Yokogawa Electric Corporation - TC10 - ENGINEERING MANUAL - PAG. 8

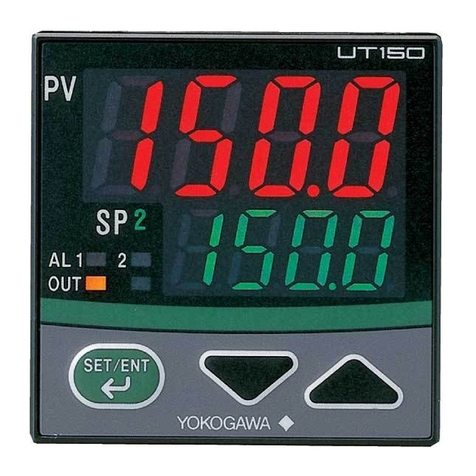

5.3.2 Complete configuration procedure

The configuration parameters are collected in various

groups. Every group defines all parameters related with a

specific function (e.g.: control, alarms, output functions).

1. Push the button for more than 3 seconds. The upper

display will show PASS while the lower display will show 0.

2. Using and buttons set the programmed password.

Notes: 1. The factory default password for configuration

parameters is equal to 30.

2. During parameter modification the instrument

continue to perform the control.

In certain conditions, when a configuration chan-

ge can produce a heavy bump to the process, it is

advisable to temporarily stop the controller from

controlling during the programming procedure

(control output will be OFF).

Apasswordequalto2000+theprogrammed

value(e.g.2000+30=2030).

The control will restart automatically when the

configuration procedure will be manually closed.

Push the button

If the password is correct the display will show the acronym

of the first parameter group preceded by the symbol: ]

.

In other words the upper display will show: ]inp

(group of the Input parameters).

The instrument is in configuration mode.

5.4 HOW TO EXIT THE “CONFIGURATION

MODE”

Push button for more than 3 seconds, the instrument will

come back to the “standard display”.

5.5 KEYBOARD FUNCTIONS DURING

PARAMETER CHANGING

A short press allows to exit from the current parameter

group and select a new parameter group.

A long press allows you to close the configuration

parameter procedure (the instrument will come back

to the “standard display”).

When the upper display is showing a group and the

lower display is blank, this key allows to enter in the

selected group.

When the upper display is showing a parameter and

the lower display is showing its value, this key allows

to store the selected value for the current parameter

and access the next parameter within the same group.

Allows to increase the value of the selected parameter.

Allows to decrease the value of the selected parameter.

+ These two keys allow to return to the previous

group. Proceed as follows:

Push the button and maintaining the pressure,

then push the button; release both the buttons.

Note: The group selection is cyclic as well as the selection

of the parameters in a group.

5.6 FACTORY RESET - DEFAULT

PARAMETERS LOADING PROCEDURE

Sometime, e.g. when you re-configure an instrument

previously used for other works or from other people or when

you have made too many errors during configuration and

you decided to re-configure the instrument, it is possible to

restore the factory configuration.

This action allows to put the instrument in a defined

condition (the same it was at the first power ON).

The default data are those typical values loaded in the

instrument prior to ship it from factory.

To load the factory default parameter set, proceed as follows:

1. Press the button for more than 5 seconds. The upper

display will show PASS while the lower display shows 0;

2. Using and buttons set the value -481;

3. Push button;

4. The instrument will turn OFF all LEDs for a few seconds,

then the upper display will show dFLt (default) and then

all LEDs are turned ON for 2 seconds. At this point the

instrument restarts as for a new power ON.

The procedure is complete.

Note: The complete list of the default parameters is available

in Appendix A.

