Camera Resolution: ....380 horizontal x 350 vertical

Standard Equipment

KD-125M –Unit with monitor (and power pack

inside monitor casing), 125′of push rod, camera

head, reel, wheel and frame assembly, and stan-

dard accessories which include:

• Operator’s Manual

• 3

″

and 6

″

Centering Guides

• 6 Snap Rings (for Centering Guides)

• 1-BNC to RCA Adapter

• 1-Interconnect Cable

• 1 Spanner Wrench (for Camera Head removal)

• 1 RCA to RCA Video Cable

• 1 Pair of Plastic Coated Gloves

KD-125P –Unit with power pack, 125′of push rod,

camera head, reel, wheel and frame assembly, and

standard accessories.

KD-200M –Unit with monitor (and power pack

inside monitor casing), 200′of push rod, camera

head, reel, wheel and frame assembly, and stan-

dard accessories.

KD-200P –Unit with power pack, 200′of push rod,

camera head, reel, wheel and frame assembly, and

standard accessories.

KD-325M –Unit with monitor (and power pack

inside monitor casing) 325′of push rod, camera

head, reel, wheel and frame assembly, and stan-

dard accessories.

KD-325P –Unit with power pack, 325′of push rod,

camera head, reel, wheel and frame assembly, and

standard accessories.

Terms

(Refer to Figures 2-10)

Brake Large black knob on dolly that controls the

spinning action of reel. The purpose of the brake is to

provide a slight drag on the reel to prevent freewheel-

ing, resulting in excessive cable exiting the reel. The

brake is not intended to lock the reel.

Cable Guide The U-shaped metal bar above the

brake that the camera and push cable passes through

as it exits the reel.

Camera Head Contains a video camera module,

LED board, and control and protective components for

the video system. The camera is rated to a water

depth of 330 feet.

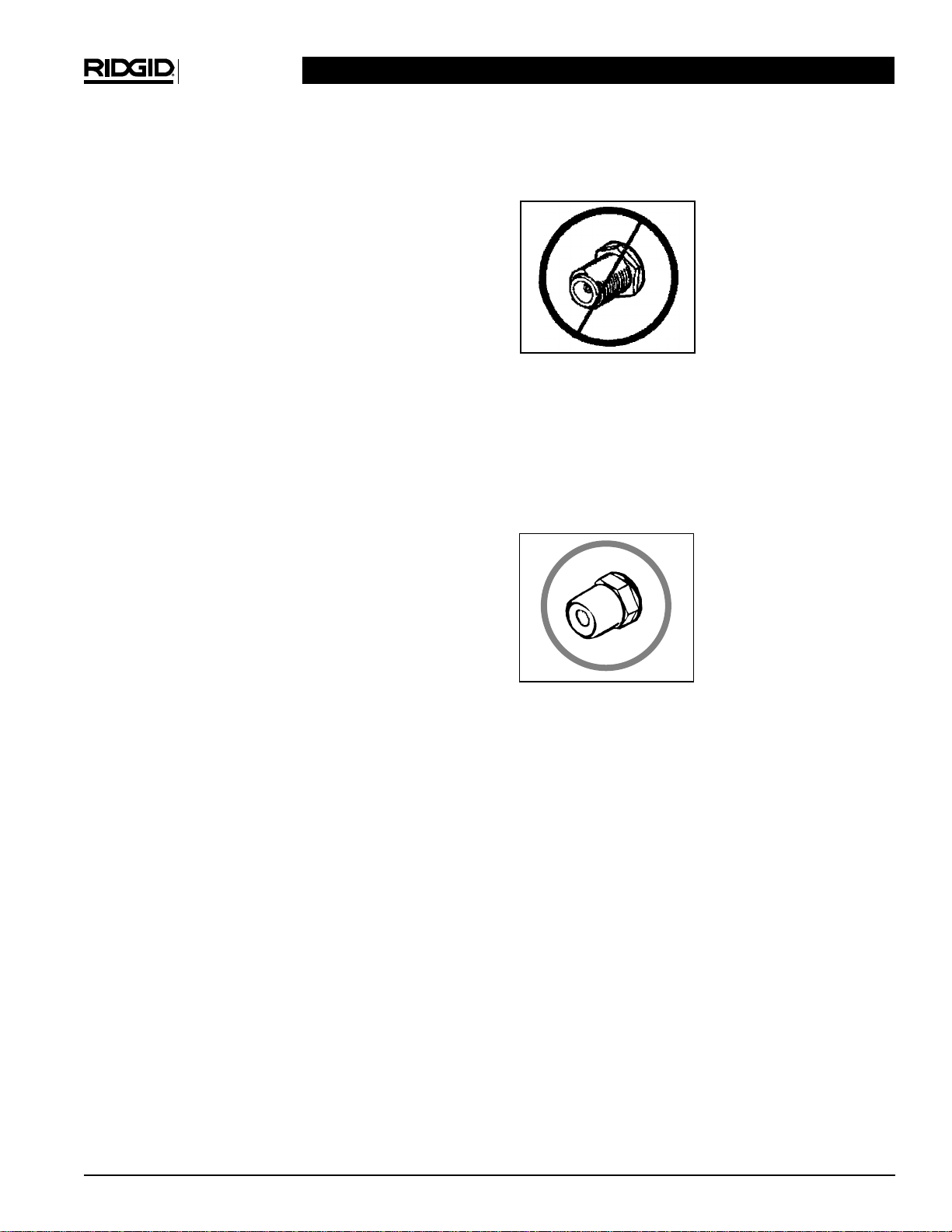

Camera Skid The small plastic ring found on the

camera head (not to be confused with centering

guides). Its purpose is to protect the stainless steel

housing from abrasion. A metal C-clip (on the side

that faces the spring assembly) holds the camera skid

in place. The skid should be replaced as soon as it

wears down to the grooves, such that it is smooth.

