Eliwell EWCFW-08 User manual

Frequency Inverter

EWCFW-08

User's Manual

07/2010

FREQUENCY

INVERTER

MANUAL

ATTENTION!

It is very important to check if the

inverter software version is the

same as indicated above.

Series: CFW-08

Software:version5.2X

Language:English

Document: 10000891866 / 00

2

Summary of Revisions

Thetablebelowdescribesallrevisionsmadetothismanual.

Revision Description Section

0 First Edition -

Summary

Quick Parameter Reference,

Fault and Status Messages

I Parameters.................................................................... 8

II FaultMessages ........................................................... 16

IIIOtherMessages........................................................... 16

CHAPTER 1

Safety Notices

1.1SafetyNotices intheManual ..................................... 17

1.2 SafetyNotices on the Product................................... 17

1.3PreliminaryRecommendations ................................. 17

CHAPTER 2

General Information

2.1AboutthisManual ...................................................... 19

2.2 Software Version....................................................... 19

2.3AbouttheCFW-08 .................................................... 20

2.4CFW-08 Identification ............................................... 24

2.5Receiving and Storing ............................................... 27

CHAPTER 3

Installation and Connection

3.1MechanicalInstallation .............................................. 28

3.1.1Environment........................................................ 28

3.1.2 Mounting Specifications...................................... 28

3.1.3 PositioningandFixing ........................................ 31

3.1.3.1PanelMounting.......................................... 32

3.1.3.2SurfaceMounting....................................... 33

3.2 ElectricalInstallation................................................. 33

3.2.1Power/ GroundingTerminals.............................. 33

3.2.2 Locationofthe PowerTerminals,Grounding

TerminalsandControlTerminalConnections...... 35

3.2.3 Power/GroundingWiringandCircuitBreakers .. 36

3.2.4 PowerConnections ............................................ 37

3.2.4.1 ACInputConnection................................ 39

3.2.4.2 OutputConnections .................................. 40

3.2.4.3 GroundingConnections............................ 40

3.2.5 Signaland ControlConnections ......................... 42

3.2.5.1 Digital Inputsas LowLevelActive

(S1:1 to OFF) ........................................... 46

3.2.5.2 DigitalInputasHighLevelActive

(S1:1to ON) ............................................. 47

3.2.6TypicalTerminalConnections ............................. 48

3.3 European EMCDirective-Requirements

forConformingInstallations ...................................... 51

3.3.1Installation ........................................................... 51

Summary

3.3.2 Emissionand ImmunityLevelsDescription ........ 52

3.3.3 InverterModels and Filters.................................. 54

3.3.4 EMC Filters Characteristics ............................... 57

CHAPTER 4

Keypad (HMI) Operation

4.1 Keypad (HMI) Description......................................... 67

4.2Useof the Keypad(HMI) ........................................... 68

4.2.1 Keypad Operation .............................................. 69

4.2.2InverterStatus ..................................................... 70

4.2.3Read-OnlyParameters ....................................... 71

4.2.4Parameter Viewingand Programming ............... 71

CHAPTER 5

Start-up

5.1 Pre-Power Checks.................................................... 74

5.2InitialPower-up.......................................................... 74

5.3Start-up...................................................................... 75

5.3.1 Start-up Operationvia Keypad(HMI)-

Type of Control: Linear V/F (P202 = 0)............... 76

5.3.2 Start-upOperationviaTerminals-

Control Mode: Linear V/F (P202 = 0) ................. 77

5.3.3 Start-upOperation via Keypad -

Control Mode: Vector (P202 = 2)........................ 78

CHAPTER 6

Detailed Parameter Description

6.1Symbols .................................................................... 83

6.2Introduction ................................................................ 83

6.2.1 Control Modes (V/F and Vector) ......................... 83

6.2.2 V/F Control ......................................................... 83

6.2.3 Vector Control (VVC).......................................... 84

6.2.4FrequencyReferenceSources ........................... 85

6.2.5 Commands......................................................... 88

6.2.6Local/Remote Operation Modes ........................ 88

6.3 Parameter Listing...................................................... 89

6.3.1 AccessandRead-onlyParameters-

P000 to P099 ..................................................... 90

6.3.2 Regulation Parameters - P100 to P199 ............. 92

6.3.3 Configuration Parameters - P200 to P398 ....... 102

6.3.4 Motor Parameters - P399 to P499 ................... 128

6.3.5 Special Function Parameters- P500 to P599 .. 131

6.3.5.1Introduction .............................................. 131

6.3.5.2 Description .............................................. 131

6.3.5.3PIDStart-up Guide................................... 134

Summary

CHAPTER 7

Diagnosticsand Troubleshooting

7.1 Faults and Possible Causes ................................... 141

7.2Troubleshooting....................................................... 144

7.3Contacting Eliwell.................................................... 145

7.4PreventiveMaintenance.......................................... 145

7.4.1CleaningInstructions......................................... 146

CHAPTER 8

CFW-08 Options andAccessories

8.1HMI-CFW08-P ........................................................ 149

8.1.1InstructionsforInsertionandRemovingof

theHMI-CFW08-P ............................................ 149

8.2TCL-CFW08 ........................................................... 149

8.3HMI-CFW08-RP...................................................... 150

8.3.1HMI-CFW08-RPInstallation.............................. 150

8.4MIP-CFW08-RP...................................................... 151

8.5 CAB-RP-1, CAB-RP-2, CAB-RP-3, CAB-RP-5,

CAB-RP-7.5, CAB-RP-10...................................... 151

8.6HMI-CFW08-RS...................................................... 151

8.6.1HMI-CFW08-RSInstallation.............................. 152

8.6.2HMI-CFW08-RS Start-up .................................. 152

8.6.3KeypadCopyFunction ..................................... 153

8.7MIS-CFW08-RS...................................................... 153

8.8 CAB-RS-1, CAB-RS-2, CAB-RS-3, CAB-RS-5,

CAB-RS-7.5, CAB-RS-10 ...................................... 153

8.9 KDC-24VR-CFW08................................................ 154

8.10 KDC-24V-CFW08................................................. 155

8.11 KCS-CFW08......................................................... 156

8.11.1 InstructionsforKCS-CFW08

InsertionandRemoval..................................... 157

8.12 KSD-CFW08 ........................................................ 157

8.13 KRS-485-CFW08 ................................................. 158

8.14 KFB-CO-CFW08 .................................................. 159

8.15 KFB-DN-CFW08 .................................................. 160

8.16 KAC-120-CFW08, KAC-120-CFW08-N1M1

KAC-120-CFW08-N1M2 ...................................... 162

8.17 KMD-CFW08-M1.................................................. 163

8.18 KFIX-CFW08-M1, KFIX-CFW08-M2 .................... 164

8.19KN1-CFW08-M1,KN1-CFW08-M2...................... 165

8.20RFIFilter ............................................................... 166