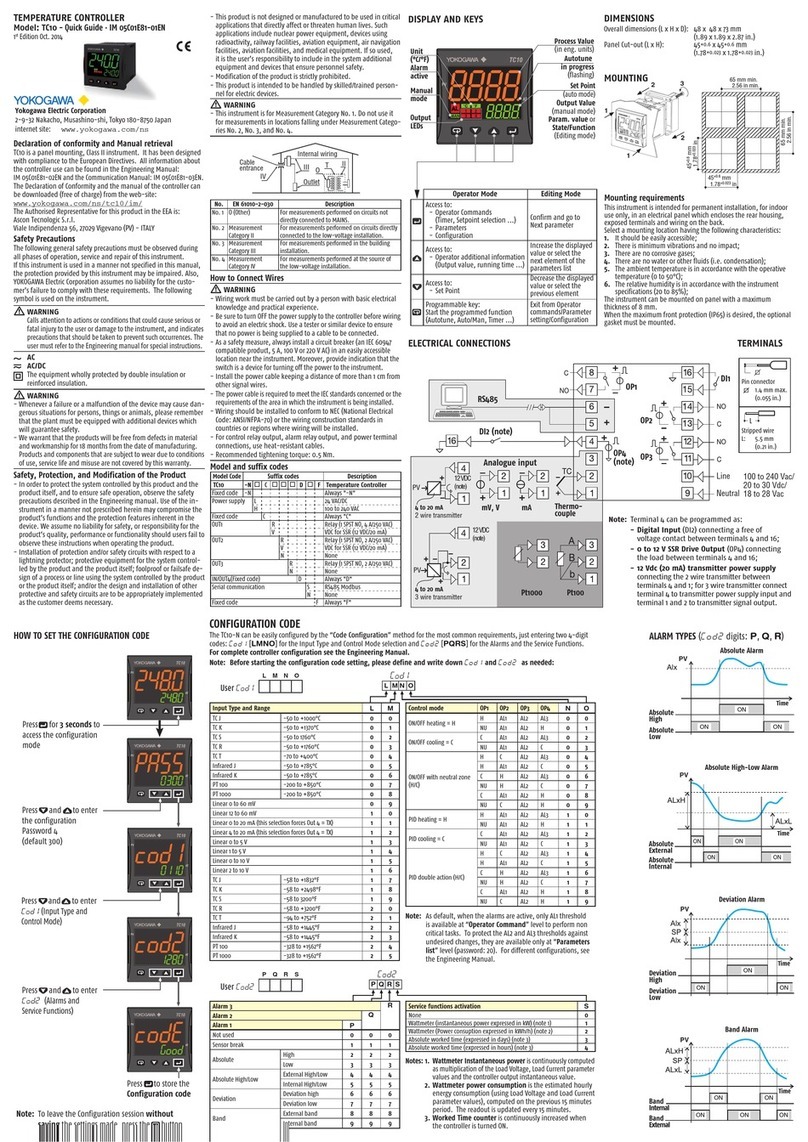

5.7 CONFIGURING ALL THE PARAMETERS

In the following pages we will describe all the parameters of

the instrument. However, the instrument will only show the

parameters applicable to its hardware options in accordance

with the specific instrument configuration (i.e. setting AL1t

[Alarm1type]tononE[notused],allparametersrelatedto

alarm 1 will be skipped).

]inP Group - Main and auxiliary input configuration

[1] SEnS - Input type

Available: Always

Range: J = TC J

crAL = TC K

S = TC S

r = TC R

t = TC T

Pt1 = RTD Pt 100

Pt10 = RTD Pt 1000

0.60 = 0 to 60 mV linear

12.60 = 12 to 60 mV linear

0.20 = 0 to 20 mA linear

4.20 = 4 to 20 mA linear

0.5 = 0 to 5 V linear

1.5 = 1 to 5 V linear

0.10 = 0 to 10 V linear

2.10 = 2 to 10 V linear

Notes: 1. When a TC input is selected and a decimal figure

is programmed (see the next parameter) the max.

displayed value becomes 999.9°C or 999.9°F.

2. Every change of the SEnS parameter setting

willforcethe[2]dP=0anditwillchangeall

parameters related with dP (e.g. set points,

proportional band, etc.).