Centering Guides Small, plastic, star-shaped devices

that mount onto the spring assembly using snap rings.

3″and 6″in diameter, they center the camera and help

keep it off of the bottom (out of the sludge).

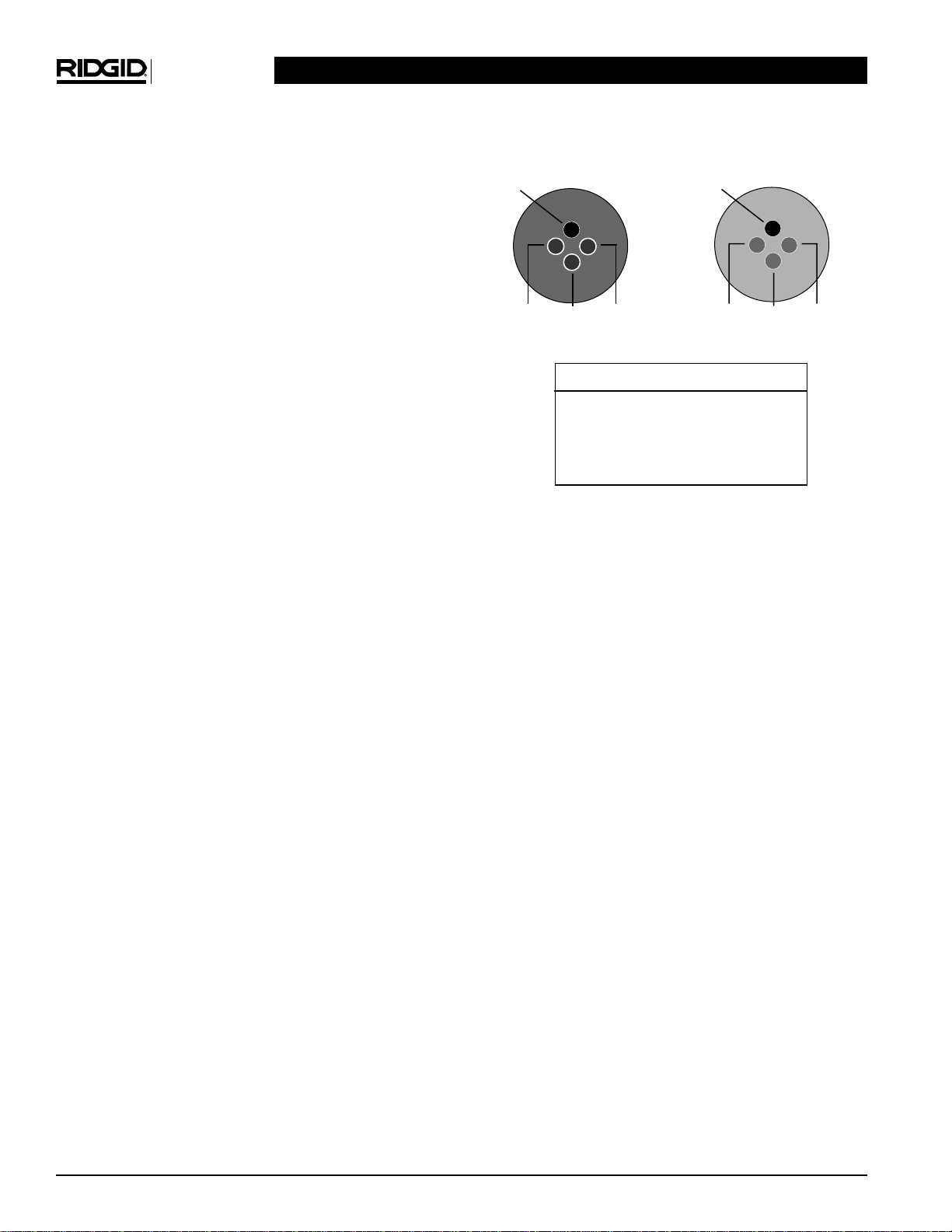

Connectors All the “plugs” in the system that con-

nect the camera; push cable; hub; interconnect cable;

monitor/power pack. These are the connectors that

have guide pins (male) and guide sockets (female).

These connectors ARE NOT to be confused with 120

volt (or 230V) AC outlet plugs, or any video/audio

jacks. Refer to Figure 1.

Dimmer A small knob found on the front of monitors,

and power packs. This allows control of power to the

LEDs to dim or brighten them as conditions vary in

pipe. For example, white PVC pipe may reflect too

much light to the camera, making the picture over-

exposed (too bright). Similarly, black ABS pipe will

reflect much less light, making the picture underex-

posed (too dark). Adjustment of the dimmer allows

fine control of the LED lighting for an optimum picture.

Dolly Metal frame that the reel is mounted to. The

dolly has a second set of feet on the back side of the

reel, allowing the system to rest on its side (open-end-

up) for greater stability. There are also three fittings

(with capped covers) that allow attachment of the

optional auxiliary handle.

Hub The center, cone-shaped portion of the reel.

Within the hub is the slip ring and axle.

Interconnect Cable Thirty-three foot cord that plugs

between the output of the hub and the monitor/power

pack. It is kept stored on the dolly, and left plugged

into the hub.

LED Light Emitting Diode. Solid-state light that, unlike

an incandescent lamp (a regular light bulb), does not

have a fragile filament. These give off red light to illumi-

nate pipe interiors. The camera module is especially

sensitive to red light, resulting in a higher quality picture.

LED Ring The polycarbonate (plastic), donut shaped

ring that protects the LEDs from abrasion. There is also

SeeSnake Diagnostic Equipment