Elko Inels Air AirIM-100L User manual

+

-

CH1

CH2

GND

+ -

3V3/

GND

1 / 4

AirIM-100

02-16/2018 Rev.: 0

9

12

1

4

6

8

6

5

13

7

11

2

10

3

14

15

ELKO EP, s.r.o.

Palackého 493

769 01 Holešov, Všetuly

Czech Republic

Tel.: +420 573 514 211

e-mail: [email protected]

www.elkoep.com

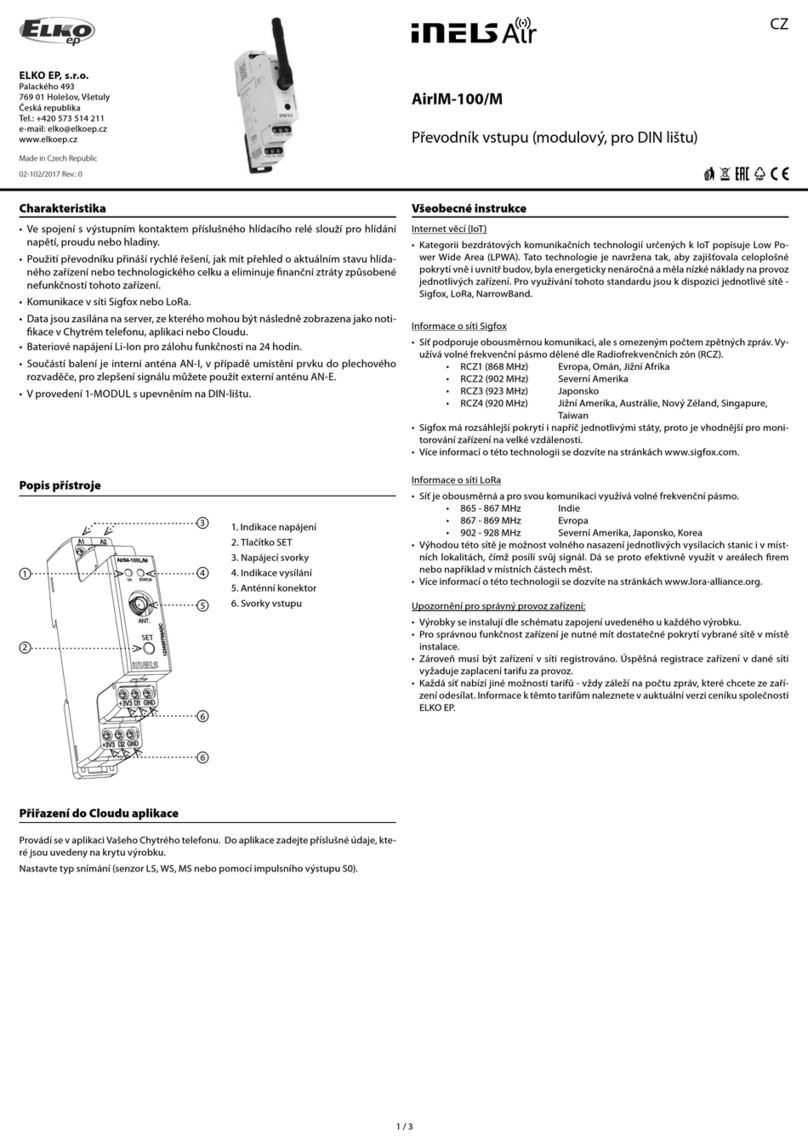

Characteristics

Description

EN

General instrucions

• The Universal input is used to detect device statuses which ensure the smooth and

trouble-free operation both in the residential and industrial sectors.

• The Universal input has a pulse, analog, binary input and terminals for connecting

the temperature sensor.

• In conjunction with the sensor it is used, for example, for monitoring the level, tem-

perature, gas, water or electricity, ooding...

• It provides a quick solution to learn about the critical condition of your device which

you can immediately respond to (e.g. service interference).

• Using the universal sensor will help you eliminate nancial losses caused by device

malfunctions, or report the need for action in advance.

• For each power meter it is necessary to have one Universal input AirIM-100.

• With the wireless solution and Sigfox / LoRa / NB-IoT communication, it can com-

municate instantly to your chosen location and be operated immediately.

