ELM 329 User manual

ELM329

Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

CAN Interpreter

Since 1996, most vehicles have been required

to monitor their own emissions performance and to

report on it through an On-Board Diagnostics (OBD)

port. Initially, several different protocols were used

for the transfer of OBD data, but since the 2008

model year (in North America), only one protocol has

been allowed - the ISO 15765-4 CAN standard.

The ELM329 is a device that can translate the

data from an ISO 15765-4 interface into a form that

may be readily used by computers, smart phones, or

other devices. In addition, the ELM329 provides

support for several other CAN protocols (including

the SAE J1939 truck and bus standard), and for

sending periodic messages, mixed ID messages,

and for monitoring the CAN bus, to name only a few.

The following pages discuss the ELM329’s

features in detail, how to use it and configure it, as

well as providing some background information on

the protocols that are supported. There are also

schematic diagrams, and circuit construction tips.

• Power Control with standby mode

• High speed RS232 interface

• Automatically searches for protocols

• Fully configurable with AT commands

• Pin compatible with the ELM327

• Low power CMOS design

• Diagnostic trouble code readers

• Automotive scan tools

• Teaching aids

Description

Applications

Features

1 of 83ELM329DSC

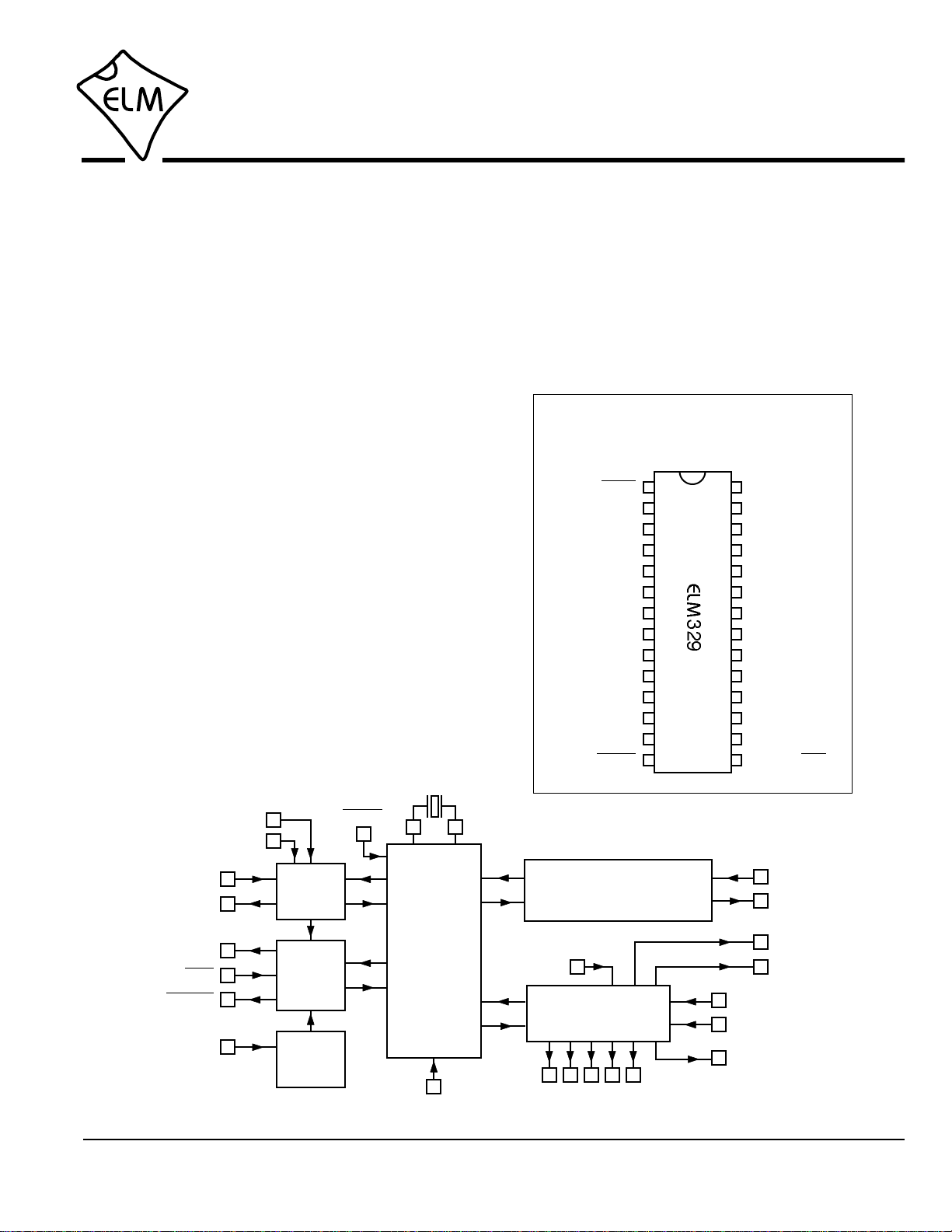

Connection Diagram

PDIP and SOIC

(top view)

OBD Tx LED

OBD Rx LED

RS232 Tx LED

RS232 Rx LED

CAN Rx

CAN Tx

M0

M1

VDD

RS232 Rx

RS232 Tx

PwrCtrl / Busy

MCLR

Memory

Baud Rate

LFmode

Active LED

XT1

XT2

VSS

In1

In2

Control

CAN Monitor

Vmeasure

VSS

Block Diagram IgnMon / RTSPwrCtrl

Command

and

Protocol

Interpreter

RS232

Interface

CAN Module

ISO 15765-4, SAE J1939

ISO 11898

4

4.00 MHz

9

10

Power

Control

15

16

14

PwrCtrl / Busy

IgnMon / RTS

PwrCtrl

11

CAN Monitor

/ A LED

Baud Rate

6

LFmode

7

18

17

RS232Tx

RS232Rx

Control

Module

status LEDs

3

26

27

25

28

24

23

CAN Rx

CAN Tx

22

21

M0

M1

5

Memory

1

MCLR

12

13

In1

In2

Control

2

Vmeasure

CAN

Monitor

ELM329

Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com 2 of 83

ELM329DSC

The Basics Description...................................................................................1

Features.......................................................................................1

Applications..................................................................................1

Block Diagram..............................................................................1

Connection Diagram.................................................................... 1

Pin Descriptions...........................................................................4

Unused Pins.................................................................................6

Absolute Maximum Ratings......................................................... 6

Electrical Characteristics..............................................................7

Using the ELM329 Overview......................................................................................8

Communicating with the ELM329................................................ 8

AT Commands...........................................................................10

AT Command Summary.............................................................10

AT Command Descriptions........................................................12

Reading the Battery Voltage......................................................26

OBD Commands........................................................................27

Talking to the Vehicle.................................................................28

Interpreting Trouble Codes........................................................ 30

Resetting Trouble Codes........................................................... 31

Quick Guide for Reading Trouble Codes...................................31

Selecting Protocols.................................................................... 32

OBD Message Formats..............................................................33

Setting the Header / ID Bits........................................................35

ISO 157645-4 Message Types.................................................. 37

Multiline Responses...................................................................38

Multiple PID Requests................................................................39

Receive Filtering - the CRA command.......................................40

Using the Mask and Filter.......................................................... 41

Monitoring the Bus.....................................................................42

Mixed ID (11 and 29 bit) Sending...............................................43

Restoring Order..........................................................................44

Advanced Features Using Higher RS232 Baud Rates...............................................45

Setting Timeouts - the AT ST and AT AT Commands...............47

SAE J1939 Messages................................................................48

Using J1939...............................................................................50

The FMS Standard.....................................................................54

The NMEA 2000 Standard.........................................................54

Periodic (Wakeup) Messages....................................................55

Altering Flow Control Messages................................................ 56

Using CAN Extended Addresses...............................................57

CAN Input Frequency Matching.................................................58

CAN (Single Wire) Transceiver Modes......................................59

Contents

ELM329

Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com 3 of 83

ELM329DSC

Contents (continued)

Advanced Features The CAN Monitor (pin 11)..........................................................60

(continued) Control Module Operation..........................................................60

Low Power Mode....................................................................... 61

Programmable Parameters........................................................64

Programmable Parameter Summary......................................... 65

Design Discussions Compatibility with the ELM327...................................................70

Modifications for Low Power Standby Operation.......................70

Maximum CAN Data Rates........................................................71

Microprocessor Interfaces..........................................................73

Example Applications.................................................................74

Figure 9 - A CAN to USB Interpreter................................... 75

Figure 10 - Parts List for Figure 9........................................76

Figure 11 - A Low Speed RS232 Interface..........................77

Figure 12 - A High Speed RS232 Interface.........................77

Figure 13 - An Alternative USB Interface............................ 78

Misc. Information Error Messages and Alerts.........................................................79

Outline Diagrams....................................................................... 81

Ordering Information..................................................................81

Copyright and Disclaimer...........................................................81

Index.......................................................................................... 82

ELM329

Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

Pin Descriptions

4 of 83

MCLR (pin 1)

A momentary (>2µsec) logic low applied to this input

will reset the ELM329. If unused, this pin should be

connected to a logic high (VDD) level.

