1.

2.

Mount the emergency LED driver by the mounting tabs using

appropriate screws (not provided). The luminaire's installation instructions

may provide guidance on the recommended mounting location.

INSTALLING THE EMERGENCY DRIVER

NOTE:

This product has been designed to reliably interface with a

wide selection of LED loads and is electrically compatible

with every simple LED array that meets criteria 1 and 2 above.

However compatibility cannot be guaranteed with all current and future

LED systems . Compatibility testing of the end-use systems is suggested .

Please contact the factory with any questions

NOTE:

After installation it will be necessary to measure the egress

lighting illumination level to ensure it complies with national

state and local code requirement.

Installation of this emergency LED driver will vary based on

the luminaire type, however generally follow these steps.

Mounting Height: This product meets or exceeds the NFPA minimum light

requirements with all loads, down to the smallest rated lamp load, at

heights up to 7.17ft (2.2m). Many factors influence emergency illumination

levels, such as the lamp load selected, luminaire design, and

environmental factors. Therefore end use verification is necessary. For

field installations, when the attached luminaire is mounted at heights

greater than 7.17ft (2.2m), the level of illumination must be measured in the

end application to ensure the requirements of NFPA 101 and local codes

are satisfied.

Remote Mounting: The emergency LED driver may be remote mounted

from the luminaire. If used in conjunction with an AC driver the allowed

distance is up to half the distance the AC driver manufacturer recommends

remote mounting the AC driver from the LED lo ad . If used without an AC

driver, and remote mounting more than 18 feet from the luminaire, please

consult the factory to determine the necessary wire gauge.

CAUTION: Remote mounting can result in reduced power output.

3.

4.

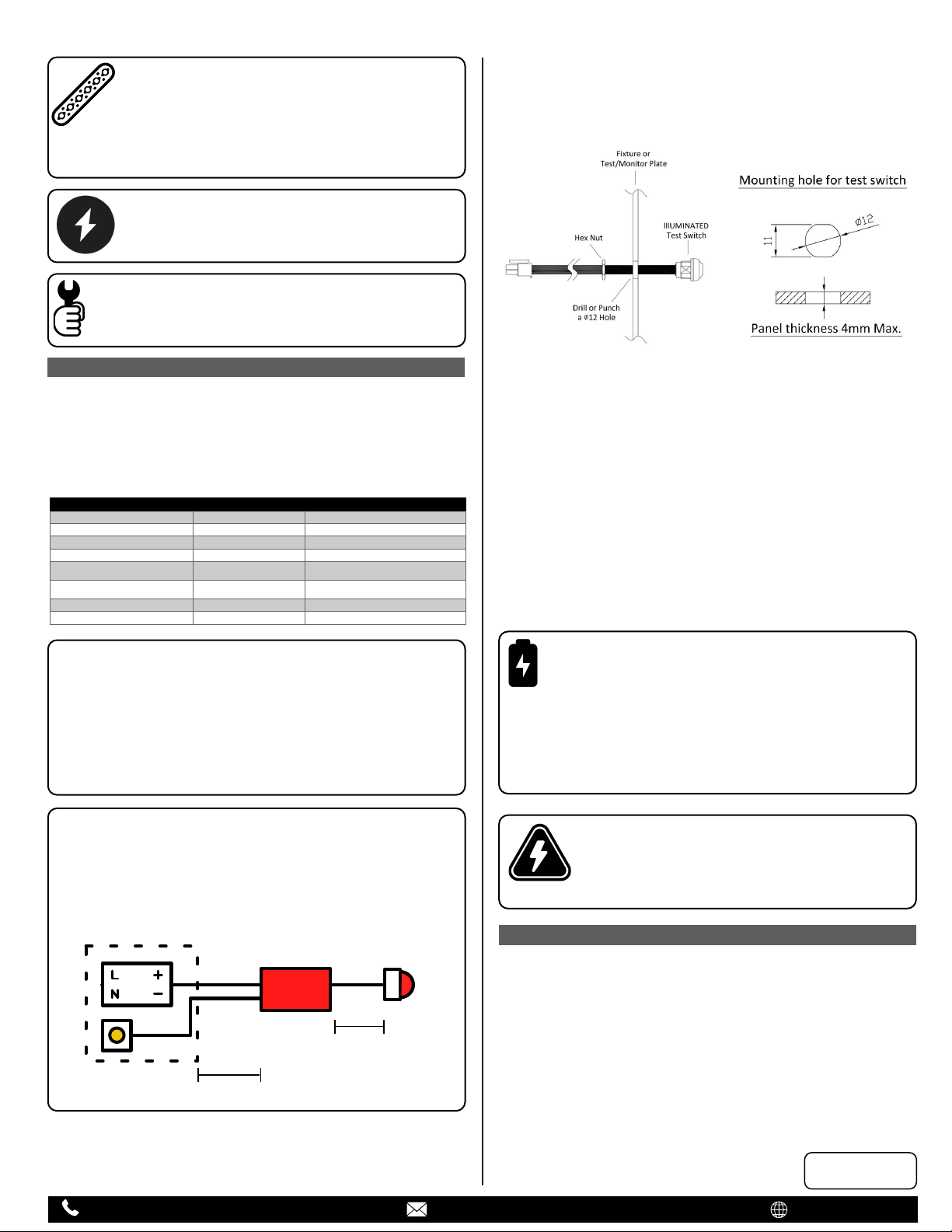

Mount the supplied 4 wire illuminated test switch in a location that is

visible and accessible by maintenance personnel. The switch mounts

through a hole which may need to be added to the luminaire or could

come pre-punched by the luminaire supplier.