• Data is sent to the server from which it can be subsequently displayed as a smart-

phone, application, or Cloud notication

• Anti-sabotage: If access to the device is unauthorized, a message is immediately

sent to the server.

• Anti-sabotage: When a cover is removed, a message is sent to the application or

ELKO Cloud.

• Power supply: 5-12 V DC or 1x 3.6 V batteries SAFT with approx. 5 years (depending

on the frequency of use)

• In the case of external power, the battery is automatically disconnected and serves

as backup power.

• Protection degree IP65.

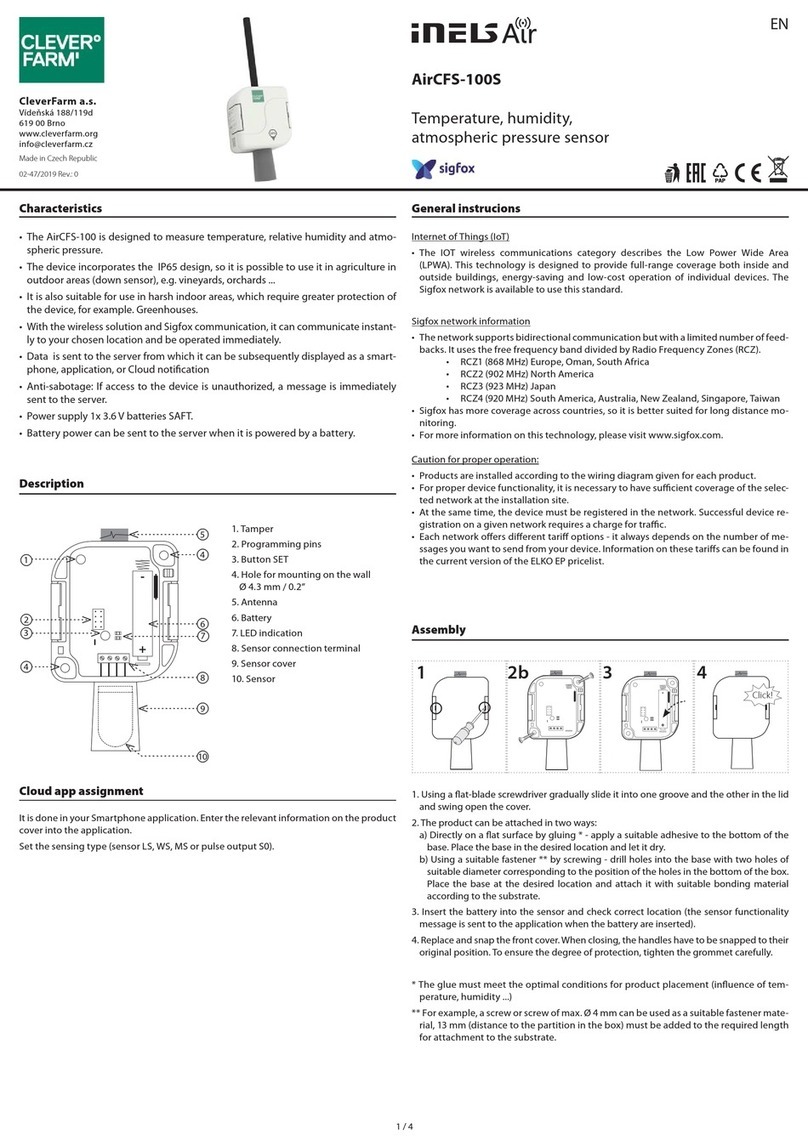

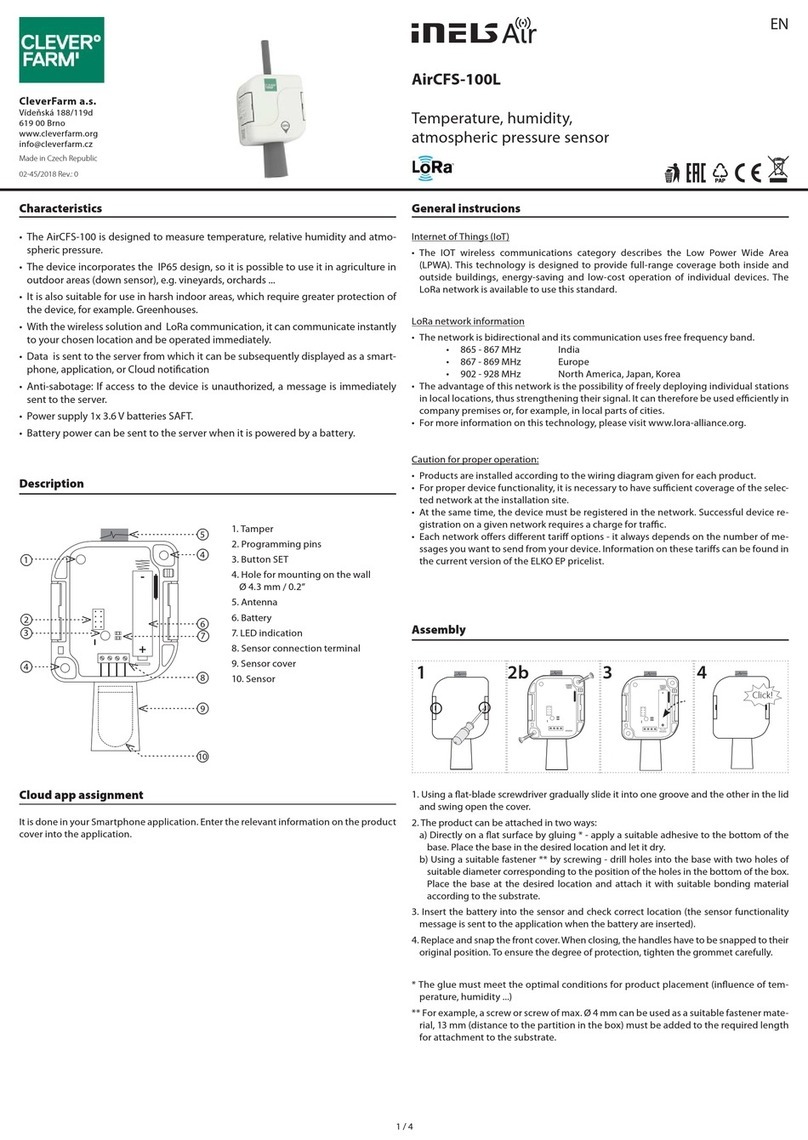

1. Tamper

2. NanoSIM slot (AirIM-100NB only)

3. LED indication

4. Button SET

5. Setting pins for 3V3 / GND clamp

6. Hole for mounting on the wall Ø

4.3 mm / 0.2”

7. Power terminal

8. Antenna

9. Magnetic contact

10. Battery

11. Sensor connection terminal

12. Bushing M16x1.5 for connecting

cable with max. diameter of 10 mm

13. Programming pins

14. Setting pins for CH2 clamp

15. Setting pins for CH1 clamp

Cloud app assignment

It is done in your Smartphone application. Enter the relevant information on the product

cover into the application.

Set the sensing type (sensor LS, WS, MS or pulse output S0).

Internet of Things (IoT)

• The IOT wireless communications category describes the Low Power Wide Area

(LPWA). This technology is designed to provide full-range coverage both inside and