Vmeasure (pin 2)

This analog input is used to measure a 0 to 5V

signal that is applied to it. The value measured is

scaled by a factor of about 5.7 and may be displayed

using the AT RV command.

Care must be taken to prevent the voltage from

going outside of the supply levels of the ELM329, or

damage may occur. If it is not used, this pin should

be tied to either VDD or VSS.

Active LED (pin 3)

This output pin is normally at a high level, and is

driven to a low level when the ELM329 has

determined that it has found a valid (active) protocol.

The output is suitable for directly driving most LEDs

through a current limiting resistor, or interfacing to

other logic circuits. If unused, this pin may be left

open-circuited.

Note that the behaviour of this pin when the ELM329

is in the low power mode may be modified by the

logic level at pin 11, or with PP 0F, bit 4.

Control (pin 4)

The level at this output may be directly controlled

through AT commands. After any reset (powerup,

AT Z, etc.), the output reverts to low level.

Pin 4 may also be used to provide an output signal

that follows the internal CAN monitor output, by

setting bit 0 of PP 0F to 1. This is a new feature with

v2.0, and is not available with v1.0 ICs.

Memory (pin 5)

This input controls the default state of the memory

option. If this pin is at a high level during power-up or

reset, the memory function will be enabled by

default. If it is at a low level, then the default will be

to have it disabled. Memory can always be enabled

or disabled with the AT M1 and AT M0 commands.

Baud Rate (pin 6)

This input controls the baud rate of the RS232

interface. If it is at a high level during power-up or

reset, the baud rate will be set to 38400 (or the rate

that has been set by PP 0C). If at a low level, the

baud rate will always be 9600 bps.

LFmode (pin 7)

This input is used to select the default linefeed mode

to be used after a power-up or system reset. If it is at

a high level, then by default messages sent by the

ELM329 will be terminated with both a carriage

return and a linefeed character. If it is at a low level,

lines will be terminated by a carriage return only.

This behaviour can always be modified by issuing an

AT L1 or AT L0 command.

VSS (pin 8)

Circuit common must be connected to this pin.

XT1 (pin 9) and XT2 (pin 10)

A 4.000 MHz oscillator crystal is connected between

these two pins. Loading capacitors as required by

the crystal (typically 27pF each) will also need to be

connected from each of these pins to circuit common

(Vss).

When laying out a printed circuit board, you may

wish to consider placing a guard ring around the

oscillator crystal, pins, and capacitors, to provide a

little isolation between them and the other signals

(particularly the pin 11 CAN input).

Note that this device has not been configured for

operation with an external oscillator, and it expects a

crystal to be connected to these pins. Use of an

external clock source is not recommended. Also,

note that this oscillator is turned off when in the low

power or ‘standby’ mode of operation.

CAN Monitor and A LED (pin 11)

This input serves two functions. If a CAN signal is

detected at this pin, the ELM329 assumes that you

wish it to monitor that signal, and possibly control the

low power operation based on it.

If no CAN signal is detected, the ELM329 assumes

that you are using this pin to control the behaviour of

the Active LED output when the IC is in the low

power mode (as it did for v1.0 ICs). In this mode, if

pin 11 is at a high level when low power operation

begins, the Active LED output will continually flash

for about 16 msec every 4 seconds. If the input is at

a low level when low power operation begins, the

ELM329DSC

Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com 5 of 83

ELM329DSC

Active LED output will be off (high) when in low

power mode. If a CAN signal was detected on pin

11, the operation of the Active LED during low power

is determined by PP 0F, bit 4.

Monitoring for a CAN signal (ie. transitions at this

input pin) is a continuous background process that

can not be disabled.

In1 and In2 (pins 12 and 13)

These two inputs may be used for the monitoring of

logic level signals. Simple AT commands may be

used to read the level at either pin. No special

amplification is required, as the inputs have Schmitt

trigger wave shaping.

PwrCtrl (pin 14)

This output provides a level that is the inverse of that

of the PwrCtrl output (pin 16). If the low power mode

is disabled (ie if bit 7 of PP 0E is set to ‘0’), this

output still provides the inverse of the level set by

PP 0E b6. To provide a ‘soft start’ feature, pin 14 will

always change state 50 msec before pin 16.

IgnMon / RTS (pin 15)

This input pin can serve one of two functions,

depending on how the Power Control options

(PP 0E) are set.

If both bit 7 and bit 2 of PP 0E are set to ‘1’, this pin

will act as an Ignition Monitor. This will result in a

switch to the low power mode of operation, if the

input goes to a low level, as would happen if the

vehicle’s ignition were turned off. An internal

‘debounce’ timer is used to ensure that the ELM329

does not shut down for noise at the input.

When the voltage at pin 15 is again restored to a

high level, and a time of 1 or 5 seconds (as set by

PP 0E bit 1) passes, the ELM329 will return to

normal operation. A low to high transition at pin 15

will always restore normal operation, regardless of

the setting of PP 0E bit 2, or whether pin 15 was the

initial cause for the low power mode. This feature

allows a system to control how and when it switches

to low power standby operation, but still have

automatic wakeup by the ignition voltage, or by a

pushbutton.

If either bit 7 or bit 2 of PP 0E are ‘0’, this pin will

function as an active low ‘Request To Send’ input.

This can be used to interrupt the OBD processing in

order to send a new command, or if connected to

ignition positive, to highlight the fact that the ignition

has been turned off. Normally kept at a high level,

this input is brought low for attention, and should

remain so until the Busy line (pin 16) indicates that

the ELM329 is no longer busy, or until a prompt

character is received (if pin 16 is being used for

power control).

This input has Schmitt trigger wave shaping. By

default, pin 15 acts as the RTS interrupt input.

PwrCtrl / Busy (pin 16)

This output pin can serve one of two functions,

depending on how the Power Control options

(PP 0E) are set.

If bit 7 of PP 0E is a ‘1’ (the default), this pin will

function as a Power Control output. The normal state

of the pin will be as set by PP 0E bit 6, and the pin

will remain in that state until the ELM329 switches to

the low power mode of operation. This output is

typically used to control enable inputs, but may also

be used for relay circuits, etc. with suitable buffering.

The discussion on page 70 (‘Modifications for Low

Power Standby Operation’) provides more detail on

how to use this output.

If bit 7 of PP 0E is a ‘0’, pin 16 will function as a

‘Busy’ output, showing when the ELM329 is actively

processing a command (the output will be at a high

level), or when it is idle, ready to receive commands

(the output will be low).

By default, pin 16 provides the PwrCtrl function.

RS232Tx (pin 17)

This is the RS232 data transmit output. The signal

level is compatible with most interface ICs (the

output is high when idle), and there is sufficient

current drive to allow interfacing using only a PNP

transistor, if desired.

RS232Rx (pin 18)

This is the RS232 receive data input. The signal

level is compatible with most interface ICs (when at

idle, the level should be high), but can be used with

other interfaces as well, since the input has Schmitt

trigger wave shaping.

VSS (pin 19)

Circuit common must be connected to this pin.

Pin Descriptions (continued)

ELM329

Absolute Maximum Ratings

Storage Temperature.......................-65°C to +150°C

Ambient Temperature with

Power Applied....................................-40°C to +85°C

Voltage on VDD with respect to VSS..... -0.3V to +7.5V

Voltage on any other pin with

respect to VSS........................... -0.3V to (VDD + 0.3V)

Note:

These values are given as a design guideline only.

The ability to operate to these levels is neither

inferred nor recommended, and stresses beyond

those listed here will likely damage the device.

6 of 83ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

ELM329

VDD (pin 20)

This pin is the positive supply pin, and should always

be the most positive point in the circuit. Internal

circuitry connected to this pin is used to provide

power on reset of the microprocessor, so an external

reset signal is not required. Refer to the Electrical

Characteristics section for further information.

