ELKHART BRASS EB-500-X User manual

EB# 98601000 REV REL

1

DIGITAL

FLOWMETER

FRC Document Number:

XE-FTD100LPM-R0A

Elkhart Brass Mfg. Co., Inc.

www.elkhartbrass.com

1302 W. Beardsly Ave., Elkhart, IN 46514

TEL 1-574-295-8330 TOLL FREE 1-800-346-0250

MODEL EB-500-XD

REV. 18DEC14

EB# 98601000 REV REL

2

QUICK START

1. Charge the BATTERY:

Plug in the external power supply cable to the meter and lock it with a ¼ turn

clockwise, and then plug the supply into a suitable wall outlet. Press and release

ON/OFF to turn on the display. TheAMBER charging indicator will turn GREEN

when fully charged, after a maximum of 2 ½ hours (or sooner, depending on the

status of the battery charging level). The meter will charge the internal battery,

even if the unit is turned OFF.

2. Measure the FLOW:

Maketightupstreamanddownstreamconnections,observingtheblueow

directionarrowonthemeter.TurnthemeterONandreadthevolumeowrate

on the display, in the units which the meter was calibrated (GPM or LPM).

3. Measure the TOTAL:

PressandreleaseTOTALtoseethetotalow(x100)sincelastreset.Pressand

hold TOTAL to manually reset it to zero; or simply press and release TOTAL to

returntothecurrentow.Themetermayalsobeprogrammedtoautomatically

reset to zero every time it is turned ON.

Typically, the unit may be used for 10 hours. The blue LOW BATT indicator

will light when the battery becomes depleted and needs a recharge. When

deeply depleted, the unit will not function until the power supply is connected,

but then can be used immediately.

The EB-500-XD is a precision instrument that has been designed to be simple

to operate. For complete details on the Specications, Operation, Features,

Programming, Calibration and Flowmeter Charging, read through each section

of this manual.

EB# 98601000 REV REL

3

CONTENTS

Table of Contents

QUICK START........................................................................................................... 2

CONTENTS................................................................................................................ 3

INTRODUCTION ...................................................................................................... 5

Overview................................................................................................................ 5

Features.................................................................................................................. 5

Specications......................................................................................................... 6