outside buildings, energy-saving and low-cost operation of individual devices. Indivi-

dual networks - Sigfox, LoRa, NarrowBand - are available to use this standard.

Sigfox network information

• The network supports bidirectional communication but with a limited number of feed-

backs. It uses the free frequency band divided by Radio Frequency Zones (RCZ).

• RCZ1 (868 MHz) Europe, Oman, South Africa

• RCZ2 (902 MHz) North America

• RCZ3 (923 MHz) Japan

• RCZ4 (920 MHz) South America, Australia, New Zealand, Singapore, Taiwan

• Sigfox has more coverage across countries, so it is better suited for long distance mo-

nitoring.

• For more information on this technology, please visit www.sigfox.com.

LoRa network information

• The network is bidirectional and its communication uses free frequency band.

• 865 - 867 MHz India

• 867 - 869 MHz Europe

• 902 - 928 MHz North America, Japan, Korea

• The advantage of this network is the possibility of freely deploying individual stations

in local locations, thus strengthening their signal. It can therefore be used eciently in

company premises or, for example, in local parts of cities.

• For more information on this technology, please visit www.lora-alliance.org.

Information about the NarrowBand network

• The network provides two-way communication and the only one to use the licensed

LTE band. Our devices allow band 1 (2100MHz), Band 3 (1800MHz), Band 8 (900MHz),

Band 5 (850MHz), Band 20 (800MHz) and Band 28 (700MHz).