M1 (pin 21) and M0 (pin 22)

These two output pins are provided for use with CAN

transceiver ICs, as are typically used for Single Wire

CAN applications. The ELM329 will set both outputs

to a high level (‘Normal’) after startup, but the level at

these pins may be changed at any time with the

AT TM commands, and the level after powerup may

be set with PP20.

CAN Tx (pin 23) and CAN Rx (pin 24)

These are the two CAN interface signals that must

be connected to a CAN transceiver IC (see the

Example Applications section for more information).

If unused, pin 24 must be connected to a logic high

(VDD) level.

RS232 Rx LED (pin 25), RS232 Tx LED (pin 26),

OBD Rx LED (pin 27) and OBD Tx LED (pin 28)

These four output pins are normally high, and are

driven to low levels when the ELM329 is transmitting

or receiving data. These outputs are suitable for

directly driving most LEDs through current limiting

resistors, or interfacing to other logic circuits. If

unused, these pins may be left open-circuited.

Note that pin 28 can also be used to turn off all of the

Programmable Parameters, if you can not do so by

using the normal interface - see page 65 for more

details.

Pin Descriptions (continued)

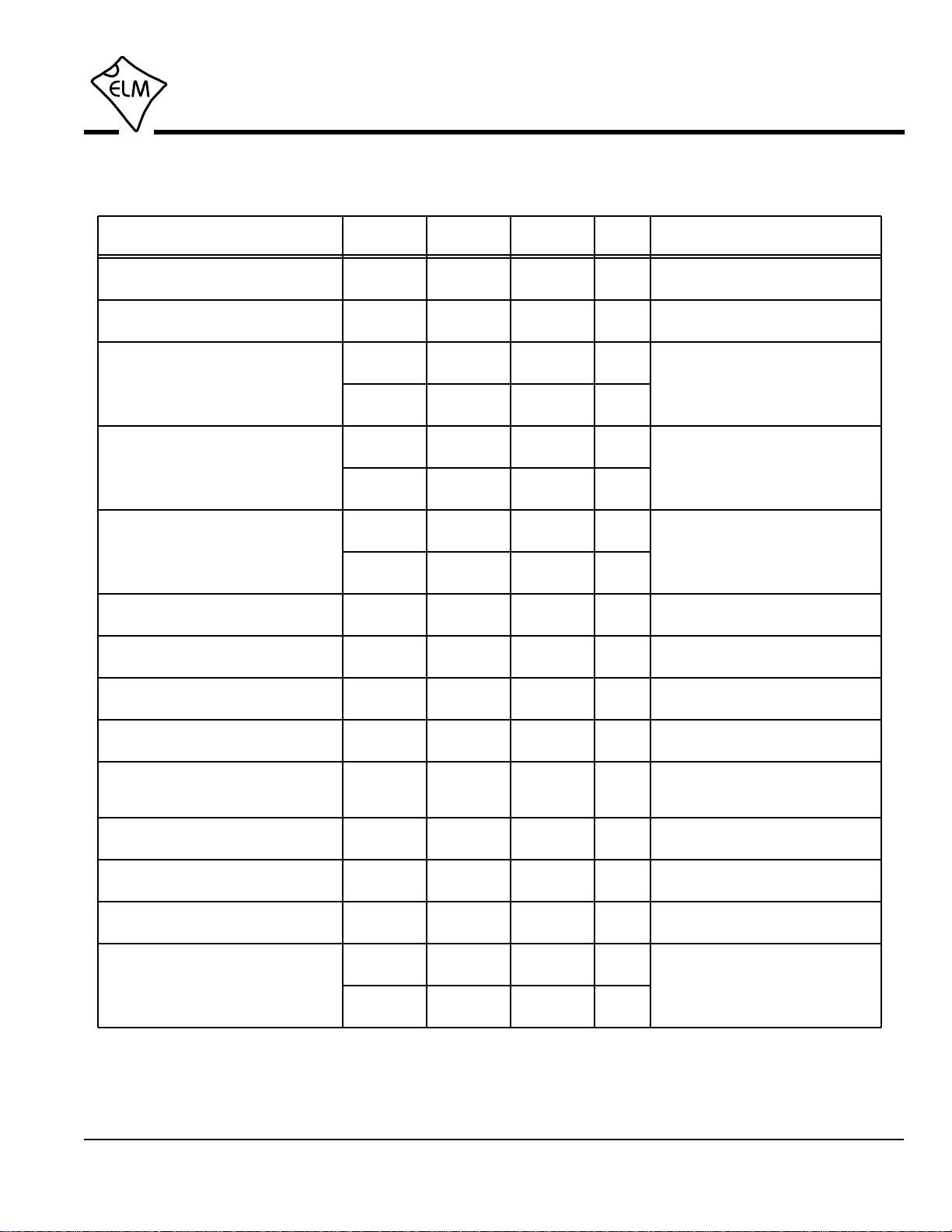

Unused Pins

When people only want to implement a portion of what the ELM329 is capable of, they often ask what to do with the

unused pins. The rule is that unused outputs may be left open-circuited with nothing connected to them, but unused

inputs must be terminated. The ELM329 is a CMOS integrated circuit that can not have any inputs left floating (or

you might damage the IC). Connect unused inputs as follows:

1 2 5 6 7 11 12 13 15 18 24Pin

Level H H H H* * * * * * *

The inputs that are shown with an asterisk (*) may be connected to either a High (VDD) or a Low (VSS) level.

Electrical Characteristics

7 of 83ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

Notes: 1. This integrated circuit is based on Microchip Technology Inc.’s PIC18F2480 device. For more detailed

device specifications, refer to the Microchip documentation (available at http://www.microchip.com/).

2. This spec must be met in order to ensure that a correct power on reset occurs. It is quite easily achieved

using most common types of supplies, but may be violated if one uses a slowly varying supply voltage, as

may be obtained through direct connection to solar cells or some charge pump circuits.

All values are for operation at 25°C and a 5V supply, unless otherwise noted. For further information, refer to note 1 below.

Characteristic Minimum Typical Maximum ConditionsUnits

Supply voltage, VDD 4.2 5.0 5.5 V

VDD rate of rise 0.05 V/ms

Average current, IDD 12 mA

Input logic levels 0.8

3.0

V

Output low voltage

Output high voltage

current (sink) = 10 mA

current (source) = 10 mA

see note 2

AT RV to beginning of response

ELM329 device only - does not

include any load currents

Schmitt trigger

input thresholds

Brown-out reset voltage 2.65 2.79 2.93 V

rising

falling

A/D conversion time 9 msec

Pins 5, 6, 7, and 24 only

V

V

0.3

4.4

V

V

2.9

1.5

Pins 1, 11, 12, 13, 15 and 18 only

1.0

4.0

ELM329

IgnMon debounce time

AT LP to PwrCtrl output time

LP ALERT to PwrCtrl output time 2.0 sec

msec

sec

50

1.0

0.15 mA

normal

low power

Pin 18 low level pulse duration to

wake the IC from low power mode µsec128 -

65

low

high VVDD

VSS

Reset time

AT WS 1.0 msec

sec1.0AT Z Measured from the end of the

command to the start of the ID

message (ELM329 v2.1)

8 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

Communicating with the ELM329

The ELM329 expects to communicate with a PC

through an RS232 serial connection. Although modern

computers do not usually provide a serial connection

such as this, there are several ways in which a ‘virtual

serial port’ can be created. The most common devices

are USB to RS232 adapters, but there are several

others such as PC cards, ethernet devices, or

Bluetooth to serial adapters.

No matter how you physically connect to the

ELM329, you will need a way to send and receive

data. The simplest method is to use one of the many

‘terminal’ programs that are available (HyperTerminal,

ZTerm, etc.), to allow typing the characters directly

from your keyboard.

To use a terminal program, you will need to adjust

several settings. First, ensure that your software is set

to use the proper ‘COM’ port, and that you have

chosen the proper data rate - this will be either 9600

baud (if pin 6 = 0V at power up), or 38400 baud (if

pin 6 = 5V and PP 0C has not been changed). If you

select the wrong ‘COM’ port, you will not be able to

send or receive any data. If you select the wrong data

rate, the information that you send and receive will be

all garbled, and unreadable by you or the ELM329.

Don’t forget to also set your connection for 8 data bits,

no parity bits, and 1 stop bit, and to set it for the proper

‘line end’ mode. All of the responses from the ELM329

are terminated with a single carriage return character

and, optionally, a linefeed character (depending on

your settings).

