Eliwell V800 Series User manual

V800

/P1 /P2 /P3 /P4

Driver for electronic expansion valve

Driver per valvola espansione elettronica

Controlador para válvula de expansión electrónica

EN

IT

ES

2 - ENV800

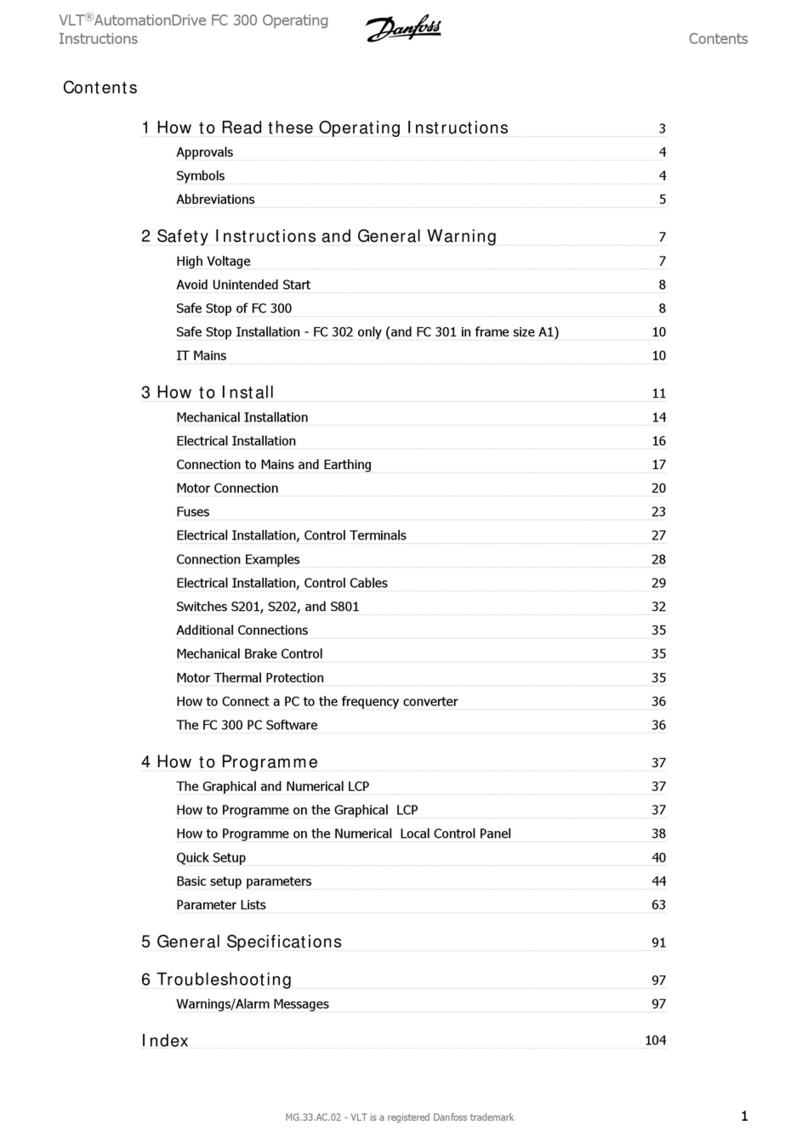

AVAILABLE MODELS, COMPONENTS & ACCESSORIES .......3-EN

COMPATIBLE VALVE LIST ................................................5-EN

MECHANICAL ASSEMBLY................................................6-EN

ELECTRICAL CONNECTIONS ..........................................7-EN

Wiring diagram description ...........................................7-EN

WIRING DIAGRAM............................................................9-EN

V800 with door open .........................10-EN

TECHNICAL DATA ...........................................................11-EN

CONDITIONS OF USE - PERMITTED USE ..................13-EN

PROHIBITED USE .............................................................13-EN

LIABILITY AND RESIDUAL RISKS .................................13-EN

USER INTERFACE .............................................................14-EN

IWK/V Keys ...........................................14-EN

LED Table ...............................................15-EN

DipSwitch Table ...................................15-EN

ACCESSING AND USING THE MENUS .......................17-EN

STATES MENU .................................................................17-EN

Setting the overheating Setpoint ....17-EN

Active alarm ..........................................17-EN

Probe display ........................................17-EN

USB COPY CARD .............................................................18-EN

USB Copy Card DipSwitch ................18-EN

USB Copy Card DipSwitch LED ........19-EN

SUPERVISION .................................................................19-EN

DipSwitch Protocol Selection...........20-EN

ALARMS ............................................................................21-EN

FUNCTIONING..................................................................24-EN

REGULATION.....................................................................25-EN

APPLICATIONS..................................................................26-EN

Stand-Alone ..........................................26-EN

Typical application ..............................26-EN

Application with multiple V800

drivers / ID985/V controllers ...........27-EN

Application with 2 V800 drivers -

1 ID985/V controller ..........................28-EN

PARAMETERS TABLE ......................................................29-EN

DISCLAIMER......................................................................33-EN

3 - EN V800

AVAILABLE MODELS, COMPONENTS & ACCESSORIES

Code Model Valve control RS485 Notes

EVD2A43BSC000 V800/P1 Imax = 300mA@230VaYes AC Output • on-board RS485

EVD2A43BXC000 V800/P2 Imax = 300mA@230VaNo AC Output

EVD2A53BSC000 V800/P3 Imax = 300mA@230VcYes DC Output • on-board RS485

EVD2A53BXC000 V800/P4 Imax = 300mA@230VcNo DC Output

Code Model Description Notes

ID34DR4SCDH00 ID985/V

Electronic controller for ventilated refrigeration units with V800 driver management via LAN