• It uses this SIM card technology for each device.

• The advantage of NarrowBand is the use of already built-up grids, which ensures su-

cient reception outside and inside buildings.

• For more information on this technology, please visit www.vodafone.cz

Caution for proper operation:

• Products are installed according to the wiring diagram given for each product.

• For proper device functionality, it is necessary to have sucient coverage of the selec-

ted network at the installation site.

• At the same time, the device must be registered in the network. Successful device re-

gistration on a given network requires a charge for trac.

• Each network oers dierent tari options - it always depends on the number of me-

ssages you want to send from your device. Information on these taris can be found in

the current version of the ELKO EP pricelist.

Universal input

Made in Czech Republic

2AirIM-100NB

1

8

Click!

5b

+

-

3b

5a

+

-

5-12 V DC

6

+

-

2 / 4

Assembly

1. Using a at-blade screwdriver gradually slide it into one groove and the other in the lid

and swing open the cover.

2. Only with AirIM-100NB: Carefully insert nanoSIM (the device must not be energized

when inserting or replacing nanoSIM!)

3. The product can be attached in two ways:

a) Directly on a at surface by gluing * - apply a suitable adhesive to the bottom of the

base. Place the base in the desired location and let it dry.

b) Using a suitable fastener ** by screwing - drill holes into the base with two holes of

suitable diameter corresponding to the position of the holes in the bottom of the box.

Place the base at the desired location and attach it with suitable bonding material

according to the substrate.

4. Thread the sensor through the bushing and plug it in according to the required function

- see chapter Functions, remove jumpers (only after setting the function).

5. Connect the supply voltage (via the power supply the transmitter functionality message

is sent to the application)

a. on the clamp

b. Insert the battery and check the correct location.

6. Set the required function (see chapter Function)

7. Fill the jumpers onto the adjustment pins (see the Function chapter).

8. Replace and snap the front cover. When closing, the handles have to be snapped to their

original position. To ensure the degree of protection, tighten the grommet carefully.

* The glue must meet the optimal conditions for product placement (inuence of tem-

perature, humidity ...)

** For example, a screw or screw of max. Ø 4 mm can be used as a suitable fastener mate-

rial, 13 mm (distance to the partition in the box) must be added to the required length

for attachment to the substrate.

Recommendations for installation

• Ensure the correct location - see Warning.

• Prior to attaching the AirIM-100, check the length of the connected sensor and the loca-

tion of the scanned device.

• The working position is arbitrary but the grommet should not be directed upwards.

• The product does not require special handling and maintenance.

When handling a device unboxed it is important to avoid contact with

liquids. avoid unnecessary contact with the components of the device. Do

not touch the metal objects inside the unit.

Safe handling

Function

When the power is connected, the transmitter sends the initial message to the server.

Any unauthorized interference with a device, regardless of the feature set, immediately

sends the message to the server.

1. S0 - pulse counting S0

• Checking the correct pulse readings: after setting the longer push (> 2) function of

the SET button, the LED will be activated, which will ash when counting the pulse.

The LED ashes with a short press or automatically after 5 minutes.

• Measured values send the sensor every 4 hours, or immediately when the 5000 pulse

limit is exceeded.

• Recommended accessories: cable for S0 output

2. Energy measurement - pulse counting from active sensor LS, MS, WS

• Checking the correct pulse readings: after setting the longer push (> 2) function of

the SET button, the LED will be activated, which will ash when counting the pulse.

The LED ashes with a short press or automatically after 5 minutes.

• Measured values send the sensor every 4 hours, or immediately when the 5000 pulse

limit is exceeded.

• Recommended accessories

- LS (LED sensor): is particularly suitable for power meters that support LED pulse

sensing

- MS (magnetic sensor): is particularly suitable for gas meters that support magnetic

sensing.

- WS (magnetic sensor for water meter): it is particularly suitable for water meters that

support magnetic sensing.

3. Flood Detection - Flood Sensor

• Flood detection - by connecting sensing contacts (by ooding with water).

• Scans every 4 seconds. The status report sends the sensor data every 12 hours, or

immediately when detected.

• Recommended accessories: ood sensor FP-1

4. Opening detection - Window / Door Magnetic Sensor (integrated inside the unit)

• Activation occurs when the magnet is attaching / removed from the sensor.