GENERAL DESCRIPTION ....................................................................................... 7

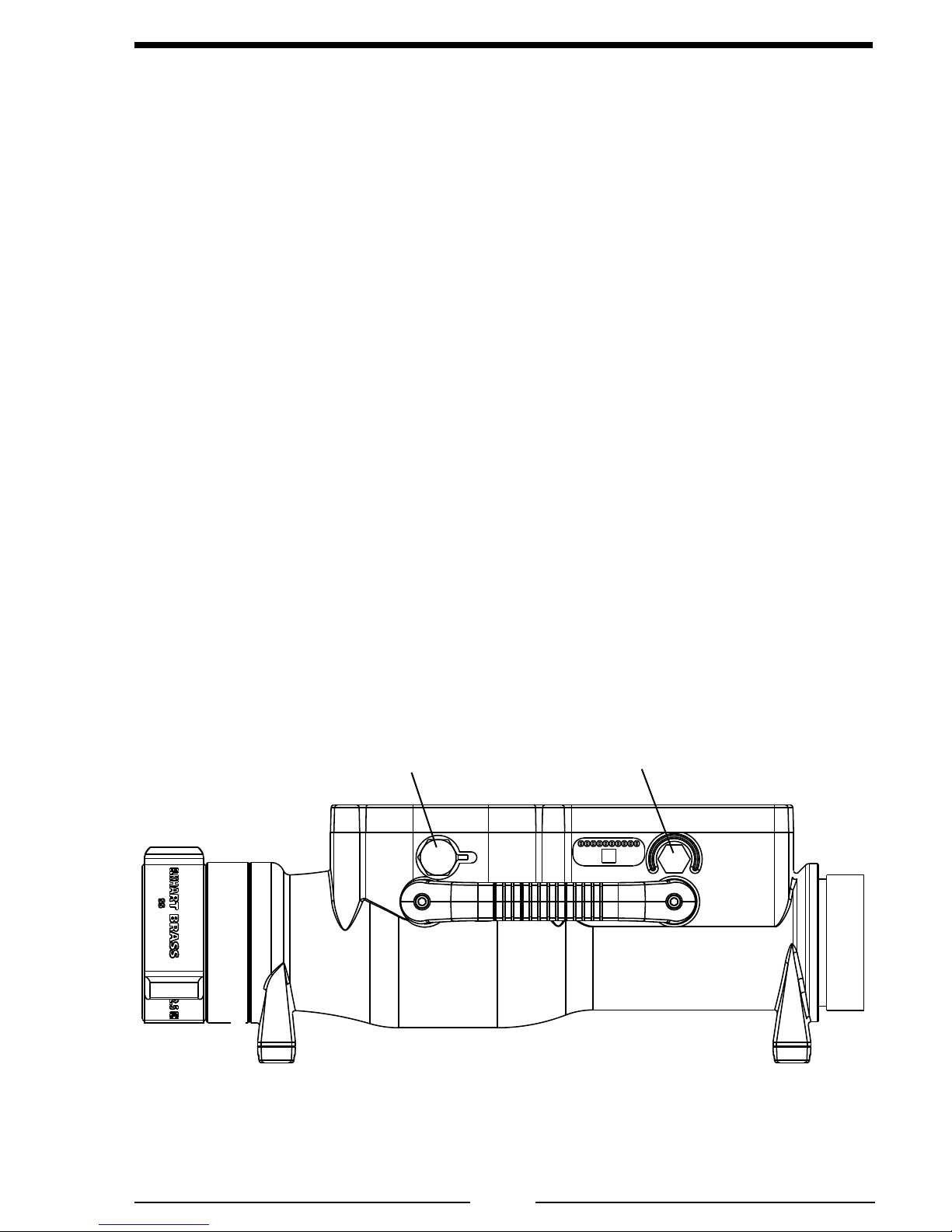

Components ........................................................................................................... 7

OPERATION .............................................................................................................. 8