serial connection See 9MAX0017 manual

WK1400100N000 IWK/V Remote terminal for parameter conguration, I/O display, alarms etc. See 9IS60000 instructions

See User Interface

4 - ENV800

Code Model Description Notes

EVK2A43BXC010 Standard Kit

includes

1 x ID985/V

1 x V800/P2

SN8P0X3002 1 x NTC ‘FAST’

probe

TD400030 1 x ratiometric probe

EVK2A43BXC020 Starter Kit

includes

1 x ID985/V

1 x V800/P2

SN8P0X3002 1 x NTC ‘FAST’

probe

TD400030 1 x ratiometric probe

CCA0BUI02N000 1 x USB

Copy Card

DMP1000002000 1 x Device

Manager CD

1 x Device Manger interface

DMI100x002000 Device Manager

Interface USB/TTL hardware interface for use in conjunction with the Device Manager software

x=1: End User

x= 2: Service

x= 3: Manufacturer

5 - EN V800

COMPATIBLE VALVES LIST

Eliwell guarantees electrical compatibility with following PULSE valves

Brand Model Brand Model

Eliwell manufactured

by Castel PXV ALCO EX2

Danfoss AKV10 PARKER HP130

Danfoss AKV15 PARKER DS1120

Danfoss AKV20

Danfoss AKV20

Danfoss AKVA (NH3)

Note : V800 Driver delivers to the valve the same voltage as its own supply voltage

Select carefully the suitable valve coil depending on the local power distribution network

For use with different valves please contact Eliwell Technical Customer Support

MECHANICAL ASSEMBLY

The device is designed for mounting on DIN guides.

The admissible ambient temperature range for correct operation is between –10 and 55 °C.

Also avoid tting the device in places where there is high humidity and/or dirt; it is suitable for use in environ-

ments with an ordinary or normal level of pollution. Keep the area around the instrument cooling slots adequately

ventilated.

Access to dip switches and connector for USB Copy Card / IWK/V

Remove the door (see gure below right) using a slotted screwdriver or the nail of your index nger.

Congure the dip switches and/or connect the USB Copy Card or connect IWK/V.

After having made the congurations, close the front panel of the keypad by pressing it with your ngers.

ID 985/V

56.4mm

5.2mm

87mm

70.2mm

61.6mm

43.6mm

7 - EN V800

ELECTRICAL CONNECTIONS

Important! Make sure the machine is switched off before working on the electrical connections. The instru-

ment is equipped with screw-on terminal boards for connection of electrical cables with a diameter of 2.5 mm2

(one conductor only per terminal for power connections): for the capacity of the terminals, see the label on the

instrument. The relay outputs are voltage free. Do not exceed the maximum permitted current; for higher loads, use

a contactor with sufcient power capacity.

Make sure that power supply is of the correct voltage for the instrument. NTC probes have no connection polar-

ity and can be extended using a normal bipolar cable (note that if the probes are extended this inuences the

device's electromagnetic compatibility - EMC: take great care with the wiring). Probe cables, power supply cables

and serial cables should be routed separately from power cables. The pressure/ratiometric probe has a connection

polarity which must be observed.