Properly connected and powered, the ELM329 will

energize the five LED outputs in sequence (as a lamp

test) and will then send the message:

ELM329 v2.1

>

In addition to identifying the version of this IC,

receiving this string is a good way to confirm that the

computer connections and terminal software settings

are correct (however, at this point no communications

have taken place with the vehicle, so the state of that

connection is still unknown).

The ‘>’ character that is shown on the second line

is the ELM329’s prompt character. It indicates that the

device is in the idle state, ready to receive characters

on the RS232 port. If you did not see the identification

string, you might try resetting the IC again with the AT

Z (reset) command. Simply type the letters A T and Z

(spaces are optional), then press the return key:

>AT Z

That should cause the LEDs to flash again, and

the identification string to be printed. If you see strange

looking characters, then check your baud rate - you

have likely set it incorrectly.

Characters sent from the computer can either be

intended for the ELM329’s internal use, or for

reformatting and passing on to the vehicle. The

ELM329 can quickly determine where the received

characters are to be directed by monitoring the

contents of the message. Commands that are

intended for the ELM329’s internal use will begin with

the characters ‘AT’, while OBD commands for the

vehicle are only allowed to contain the ASCII codes for

hexadecimal digits (0 to 9 and A to F).

Whether it is an ‘AT’ type internal command or a

hex string for the OBD bus, all messages to the

ELM329 must be terminated with a carriage return

character (hex ‘0D’) before it will be acted upon. The

one exception is when an incomplete string is sent and

no carriage return appears. In this case, an internal

timer will automatically abort the incomplete message

after about 20 seconds, and the ELM329 will print a

single question mark (‘?’) to show that the input was

not understood (and was not acted upon).

Messages that are not understood by the ELM329

Overview

The following describes how to use the ELM329 to

obtain information from your vehicle.

We begin by discussing just how to ‘talk’ to the IC

using a PC, then explain how to change options using

‘AT’ commands, and finally we show how to use the

ELM329 to obtain trouble codes (and reset them). For

the more advanced experimenters, there are also

sections on how to use some of the other features of

this product as well.

Using the ELM329 is not as daunting as it first

seems. Many users will never need to issue an ‘AT’

command, adjust timeouts, or change the headers. For

most, all that is required is a PC or smart device with a

terminal program (such as HyperTerminal or ZTerm),

and a little knowledge of OBD commands, which we

will provide in the following sections…

Communicating with the ELM329 (continued)

(syntax errors) will always be signalled by a single

question mark. These include incomplete messages,

incorrect AT commands, or invalid hexadecimal digit

strings, but are not an indication of whether or not the

message was understood by the vehicle. One must

keep in mind that the ELM329 is a protocol interpreter

that makes no attempt to assess the OBD messages

for validity – it only ensures that hexadecimal digits

were received, combined into bytes, then sent out the

OBD port, and it does not know if a message sent to

the vehicle was in error.

While processing OBD commands, the ELM329

will continually monitor for either an active RTS input

(if enabled), or an RS232 character received. Either

one can interrupt the IC, quickly returning control to

the user, while possibly aborting any initiation, etc. that

was in progress. After generating a signal to interrupt

the ELM329, software should always wait for either the

prompt character (‘>’ or hex 3E), or a low level on the

Busy output before beginning to send the next

command.

Finally, it should be noted that the ELM329 is not

case-sensitive, so the commands ‘ATZ’, ‘atz’, and

‘AtZ’ are all exactly the same to the ELM329. All

commands may be entered as you prefer, as no one

method is faster or better. The ELM329 also ignores

space characters and all control characters (tab, etc.),

so they can be inserted anywhere in the input if that

improves readability.

One other feature of the ELM329 is the ability to

repeat the last command (AT or OBD) when only a

single carriage return character is received. If you

have sent a command (for example, 01 0C to obtain

the rpm), you do not have to resend the entire

command in order to obtain an update from the vehicle

- simply send a carriage return character, and the

ELM329 will repeat the command for you. The

memory buffer only remembers the previous command

- there is no provision in the current ELM329 to

provide storage for any more.

9 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

Please Note:

There is a very small chance that NULL characters (byte value 00) may occasionally

be inserted into the RS232 data that is transmitted by the ELM329.

Microchip Technology has reported that some ICs which use the same EUSART as

in the ELM329 may, under very specific (and rare) conditions, insert an extra byte

(always of value 00) into the transmitted data. If you are using a terminal program to view

the data, you should select the ‘hide control characters’ option if it is available, and if you

are writing software for the ELM329, then monitor incoming bytes, and ignore any that

are of value 00 (ie. remove NULLs).

Several parameters within the ELM329 can be

adjusted in order to modify its behaviour. These do not

normally have to be changed before attempting to talk

to the vehicle, but occasionally the user may wish to

customize these settings – for example by turning the

character echo off, adjusting a timeout value, or

changing the header (ID) bytes. In order to do this,

internal ‘AT’ commands must be used.

Those familiar with PC modems will immediately

recognize AT commands as a standard way in which

modems are internally configured. The ELM329 uses

essentially the same method, always watching the

data sent by the PC, looking for messages that begin

with the character ‘A’ followed by the character ‘T’. If

found, the next characters will be interpreted as an

internal configuration or ‘AT’ command, and will be

executed upon receipt of a terminating carriage return

character. If the command is just a setting change, the

ELM329 will reply with the characters ‘OK’, to say that

it was successfully completed.

Some of the commands require that numbers be

provided as arguments, in order to set the internal

values. These will always be hexadecimal numbers

which must generally be provided in pairs. The

hexadecimal conversion chart in the OBD Commands

section (page 27) may be helpful if you wish to

interpret the values. Also, one should be aware that for

the on/off types of commands, the second character is

the number 1 or the number 0, the universal terms for

on and off.

The remainder of this page, and the next page

following provide a summary of all of the commands

that the current version of the ELM329 recognizes. A

more complete description of each command begins

on page 12.

10 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Summary

AT Commands

ELM329 Options

<CR> repeat the last command

BRD hh try Baud Rate Divisor hh

BRT hh set Baud Rate Timeout

Dset all to Defaults

E0, E1 Echo off, or on*

Iprint the version ID

L0, L1 Linefeeds off, or on

LP go to low power mode

M0, M1 Memory off, or on

RD Read the stored Data

SD hh Save Data byte hh

WS Warm Start (quick software reset)

Zreset all

@1 display the device description

@2 display the device identifier

@3 cccccccccccc store the @2 identifier

Programmable Parameters

PP xx OFF disable Prog Parameter xx

PP FF OFF all Prog Parameters disabled

PP xx ON enable Prog Parameter xx

PP FF ON all Prog Parameters enabled

PP xx SV yy for PP xx, Set the Value to yy

PPS print a PP Summary

Voltage Readings

CV dddd Calibrate the Voltage to dd.dd volts

CV 0000 restore CV value to factory setting

RV Read the input Voltage

Other

C0, C1 Control Output off*, or on

IGN read the IgnMon input level

IN1 read INput 1 level

IN2 read INput 2 level

Note: Settings shown with an asterisk (*)

are the default values

11 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Summary (continued)

General OBD Commands

AT0, 1, 2 Adaptive Timing off, auto1*, auto2

BD perform a Buffer Dump

BI Bypass the Initialization sequence

DP Describe the current Protocol

DPN Describe the Protocol by Number

H0, H1 Headers off*, or on

MA Monitor All

PC Protocol Close

R0, R1 Responses off, or on*

S0, S1 printing of Spaces off, or on*

SH xyz Set Header (11 bit ID) to xyz

SH xxyyzz Set Header (29 bit ID) to xxyyzz

SH wwxxyyzz Set Header (29 bit ID) to wwxxyyzz

SP h Set Protocol to h and save it

SP Ah Set Protocol to Auto, h and save it

ST hh Set Timeout to hh x 4 msec

TA hh set Tester Address to hh

TP h Try Protocol h

TP Ah Try Protocol h with Auto search

J1939 CAN Specific Commands (protocols A to F)

DM1 monitor for DM1 messages

JE use J1939 Elm data format*

JHF0, JHF1 Header Formatting off, or on*

JS use J1939 SAE data format

JTM1 set Timer Multiplier to 1*

JTM5 set Timer Multiplier to 5

MP hhhh Monitor for PGN 0hhhh

MP hhhh n “ “ and get n messages

MP hhhhhh Monitor for PGN hhhhhh

MP hhhhhh n “ “ and get n messages

CAN Specific Commands (protocols 6 to F)

. [1 - 8 bytes] send bytes with the 11 bit ID

: [1 - 8 bytes] send bytes with the 29 bit ID

CA is there CAN Activity at pin 11?