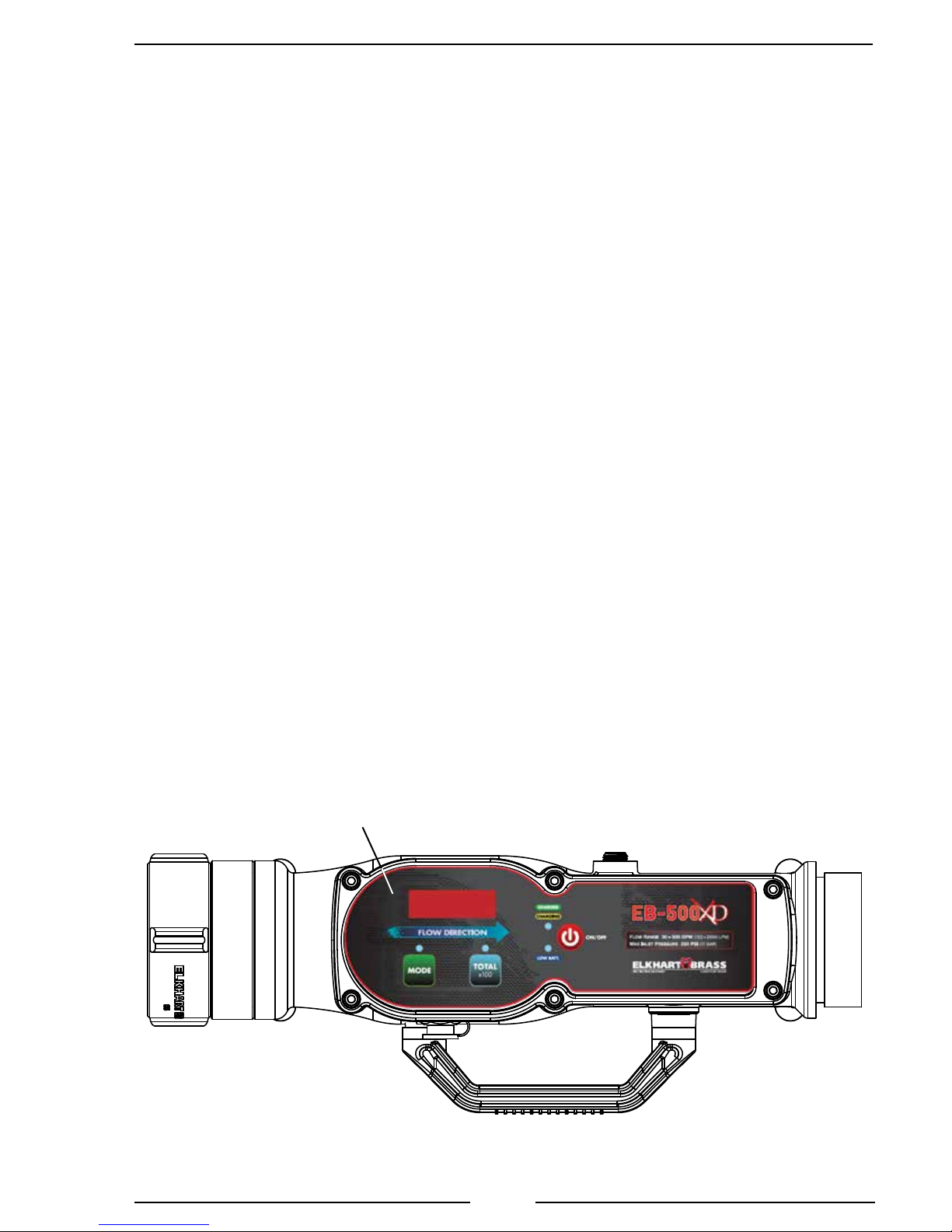

Controls and Indicators.......................................................................................... 9

Program Features ................................................................................................. 10

TOTAL Button..................................................................................................... 10

PROGRAMMING .................................................................................................... 11

Inputs ................................................................................................................... 11

DisplayModuleIdenticationMode................................................................... 11

Program Access Mode ......................................................................................... 12

Program Code Descriptions................................................................................. 14

CALIBRATION........................................................................................................ 17

Flow Calibration, Single Point (Code 321) ......................................................... 17

Flow Calibration, Multiple Point (Code 322)...................................................... 18

FLOWMETER CHARGING.................................................................................... 19

EB# 98601000 REV REL

4

List of Tables

Table 1. Program Code Quick Reference ................................................................ 13

List of Figures

Figure 1. Components................................................................................................ 7

Figure 2. Controls and Indicators............................................................................... 9

Figure 3. Charging ................................................................................................... 19

EB# 98601000 REV REL

5

INTRODUCTION

Overview

Thedigitalowmeterhasa4-digitLEDdisplaywithdaylightbrightdigits0.56

inch high. The meter electronics are self-contained and all program features are accessed

via pushbutton switches on the front of the display.

Theportable500GPMowmeterwasdesignedtoconnecttothereapparatusin

theeld,andthisallowsforexibilityintestingapplications.Thisowmeterdisplays

owratesandthetotalizationofow.Flowrateinformationisprovidedbyapaddlewheel

typeowsensor,whichishousedinternally.Thisinformationisprocessedandshown

on the digital display.

Additionally, in the identication mode, the display shows the serial number,

manufactured date and software revision. In the program access mode, the display

shows program options and operator input selections. Selections are made using two

pushbutton switches on the front of the display module. The device also has all controls

and indicators on the front: including the battery charging status, ON/OFF pushbutton,

Low Battery Indicator, MODE, TOTAL buttons and TOTAL indicator.

Features

LED Display Brightness Automatically Adjusts for Lighting Environment

Single Point and Multiple Point Flow Rate Calibration

Pressure Port for Optional External Gauge (Not Provided)

Threads - 2.5"NH (Standard). Others available upon request.