8.21 Line Reactor.......................................................... 167

8.21.1Application Criteria ....................................... 167

8.22 Load Reactor ........................................................ 170

8.23 Dynamic Braking................................................... 171

8.23.1ResistorSizing.............................................. 171

8.23.2Installation ..................................................... 172

8.24Serial Communication........................................... 173

Summary

8.24.1Introduction.................................................... 173

8.24.2RS-485 and RS-232Interfaces Description . 174

8.24.2.1RS-485 .............................................. 175

8.24.2.2RS-232 .............................................. 176

8.24.3 Definitions..................................................... 176

8.24.3.1UsedTerms ....................................... 176

8.24.3.2Parameter/Variables Resolution........ 177

8.24.3.3CharacterFormat .............................. 177

8.24.3.4Protocol ............................................. 177

8.24.3.5 Execution and Message Test............. 180

8.24.3.6 Message Sequence .......................... 180

8.24.3.7 Variable Code ................................... 180

8.24.4 Message Examples ...................................... 181

8.24.5 Variables and Errors of the Serial

Communication ............................................ 181

8.24.5.1 Basic Variables ................................. 181

8.24.5.2 Message Examples with Basic

Variables............................................ 184

8.24.5.3ParametersRelatedtotheSerial

Communication ................................... 185

8.24.5.4 ErrorsRelated tothe Serial

Communication ................................. 186

8.24.6Timefor Read/Write of Messages ................ 186

8.24.7PhysicalConnectionRS-232andRS-485.... 187

8.25Modbus-RTU......................................................... 188

8.25.1IntroductiontoModbus-RTUProtocol ........... 188

8.25.1.1Transmission Modes ......................... 188

8.25.1.2MessageStructure in RTUMode ...... 188

8.25.2Operation of the CFW-08 in the

Modbus-RTUNetwork .................................. 191

8.25.2.1RS-232andRS-485Interface

Description ....................................... 191

8.25.2.2 InverterConfigurationinthe

Modbus-RTU Network ..................... 191

8.25.2.3AccesstotheInverterData ............... 192

8.25.3Detailed Function Description ...................... 195

8.25.3.1 Function 01 -Read Coils .................. 195

8.25.3.2Function 03 - Read Holding Register 196

8.25.3.3Function 05- Write Single Coil ......... 197

8.25.3.4 Function 06- Write Single Register .. 198

8.25.3.5 Function15 - Write Multiple Coils...... 198

8.25.3.6Function16 -WriteMultipleRegisters199

8.25.3.7 Function 43 -Read Device

Identification ..................................... 200

8.25.4Modbus-RTUCommunicationErrors............ 202

8.25.4.1 Error Messages ............................... 203

Summary

CHAPTER 9

TechnicalSpecifications

9.1Power Data.............................................................. 204

9.1.1 200-240 V Power Supply.................................. 204

9.1.2 380-480 V Power Supply.................................. 205

9.2Electronics/General Data ........................................ 208

9.3 WEG StandardIV-Pole Motor Data......................... 209

8

CFW-08 - QUICK PARAMETER REFERENCE

Software: V5.2X

Application:

Model:

SerialNumber:

Responsible:

Date: / / .