Wiring diagram description

Terminal Label Description Notes Par. / Notes

2-3-4 RS485 Televis/Modbus serial port models /P1 /P3 only models /P1 /P3 only

6-7-8 DO1 Relay output (6= C; 7= NC; 8= NO) H21

9-10 Supply Power Supply 100...240Va (9= L; 10= N)

11-12 Valve Output Valve Output (11= VO; 12= VO) AC Valve Output models /P1 /P2

DC Valve Output models /P3 /P4

8 - ENV800

Terminal Label Description Notes Par. / Notes

14 DI1 Digital input 1 it is strictly prohibited

to connect the Digital

Input to a power source

H11, H30

15 DI2 Digital Input 2 H12, H30

16 DO2 Open Collector Output H22

17 GND Ground

18 AO1 Analogue Output repeat in 0-10V scale VO valve output (terminals 11-12)

19 AI1 Analogue Input 1 overheating probe H00 congurable NTC/4...20mA*

20 5VcProbes Power Supply **Power supply for ratiometric probe (terminal 21)

21 AI2 Analogue Input 2 saturation probe H01 congurable NTC/4...20mA*/0-5V (ratiomet-

ric)**/ LAn (remote, shared pressure transducer)

22 12VcProbes Power Supply *Power supply for 4...20mA current input (terminals 19/ 21)

23-24 LAN Powered serial port ID985/V connection

DMI/CC Serial port for connection to

• USB Copy Card / • IWK/V See DipSwitch

TTL Serial port for connection

to Televis / Modbus PtS, dEA, FAA, PtY, Ptb

9 - EN V800

DO1

V800

NONC

CVOVO

N

L

RS-485

/P1 /P3 Models

only

Supply

100...240Vac

Televis/

Modbus

(use BusAdapter)

Televis/

Modbus

(direct connection)

7 8

9 10 11 12

6

19 20 21 22 23 2418

-+

G

3 42

5VcAI1

AO1 GNDLAN

12Vc

AI2

15 16 1714

DO2DI2

DI1 GND

Valve Output

AC output /P1 /P2

DC output /P3 /P4

Check carefully

ON

12

ON

34

ON

56

ON

78

ON

910

DMI/CC

Keyb

A

B

C

20 21 22 23 24

12Vc

AI2

I

SIG +

20 21 22 23 24

5VcGND

AI2

V

SIG + -

NTC

4...20mA

ratiometric

0-5V

19 20 21 22 23 24

AI1 GND

AI2

15 16 1714

DI2

default configuration

DI1 GND

19 20 21 2218

12Vc

16 17

DO2

Open Collector

LOAD

max 35mA

I

SIG +

‘Stand-Alone’ mode alone

repeats

Valve Output

scale 0-10V

WIRING DIAGRAM

10 - ENV800

ON

12

ON

34

ON

56

ON

78

ON

910

TTL

A

B

CTTL

IWK/V rear

Supply from V800

1 2 3 4 5 6 7 8 9

+

14 15 16 17 18 19 20

A B C D

LAN

SUPPLY

100...240Va 2.5W max

TTL

LAN

GND

+-

-

12 13

ID985/V

+-

set

f nc

IWK/V

%T1 T2 ∆T

DO1

V800

NONC

CVOVO

N

L

RS-485

/P1 /P3 Models

only

Supply

7 8

9 10 11 12

6

19 20 21 22 23 2418

-+

G

3 42

5VcAI1

AO1 GNDLAN

12Vc

AI2

15 16 1714

DO2DI2

DI1 GND

Valve Output

ON

12

ON

34

ON

56

ON

78

ON

910

Keyb

A

B

C

CIRCUIT DIAGRAM - V800 with open door

USB Copy Card connection

• Display DipSwitch and use of DMI/CC

connector for USB/Copy Card

IWK/V / LAN connection

• Display DipSwitch and use of Keyb connector for IWK/V.

• Display LAN connection with ID985/V

11 - EN V800

TECHNICAL DATA

Container: PC+ABS UL94 V-0 plastic resin casing

Dimensions: front 70.2x87 mm, depth 61.6 mm

Mounting: on DIN guide

Terminals: screw-on for cables with a diameter of 2.5 mm2

Serials: • TTL (DMI/CC) for connection to USB Copy Card or IWK/V remote terminal.

• TTL for Televis / Modbus connection

models /P1 /P3 only: RS485 for direct connection to Televis / Modbus

LAN: for connection to powered 3-wire interface. Max. distance 100m

Temperature: • Operating: –10 … +55 °C

• Storage: –30 … +85 °C

Ambient operating and storage humidity: 10…90% RH (non-condensing).