Integrated, Rechargeable NiMH Battery with Low Battery Indicator

Quick Charge High Capacity Battery

Totalizer Flow Function with Programmable Auto-Reset

Programmable High and Low Flow Warnings

Charging LED Indicator

Portable for Easy Transport (Balanced Weight for Stability)

Unit can be Tilted forward onto the Handle for Easy Angled Viewing

Waterproof, Durable and Rugged for Tough Applications

EB# 98601000 REV REL

6

Specications

Display Module

Supply Voltage: 12 to 29VDC

External Current: 2 Amps Maximum @ 15 VDC; 30 Watts

Universal Input: 15V Power Supply (Provided)

(Optional Methods of Charging Available)

Dimensions:

Length 16 3/8"

Width 6"

Height 5 7/8"

Weight 8.40 lbs.

Flow Sensor (Integral)

Type: Paddlewheel

Sensor Material: Acetal (Delrin) with Stainless Steel (316) Shaft

Flow Range: 30–500 GPM (120–2000 LPM)

Pressure (Maximum): 250 PSI (17 BAR)

Battery (Integral)

Type: NiMH

Number of Cells: 6 Series

Voltage: 7.2 Nominal

Features: Current Monitoring

Thermal Monitoring

Input Voltage Monitoring

Input Surge Suppression Monitoring

Run Time: Up to 10 hours possible

Recharge Time: 2.5 hours fast-charge (typical)

EB# 98601000 REV REL

7

GENERAL DESCRIPTION

Components

Thebasicowmeterkitconsistsofthefollowingcomponents:

EB-500-XD Flowmeter (2.5" NH)

Charging Wall Power Supply

Protective Case

EB-500-XD Operator's Manual

Additional Kits and Options are Available

Portable Flowmeter

Thisrugged,portableowmeteriswaterproofandwasdesignedtobeintuitive,easy

tooperateandhaveunsurpassedaccuracy.Properplacementoftheowmeterisessential

for accuracy and there should not be any elbows, tees or valves immediately upstream.

Charging Methods

Forchargingand/oroperationoftheowmeter,awalloutlettransformerwith

cable is supplied.

NOTE:Theowmetermaybeusedwhilepluggedinandcharging.Optionalcar

charger available.

Figure 1. Components

Charging Port

(12/24 VDC) Vent

Side View

EB# 98601000 REV REL

8

OPERATION

Onpower-uptheowmeterisinnormaloperatingmode.Informationfromapaddlewheel

typeowsensorisprocessedanddisplayed.

TheEB-500-XDportableowmeterissimpleandintuitivetooperate.Thefollowing

steps will be useful for general operation, and are only examples of how it may be used

(not exact scenarios).

1. Make tight upstream and downstream connections to the coupling and threaded

ends. Observe the blue arrow in the FLOW Display for direction.

2. Press and release the ON/OFF button to activate the unit. The display will

lightupshowingtheowrate.

3. Press and release the TOTAL button to see the totalized amount that has been

owed.TheTOTAL LED will be lit.

4. Press and hold the TOTAL button to manually reset the display to read “0”

(zero). Alternatively, upon powering on, the unit can restore the last value, or

be programmed to reset to zero.

5. Observe the LOW BATT (low battery) indicator. When the battery is low, this

LED will illuminate to indicate that the unit should be plugged into an external

power source.

6. Plug in an external power source to the unit. It can be operated normally and

will simultaneously charge the battery. The AMBER CHARGING indicator

will indicate that the battery is accepting power from the external power source.

7. The CHARGING indicator LED light automatically changes color from

AMBERtoGREENtoindicatethattheowmeterhascompleteditscharging

cycle, and the power source may be removed. If the power source is left

connected,theowmeterwillkeepthebatteryatfullcapacityautomatically.

8. Theowmeterwillcontinuetochargeandmaintainthebattery,evenifthe

power is OFF and all LEDs are off. To check the battery status, simply turn

the unit on with the ON/OFF pushbutton.