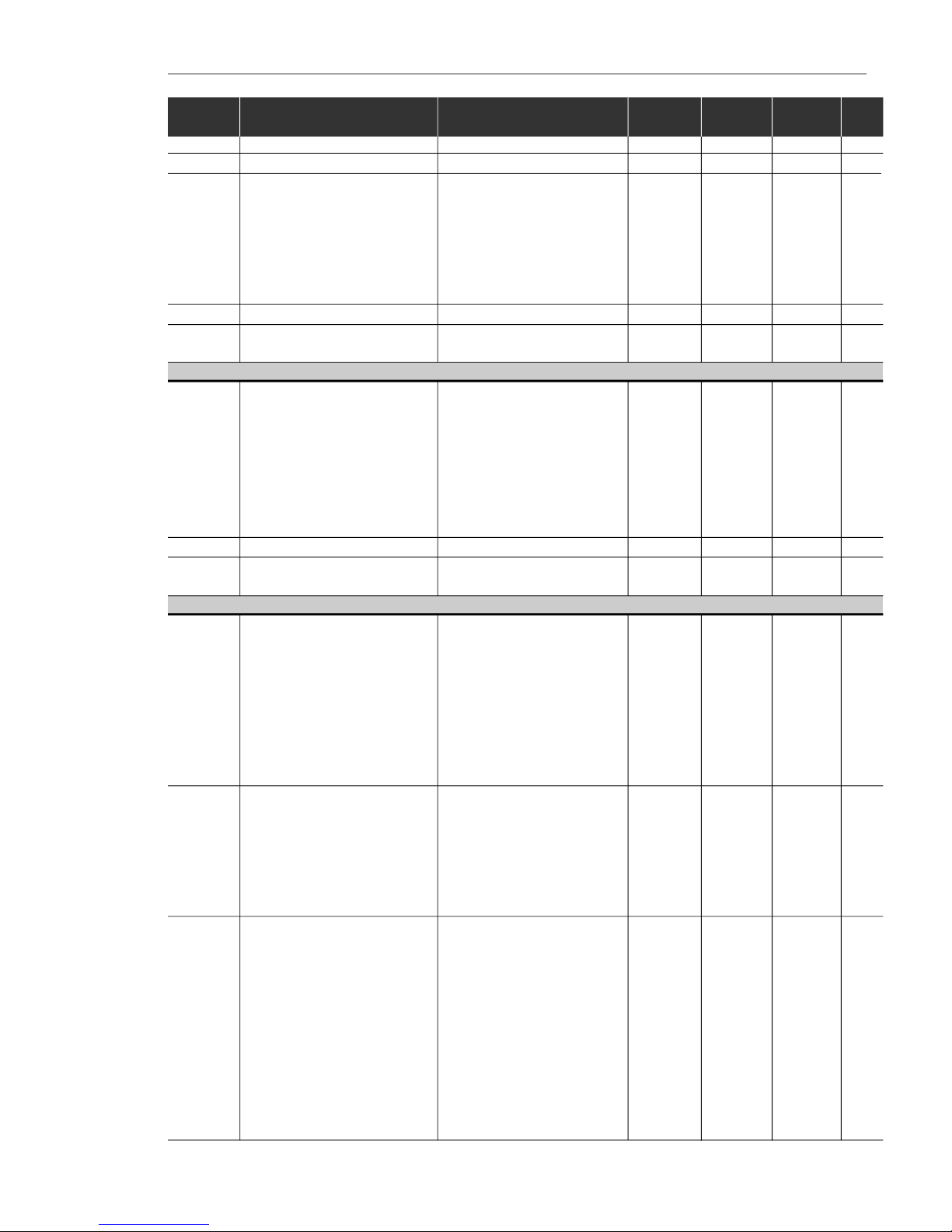

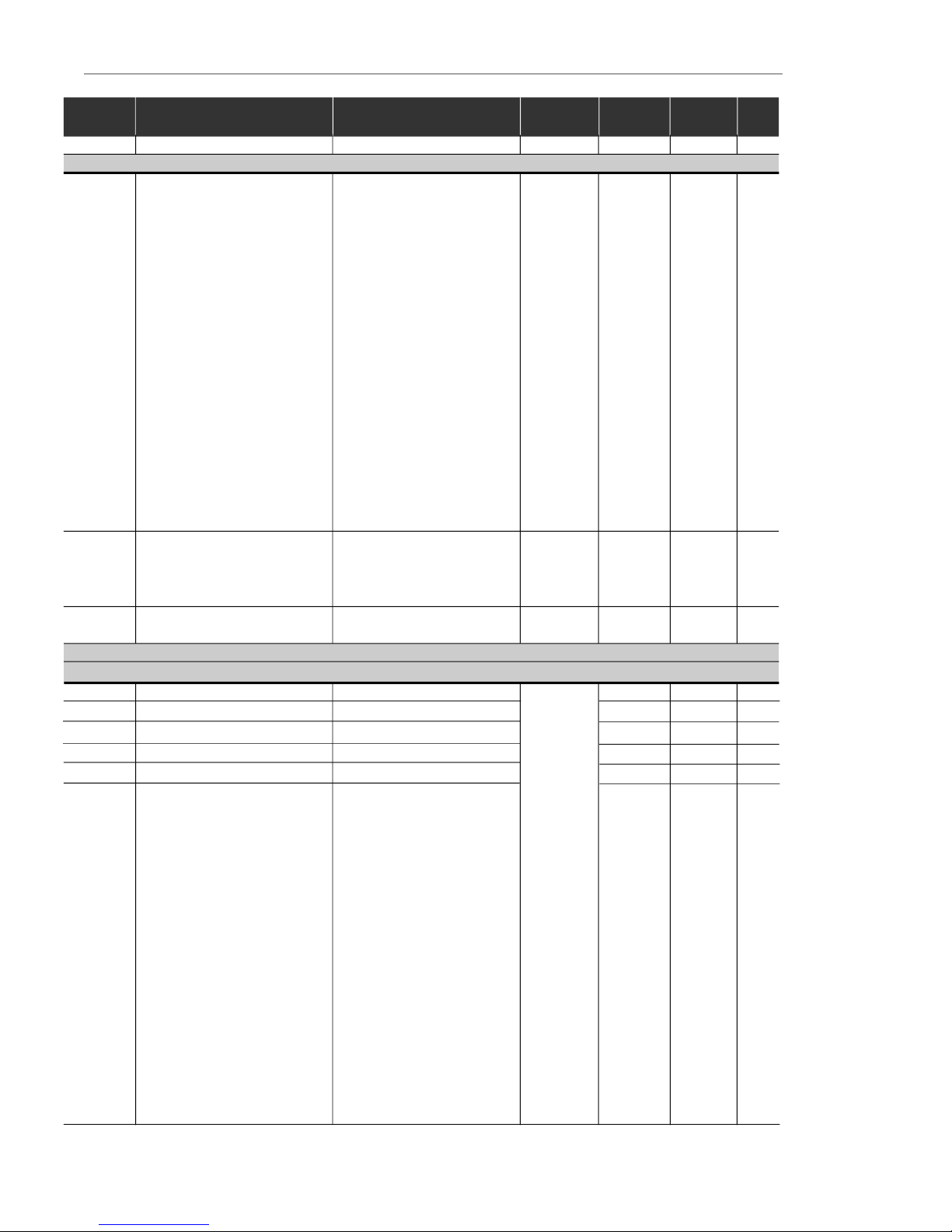

I.Parameters

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

P000 ParameterAccess 0 to 4 = Read 0 - 90

5 = Alteration

6 to 999 = Read

READ ONLY PARAMETERS - P002to P099

P002 FrequencyProportional Value 0 to 6553 - - 90

(P208xP005)

P003 MotorOutputCurrent 0 to 1.5xInom - A 90

P004 DCLink Voltage 0 to 862 - V 90

P005 Motor Output Frequency 0.00 to 300.0 - Hz 90

P007 Motor Output Voltage 0 to 600 - V 90

P008 HeatsinkTemperature 25 to 110 - °C 91

P009 (1) MotorTorque 0.0 to 150.0 - % 91

P014 Last Fault 00 to 41 - - 91

P023 SoftwareVersion x . y z - - 91

P040 PID Process Variable 0 to 6553 - - 91

(Value % x P528)

