Johnson Controls York AYK550 User manual

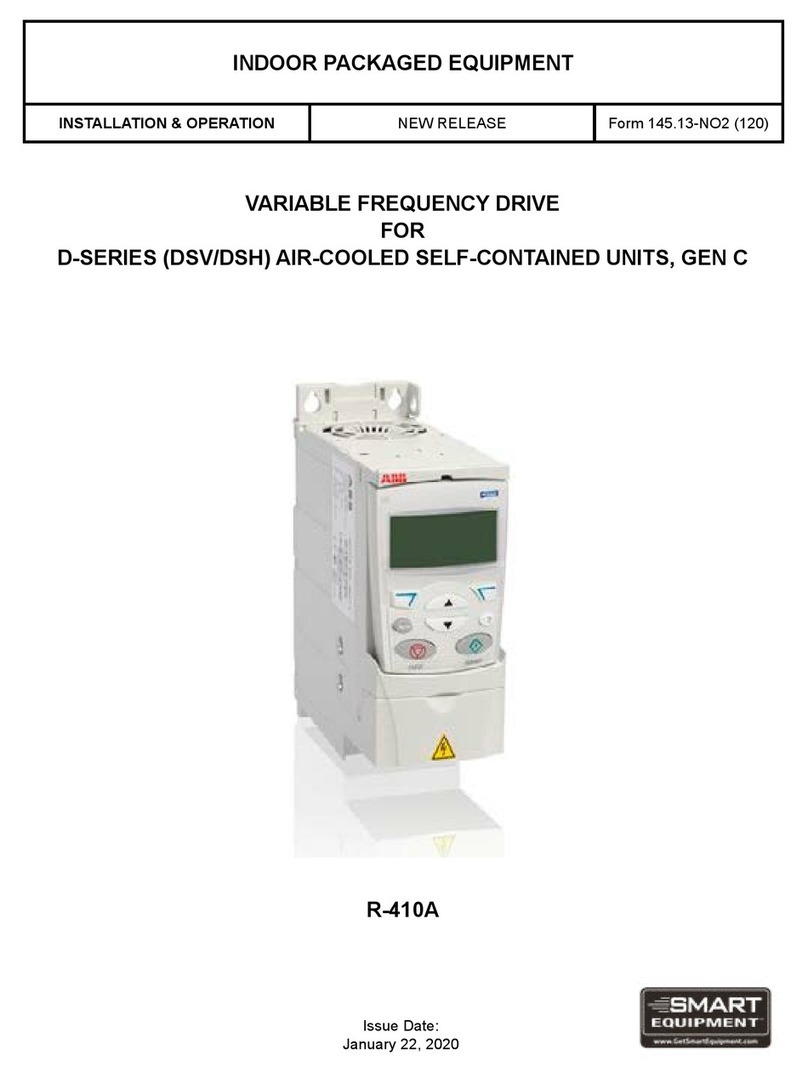

Other Johnson Controls DC Drive manuals

Johnson Controls

Johnson Controls VFD67 Series User manual

Johnson Controls

Johnson Controls Frick vyper VYA PG -46 User manual

Johnson Controls

Johnson Controls VFD66JCB-1 User manual

Johnson Controls

Johnson Controls YORK HYP1100A User manual

Johnson Controls

Johnson Controls Penn VFD68D Series Service manual

Johnson Controls

Johnson Controls VFD Series Guide

Johnson Controls

Johnson Controls VA-707 Series User manual

Johnson Controls

Johnson Controls VFD67 Series User manual

Johnson Controls

Johnson Controls VFD67 Series User manual

Johnson Controls

Johnson Controls VFD66 Series User manual

Johnson Controls

Johnson Controls VSD II Series User manual

Johnson Controls

Johnson Controls VSD Series User manual

Johnson Controls

Johnson Controls VSD II Series Installation and operating instructions

Johnson Controls

Johnson Controls PENN VFD68 User manual

Johnson Controls

Johnson Controls VFD-2DS-234HE-2 Guide

Johnson Controls

Johnson Controls PENN VFD68 User manual