Elotech R 1300 Manual

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 1/20

R 1300

Multifunctional Controller

DIN-Format: 96 x 96 mm

Installation depth: 122 mm

Description and Operating Manual

ELOTECH Industrieelektronik GmbH

Verbindungsstrasse 27

D –40723 HILDEN

FON +49 2103 / 255 97 0 FAX +49 2103 / 255 97 29

www.elotech.de Email: info@elotech.de

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 2/20

I. Contents

I. Contents .......................................................................................................2

II. Type Code....................................................................................................2

III. Connection Diagram.....................................................................................3

IV. Technical Data..............................................................................................4

V. Display and Keyboard ..................................................................................5

VI. Operating Levels ..........................................................................................6

VII. Configuration Level.......................................................................................7

VIII. Parameter Level .........................................................................................13

IX. Operating Level ..........................................................................................17

X. Error displays..............................................................................................19

XI. Installation Instructions...............................................................................19

Please read this operating manual carefully before starting up.

Observe the installation and connecting instructions.

Take care to the separat interface- and data transmission descriptions.

Only trained personnel following the regional safety regulations may operate the hereby discribed

instruments. It is essential, that one has well experience in installing electric devices.

The instrument is not suitable for installation in hazardous areas.

Do not open the device while the power lines are connected.

Before operation, the unit must be configurated for its intended purpose under an expert guidance.

(e.g. controller type, sensor type and range, alarm adjustment etc.)

See: „Configuration Level“ and „Parameter Level”

Attention: The „heating“- or „cooling“-outputs can be active while programming or configuring

the controller. This can cause a damage either to the plant itself or its contents.

Disclaimer of liability

We have checked the contents of the document for conformity with the hardware and software described. Nevertheless, we are unable

to preclude the possibility of deviations so that we are unable to assume warranty for full compliance. The information given in the

publication is, however, reviewed regularly. Necessary amendments are incorporated in the following editions.

We would be pleased to receive any improvement proposals which you may have.

This document may not be passed on nor duplicated, nor may its contents be used or disclosed unless expressly permitted. Violations

of this clause will necessarily lead to compensation in damages.

II. Type Code

R 1300 - x - 00 - z

1: Power supply: 230 VAC (internal jumper : 115 V ac)

2: Power supply: 115 VAC (internal jumper : 230 V ac)

2: Power supply: 24 VDC , +/- 20%

1: OUT1, OUT2: Relay and bistab. voltage output for

2-point-, 3-point- and 3-point-step-controller

2: OUT1, OUT2: Relay and bistab. voltage output for

2-point-, 3-point- and 3-point-step-controller

OUT4, continuous: Controller output: 0/4...20mA, 0/2...10 VDC

to control "heating" or "cooling"

Ser. Interface: RS 485 (RS232 upon request)

3: OUT1, OUT2: Relay and bistab. voltage for

2-point-, 3-point- and 3-point-step-controller

OUT4, continuous: Programable: Controller output 0/4...20mA, 0/2...10 VDC

Process value output 0/4...20mA, 0/2...10 VDC

Setpoint value output 0/4...20mA, 0/2...10 VDC

OUT5, continuous: Programable: Controller output 0/4...20mA, 0/2...10 VDC

Process value output 0/4...20mA, 0/2...10 VDC

Setpoint value output 0/4...20mA, 0/2...10 VDC

Ser. Interface: RS 485 (RS232 upon request)

Analog. Setpoint-Input: 0/4...20mA, 0...10 VDC

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 3/20

III. Connection Diagram

L / - 129 +15 + OUT 2:bistable, 0/18 VDC

OUT 4, Continuous

N / + 230 -16 Com. GND

3 31 +17 + OUT 1:bistable, 0/18 VDC

OUT 5, Continuous

4 32 -18

OUT 1

5 33 B RxD in 19

Relay RS485 RS232

6 34 A TxD out 20

7 35 TxD in 21

8 36 RxD out 22 GND, Analogue Setpoint Input

OUT 2

9 37 GND 23 + 0/4...20 mA, Analogue Setpoint Input

Relay

10 24 +0...10 VDC, Analogue Setpoint Input

11 25 +

12 26 + +

OUT 3

13 27 - -

Relay

14 28

Z1

It is not permitted to connect the grounds of the sensor-, bist. voltage- and continuous-outputs with each

other.

RTD 2-wire connection: jumper between terminals 27 and 26.

OUT1: Control output 2-point-controller: "Heating" e.g „Cooling“

3-point-controller: „Heating“

3-point-step-controller: „On“

OUT2: Control output 2-point-controller: Alarm 2

or alarm output 3-point-controller: „Cooling“

3-point-step-controller: „Off“

OUT3: Alarm Output Alarm 3

OUT4: Continuous Output R1300-2: Controller Output

R1300-3: Function: See Configuration Level. Controller output or

analogue process value output or analogue setpoint output

OUT5: Continuous Output R1300-3: Function: See Configuration Level. Controller output or

analogue process value output or analogue setpoint output

Setpoint Controlling: K1: open = Setpoint 1 (SP1) valid

K1: closed = Depends of the configuration (see Parameter Co.SP):

Setpoint 2 (SP2) or external, analog Setpoint value (SPA) valid

Adjustment lock (LOC): K2: open = Adjustment lock only via "Software Code"

K2: closed.= Adjustment locked (according to the chosen Software Code)

R Load

R Load

K1

K2

Pt 100 / RTD

TC

0...10 VDC

0/4...20mA

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 4/20

IV. Technical Data

Input Thermocouple: Built-in internal compensation point and protection against sensor breakage

and incorrect polarity.

Re-calibration not required for a line resistance of up to 50 Ohms.