CEA turn off CAN Extended Addressing

CEA hh use CAN Extended Address hh

CAF0, CAF1 Automatic Formatting off, or on*

CF hhh set the ID Filter to hhh

CF hhhhhhhh set the ID Filter to hhhhhhhh

CFC0, CFC1 Flow Controls off, or on*

CM hhh set the ID Mask to hhh

CM hhhhhhhh set the ID Mask to hhhhhhhh

CP hh set CAN Priority to hh (29 bit)

CRA reset the Receive Address filters

CRA hhh set CAN Receive Address to hhh

CRA hhhhhhhh set the Rx Address to hhhhhhhh

CS show the CAN Status counts

CSM0, CSM1 Silent Monitoring off, or on*

D0, D1 display of the DLC off*, or on

FC SD [1 - 8 bytes] FC, Set Data to [...]

FC SM h Flow Control, Set the Mode to h

FC SH hhh FC, Set the Header to hhh

FC SH hhhhhhhh “ “ hhhhhhhh

PB xx yy Protocol B options and baud rate

TM0, 1, 2, 3 set Transceiver Mode to 0,1,2, or 3*

RTR send an RTR message

V0, V1 use of Variable DLC off*, or on

Periodic Message Commands

SW hh Set Wakeup interval to hhx20 msec

SW 00 turn off Wakeup messages

WD [1 - 8 bytes] set the Wakeup Data

WH hhh set the Wakeup Header (11 bit)

WH hhhhhhhh set the Wakeup Header (29 bit)

WM [1 - 8 bytes] set the Wakeup Message

WM0, 1, 2 set the Wakeup Mode to 0*, 1 or 2

Note: Settings shown with an asterisk (*)

are the default values

12 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Descriptions

<CR> [ repeat the last command ]

Sending a single carriage return character causes

the ELM329 to repeat the last command that it

performed. This is typically used when you wish to

obtain updates to a value at the fastest possible rate -

for example, if you send 01 0C to obtain the engine

rpm, you need only send a carriage return character

each time you wish to receive an update.

Do not use ‘AT’ before this command.

. [1 - 8 bytes] [ send bytes with the 11 bit ID ]

If your currently active protocol uses a 29 bit ID,

there may be times when you would like to send a

single message that has an 11 bit ID. This command is

used for that.

A single period (‘.’) followed by 1 to 8 data bytes

will cause the ELM329 to send those data bytes along

with the currently defined 11 bit ID. The data will be

sent exactly as provided - no formatting bytes or filler

bytes will be added, and the number of data bytes sent

will be the same as what you provide (so if you need to

send 8 bytes as for ISO 15765, then you must provide

all 8 of them). The default value used for the 11 bit ID

is 7DF, but this may be changed with the AT SH xyz

command. See the ‘Mixed ID (11 and 29 bit) Sending’

section for more information.

A protocol must be active before you can use this

command, as the ELM329 needs to know the current

baud rate, etc., but it does not have to be a 29 bit one.

That is, you may use this ‘dot’ command with an 11 bit

ID protocol, for example, if you needed to send

unformatted data along with ISO 15765 formatted data

(but the current firmware only allows you to define one

11 bit ID/header).

Do not use ‘AT’ before this command.

: [1 - 8 bytes] [ send bytes with the 29 bit ID ]

If your currently active protocol uses an 11 bit ID,

there may be times when you would like to send a

single message that has a 29 bit ID. This command is

used for that.

A single colon (‘:’) followed by 1 to 8 data bytes

will cause the ELM329 to send those data bytes along

with the currently defined 29 bit ID. The data will be

sent exactly as provided - no formatting bytes or filler

bytes will be added, and the number of data bytes sent

will be the same as what you provide (so if you need to

send 8 bytes as for ISO 15765, then you must provide

all 8 of them). The default value used for the 29 bit ID

is 18 DB 33 F1, but this may be changed with the

AT SH xxyyzz or AT SH wwxxyyzz commands. See

the ‘Mixed ID (11 and 29 bit) Sending’ section for more

information.

A protocol must be active before you can use this

command, as the ELM329 needs to know the current

baud rate, etc., but it does not have to be an 11 bit

one. That is, you may use this ‘colon’ command with a

29 bit ID protocol, for example, if you needed to send

unformatted data along with ISO 15765 formatted data

(but the current firmware only allows you to define one

29 bit ID/header).

Do not use ‘AT’ before this command.

AT0, AT1 and AT2 [ Adaptive Timing control ]

After an OBD request has been sent, the ELM329

waits to see if any responses are coming from the

vehicle. The maximum time that it waits is set by the

AT ST hh setting, but this setting is purposely a little

longer than it needs to be, in order to ensure that the

IC will work with a wide variety of vehicles. Although

the setting is adjustable, many people do not have the

equipment or experience that it would take to

determine an optimal value.

The Adaptive Timing feature automatically sets the

timeout value for you, to a value that is based on the

actual response times that your vehicle is responding

in. As conditions such as bus loading, etc. change, the

algorithm learns from them, and makes appropriate

adjustments. Note that it always uses your AT ST hh

setting as the maximum setting, and will never choose

one which is longer.

There are three adaptive timing settings that are

available for use. By default, Adaptive Timing option 1

(AT1) is enabled, and is the recommended setting.

AT0 is used to disable Adaptive timing (so the timeout

The following describes each AT Command that the

current version of the ELM329 supports, in a little more

detail. Many of these commands are also described

further in other sections:

13 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Descriptions (continued)

is always as set by AT ST), while AT2 is a more

aggressive version of AT1 (the effect is more

noticeable for very slow connections – you may not

see much difference with faster OBD systems). The

J1939 protocol does not support Adaptive Timing – it

uses fixed timeouts as set in the standard.

BD [ perform an OBD Buffer Dump ]

All messages sent and received by the ELM329

are stored temporarily in a set of twelve memory

storage locations called the OBD Buffer. Occasionally,

it may be useful to see the contents of this buffer,

perhaps to see why a request failed, to see the header

bytes in the last message, or just to learn more of the

structure of OBD messages. You can ask at any time

for the contents of this buffer to be ‘dumped’

(ie printed). When you do, the ELM329 sends a length

byte (representing the length of the current message in

the buffer) followed by the contents of all twelve OBD

buffer locations. For example, here’s one ‘dump’:

>AT BD

0C 00 00 07 E8 03 41 05 42 00 00 00 00

The 0C is the length byte - it tells us that the

following 12 bytes are valid. The actual bytes that have

been sent or received appear after the length. Note

that wakeup (CAN periodic) messages do not use the

buffer as an intermediate step, so you are not able to

see them with AT BD.

BI [ Bypass the Initialization sequence ]

This command should be used with caution. It

allows the currently selected protocol to be made

active without requiring any sort of initiation or

handshaking to occur. The initiation process is

normally used to validate the protocol, and without it,

results may be difficult to predict. It should not be used

for routine OBD use, and has only been provided to

allow the construction of ECU simulators and training

demonstrators.

BRD hh [ try Baud Rate Divisor hh ]

This command is used to change the RS232 baud

rate divisor to the hex value provided by hh, while

under computer control. It is not intended for casual

experimenting - if you wish to change the baud rate

from a terminal program, you should use PP 0C.

Since some interface circuits are not able to be

operated at high data rates, the BRD command uses a

sequence of sends and receives to test the interface,

with any failure resulting in a fallback to the previous

baud rate. This allows several baud rates to be tested

and a reliable one chosen for the communications.

The entire process is described in detail in the ‘Using

Higher RS232 Baud Rates’ section, on pages 45 and

46. If successful, the actual baud rate (in kbps) will be

4000 divided by the divisor (hh).

BRT hh [ set Baud Rate Timeout to hh ]

This command allows the timeout used for the

Baud Rate handshake (ie. AT BRD) to be varied. The

time delay is given by hh x 5.0 msec, where hh is a

hexadecimal value. The default value for this setting is

0F, providing a 75 msec timeout. Note that a value of

00 does not result in 0 msec - it provides the

maximum time of 256 x 5.0 msec, or 1.28 seconds.

C0 and C1 [ Control output off* or on ]

These commands are used to set the level at the

Control output (pin 4). The AT C0 command sets it to a

low logic level (0V), while AT C1 sets it to a high level

(5V). After a system reset or wakeup from low power

mode (unless PP 0F bit 0 = ‘1’), the Control output will

be reset to a low level.