REGULATION PARAMETERS - P100 to P199

Ramps

P100 Acceleration Time 0.1 to 999 5.0 s 92

P101 DecelerationTime 0.1 to 999 10.0 s 92

P102 Ramp2AccelerationTime 0.1 to 999 5.0 s 92

P103 Ramp2DecelerationTime 0.1 to 999 10.0 s 92

P104 S Ramp 0 = Inactive 0 - 92

1 = 50 %

2 = 100 %

Frequency Reference

P120 Digital ReferenceBackup 0 = Inactive 1 - 93

1 =Active

2 = Backup by P121

P121 KeypadReference P133 to P134 3.00 Hz 93

P122 JOGSpeedReference 0.00 to P134 5.00 Hz 94

P124 Multispeed Reference 1 P133 to P134 3.00 Hz 94

P125 Multispeed Reference 2 P133 to P134 10.00 Hz 94

P126 Multispeed Reference 3 P133 to P134 20.00 Hz 94

P127 Multispeed Reference 4 P133 to P134 30.00 Hz 95

P128 Multispeed Reference 5 P133 to P134 40.00 Hz 95

P129 Multispeed Reference 6 P133 to P134 50.00 Hz 95

P130 Multispeed Reference 7 P133 to P134 60.00 Hz 95

P131 Multispeed Reference 8 P133 to P134 66.00 Hz 95

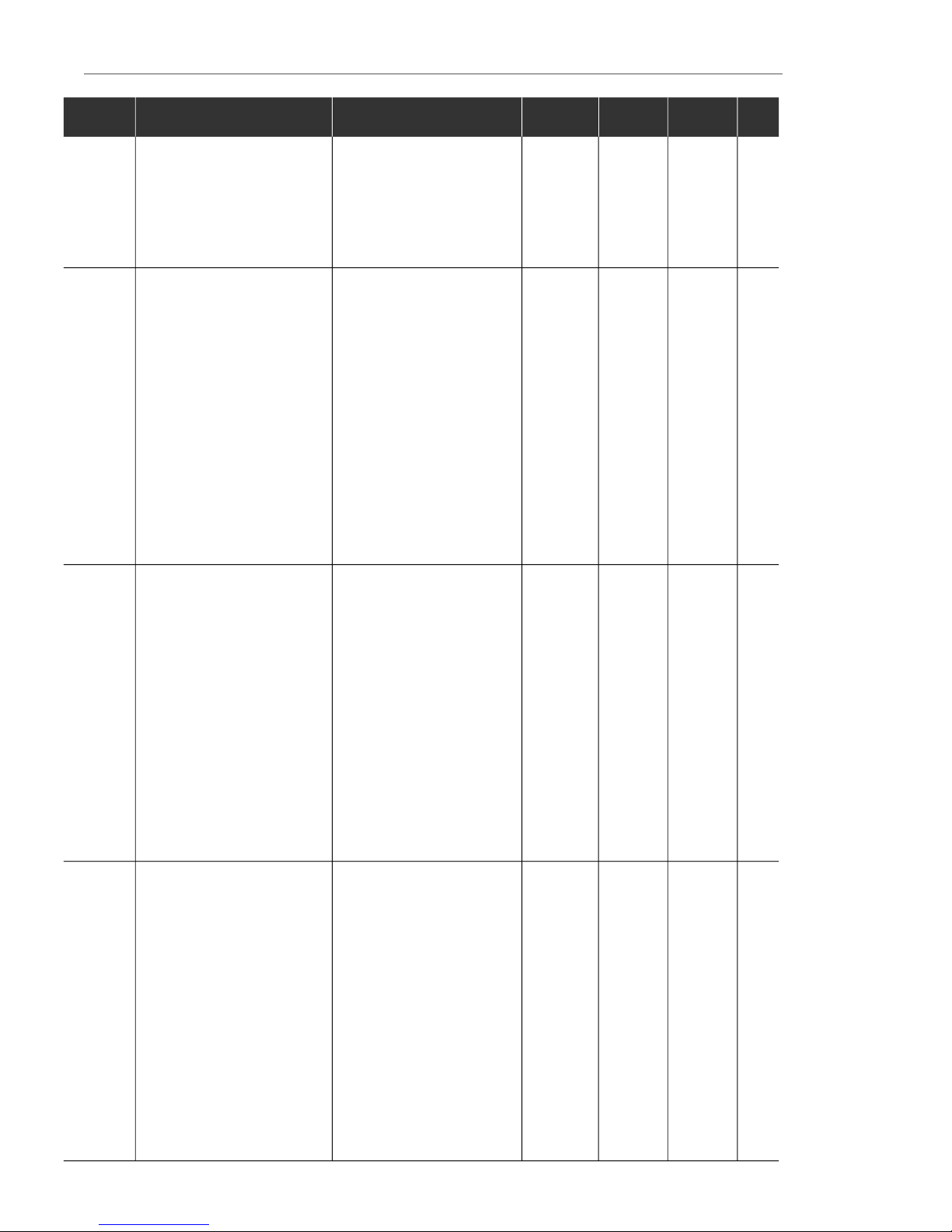

9

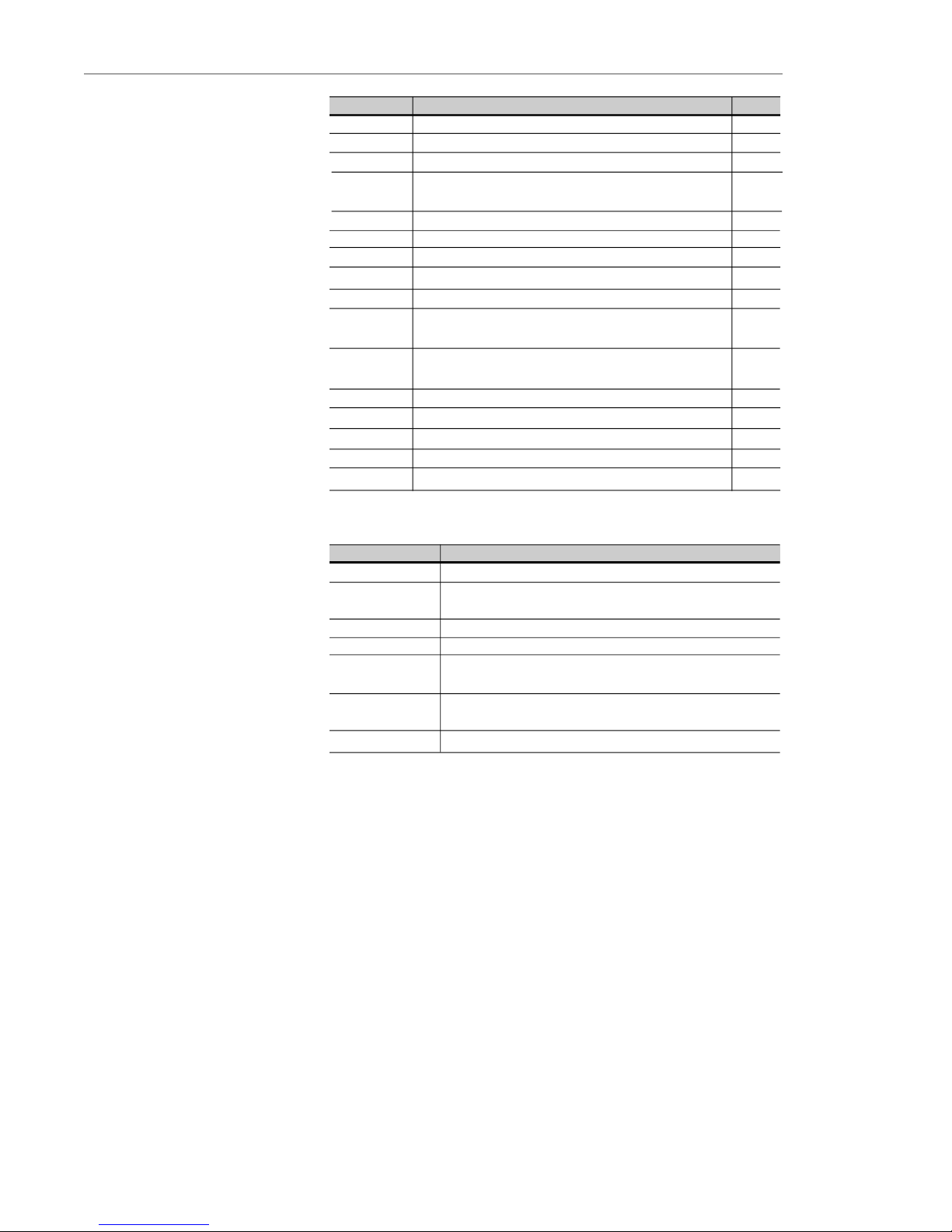

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

(*) The factory default of parameter P136 depends on the inverter model as follows:

- models 1.6-2.6-4.0-7.0 A/200-240 V and 1.0-1.6-2.6-4.0 A/380-480 V: P136 = 5.0 %;

- models 7.3-10-16 A/200-240 V and 2.7-4.3-6.5-10 A/380-480 V: P136 = 2.0 %;

- models 22-28-33 A/200-240 V and 13-16-24-30 A/380-480 V: P136 = 1.0 %.

Speed Limits

P133 Minimum Frequency(Fmin) 0.00 to P134 3.00 Hz 95

P134 Maximum Frequency (Fmax) P133 to 300.0 66.00 Hz 96

V/F Control

P136 (2) (*) ManualTorqueBoost 0.0 to 30.0 5.0 or % 96

(IxRCompensation) 2.0 or

1.0 (*)

P137 (2) AutomaticTorque Boost 0.00 to 1.00 0.00 - 97

(AutomaticIxRCompensation)

P138 (2) SlipCompensation 0.0 to 10.0 0.0 % 97

P142 (2) (3) Maximum Output Voltage 0 to 100 100 % 98

P145 (2) (3) FieldWeakening P133 to P134 50.00Hzor Hz 98

Frequency(Fnom) 60.00 Hz

depending

on the

market

DC Link Voltage Regulation

P151 DCLinkVoltageRegulation 200 V models: 325 to 410 380 V 99

Level 400 V models: 564 to 820 780

Overload Current

P156 MotorOverloadCurrent 0.2xInom to 1.3xInom 1.2xP401 A 100

Current Limitation

P169 Maximum Output Current 0.2xInom to 2.0xInom 1.5xP295 A 101

Flux Control

P178 (1) Rated Flux 50.0 to 150 100 % 101

CONFIGURATION PARAMETERS - P200 to P398

Generic Parameters

P202 (3) ControlMode 0 = Linear V/F Control 0 - 102

(Scalar)

1 = Quadratic V/F Control

(Scalar)

2 = SensorlessVector Control

P203 (3) Special Function Selection 0 = No function 0 - 103

1 = PID Regulator

P204 (3) Load Factory Setting 0 to 4 = No Function 0 - 104