Analogue inputs: 2 • 1 NTC congurable input / 4...20mA

• 1 NTC congurable input / 4...20mA / 0-5V / LAn (remote,shared pressure transducer)

Digital inputs: 2 2 congurable voltage-free inputs

Digital outputs: 2

• 1 SPDT relay: N.O. 5A 250Va, N.C. 2A 250Va

• 1 Open Collector, max current 35mA. Load shall be siupplied through 12V available

on terminal 22.

Analogue output: 1 output 0-10V max. load 20mA.

Resolution 0.1%; Accuracy 1% e.o.s.

Measurement range: from –55 to 140 °C.

Accuracy: better than 0.5% of full-scale +1 digit.

Resolution: 1 or 0.1 °C.

Power draw: 3 VA coil consumption excluded.

Power supply: 100...240Va ±10% 50/60 Hz

12 - ENV800

•

For each circuit, type of disconnection or interruption : disconnection microswitch

•

PTI of materials used for insulation : PTI 250V

•

Period of electrical stress on the insulating parts : long period

The device is classied as follows :

•

According to the manufacturing type : integrated temperature-sensitive automatic electronic control device

•

According to the automatic operation characteristics : action type 1B control device

•

Relating to software class and structure : Class A device

•

Relating to the pollution control : class 2 (normal) device

•

Relating to the re and heat resistance : category D

•

According to over voltage category : class II device

13 - EN V800

CONDITIONS OF USE - PERMITTED USE

For safety reasons, the device must be installed and used according to the instructions provided. In particular,

parts carrying dangerous voltages must not be accessible in normal conditions.

The device must be adequately protected from water and dust with regard to the application, and must only be

accessible using tools (with the exception of the front panel).

The device is suitable for use in household refrigeration appliances and/or similar equipment and has been tested

for safety aspects in accordance with the harmonised European reference standards. It is rated:

• according to its construction, as an independently mounted automatic electronic control device;

• in terms of automatic operating characteristics, as a type 1B controller;

• in terms of software class and structure, as a Class A controller.

PROHIBITED USE Any use other than that expressly permitted is prohibited.

Note that the relay contacts provided are of a functional type and subject to failure: any protection devices

required by product standards, or suggested by common sense for obvious safety requirements, must be installed

externally to the instrument.

LIABILITY AND RESIDUAL RISKS

ELIWELL CONTROLS SRL declines any liability for damage due to:

• installation/uses other than those expressly specied and, in particular, failure to comply with the safety require-

ments of established standards and/or instructions specied in this document;

• use on panels that do not provide adequate protection against electric shocks, water or dust when assembled;

• use on panels allowing access to dangerous parts without having to use tools;

• tampering with and/or modication of the product;

• installation/use on panels which are not compliant with current standards and regulations.

14 - ENV800

USER INTERFACE

To operate on V800 use a IWK/V remote terminal connected to the TTL connector (DMI/CC) and supplied directly

from V800.

Connect the cable supplied with the IWK/V to the connector housed inside the door on the front panel.

IWK/V Keys

Key Description Key Description

UP

Scrolls through menu items fnc fnc Exits the menu (ESC)

Increases values

Displays values:

• %: valve opening percentage

• DT: overheating

• T2: saturation temperature

• T1: overheating temperature

LED ON when the corresponding

value appears on the display set set

Displays alarms - if alarms active

DOWN

Scrolls through menu items Accesses menus

Decreases values press for at least 5 secs.

Opens the programming menu

Displays values - See UP key Conrms commands

15 - EN V800

LED Table

LED colour ON blinking OFF Notes

EEV (PXV) green valve control valve closed

setpoint reached /

EEV (PXV)

LED OFF

means no power supply

Defrost yellow defrost ON

(valve closed) /no serial

connection

/ Defrost

Alarm red NA Alarm / Alarm

DipSwitch Table

Dip1 2 3 4 5 6 7 8 9 10

Function Upload / Download parameters from Copy Card

Upload ON OFF /

Download OFF ON /

Protocol Protocol Selection

LAN OFF /

Televis*/Modbus

*Set Ptb parameter = 96 (96000 baud) ON /

16 - ENV800

Dip1 2 3 4 5 6 7 8 9 10

Refrigerant Refrigerant selection

0 R404A OFF OFF OFF /

1 R22 ON OFF OFF /

2 R410A OFF ON OFF /

3 R134A ON ON OFF /

4 R744 (CO

2

) OFF OFF ON /

5 R507A ON OFF ON /

6

refrigerant customisable via USB

Copy Card / Device Manager

Default setting R717(NH3)

OFF ON ON /

7 set from parameter H10 ON ON ON /

Slave address Network address selection

1 OFF OFF OFF /

2 ON OFF OFF /

3 OFF ON OFF /

4 ON ON OFF /

5 OFF OFF ON /

6 ON OFF ON /

7 reserved DO NOT use OFF ON ON /

8 reserved DO NOT use ON ON ON /

Note: Dip10 is NOT used

17 - EN V800

ACCESSING AND USING THE MENUS

Resources are organised into menus and viewed by briey tapping the ‘set’ key (‘Machine state’ menu) or by

keeping the ‘set’ key pressed for more than 5 seconds (‘Programming’ menu). Press the ‘set’ key once to view the

contents of any folder highlighted by the corresponding label.