CA [is there CAN Activity at pin 11?]

This command is used to determine if there is a

CAN signal present at pin 11 (the CAN Monitor pin). If

there is, the response will be the letter ‘Y’ (for yes),

while if there is no signal, the response will be the

letter ‘N’, for no. If there has been no signal detected

since the last reset, the output will be a dash (‘-’).

CAF0 and CAF1 [ CAN Auto Formatting off or on ]

These commands determine whether the ELM329

assists you with the formatting of the CAN data that is

sent and received. With CAN Automatic Formatting

enabled (CAF1), the IC will automatically generate the

formatting (PCI) bytes for you when sending, and will

remove them when receiving. This means that you can

continue to issue OBD requests (01 00, etc.), without

regard to the extra bytes that some CAN systems

require. Also, with formatting on, any extra (unused)

14 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

data bytes that are received in the frame will be

removed, and any messages with invalid PCI bytes will

be ignored. (When monitoring, however, messages

with invalid PCI bytes will be shown, with a ‘<DATA

ERROR’ message beside them).

Multi-frame responses may be returned by the

vehicle with ISO 15765 and J1939. To make these

more readable, the Auto Formatting mode will extract

the total data length and print it on one line, then show

each line of data with the segment number followed by

a colon (‘:’), and then the data bytes.

You may also see the characters 'FC:' on a line (if

you are experimenting). This identifies a Flow Control

message that has been sent as part of the multi-line

message signalling. Flow Control messages are

automatically generated by the ELM329 in response to

a ‘First Frame’ reply, as long as the CFC setting is on

(it does not matter if auto formatting is on or not).

Another type of message – the RTR (or ‘Remote

Transmission Request’) – will be automatically hidden

for you when in the CAF1 mode, since they contain no

data. When auto formatting is off (CAF0), you will see

the characters 'RTR' printed when one of these frames

has been received.

Turning the CAN Automatic Formatting off (CAF0),

will cause the ELM329 to print all of the received data

bytes. No bytes will be hidden from you, and none will

be inserted for you. Similarly, when sending a data

request with formatting off, you must provide all of the

required data bytes exactly as they are to be sent –

the ELM329 will not perform any formatting for you

other than to add some trailing 'padding' bytes to

ensure that eight data bytes are sent, if required. This

allows operation in systems that do not use PCI bytes.

Note that turning the display of headers on (with

AT H1) will override some of the CAF1 formatting of

the received data frames, so that the received bytes

will appear much like in the CAF0 mode (ie. as

received). It is only the printing of the received data

that will be affected when both CAF1 and H1 modes

are enabled, though; when sending data, the PCI byte

will still be created for you and padding bytes will still

be added. Auto Formatting on (CAF1) is the default

setting for the ELM329.

CEA [ turn off the CAN Extended Address ]

The CEA command is used to turn off the special

features that are set with the CEA hh command.

CEA hh [ set the CAN Extended Address to hh ]

Some CAN protocols extend the addressing fields

by using the first of the eight data bytes as a target or

receiver’s address. This type of formatting does not

comply with any OBD standard, but by adding it, we

allow for some experimentation.

Sending the CEA hh command causes the

ELM329 to insert the hh value as the first data byte of

all CAN messages that you send. It also adds one

more filtering step to received messages, only passing

ones that have the Tester Address in the first data byte

position (in addition to requiring that ID bits match the

patterns set by AT CF and CM, or CRA). The AT CEA

hh command can be sent at any time, and changes

are effective immediately, allowing for changes of the

address ‘on-the-fly’. There is a more lengthy

discussion of this extended addressing in the ‘Using

CAN Extended Addresses’ section on page 57.

The CEA mode of operation is off by default, and

once on, can be turned off at any time by sending AT

CEA, with no address. Note that the CEA setting has

no effect when J1939 formatting is on.

CF hhh [ set the CAN ID Filter to hhh ]

The CAN Filter works in conjunction with the CAN

Mask to determine what information is to be accepted

by the receiver. As each message is received, the

incoming CAN ID bits are compared to the CAN Filter

bits (when the mask bit is a ‘1’). If all of the relevant

bits match, the message will be accepted, and

processed by the ELM329, otherwise it will be

discarded. This version of the CAN Filter command is

used to set filters with 11 bit ID CAN systems. Only the

rightmost 11 bits of the provided nibbles are used, and

the most significant bit is ignored.

CF hh hh hh hh [ set the CAN ID Filter to hhhhhhhh ]

This command allows all four bytes (actually 29

bits) of a CAN Filter to be set at once. The 3 most

significant bits will always be ignored, and may be

given any value. This command may be used to create

11 bit ID filters as well, since they are stored in the

same locations internally (entering AT CF 00 00 0h hh

is exactly the same as entering the shorter AT CF hhh

command).

CFC0 and CFC1 [ CAN Flow Control off or on ]

The ISO 15765-4 CAN protocol expects a ‘Flow

AT Command Descriptions (continued)

15 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

Control’ message to always be sent in response to a

‘First Frame’ message, and the ELM329 automatically

sends these without any intervention by the user. If

experimenting with a non-OBD system, it may be

desirable to turn this automatic response off, and the

AT CFC0 command has been provided for that

purpose. The default setting is CFC1 - Flow Controls

on. Note that during monitoring (ie AT MA), there are

never any Flow Controls sent no matter what the CFC

option is set to.

CM hhh [ set the CAN ID Mask to hhh ]

There can be a great many messages being

transmitted in a CAN system at any one time. In order

to limit what the ELM329 views, there needs to be a

system of filtering out the relevant ones from all the

others. This is accomplished by the filter, which works

in conjunction with the mask. A mask is a group of bits

that show the ELM329 which bits in the filter are

relevant, and which ones can be ignored. A ‘must

match’ condition is signalled by setting a mask bit to

'1', while a 'don't care' is signalled by setting a bit to '0'.

This three digit variation of the CM command is used

to provide mask values for 11 bit ID systems (the most

significant bit is always ignored).

Note that a common storage location is used

internally for the 29 bit and 11 bit masks, so an 11 bit

mask could conceivably be assigned with the next

command (CM hh hh hh hh), should you wish to do the

extra typing.

CM hh hh hh hh [ set the CAN ID Mask to hhhhhhhh ]

This command is used to assign mask values for

29 bit ID systems. See the discussion under the

CM hhh command as it is essentially identical, except

for the length. Note that the three most significant bits

that you provide in the first digit will be ignored.

CP hh [ set CAN Priority bits to hh ]

This command is used to modify the five most

significant bits of a 29 bit CAN ID for sending

messages (the other 24 bits are set with one of the AT

SH commands). Many systems use these bits to

assign a priority value to messages, and to determine

the protocol. Any bits provided in excess of the five

required are ignored, and not stored by the ELM329 (it

only uses the five least significant bits of this byte).

The default value for these priority bits is hex 18,

which can be restored at any time with the AT D

command.

CRA [reset the CAN Rx Addr]

The AT CRA command is used to restore the CAN

receive filters to their default values. Note that it does

not have any arguments (ie no data).

CRA xyz [set the CAN Rx Addr to xyz]

Setting the CAN masks and filters can be difficult

at times, so if you only want to receive information

from one address (ie. one CAN ID), then this

command may be very welcome. For example, if you

only want to see information from 7E8, simply send AT

CRA 7E8, and the ELM329 will make the necessary

adjustments to both the mask and the filter for you.

If you wish to allow the reception of a range of

values, you can use the letter X to signify a ‘don’t care’

condition. That is, AT CRA 7EX would allow all IDs

that start with 7E to pass (7E0, 7E1, etc.). For a more

specific range of IDs, you may need to assign a mask

and filter.

CRA wwxxyyzz [set the CAN Rx Addr to wwxxyyzz]

This command is identical to the previous one,

except that it is used to set 29 bit CAN IDs, instead of

11. Sending AT CRA will also reverse the changes

made by this command.

CS [ show the CAN Status counts ]

The CAN protocol requires that statistics be kept

regarding the number of transmit and receive errors

detected. If there should be a significant number of

errors (due to a hardware or software problem), the

device will go off-line in order to not affect other data

on the bus. The AT CS command lets you see both

the transmitter (Tx) and the receiver (Rx) error counts,

in hexadecimal. If the transmitter should be off (count

>FF), you will see ‘OFF’ rather than a specific count.