9. Theowmeterisaprecisioninstrument.Itishighlyrecommendedtogently

ushtheunitwithcleanwaterpriortostorage.Avoidrotatingthepaddlewheel

at rapid speeds, as this will cause inaccurate readings, or even permanently

damage the sensor. (Do not use compressed air.)

EB# 98601000 REV REL

9

Figure 2. Controls and Indicators

Controls and Indicators

Refer to Figure 2 below for a diagram showing the pushbuttons and LED indicators

ontheowmeter.

ON/OFF Button

Pressandreleasethispushbuttontoturntheowmeteronoroff.

Display

Duringnormaloperationthe4-digitLEDdisplayindicatesowrate.Whenthe

displaymoduleidenticationorprogramaccessmodesareselected,modulespecic

information, program codes, and settings are displayed. (Refer to Programming Section

for more information.)

MODE Button

The MODEbuttonaccessestheidenticationmode.ItisusedwiththeTOTAL

button to input data when in the program access mode. (Refer to Programming Section

for more information.)

TOTAL Button

The TOTALbuttonallowstheoperatortodisplaytotalowforadischarge.When

the button is pressed, the value shown in the digital display, times 100, is the total

ow.ItisusedwiththeMODE button to input data when in the program access mode.

(Refer to Programming Section for more information.)

TOTAL x 100 LED

This green LED above the TOTAL button is on to indicate that the displayed value

times100equalsthetotalaccumulatedow.

Display

EB# 98601000 REV REL

10

Program Features

See Programming Section for more detailed information.

High and Low Flow Warning (Codes 315 and 316)

Whentheowrateisabovetheprogrammedhighowvalue,aashing-HI-is

showninthedigitaldisplay.Whentheowrateisbelowtheprogrammedlowow

value,aashing-LO-isshowninthedigitaldisplay.Thetypicalsettingis30-500GPM

(120-2000 LPM).

Flow Cutoff (Codes 318 or 319)

Thedigitaldisplayindicates0whentheowrateisbelowtheprogrammedow

cutoff value.

TOTAL Button

The TOTALbuttonperformstwofunctions,displaytotalowforadischargeor

resetthetotalizedowvalueto0(iftotalizerresetfunctionissettoYES).

Display Total Flow

When the TOTAL button is pressed and released the digital display shows the

totalaccumulatedowandtheTOTALx100 LED is on. (Multiply the value show in

the display by 100.)

Press and release the TOTALbuttonagaintoshowcurrentowrate.

Flowtotalisresetto0duringoperationsbydisplayingthetotalowandthen

pressing and holding the TOTAL button until the display shows 0.

Reset Total Flow to 0

Bydefault,TotalFlowisrestoredwhenpowerisappliedtotheowmeter.Also,

it can automatically reset to 0 upon power up. (Refer to Programming Section).

EB# 98601000 REV REL

11

PROGRAMMING

The program access mode is selected and inputs are made using the two pushbutton

switches on the front of the display module. The digital display shows stored data and

operator inputs. (Refer to Figure 1.)

Note: When entering codes in the program access mode there is a time-out

feature that requires an operator input every three seconds. If an input is

notdetectedwithinvesecondstheprogramreturnstonormaloperation.

Inputs

The two pushbutton switches on the front of the display module allows the operator

access to stored data and program functions.

Both the MODE and TOTAL buttons are used to enter program codes.

Once a program code is entered, the MODE button selects the digit to change and

the TOTAL button changes the digit or option choice.

Display Module Identication Mode

Wheninthemoduleidenticationmode,thedigitaldisplayshowsthemodule

serial number, manufactured date, software revision, function code, and ID number.

Themoduleidenticationmodeisadisplay-onlymodeandnochangescanbemade

to program information.

Note: There is a time-out feature that returns the program to normal operation

invesecondsifinputisnotdetected.