Wire the test switch per wiring diagrams provided on this instruction.

5.

If wired correctly, the test switch indicator light should be ON when AC

power is supplied to the fixture, and the battery switch is “ON”

indicating that the emergency battery is charging.

NOTE:

For 10W models, a short term discharge test may be

conducted after the emergency driver has been charged for

one hour. A 24 hour charging period must be performed

before conducting a long term discharge test. For 20W models, a

short term discharge test may be conducted after the emergency

driver has been charged for one hour. A 48 hour charging period

must be performed before conducting a long term discharge test.

Refer to the OPERATION section of specs.

CAUTION:

This unit has more than one power connection point.

To reduce the risk of electric shock, disconnect both the

branch circuit breakers or fuses and emergency power

supplies before servicing.

OPERATION

PAGE 2 OF 4

O.R.-Revision C: 2/24/21

Disconnect AC power from the LED luminaire.

6.

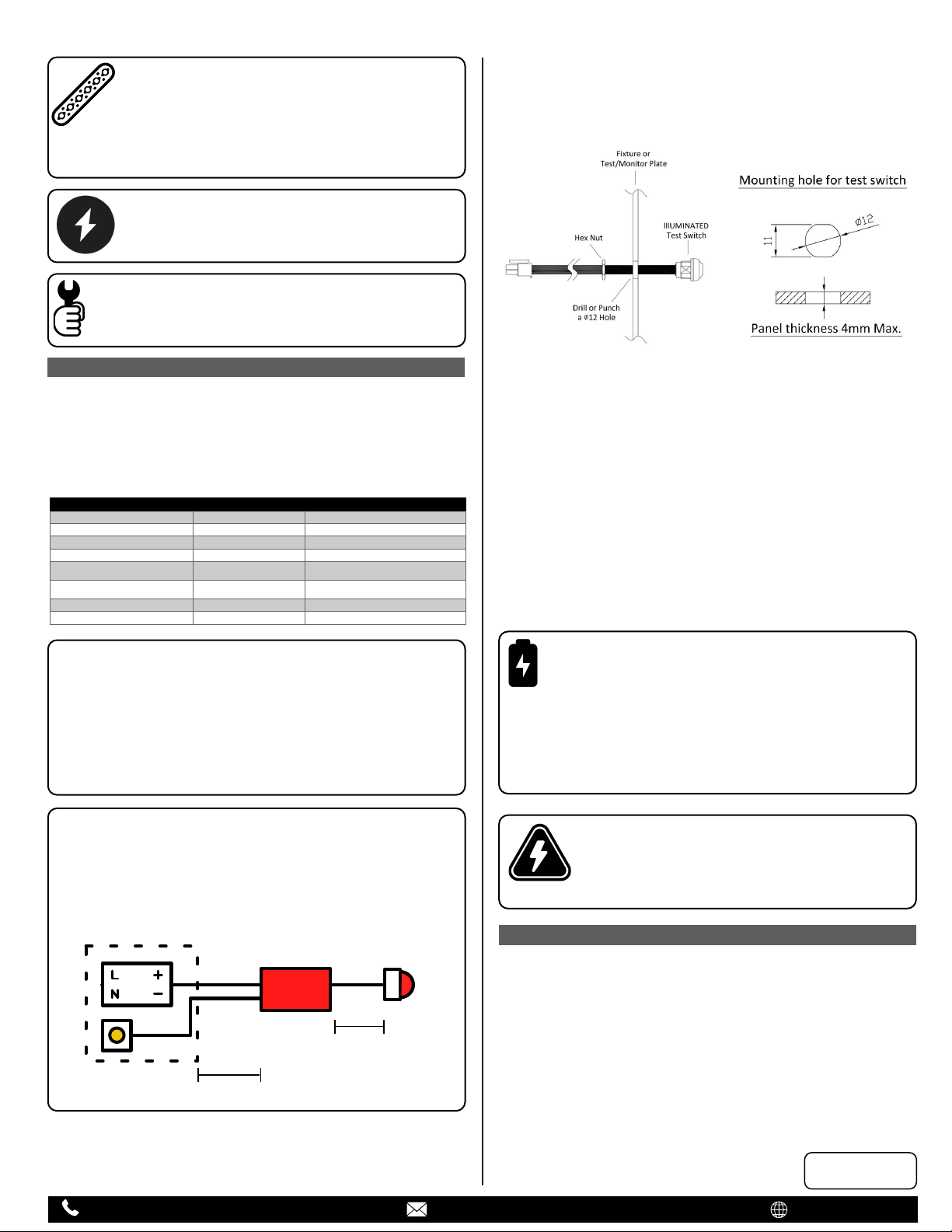

Select the appropriate wiring diagram to connect the emergency

driver to the AC driver and LED load. Make sure all connections are in

accordance with the National Electrical Code and any local

regulations. After installation is complete, supply AC power to the

emergency driver and turn on battery switch/join battery connector. At

this point, power should be connected to both the AC driver and the

emergency driver, and the Charging Indicator Light should illuminate

indicating the battery is charging.

Test Switch is integrated, Power Flex

Test Switch is integrated, Power Flex

During normal operation AC power is applied, to the driver, and the

charging indicator light is illuminated, which indicates that the battery

is being charged. When power fails, the emergency LED driver will

automatically switch to emergency power (internal battery), operating

the LED load for a minimum of 90 minutes. When AC power is

restored, the emergency driver returns to the charging mode.

Max

18ft

Contact

Elite

Emergency Test

Switch

Fixture