CSM0 and CSM1 [ CAN Silent Monitoring off or on ]

The ELM329 was designed to be completely silent

while monitoring a CAN bus. Because of this, it is able

to report exactly what it sees, without colouring the

information in any way. Occasionally (when bench

testing, or when connecting to a dedicated CAN port),

it may be preferred that the ELM329 does not operate

AT Command Descriptions (continued)

16 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

silently (ie you may want it to generate ACK bits, etc.),

and this is what the CSM command is for. CSM1 turns

silent monitoring on (no ACKs), CSM0 turns it off. The

default value is CSM1, but it may be changed with

PP 21.

CV dddd [ Calibrate the Voltage to dd.dd volts ]

The voltage reading that the ELM329 shows for an

AT RV request can be calibrated with this command.

The argument (‘dddd’) must always be provided as 4

digits, with no decimal point (it assumes that the

decimal place is between the second and the third

digits).

To use this feature, simply use an accurate meter

to read the actual input voltage, then use the CV

command to change the internal calibration (scaling)

factor. For example, if the ELM329 shows the voltage

as 12.2V while you measure 11.99 volts, then send

AT CV 1199 and the ELM329 will recalibrate itself for

that voltage (it will actually read 12.0V due to digit

roundoff). See page 26 for some more information on

how to read voltages and perform the calibration.

CV 0000 [ restore the factory Calibration Value ]

If you are experimenting with the CV dddd

command but do not have an accurate voltmeter as a

reference, you may soon get into trouble. If this

happens, you can always send AT CV 0000 to restore

the ELM329 to the original calibration value.

D[ set all to Defaults ]

This command is used to set the options to their

default (or factory) settings, as when power is first

applied. The last stored protocol will be retrieved from

memory, and will become the current setting (possibly

closing a protocol that was active). Any settings that

the user had made for custom headers, filters, or

masks will be returned to their default values, and all

timer settings will also be restored to their defaults.

D0 and D1 [ display of DLC off or on ]

Standard CAN (ISO 15765-4) OBD requires that

all messages have 8 data bytes, so displaying the

number of data bytes (the DLC) is not normally very

useful. When experimenting with other protocols,

however, it may be useful to be able to see what the

data lengths are. The D0 and D1 commands control

the display of the DLC digit (the headers must also be

on in order to see this digit). When displayed, the

single DLC digit will appear between the ID (header)

bytes and the data bytes. The default setting is

determined by PP 29.

DM1 [ monitor for DM1s ]

The SAE J1939 Protocol broadcasts trouble codes

periodically, by way of the Diagnostic Mode 1 (DM1)

messages. This command sets the ELM329 to

continually monitor for this type of message for you,

even following multi-segment transport protocols if

required. Note that a combination of masks and filters

could be set to provide a similar output, but they would

not allow multiline messages to be detected. The DM1

command adds the extra logic that is needed for

multiline messages.

This command is only available when a protocol

has been selected for J1939 formatting. It returns an

error if attempted under any other conditions.

DP [ Describe the current Protocol ]

The ELM329 automatically detects a vehicle’s

OBD protocol, but does not normally report what it is.

The DP command is a convenient means of asking

what protocol the IC is currently set to (even if it has

not yet ‘connected’ to the vehicle).

If a protocol is chosen and the automatic option is

also selected, AT DP will show the word 'AUTO' before

the protocol description. Note that the description

shows the actual protocol names, and the data rates, it

does not provide the numbers used by the protocol

setting commands (see DPN for this).

DPN [ Describe the Protocol by Number ]

This command is similar to the DP command, but

it returns a number which represents the current

protocol. If the automatic search function is also

enabled, the number will be preceded with the letter

‘A’. The number is the same one that is used with the

set protocol and test protocol commands (see page 32

for a list of them).

E0 and E1 [ Echo off or on ]

These commands control whether or not the

characters received on the RS232 port are echoed

(retransmitted) back to the host computer. Character

echo can be used to confirm that the characters sent

AT Command Descriptions (continued)

to the ELM329 were received correctly. The default is

E1 (or echo on).

FC SD [1-8 bytes] [ Flow Control Set Data to… ]

The data bytes that are sent in a CAN Flow

Control message may be defined with this command.

One to eight data bytes may be specified, with the

remainder of the bytes in the message being

automatically set to the default CAN filler byte, if more

bytes are required by the protocol. Note that no

formatting bytes (PCI, etc.) are added by this

command - the data is used exactly as provided,

except for the filler bytes. AT FC SD is used with Flow

Control modes 1 and 2.

FC SH xyz [ Flow Control Set Header to… ]

The header (or more properly ‘CAN ID’) bytes

used for CAN Flow Control messages can be set using

this command. Only the right-most 11 bits of those

provided will be used - the most significant bit is

always ignored. This command only affects Flow

Control mode 1.

FC SH wwxxyyzz [ Flow Control Set Header to… ]

This command is used to set the header (or ‘CAN

ID’) bits for Flow Control responses with 29 bit CAN ID

systems. Since the 8 nibbles define 32 bits, only the

right-most 29 bits of those provided will be used - the

most significant three bits are always ignored. This

command only affects Flow Control mode 1.

FC SM h [ Flow Control Set Mode to h ]

This command sets how the ELM329 responds to

First Frame messages when automatic Flow Control

responses are enabled. The single digit provided can

either be ‘0’ (the default) for fully automatic responses,

‘1’ for completely user defined responses, or ‘2’ for

user defined data bytes in the response. Note that FC

modes 1 and 2 can only be enabled if you have

defined the needed data and possibly ID bytes. If you

have not, you will get an error message. More

complete details and examples can be found in the

Altering Flow Control Messages section (page 56).

H0 and H1 [ Headers off or on ]

These commands control whether or not the

header (ID and possibly DLC) bytes of information are

shown in the responses from the vehicle. These are

not normally shown by the ELM329, but may be of

interest (especially if you receive multiple responses

and wish to determine what modules they were from).

Turning the headers on (with AT H1) actually

shows more than just the header bytes – you will see

the complete message as transmitted, including the

PCI bytes, and the CAN data length code (DLC) if it

has been enabled. The current version of this IC does

not display the CAN CRC code.

I[ Identify yourself ]

Issuing this command causes the chip to identify

itself, by printing the startup product ID string (currently

‘ELM329 v2.1’). Software can use this to determine

exactly which integrated circuit it is talking to, without

having to reset the IC.

IGN [ read the IgnMon input level ]

This command reads the signal level at pin 15. It

assumes that the logic level is related to the ignition

voltage, so if the input is at a high level, the response

will be ‘ON’, and a low level will report ‘OFF’. This

feature is most useful if you wish to perform the power

control functions using your own software. If you

disable the automatic response to a low input on this

pin (by setting bit 2 of PP 0E to 0), then pin 15 will

function as the RTS input. A low level on the input will

not turn the power off, but it will interrupt any OBD

activity that is in progress. All you need to do is detect

the ‘STOPPED’ message that is sent when the

ELM329 is interrupted, and then check the level at pin

15 using AT IGN. If it is found to be OFF, you can

perform an orderly shutdown yourself.

IN1 [ read the level at INput 1 ]

This command causes the ELM329 to read the

logic level at pin 12. If it is at a low level, ‘0’ will be

reported, while a high level results in a ‘1’. The level

shown is subject to the hysteresis effects of the

Schmitt trigger wave shaping of the input circuitry.

IN2 [ read the level at INput 2 ]

This command causes the ELM329 to read the

logic level at pin 13. If it is at a low level, ‘0’ will be

reported, while a high level results in a ‘1’. The level

shown is subject to the hysteresis effects of the

Schmitt trigger wave shaping of the input circuitry.

17 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Descriptions (continued)

18 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

JE [ enables the J1939 ELM data format ]

The J1939 standard requires that PGN requests

be sent with the byte order reversed from the standard

‘left-to-right’ order, which many of us would expect. For

example, to send a request for the engine temperature

(PGN 00FEEE), the data bytes are actually sent in the

reverse order (ie EE FE 00), and the ELM329 would

normally expect you to provide the data in that order

for passing on to the vehicle.

When experimenting, this constant need for byte

reversals can be quite confusing, so we have defined

an ELM format that reverses the bytes for you. When

the J1939 ELM (JE) format is enabled, and you have a

J1939 protocol selected, and you provide three data

bytes to the ELM329, it will reverse the order for you

before sending them to the ECU. To request the

engine temperature PGN, you would send 00 FE EE

(and not EE FE 00). The ‘JE’ type of automatic

formatting is enabled by default.