5 = Loads Factory Default

P205 DisplayDefault Selection 0 = P005 2 - 104

1 = P003

2 = P002

3 = P007

4, 5 = Not Used

6 = P040

P206 Auto-ResetTime 0 to 255 0 s 104

P208 ReferenceScaleFactor 0.00 to 99.9 1.00 - 104

P212 Frequency to Enable the Sleep 0.00 to P134 0.00 Hz 105

Mode

P213 Time Delayto Activate the 0.1 to 999 2.0 s 105

SleepMode

P215 (3) (4) Keypad Copy Function 0 = Not Used 0 - 106

1 = Copy(inverter keypad)

2 =Paste (keypadinverter)

P219 (3) Switching Frequency 0.00 to 25.00 6.00 Hz 107

Reduction Point

10

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

(**) Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

Local/Remote Definition

P220 (3) Local/Remote 0 = Always Local 2 - 108

Selection Source 1 = Always Remote

2 = HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:local)

3 = HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:remote)

4 = DI2 to DI4

5=SerialorHMI-CFW08-RS

Keypad (default: local)

6=SerialorHMI-CFW08-RS

Keypad(default:remote)

P221 (3) FrequencyLocalReference 0 = Keypad and 0 - 109

Selection 1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 =Add AI0

8 = Add AI

P222 (3) FrequencyRemoteReference 0 = Keypad and 1 - 109

Selection 1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 =Add AI0

8 = Add AI

P229 (3) LocalCommand Selection 0 = HMI-CFW08-P or 0 - 109

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P230 (3) RemoteCommandSelection 0 = HMI-CFW08-P or 1 - 109

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P231 (3) Forward/ReverseSelection 0 = Forward 2 - 110

- Local and Remote 1= Reverse

2 = Commands

3 = DIx

Analog Input (s)

P233 Analog Input DeadZone 0 = Inactive 1 - 110

1 =Active

P234 AnalogInputAI1Gain 0.00 to 9.99 1.00 - 111

P235 (3) (5) Analog InputAI1Function 0 = (0 to 10) V/(0 to 20) mA / 0 - 112

(-10 to +10) V(**)

1 = (4 to 20) mA

2 = DI5 PNP

3 = DI5 NPN

4=DI5 TTL

5 = PTC

11

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

P236 AnalogInputAI1Offset -999 to +999 0.0 % 113

P238 (6) AnalogInputAI2Gain 0.00 to 9.99 1.00 - 113

P239 (3)(5)(6) Analog InputAI2 Function 0 = (0 to 10) V/(0 to 20) mA/ 0 - 113

(-10 to +10) V(**)

1 = (4 to 20) mA

2 = DI6 PNP

3 = DI6 NPN

4=DI6 TTL

5 = PTC

P240 (6) AnalogInputAI2Offset -999 to +999 0.0 % 113

P248 Analog Inputs Filter 0 to 200 10 ms 113

TimeConstant

Analog Output

P251 (6) AnalogOutput 0 = Output Frequency (Fs) 0 - 114

AO Function 1 = Input Reference (Fe)

2 = Output Current (Is)

3, 5, 8 = Not Used

4 = Motor Torque

6 = Process Variable (PID)