At this point it will be possible to scroll through the contents of the folder and edit it or use the functions it con-

tains. Either do not press any keys for 15 seconds (time-out) or press the ‘fnc’ key once, to conrm the last value

displayed and return to the previous screen.

STATES MENU (SETPOINTS / PROBES / ALARMS)

To access the ‘States’ menu press and release the ‘set’ key.

If no alarms are active, the ‘SEt’ label appears. Use the ‘UP’ and ‘DOWN’ keys to scroll through the other resources

in the menu.

Setting the Overheating Setpoint

Press and release the ‘set’ key. The ‘SEt’ folder label appears. To display the Setpoint value press the ‘set’ key once

again. The Setpoint value appears on the display. To change the Setpoint value, press the ‘UP’ and ‘DOWN’ keys

within 15 seconds. If the parameter LOC = y the Setpoint cannot be modied.

Active alarm

Press and release the ‘set’ key. If there is an active alarm condition, the ‘AL’ folder label will appear (see ‘Alarms’

section).

Probe display

When the corresponding label is displayed, pressing ‘set’ displays the value of the probe on the associated label.

18 - ENV800

USB COPY CARD

The USB Copy Card is an accessory connected to the DMI/CC serial port and is used for quick programming of the

device parameters (upload and download a parameter map to one or more devices of the same type). The opera-

tions are performed as follows:

• insert USB Copy Card in the suitable connector with device ON

• set DipSwitch 1 and 2, which are housed inside the door, as described in the following table

• wjen completed remove the USB Copy Card

• set DipSwitch to OFF position

Dip Switch USB Copy Card

Upload / Download parameters from USB Copy Card

Function Dip1 2

Upload ON OFF

Download OFF ON

UPLOAD: device --> USB Copy Card This operation

uploads the programming parameters to the USB

Copy Card.

NOTE: USB Copy Card will be formatted before use

DOWNLOAD: USB Copy Card --> device This opera-

tion downloads the programming parameters to the

device.

19 - EN V800

USB Copy Card Dip Switch LED

LED UPLOAD DOWNLOAD

colour in progress completed correctly failed in progress completed correctly failed

A green blinking ON ON / / /

B green / / / blinking ON ON

C yellow / / blinking / / blinking

NOTE:

• after the parameters have been downloaded, the device uses the downloaded parameter map settings.

SUPERVISION

The protocol can be modied without using the IWK/V remote terminal by positioning DipSwitch 3, which is

housed inside the door, as described in the next page table:

LAN

The LAN function makes it possible to link up to 4 ID985/V devices connected to V800 in a network (see ID985/V

manual, code 9MAX0017). The maximum distance between one device and the other must not exceed 7 metres,

while the maximum distance between the rst and the last device in the network must be approximately 50m.

Televis/Modbus

The connection to TelevisSystem / Modbus RTU can take place:

• via TTL serial port. It is necessary to use the TTL/RS485 converter BusAdapter 130 or 150

• models /P1 /P3 only directly via RS485 serial port.

20 - ENV800

(To congure the device for this purpose, open the folder identied by the ‘Add’ label and use parameters:

• PtS to select the TelevisSystem / Modbus RTU protocol

• TelevisSystem: dEA and FAA.

• Modbus RTU: dEA / FAA / PtY for the parity / Ptb for the baud rate.

NOTE: the connection serial port between the devices is powered.

Dip Switch Protocol Selection

Protocol Selection LED C

Protocol 3 yellow

LAN OFF OFF

Televis/Modbus ON ON

LAN

DipSwitch3=OFF only for use with IWK/V

NOTE: TTL port shall NOT be connected to any

device

Televis/Modbus

DipSwitch3=ON per Televis/Modbus supervision or use

with DMI/CC

NOTA: IWK/V shall NOT be connected

This manual suits for next models

4

Table of contents

Languages:

Other Eliwell DC Drive manuals