• The sensor sends a data message every 12 hours. In case of a state change, it sends

the data message immediately.

• Recommended accessories: Magnet D / WD

• Note: The universal sensor has a magnet sensor located only on one side, so be care-

ful about the correct position relative to the magnet.

5. Analog measurement. Voltage 0 - 10 V

• Measured at 10 second intervals. Report on the measured values, the sensor sends:

- every hour

- immediately if it measures the change by more than 1V since the last measurement

- Immediately when dropping below 1 V

- immediately when the 9 V is exceeded

6. Analog measurement. Current 0 - 20 mA

• Measured at 10 second intervals. Report on the measured values, the sensor sends:

- every hour

- immediately if it measures the change by more than 1mA since the last measure-

ment

- Immediately when dropping below 4 mA

- immediately when the 19 mA is exceeded

7. Battery measurement 12/24 V - voltage measurement 0 - 24V

• Measured at 10 second intervals. Report on the measured values, the sensor sends:

- every hour

- immediately if it measures the change by more than 1V since the last measurement

- Immediately when dropping below 22 V

- immediately when the 24 V is exceeded

8. Temperature measurement

• The temperature is measured every 5 minutes. The sensor reads out the measured

value message:

- every hour

- immediately if it measures the change of ± 5 ° C since the last measurement

- immediately at 30 °C

- Immediately when the temperature drops below 0 °C

• Recommended accessories: TC or TZ temperature sensor

9. HTM2500LF - Temperature and Humidity Sensor Measurement HTM2500LF

• Temperature and humidity read every 5 minutes. Report on the measured values,

the sensor sends:

- every hour

- immediately if it measures the change of ± 5 °C since the last measurement

- Immediately when a change is measured of more than ± 20% RH from the last

measurement

• Recommended accessories: HTM2500LF sensor

10. Alarm function - check the contact

• A contact status message is sent every 12 hours. When there is change (connection /

disconnection contact) message is sent immediately.

3 / 4

NTC

NTC

K1

K2

VCC

H

GND

T

1.

S0

S0

3.

K1

K2

2.

VCC

Signal

GND

5. 7.

I+

I-

6.

V+

V-

8. 10.9.

V+

V-

AirIM-100S AirIM-100L AirIM-100NB

1

+

-

2 3

Click!

Restart

• Open the cover. Power interruption (remove the battery from the device).

• Press SET> 1min.

• Connect power (insert battery). Close the cover.

power supply (external or battery), reset unit

start unit ok

opening the cover

non contact / contact magnet

test, cancel, „long press“

setting mode (signaling of measurement / pulses)

impulse LS / MS / WS / S0, temperature measurement, ...

sending / receiving data

it is necessary to disconnect the power supply (external or battery), after 60 seconds after the LED goes out, insert the battery

the battery may be discharged

a discharged battery or a damaged product

Device states

x Search availability BTS

error MAC / error MODULU / error SIM

Unit initialization

Start

Search for BTS * 2)

SIM ERR *2)

ERR *2)

Successful network connection * 2)

Measurement

Tamper

Magnet

SET button short press (> 2s)

SET button longer press (> 2s / <5s)

Measurement signaling * 1)

Communication

Communication

Other known states

Does not respond to the SET button

The unit is still in reset

The unit does not respond even after

removal insert the battery

Indication

3 x R + G blinks

2 x ashes R (2xR _ 2xR _ ...)

5 x ashes R (repeatedly)

1 x ashes R

without indication

3 x ashes G

1 x ashes G

2 x ashes G

1 x ashes G

1 x ashes R

any LED lights

still indicates start

without indication

When the tamper is pressed, the LED is turned o!

Note:

R... LED red

G... LED green

* 1) Indicates only when you press SET> 2 s (setting mode)

* 2) Planned

Replacing batteries

1. Using a at-blade screwdriver gradually slide it into one and then the other groove in

the lid and swing open the cover.

2. Remove the discharged battery and insert a new battery into the holder. Beware of

polarity. Both LEDs will ash 3 times (see device status indication).