7 =Active Current

9 = PID Setpoint

P252 (6) AnalogOutputAO Gain 0.00 to 9.99 1.00 - 114

P253 Analog OutputAO Signal 0 = (0 to 10) V/(0 to 20) mA 0 - 114

1 = (4 to 20) mA

Digital Inputs

P263 (3) Digital Input DI1 Function 0 = No Function or General 0 - 115

Enable

1 to 7 and 10 to 12 =

GeneralEnable

8 = Forward Run

9 = Start/Stop

13 = FWD Run Using

Ramp2

14 = On

P264 (3) Digital Input DI2 Function 0=Forward/Reverse 0 - 115

1 = Local/Remote

2 to 6 and 9 to 12 = Not Used

7 = Multispeed (MS2)

8= Reverse

13 = REV Run - Ramp 2

14 = Off

P265 (3) (7) Digital Input DI3 Function 0=Forward/Reverse 10 - 115

1 = Local/Remote

2 = General Enable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS1)

8 = No Function or

Start/Stop

9 = Start/Stop

10 = Reset

(**) Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

12

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

11, 12 = Not Used

13 = Flying Start Disable

14 = Multispeed (MS1)

UsingRamp2

15 = Manual/Automatic (PID)

16 = Increase E.P. with

Ramp2

P266 (3) Digital Input DI4 Function 0=Forward/Reverse 8 - 115

1 = Local/Remote

2 = General Enable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Multispeed (MS0)

8 = Not Used or

Start/Stop

9 = Start/Stop

10 = Reset

11, 12, 14and 15 = Not Used

13 = Flying Start Disable

16 = Decrease E.P. with

Ramp2

P267 (3) (5) Function of the Digital 0 = FWD/REV 11 - 115

Input DI5 (onlydisplayed 1 = Local/Remote

when P235 = 2, 3 or 4) 2 = General Enable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS2)

8 = No Function or Start/Stop

9 = Start/Stop

10 = Reset

11 and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Increase E.P. with

Ramp2

P268 (3) (5) (6) Function of the Digital 0 = FWD/REV 11 - 115

Input DI6 (onlydisplayed 1 = Local/Remote

when P239 = 2, 3 or 4) 2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Not Used

8 = No Function or Start/Stop

9 = Start/Stop

10 = Reset

11 and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Decrease E.P. with

Ramp2

13

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

(*) It is not possible to set P297 = 7 (15 kHz) in vector control mode (P202 = 2) or when the external serial keypad (HMI-CFW08-RS) is used.

According

to the

inverter

model

DigitalOutput(s)

P277 (3) RelayOutput RL1 Function 0 = Fs > Fx 7 - 120

1 = Fe > Fx

2 = Fs = Fe

3 = Is>Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

P279 (3) (6) RelayOutput RL2 Function 0 = Fs > Fx 0 - 120

1 = Fe > Fx

2 = Fs = Fe

3 = Is > Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

Fx and Ix

P288 Fx Frequency 0.00 to P134 3.00 Hz 122

P290 IxCurrent 0 to 1.5xInom 1.0xInom A 122

Inverter Data

P295 (3) RatedInverter 300 = 1.0 A - 122

Current(Inom) 301 = 1.6 A

302 = 2.6 A

303 = 2.7 A

304 = 4.0 A

305 = 4.3 A

306 = 6.5 A

307 = 7.0 A

308 = 7.3 A

309 = 10 A

310 = 13 A

311 = 16 A

P297 (3) Switching Frequency 4 = 5.0 4 kHz 122

5 = 2.5

6 = 10

7 = 15 (*)

DC Braking

P300 DCBrakingTime 0.0 to 15.0 0.0 s 124

P301 DC Braking Start Frequency 0.00 to 15.00 1.00 Hz 124

P302 DCBrakingCurrent 0.0 to 130 0.0 % 124

Skip Frequencies

P303 Skip Frequency 1 P133 to P134 20.00 Hz 125

P304 Skip Frequency 2 P133 to P134 30.00 Hz 125

P306 Skip BandRange 0.00 to 25.00 0.00 Hz 125

Serial Communication Interface I

P308 (3) InverterAddress 1 to 30 (Serial Wbus) 1 - 125

1to247(Modbus-RTU)

Flying Start and Ride-Through

P310 (3) Flying Start and Ride-Through 0 = Inactive 0 - 126

1 = Flying Start

2 = Flying Start and

Ride-Through

3=Ride-Through

312 = 22 A

313 = 24 A

314 = 28 A

315 = 30 A

316 = 33 A

14

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

P311 VoltageRamp 0.1 to 10.0 5.0 s 126

Serial Communication Interface II

P312 (3) SerialInterface Protocol 0 = Serial WBus 0 - 127

1 = Modbus-RTU 9600 bps

without parity

2 = Modbus-RTU 9600 bps

with odd parity

3 = Modbus-RTU 9600 bps

withevenparity

4 = Modbus-RTU 19200 bps

without parity

5 = Modbus-RTU 19200 bps

with odd parity

6 = Modbus-RTU 19200 bps

withevenparity

7 = Modbus-RTU 38400 bps

without parity

8 = Modbus-RTU 38400 bps

with odd parity

9 = Modbus-RTU 38400 bps

withevenparity

P313 Serial InterfaceWatchdog 0 = Disabling by ramp 2 - 127

Action 1 = General disable

2 = Shows only E28

3 = Goes to local mode

P314 SerialInterfaceWatchdog 0.0 = Disables the function 0.0 s 128

Timeout 0.1 to 99.9 = Setvalue

MOTOR PARAMETERS - P399 to P499

Rated Parameters

P399 (1) (3) Rated Motor Efficiency 50.0 to 99.9 % 128

P400(1) (3) RatedMotorVoltage 0 to 600 V 128

P401 Rated MotorCurrent 0.3xP295 to 1.3xP295 A 128

P402(1) RatedMotor Speed 0 to 9999 rpm 129

P403 (1) (3) Rated Motor Frequency 0.00 to P134 Hz 129

P404 (1) (3) RatedMotorPower 0 = 0.16 HP / 0.12 kW - 129

1 = 0.25 HP / 0.18 kW

2 = 0.33 HP / 0.25 kW

3 = 0.50 HP / 0.37 kW

4 = 0.75 HP / 0.55 kW

5 = 1 HP / 0.75 kW

6 = 1.5 HP / 1.1 kW

7 = 2 HP / 1.5 kW

8 = 3 HP / 2.2 kW

9 = 4 HP / 3.0 kW

10 = 5 HP / 3.7 kW

11 = 5.5 HP / 4.0 kW

12 = 6 HP / 4.5 kW

13 = 7.5 HP / 5.5 kW

14 = 10 HP / 7.5 kW

15 = 12.5 HP / 9.2 kW

16 = 15 HP / 11.2 kW

17 = 20 HP / 15.0 kW

According

to the

inverter

model

(motor

matched

to the

inverter-

referto

item 9.3)

and sales

market

15

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function Adjustable Range Factory Unit User Page

Setting Setting

Notes foundontheQuickParameterReference:

(1) This parameteris onlydisplayed in vector mode (P202 = 2).