Select Display Module Identication Mode

Turn on power. Press and hold the MODE button, then press the TOTAL button

andreleaseboth.Theprogramentersthedisplaymoduleidenticationmodeandthe

display shows the module serial number. Press the MODE button a second time and

the display shows the manufacturing date. Each time the MODE button is pressed the

displayshowsthenextblockofstoredidenticationdata.

NOTE:Ifthebuttonisnotpressedforvesecondstheprogramrevertsto

normal operation.

EB# 98601000 REV REL

12

Program Access Mode

To gain access to the program features a three-digit program code must be entered.

Review the Program Code Descriptions or refer to Table 1. Program Code Quick

Reference for the proper three-digit code.

Note: There is a time-out feature that returns the program to normal operation

invesecondsifinputisnotdetected.

Select Program Access Mode

Turn on power. Press the MODE button and hold it until the display shows four

dashes. The program is ready for a three-digit program code to be entered.

Enter Program Code

Note: There is a time-out feature that returns the program to normal operation

invesecondsifinputisnotdetected.

1. Select the Program Access Mode (four dashes are shown in the display).

2. Press the MODEbutton.Thenumber100showsinthedisplaywiththerst

digit(1)ashing.EachtimetheMODE button is pressed the number increments

by1.Settherstdigittothedesirednumber.

3. Press the TOTALbutton.Theseconddigitashes.EachtimetheTOTAL button

is pressed the number increments by 1. Set the second digit to the desired number.

4. Press the MODEbutton.Thethirddigitashes.EachtimetheMODE button is

pressed the number increments by 1. Set the third digit to the desired number.

When a valid three-digit program code is entered, a program value or an option

shows in the display. If an invalid code is entered an error code shows in the display.

Note: When a valid code has been entered and a program value or an option

shows in the display, the time-out feature is disabled.

Change Values or Options

Press the MODEbuttontoselectthedigittobechange.Thedigitashes.Press

the TOTAL button to change the digit or the option choice.

Exit Program Access Mode

Press and hold the MODE button and then press the TOTAL button and hold them

until the display shows four dashes. Release the buttons and enter a new code, or after

vesecondstheprogramtimesoutandreturnstonormaloperation.

EB# 98601000 REV REL

13

CODE FEATURE OPTION

311 Flow Rate Increment Set Point 0000 to 9999

315 High Flow Warning 0001 to 9999

0 = Disabled

316 Low Flow Warning 0001 to 9999

0 = Disabled

317 Totalizer Reset Yes=Resetsto0atPowerOn

No = Stores Total Flow at Power Off

318* Flow Cutoff (Frequency) 0 to 99.9 Hz

319* Flow Cutoff (Flow Rate) 0 to 999

321 Flow Calibration (Single Point) 1 Calibration Point

322 Flow Calibration (Multiple Point) 9 Calibration Points

E202 Invalid Program Code Entered Re-Enter Code

E204 No Flow Sensor Signal Check Water Flow

E206 Invalid Calibration Point Select Different Calibration Point

E210 Exceeded Maximum Calibration

Points

Exit Calibration Procedure

Table 1. Program Code Quick Reference

Notes:

- Refer to Program Code Descriptions for detailed information.

- The time-out feature returns the program to normal operation in ve

seconds if input is not detected.

- When a valid code has been entered and a programed value or option is

shown in the display, the time-out feature is disabled.

* Code 318 is valid when the code 319 is set to 0. When a value is set for

code 319, code 318 is ignored.

EB# 98601000 REV REL

14

Program Code Descriptions

When a valid three-digit program code has been entered, a program value or option

shows in the display. The MODE and TOTAL buttons are used change the data.

Press the MODEbuttontoselectthedigittobechange.Thedigitashes.Press

the TOTAL button to change the digit or the option choice.

Code 311 Flow Rate Increment Set Point

Factory programmed value: 500 GPM

Options: 0000 to 9999

This code sets where the digital display changes from increments of 1 to increments

of10.Thedisplayvaluesincrementby1atowratesbelowthesetpointandby10at

owratesabovethesetpoint.Thiscodedoesnotimpactowwarnings,owcutoff

settings,orowratedisplaywheninthecalibrationprogram.