JHF0 and JHF1 [ J1939 Header Formatting off or on ]

When printing responses, the ELM329 normally

formats the J1939 ID (ie Header) bits in such a way as

to isolate the priority bits and group all the PGN

information, while keeping the source address byte

separate. If you prefer to see the ID information as four

separate bytes (which a lot of the J1939 software

seems to do), then simply turn off the formatting with

JHF0. The CAF0 command has the same effect (and

overrides the JHF setting), but also affects other

formatting. The default setting is JHF1.

JS [ enables the J1939 SAE data format ]

The AT JS command disables the automatic byte

reordering that the JE command performs for you. If

you wish to send data bytes to the J1939 vehicle

without any manipulation of the byte order, then select

JS formatting.

Using the above example for engine temperature

(PGN 00FEEE) with the data format set to JS, you

must send the bytes to the ELM329 as EE FE 00 (this

is also known as little-endian byte ordering).

The JS type of data formatting is off by default.

JTM1 [ J1939 Timer Multiplier to 1 ]

This command sets the J1939 AT ST time

multiplier to 1, reversing any changes made by JTM5.

JTM1 is the default setting. It has no effect for non-

J1939 protocols.

JTM5 [ J1939 Timer Multiplier to 5 ]

When using a J1939 protocol, it is occasionally

useful to be able to set the AT ST time to values

longer than one second. The JTM5 command will

multiply the AT ST setting by a factor of 5, in order to

provide longer times for the J1939 protocols (only). By

default, this multiplier is off.

L0 and L1 [ Linefeeds off or on ]

This option controls the sending of linefeed

characters after each carriage return character. For

AT L1, linefeeds will be generated after every carriage

return character, and for AT L0, they will be off. Users

will generally wish to have this option on if using a

terminal program, but off if using a custom computer

interface (as the extra characters transmitted will only

serve to slow the communications down). The default

setting is determined by the voltage at pin 7 during

power on (or reset). If the level is high, then linefeeds

are on by default; otherwise they will be off.

LP [ go to the Low Power mode ]

This command causes the ELM329 to shut off all

but ‘essential services’ in order to reduce the power

consumption to a minimum. The ELM329 will respond

with an ‘OK’ (but no carriage return) and then, one

second later, will change the state of the PwrCtrl

outputs (pins 14 & 16) and will enter the low power

(standby) mode. The IC can be brought back to normal

operation with an RS232 input, CAN activity, or a

rising edge at the IgnMon (pin 15) input, in addition to

the usual methods of resetting the IC (power off then

on, a low on pin 1, or a brownout). See the ‘Low Power

Mode’ section (page 61) for more information.

M0 and M1 [ Memory off or on ]

The ELM329 has internal ‘non-volatile’ memory

that is capable of remembering the last protocol used,

even after the power is turned off. This can be

convenient if the IC is often used for one particular

protocol, as that will be the first one attempted when

next powered on. To enable this memory function, it is

necessary to either use an AT command to select the

M1 option, or to have chosen ‘memory on’ as the

default power on mode (by connecting pin 5 of the

AT Command Descriptions (continued)

19 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Descriptions (continued)

ELM329 to a high logic level).

When the memory function is enabled, each time

that the ELM329 finds a valid OBD protocol, that

protocol will be memorized (stored) and will become

the new default. If the memory function is not enabled,

protocols found during a session will not be

memorized, and the ELM329 will always start at power

up using the same (last saved) protocol.

If the ELM329 is to be used in an environment

where the protocol is constantly changing, it would

likely be best to turn the memory function off, and

issue an AT SP 0 command once. The SP 0 command

tells the ELM329 to start in an 'Automatic' protocol

search mode, which is the most useful for an unknown

environment. ICs come from the factory set to this

mode. If, however, you have only one vehicle that you

regularly connect to, storing that vehicle’s protocol as

the default would make the most sense.

The default setting for the memory function is

determined by the voltage level at pin 5 during power

up (or system reset). If it is connected to a high level

(VDD), then the memory function will be on by default.

If pin 5 is connected to a low level, the memory saving

will be off by default.

MA [ Monitor All messages ]

This command places the ELM329 into a bus

monitoring mode, in which it continually monitors for

(and displays) all messages that it sees on the OBD

bus. It is a quiet monitor, not sending Acknowledge

bits or Wakeup (CAN periodic) messages. Monitoring

will continue until it is stopped by activity on the RS232

input, or the RTS pin.

To stop the monitoring, simply send any single

character to the ELM329, then wait for it to respond

with a prompt character (‘>’), or a low level output on

the Busy pin. (Setting the RTS input to a low level will

interrupt the device as well.) Waiting for the prompt is

necessary as the response time varies depending on

what the IC was doing when it was interrupted. If for

instance it is in the middle of printing a line, it will first

complete that line then return to the command state,

issuing the prompt character. If it were simply waiting

for input, it would return immediately. Note that the

character which stops the monitoring will always be

discarded, and will not affect subsequent commands.

All messages that are received by the ELM329 will

be printed as found, even if the CAN auto formatting is

on. Normally, the automatic formatting will clean up

what is displayed, hiding errors, improperly formatted

messages, etc. but when monitoring, you will see all

messages that pass through the receive filter, and the

error messages.

If the filter and/or mask are set (with the CF, CM or

CRA commands) before sending AT MA, then the data

displayed will be restricted to only those messages

that meet the criteria. This is normally desired, but

occasionally brings unexpected results when users are

not aware. If you truly want to see all data, then you

may want to be sure there is no filtering of data (send

AT CRA before the AT MA).

The MA monitoring command operates by closing

the current protocol (an AT PC is executed internally),

then configuring the IC for silent monitoring of the data

(no wakeup messages, or acknowledges are sent by

the ELM329). When the next OBD command is to be

transmitted, the protocol will again be initialized, and

you may see messages stating this. ‘SEARCHING...’

may also be seen, depending on what changes were

made while monitoring.

MP hhhh [ Monitor for PGN hhhh ]

The AT MA command is quite useful for when you

wish to monitor for a specific byte in the header of an

OBD message. For the SAE J1939 Protocol, however,

it is often desirable to monitor for the multi-byte

Parameter Group Numbers (or PGNs), which can

appear in either the header, or the data bytes. The MP

command is a special J1939 only command that is

used to look for responses to a particular PGN

request.

Note that this MP command lets you set four of the

six PGN digits, but provides no means to set the first

two digits, so they are always assumed to be 00. For

example, the DM2 PGN has an assigned value of

00FECB (see SAE J1939-73). To monitor for DM2

messages, you would issue AT MP FECB, eliminating

the 00, since the MP hhhh command always assumes

that the PGN is preceded by two zeros.

This command is only available when a protocol

has been selected for SAE J1939 formatting. It returns

an error if attempted under any other conditions. Note

also that this version of the ELM329 only displays

responses that match the criteria, not the requests that

are asking for the PGN information.

MP hhhh n [ Monitor for PGN, get n messages ]

This is very similar to the previous command, but

20 of 83

ELM329

ELM329DSC Elm Electronics – Circuits for the Hobbyist

www.elmelectronics.com

AT Command Descriptions (continued)

adds the ability to set the number of messages that

should be fetched before the ELM329 automatically

stops monitoring and prints a prompt character. The

value ‘n’ may be any single hex digit.

MP hhhhhh [ Monitor for PGN hhhhhh ]

This command is very similar to the MP hhhh

command, but it extends the number of bytes provided

by one, so that there is complete control over the PGN

definition (it does not make the assumption that the

Data Page bit is 0, as the MP hhhh command does).

This allows for future expansion, should additional

PGNs be defined with the Data Page bit set. Note that

internally, the filter and mask are set using the values

provided, but only the Data Page bit is relevant in the

mask - the other bits are ignored. If you need more

precise matching of the priority and EDP bits, you

might consider the AT CM and AT CF commands to

set the filter and mask, then use AT MA.

MP hhhhhh n [ Monitor for PGN, get n messages ]

This is very similar to the previous command, but it

adds the ability to set the number of messages that

should be fetched before the ELM329 automatically

stops monitoring and prints a prompt character. The

value ‘n’ may be any single hex digit.

PB xx yy [ set Protocol B parameters ]

This command allows you to change the protocol

B (USER1) options and baud rate without having to

change the associated Programmable Parameters.

This allows for quicker testing, and program control.

To use this feature, simply set xx to the value for

PP 2C (the formatting options), and yy to the value for

PP 2D (the baud rate divisor), and send this

command. The next time that the protocol is initialized

it will use these values.

For example, assume that you wish to try

monitoring a system that uses 11 bit CAN at

33.3 kbps. If you do not want any special formatting,