(2) This parameter is only displayed in scalar mode P202 = 0 or 1.

(3) This parametercan bechanged onlywhenthe inverteris disabled(stopped motor).

(4) ThisparameterisonlyavailablewithHMI-CFW08-RS.

(5) Theanaloginputvalueisrepresentedbyzerowhenitisnotconnectedtoanexternalsignal.

In order to use an analog input as a digital input with NPN logic (P235 or P239 = 3), it is

necessary to connect a 10 kresistor from terminal 7 to 6 (AI1) or 8 (AI2) of the control

terminalstrip.

(6) ThisparameterisonlyavailableintheCFW-08Plusversion.

(7) TheparametervaluechangesautomaticallywhenP203=1.

P407 (3) RatedMotorPower 0.50 to 0.99 - 130

Factor

Measured Parameters

P408 (1) (3) RunSelf-Tuning 0 = No 0 - 130

1 = Yes

P409 (3) Motor Stator Resistance 0.00 to 99.99 130

SPECIAL FUNCTION - P500 to P599

PID Regulator

P520 PID ProportionalGain 0.000 to 7.999 1.000 - 138

P521 PIDIntegralGain 0.000 to 9.999 1.000 - 138

P522 PIDDifferentialGain 0.000 to 9.999 0.000 - 138

P525 Setpoint (Via Keypad) of the 0.00 to 100.0 0.00 % 138

PIDRegulator

P526 Process Variable Filter 0.01 to 10.00 0.10 s 138

P527 PIDAction 0 = Direct 0 - 138

1= Reverse

P528 ProcessVariable 0.00 to 99.9 1.00 - 139

Scale Factor

P535 Wake up Band 0.00 to 100.00 1.00 % 139

P536 Automatic Setting of P525 0 =Active 0 - 140

1 = Inactive

According to

theinverter

model

(referto

item 9.3)

According to

theinverter

model

16

CFW-08 - QUICK PARAMETER REFERENCE

Display Description Page

E00 Outputovercurrent/short-circuit/outputgroundfault 141

E01 DClinkovervoltage 141

E02 DClinkundervoltage 142

E04 Overtemperature at the power heatsink or in the 142

inverterinternalair

E05 Outputoverload(Ixt function) 142

E06 External fault 142

E08 CPUerror(Watchdog) 142

E09 Programmemoryerror(Checksum) 142

E10 Keypad copy function error 142

E14 Self-tuning routine(estimation of the motor 142

parameters)error

E22,E25, Serialcommunicationerror 142

E26 and E27

E24 Programmingerror 142

E28 Serial interfaceWatchdogtimeouterror 143

E31 Keypadconnectionfault (HMI-CFW08-RS) 143

E32 Motorovertemperature(externalPTC) 143

E41 Self-diagnosisfault 143

II.FaultMessages

III.OtherMessages Display Description

rdy Inverter is readyto be enabled

Sub Power supplyvoltage is too low for the inverter

operation(undervoltage)

dcbr InverterinDCbrakingmode

auto Inverterisrunningself-tuningroutine

copy Keypad copyfunction in progress (onlyavailable in

theHMI-CFW08-RS)-inverterto keypad

past Keypad copyfunction in progress (only available in

theHMI-CFW08-RS)-keypadto inverter

Srdy Inverter in the sleep rdymode

17

CHAPTER1

SAFETYNOTICES

This Manual contains necessary information for the correct

useoftheCFW-08frequencyinverter.

This Manual was developed for qualified personnel with

suitabletrainingandtechnicalqualificationtooperatethistype

ofequipment.