3. Replace and snap the front cover.

Notice:

Only use batteries designed for this product correctly inserted in the device! Immediately replace

weak batteries with new ones. Do not use new and used batteries together. If necessary, clean the

battery and contacts prior to using. Avoid the shorting of batteries! Do not dismantle batteries, do

not charge them and protect them from extreme heating - danger of leakage! Upon contact with acid,

immediately rinse the aected area with a stream of water and seek medical attention. Keep batteries

out of the reach of children. Batteries must be recycled or returned to an appropriate location (e.g.

collection container) in accordance with local legal provisions.

Setting functions 1-3, 5-10:

• Long press SET (> 5s) to enter programming mode.

• The green LED will ash by function (function 1 - 1x, 2 - 2x ...).

• Short (<1s) by pressing the SET button to move upwards in the function selection, press

(> 2 / <5s) longer to go down the function selections.

• Pressing the button (> 5s) long saves the set function and restarts the device.

Connection to the network

SIM Error - cannot be loaded (SIM

card insertion and rotation check) / or

NB-IoT MODULE error

4 / 4

AirIM-100S AirIM-100L AirIM-100NB

Warning

Technical parameters

Read the operating instructions before installing the device and putting it into opera-

tion. Instruction manual is designated for mounting and also for user of the device. It is

always a part of its packing. Installation and connection can be carried out only by a per-

son with adequate professional qualication upon understanding this instruction man-

ual and functions of the device, and while observing all valid regulations. Trouble-free

function of the device also depends on transportation, storing and handling. In case you

notice any sign of damage, deformation, malfunction or missing part, do not install this

device and return it to its seller. It is necessary to treat this product and its parts as elec-

tronic waste after its lifetime is terminated. Before starting installation, make sure that all

wires, connected parts or terminals are de-energized. While mounting and servicing ob-

serve safety regulations, norms, directives and professional, and export regulations for

working with electrical devices. Do not touch parts of the device that are energized – life

threat. To ensure the transmission of the radio signal, make sure that the devices in the

building where the installation is installed are correctly located. Unless otherwise stated,

the devices are not intended for installation in outdoor and damp areas, they must not

be installed in metal switchboards or in plastic cabinets with metal doors - this prevents

transmission of the radio frequency signal. iNELS Air is not recommended for control-

ling life-saving instruments or for controlling hazardous devices such as pumps, heaters

without thermostat, lifts, hoists, etc. - radio frequency transmission may be overshad-

owed by obstruction, interference, transmitter battery may be discharged etc., thereby

disabling the remote control.

* Not included in the package

** Multiple frequency bands of B1 / B3 / B5 / B8 / B20 / B28

*** Depending on network coverage

**** Pay attention to the operating temperature of batteries -60...+85 °C

Sigfix Ready Certification

Certicate ID for AirIM-100S Universal Sensor: P_ 00 94 _ 56 EE _ 01

Power supply

Battery power:

Battery life:

External power supply:

Supply voltage tolerance:

Standby consumption:

Transmitting power consumption:

Setting

Setting:

Alarm Detection:

Battery status view:

Control

Control:

Analog inputs

Thermal:

Voltage:

Current:

Battery measurement:

Flooding:

Digital inputs

Inputs:

Supported sensors for energy

measurements:

Detection of the magnet sensor

Closed:

Open:

Reliability:

Other supported sensors

Flood probe:

Tempe. and humidity measurement:

Temperature measurement range

Thermo sensor TC:

Thermo sensor TZ:

Sensor HTM2500LF:

Communication

Protocol:

Transmitter frequency:

Range in open space:

Other parameters

Working temperature:

Storage temperature:

Operating position:

Mounting:

Protection degree:

Connecting External Power:

Connection of the sensor:

Cable gommet:

Dimension:

Weight:

1x 3.6V LS 14500 Li-SOCl2AA

max. 5 years max. 3 years

(depending on the frequency of use)

5 – 12 V DC (on terminal)

+10 %; -15%

0.2 mW

250 mW 150 mW 850 mW

With a message from the server

using setting pins,

SET button, programming cable

message to the server

only when the battery is powered by a message on the server

button SET

Magnetic contact

Tamper

TC / TZ*

AIN 0(1) - 10 V

AIN 0(4) - 20 mA

12 V/24 V

Flood probe*

IN1, IN2

LS (LED sensor)*

MS, WS (magnetic sensor)*

SO (Contact, open collector)