Code 315 High Flow Warning

Factory programmed value: Default – 500 GPM

Options: 0001 to 9999

This code sets the high ow warning. When the ow rate is above the high

ow warning programmed value, the ow display alternately ashes the ow rate

and -HI-.

Code 316 Low Flow Warning

Factory programmed value: Default – 30 GPM

Options: 0001 to 9999

Thiscodesetsthelowowwarning.Whentheowrateisbelowthelowow

warningprogrammedvalue,theowdisplayalternatelyashesbetweentheowrate

and -LO- .

Code 317 Totalizer Reset

Factory programmed value: NO

Options: YES,no

Thiscodetogglestheowtotalizerresetfunctiononandoff.Thetotalizerreset

functionhastwoprogramsettings;YESandno.Fortheresetfunctiontoworkthe

totalizerresetissettoYES.Flowtotalisresetandstartsfrom0whenpowerisapplied.

Flow total is reset to 0 when the TOTAL button is pressed and held. When the totalizer

resetissettono,theowtotalcontinuestoaccumulateanddoesnotresetto0even

when power is removed.

EB# 98601000 REV REL

15

Code 318 Flow Cutoff (Frequency)

Factory programmed value: 0

Options: 0 to 99.9 Hz

This code sets a cutoff frequency for the ow sensor. There is always some

turbulenceinthe pipethatcouldcausethe owsensor toturn whenthedischarge

isclosed.Thiscancausethedisplaytoshowaowratewhenthereisnoow.The

frequencycutoffissetsothatthedisplayshows0owwhentheowsensorsignalis

below the programmed value.

Note: Code 318 is valid when the code 319 is set to 0. When a value is set

for code 319, code 318 is ignored.

Code 319 Flow Cutoff (Flow Rate)

Factory programmed value: F 0

Options: 0 to 999

Thiscodesetsacutoffowratefortheowsensor.Thereisalwayssometurbulence

inthepipethatcouldcausetheowsensortoturnwhenthedischargeisclosed.This

cancausethedisplaytoshowaowratewhenthereisnoow.Theowratecutoff

issetsothattheowdisplayshows0owwhentheowsensorsignalisbelowthe

programmed value.

Code 321 Flow Calibration (Single Point)

Options: 1 Calibration Point

Thiscodestartsthecalibrationprogramforasingleowrate.

Refer to Calibration Section.

Code 322 Flow Calibration (Multiple Point)

Options: 9 Calibration Points

Thiscodestarts thecalibrationprogramformultiple owrates. Itcorrectsfor

nonlinearowtoprovideanaccurateowratedisplay.

Refer to Calibration Section.

EB# 98601000 REV REL

16

Error Code E202

An invalid program code has been entered. Re-enter the program code when the

digital display resets.

Error Code E204

There is no signal from the sensor. This code is displayed only when in a calibration

program.Troubleshootthesensorbyspinningitbyhandandthenconrmingifthe

displayshowsownumbervalues.

Error Code E206

A selected calibration point is too close to the previous point. (There is less than

5% difference between two calibration points.) Select a different point to continue with

the calibration procedure.

Error Code E210

The number of available calibration points have been exceeded. Exit the

calibration program.

Exit Program Access Mode

Press and hold the MODE button and then press the TOTAL button and hold them

until the display shows four dashes. Release the buttons and enter a new code, or after

vesecondstheprogramtimesoutandreturnstonormaloperation.

EB# 98601000 REV REL

17

CALIBRATION

Theowmeterisprecalibratedandtestedatthefactory.Itisrecommendedthat

theowmeterischeckedafterinstallationforaccuracyandcalibratedwhennecessary.

Review the Programming Section procedures for using the Program Access Mode.

Error Code E204

IferrorcodeE204isshown,thereisnosignalfromtheowsensor.Thiscodeis

displayed only when in a calibration program.

Note: To calibrate the owmeter, use a precalibrated water ow test kit

(connected to the discharge according to the instructions provided) or a

Pitot gauge as a reference.