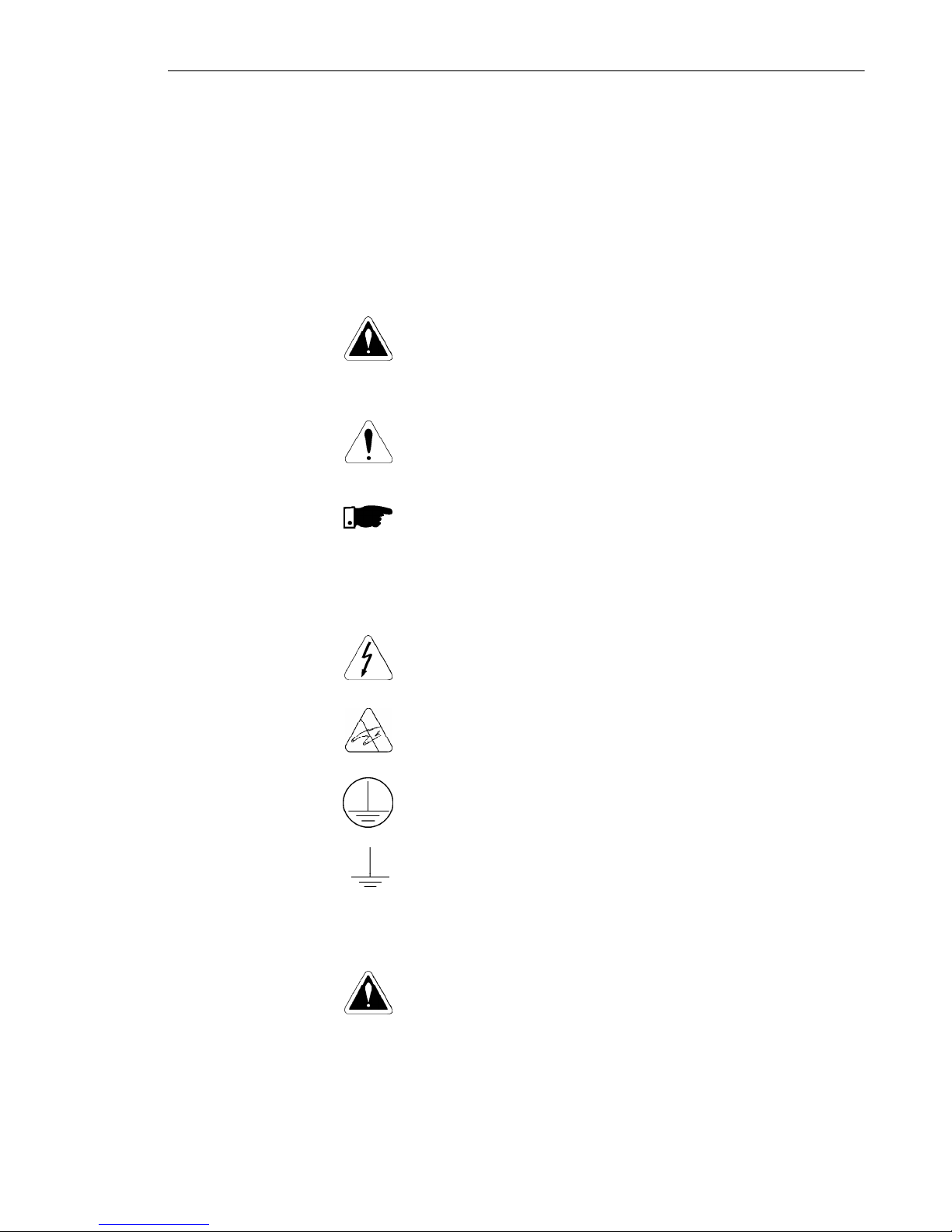

Thefollowingsafetynoticesareusedinthismanual:

DANGER!

Iftherecommendedsafetynoticesarenotstrictlyobserved,it

canleadtoseriousorfatalinjuriesofpersonneland/ormaterial

damage.

ATTENTION!

Failure to observetherecommended safetyprocedurescan

lead to material damage.

NOTE!

This notice provides important information for the proper

understandingandoperationoftheequipment.

Thefollowingsymbolsmaybeattachedtotheproduct,serving

assafetynotice:

High Voltages.

Componentssensitive to electrostaticdischarge. Do not

touch them without proper grounding procedures.

Mandatory connection to ground protection (PE).

Shield connection to ground.

DANGER!

Only qualified personnel should plan or implement the

installation, start- up, operation and maintenance of this

equipment. Personnel must review entire Manual before

attempting to install,operate ortroubleshoot the CFW-08.

Thesepersonnel mustfollowall safetyinstructionsincluded

in this manual and/ordefinedbylocal regulations.

Failure to comply with these instructions may result in

personnelinjuryand/orequipmentdamage.

1.3 PRELIMINARY

RECOMMENDATIONS

1.2 SAFETYNOTICES

ONTHEPRODUCT

1.1 SAFETYNOTICESIN

THEMANUAL

18

CHAPTER 1 - SAFETY NOTICES

NOTE!

Inthismanual,qualifiedpersonnelare definedaspeoplethatare

trainedto:

1. Install,ground,power upandoperatetheCFW-08according

tothismanual andthelocal requiredsafetyprocedures;

2. Useofsafetyequipmentaccordingtothelocalregulations;

3. Administer FirstAid.

DANGER!

Theinvertercontrol circuit(ECC3,DSP)andtheHMI-CFW08-P

arehigh voltagecircuitsand are not grounded.

DANGER!

Always disconnect the supply voltage before touching any

electricalcomponentinside theinverter.

Many components are charged with high voltage and/or in

movement(fans), even afterthe incomingAC powersupplyhas

beendisconnectedorswitchedOFF. Waitatleast10minutesfor

the total dischargeof the powercapacitors.

Alwaysconnecttheframeoftheequipmenttotheground (PE)at

thesuitableconnectionpoint.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Never touch any of the electrical

components or connectors without following proper grounding

procedures. If necessaryto do so, touch the properlygrounded

metallic frame oruse asuitable groundstrap.

NOTE!

Inverterscaninterferewithotherelectronicequipment.Inorderto

reduce this interference, adopt the measures recommended in

chapter3-InstallationandConnection.

NOTE!

ReadthisentiremanualbeforeinstallingoroperatingtheCFW-08.

Do not apply high voltage (high pot) test on the inverter!

If this test is necessary, contact Eliwell.

19

Thischapterdefinesthecontentsandpurposesofthismanu-

al and describes the main characteristics of the CFW-08

frequency inverter. Identification, receiving inspections and

storagerequirements are also provided.

This manualis divided into9 chapters, providinginformation

to the user on how receive, install, start-up and operate the

CFW-08.

Chapter 1 - Safetynotices.

Chapter 2 - GeneralinformationandreceivingtheCFW-08.

Chapter 3 - RFI filters,mechanical and electrical installation

(powerandcontrolcircuit).

Chapter 4 - Using the keypad (Human Machine Interface -

HMI).

Chapter 5 - Start-upand stepstofollow.

Chapter 6 - Setup and read only parameters detailed

description.

Chapter 7 - Solving problems, cleaning instructions and

preventivemaintenance.

Chapter 8 - CFW-08 optional devices description, technical

characteristicsandinstallation.

Chapter 9 - CFW-08ratings,tablesandtechnicalinformation.

This manual provides information for the correct use of the

CFW-08. This frequency inverter is very flexible and allows

the operation in many different modes as described in this

manual.

AstheCFW-08canbeappliedinseveralways,itisimpossible

todescribeherealloftheapplicationpossibilities.Eliwelldoes

not accept any responsibility when the CFW-08 is not used

accordingto this manual.

Nopartofthismanualmaybereproducedinanyform,without

thewrittenpermissionofEliwell.

It is important to note the software version installed in the

CFW-08,sinceitdefinesthefunctionsandtheprogramming

parameters of the inverter.

This manual refers to the software version indicated on the

insidecover.Forexample,theversion3.0Xappliestoversions

3.00 to 3.09, where “X” is a variable that will change due to

minor software revisions. The operation of the CFW-08 with

these software revisions are still covered by this version of

themanual.

The software version can beread in the parameterP023.

GENERALINFORMATION

2.1 ABOUTTHIS

MANUAL

2.2 SOFTWARE

VERSION

CHAPTER2

Other manuals for EWCFW-08

1

Table of contents

Other Eliwell DC Drive manuals

Popular DC Drive manuals by other brands

Siemens

Siemens SINAMICS SM150 6SL3815-7NP41-0AA1 Operating instructions & installation instructions

ABB

ABB ACS880 Series Supplement

Xinje

Xinje DP3F Series user manual

RHINO

RHINO RMCS-3002 operating manual

Unimotion

Unimotion MCE Assembly and maintenance instructions

SEW-Eurodrive

SEW-Eurodrive MOVIMOT D EtherNet/IP Compact manual