< 1.5 cm

> 2 cm

99.9 %

FP-1*

HTM2500LF*

0. .. 70 °C

-40 .. 125 °C

-40 .. 85 °C

Sigfox LoRa NB-IoT

RCZ1 868 MHz 868 MHz LTE Cat NB1**

Approx. 50 km*** Approx. 10 km*** Approx. 30 km***

-30…+60°C (Pay attention to the operating

temperature of batteries)****

-30…+70°C

any

glue / screws

IP65

terminals, wires 0.5 – 1 mm2

terminals, wires 0.5 – 1 mm2

M16 x 1.5 for cable ø max. 10 mm

182 x 62 x 34 mm

108 g (without battery)

Other manuals for Inels Air AirIM-100L

1

This manual suits for next models

3

Other Elko Measuring Instrument manuals

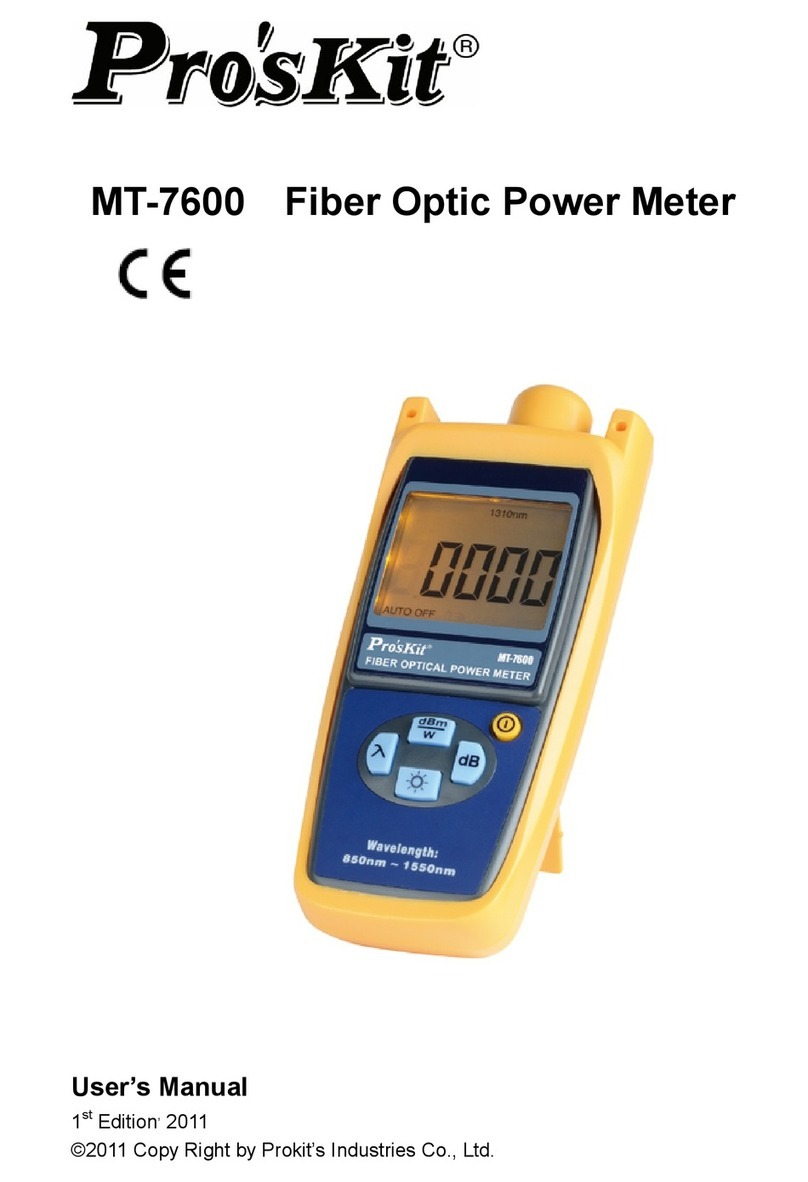

Popular Measuring Instrument manuals by other brands

POTOMAC INSTRUMENTS INC.

POTOMAC INSTRUMENTS INC. FIM-41 instruction manual

AU Tool

AU Tool X91 TPMS user manual

B.M. Tecnologie Industriali

B.M. Tecnologie Industriali TTFM100B-HH-NG instruction manual

Phase Technologies

Phase Technologies 70Xi Quick installation guide

AutomationDirect

AutomationDirect ProSense DPM2 Series user manual

Powerline

Powerline XL2G instruction manual