preparing the tractor......................................................................................................... 53

9.6.2 Hydraulic connections......................................................................................................53

9.6.3 Putting the machine into transport position...................................................................... 53

9.6.4 Putting the machine into work position............................................................................. 56

9.6.5 Adjustments...................................................................................................................... 57

9.6.6 Maintenance..................................................................................................................... 59

9.6.7 Storage............................................................................................................................. 59