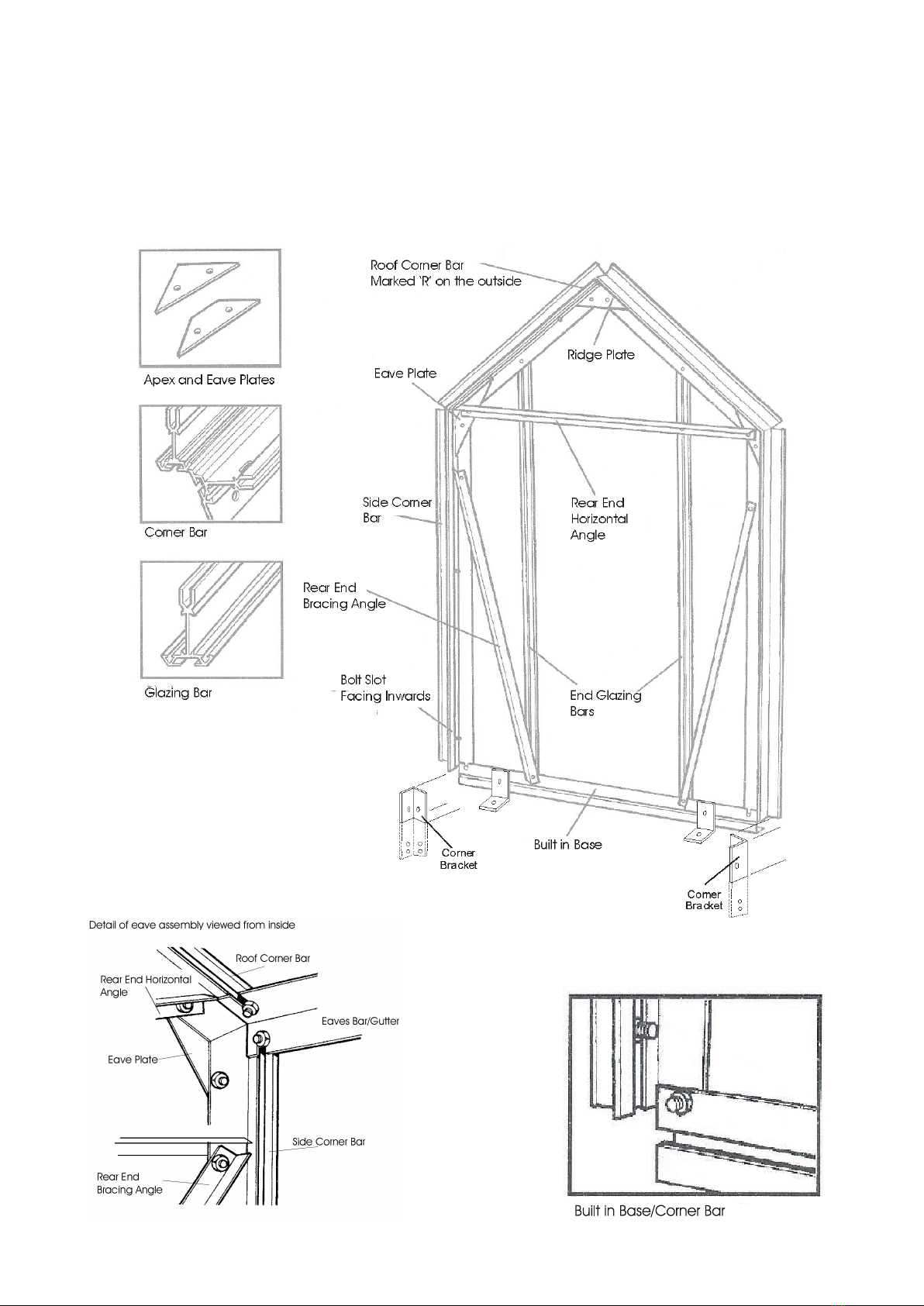

From the main bag of fittings you will require the nuts and bolts, two eave plates and one ridge

plate. These are packed with the casement stay and are separated from the main bag of fittings.

Components:

1 alloy built in base

2 glazing bars

2 rear end bracing angles

1 rear end horizontal angle

2 roof corner bars (marked “R” at the apex)

2 side corner bars (unmarked)

Corner bars are in two packs of 4 and are identical for both gables. They are marked “corner

bars”.

INSTRUCTIONS

1. Slide the glazing beading into each glazing bar and corner bar taking care not to stretch the

material. Trim off any surplus level with the ends of the glazing bar. The corner bars have 3 grooves

to receive beading. Do not use the middle one, only the two outer grooves require beading.

2. Lay out the frame as though you were standing on the inside i.e. with the bolt slot uppermost,

roof corners marked “R” at the apex, opposite each other, facing downwards (i.e. “R” on outside).

The roof corner bars are mitred at both ends where as side corner bars are mitred at one end only

(Key Point). The bolt slot is on the inside and faces inwards during initial construction. If you have

a painted greenhouse there is no letter “R” on the corner bar. You must ensure that the “middle”

hole is nearer to the eave plate than the ridge plates. (Key Point).

3. Slide two bolts into the bolt channel of each corner bar, put a nut on and finger tip tighten ap-

prox. 3” from the end of the bar. These will later be used in the general assembly for fixing the

ridge, eave and built in base to the ends. Now secure the ridge plate and eaves plates by inserting

bolts through the ‘plates’ and into the holes punched in the flange of the corner bar, at the apex and

eave. Do not tighten the nuts and bolts in the plates at this stage, finger tip tighten is sufficient.

N.B. If you have the 4’ option the roof vent slam bar will attach to one of the corner bars. You will

need to insert an extra bolt into the bolt slot of the roof corner bar onto which the vent will close.

4. Attach the built in base to the side corner bars by inserting a bolt through the hole in the

flange of the corner bar and into the slot in the built in base.

5. Attach the vertical glazing bars to the built in base by inserting a bolt into the bolt channel of

the glazing bars and locating it with the punched holes in the built in base. Before securing the nuts

attach the rear end bracing angle which goes diagonally from the spare hole in the corner bar near to

the eave plate down to the built in base to the same bolt as illustrated. The top of the diagonal angle

tie now attaches to the pre-fabricated holes approx. 8” from the top of the side corner bar.

6. Slide two bolts into the bolt channel at the top of the two vertical glazing bars and secure the

second one to the roof corner bars by inserting the bolt through the punched hole in the flange.

7. You can now attach the rear end horizontal angle to the top bolt of the eave plate and to the

other bolts in the glazing bars you inserted in 6, above.