Flow Calibration, Single Point (Code 321)

Selectaowrateforcalibrationthatiswithinthemostcommonlyuseddischarge

owrange.

1. Enter code 321.

Result:Thedigitaldisplayshowsowratewiththelastdigitashing.

2. Flow water through the discharge at the ow rate selected for calibration.

Ensureaconstantpressureismaintainedtoobtainasteadyowrate.

3. Adjustthedisplayedowratetomatchthereferenceowrate.

The MODEbuttonselectsthedigittochange.Thedigitwillash.

The TOTALbuttonchangesthevalueoftheashingdigit.

4. To exit the calibration program:

Press and hold the MODE button and then press the TOTAL button and hold them

until the display shows four dashes. Release the buttons and enter a new code, or

aftervesecondstheprogramtimesoutandreturnstonormaloperation.

5. Varythewaterowthroughthedischargeandensuretheowratedisplayed

matchesthereference.Iftherearedifferencesatotherowrates,themultiple

point calibration may be necessary.

EB# 98601000 REV REL

18

Flow Calibration, Multiple Point (Code 322)

Thisfunction isused when theow sensor isinstalledin adifcultplumbing

locationwhereowisnotlinear.Itcorrectsfornonlinearowtoprovideanaccurate

owratedisplay.

Select calibration points (up to 9) that are within the most commonly used range.

Note: There must be at least a 5% difference between each calibration point.

If a selected calibration point is too close to the previous point, an E206

error code shows on the display.

1. Enter code 322.

Result: The digital display shows Pt1 (program is ready to set the rst

calibration point).

2. Flowwaterthroughthedischargeattheowrateselectedforthecalibration

point.Ensureaconstantpressureismaintainedtoobtainasteadyowrate.

3. Press the MODE button.

Result:Thedisplayshowsowratewiththelastdigitashing.

4. Adjustthedisplayedowratetomatchthereferenceowrate.

The MODEbuttonselectsthedigittochange.Thedigitwillash.

The TOTALbuttonchangesthevalueoftheashingdigit.

5. Press and hold the MODE button, momentarily press the TOTAL button, release

the buttons. The next calibration point is displayed. (If the buttons are pressed

too long, the program exits the calibration mode.)

Result: The display shows Pt2 (or the next calibration point).

6. Repeatsteps2through5foreachowratetobecalibrated.

7. To exit the calibration program:

Press and hold the MODE button and then press the TOTAL button and hold them

until the display shows four dashes. Release the buttons and enter a new code, or

aftervesecondstheprogramtimesoutandreturnstonormaloperation.

EB# 98601000 REV REL

19

FLOWMETER CHARGING

Thefollowingguresincludewiringandcableinformation.

2-Pin Connector/Cable

Pin Description

1 Power

2 Ground

Figure 3. Charging

Charging Port

(12/24 VDC) Vent

Pin 1 Pin 2

AC to DC Switching Adapter

Input: 100-240 VAC

50-60 Hz

0.7A

Output: 15V

2A

Status: Blue LED on the power adapter indicates

power is available.

EB# 98601000 REV REL

20

Table of contents

Other ELKHART BRASS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Wintriss

Wintriss AutoSet PAC 120 VAC user manual

HT Instruments

HT Instruments SOLAR03 user manual

PCB Piezotronics

PCB Piezotronics IMI Sensors TO625B01 Installation and operating manual

Hinds Instruments

Hinds Instruments EXICOR 150AT user manual

LORD

LORD 3DM -CV5-10 user manual

Danmeter

Danmeter CSM Refill Manual

CHAMELEON

CHAMELEON IHD6-CAD-PPMID manual

Siemens

Siemens AlgoRex DJ1191-Ex installation instructions

Assured Automation

Assured Automation WM-NLD Series Installation, operation & maintenance manual

PCME

PCME QAL 181 X user manual

MARTINDALE

MARTINDALE PSI4000 instruction manual

Signal Hound

Signal Hound BB60D product manual