Calibration accuracy: < 0,25%

Input RTD, Pt 100 (DIN): 2- or 3- wire connection possible.

Built-in protection against sensor breakage and short circuit.

Max. permissible line resistance by 3-wire connection: 80 Ohms

Sensor current: < 0,5 mA

Calibration accuracy: < 0,2 %

Linear error: < 0,2 %

Influence of the ambient temperature: < 0,01 % / K

Setpoint selection: Ext. potential-free contact, switching voltage appr. 24 V dc, max. 1 mA.

Selection between SP1 and SP2 or

between SP1 and the analogue setpoint signal SPA.

Control outputs: -OUT 1: Relay (UR appr.), (changeover contact) max. 250 Vac, max. 3 A (resistive load) and

bist. voltage signal, 0/18 V dc, max. 10 mA, short-circuit proof

-OUT 2: Relay (UR appr.), (changeover contact) max. 250 Vac, max. 3 A (resistive load) and

bist. voltage signal, 0/18 V dc, max. 10 mA, short-circuit proof

-OUT 4 or OUT 5: Continuous ( version > R1300-2)

The output signal (current or voltage) is determinated automatically, dependand on load.

0/4...20 mA, load of max. 500 Ohm

0/2...10 V dc, load of > 1 k-Ohm

Linearity: < 1,5 %

Delay time: app. 2 secs.

Alarm output: -OUT 2: Relay (UR appr.), (changeover contact) max. 250 Vac, max. 3 A (resistive load).

Only for 2-point-controller and continuous-controller configuration.

-OUT 3: Relay (UR appr.), (changeover contact) max. 250 Vac, max. 3 A (resistive load).

Setpoint input: (Only version R1300-3), equivalent to the choosen range

(analogue) 0...10 V dc

0...20 mA

4...20 mA

Process output: -OUT4 or OUT5: (Only version R1300-3), equivalent to the choosen range

(analogue) 0...10 V dc

0...20 mA

4...20mA

Load max. 500 Ohms

Ser. Interface: ( > version R1300-2) RS 485, Protokoll: Standard (RS232: Option)

7-Segment-Display: Process: 10 mm red, Set: 10 mm red

Data protection: EAROM

CE-Mark Tested according to 2004/108/EC; EN 61326-1, industrial ares

Electr. safety: EN 61010-1

Power supply: Standard: 230 V ac, (internal jumper 115 V ac). Others possible. See Type Code.

± 10 %, 48...62 Hz

Connections: Screw terminals (UR appr.). Protection mode IP 20 (DIN 40050), Insulation class C.

Permissible operating conditions: Operating temperature: 0...50 °C / 32...122 °F

Storage temperature: -30...70 °C / -22...158 °F

Climate class: KWF DIN 40040;

equivalent to annual average max. 75 % rel. humidity, no condensation

Casing: Format: 96 x 96 mm (DIN 43700), installation deepth 122 mm

Panel cutout: 92 +0,5 mm x 92 +0,5 mm

Material: Noryl, self-extinguishing, non-drip, UL 94-V1

Protection mode: IP 20 (DIN 40050),

IP 50 front side

Weight: app. 650g (R1300-1); app. 800g (R1300-2, R1300-3)

Subject to technical improvments!

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 5/20

V. Display and Keyboard

Display PROCESS : Process Value

Display SET : Setpoint Value

LED OUT 1: Output OUT1 active: Control Output

LED OUT 2: Output OUT2 active: Control Output or Alarm Output A2

LED OUT 3: Output OUT3 active: Alarm Output A3

LED :Setpoint ramp active

LED SP2 : Setpoint 2 active

P Parameter key

Adjustment of chosen parameter (e.g. setpoint) to higher or lower values.

Short operation: single-step adjustment

Longer operation: quick-scanning

When the parameter adjustments have been altered but not entered,

The display will flash bright/dark.

E Confirmation and storage of the pre-selected values

The display will shortly be switched dark as a control of this function.

P Sets the parameter back to the originally stored value.

Any alterations made to the parameters, that are not confirmed (E-key) within

30 seconds, will not be accepted and the parameter will return to ist originally

stored value.

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 6/20

P

P

VI. Operating Levels

The operation of the controller is divided into three levels.

Two seconds after switching on the unit, the controller will automatically be in the operating level.

press press

and and

appr. 5 sec.

Power: Operating Parameter Configuration

„on“ Level Level Level

Process Value Y (Ratio Output) ConF

Setpoint Value

1 LY Out1

SP2

AL3 OFSt EL .xx

Back into operating level:

- Press appr. 1 sec. or

- after 30sec. automatically

Operating level

Process- and Setpoint value will be displayed simultaneously.

Within the operating level the setpoints, the setpoint-ramp and the alarm value can be adjusted

by pressing the " " / " " - keys.

Every adjustment has to be quit by pressing the „ E“ -key.

All parameters within the operating level can , in succession, be displayed by pressing the „ P “ - key

and adjusted by pressing the " " / " " - keys.

Parameter level

Within the parameter level the values are adjusted to suit each individual process.

This level is reached by simultaneously pressing the "P" - and " E" -keys.

Configuration level

In the configuration level the controller type, input type, sensor range, alarm behaviour and the

output type can be pre-selected.

This primary information has to be entered before taking the controller into operation.

The configuration level is reached by simultaneously pressing the "P" - and " E" - keys

for a period of approx. 5 seconds.

The display of each single parameter within the parameter and configuration levels, and their adjustment,

are made in the same fashion as within the operating level.

After either pressing the „E“ - key for approx. 1 second, or waiting for a period of approx. 30 seconds,

the unit will automatically return to the operating level (display of process value and setpoint).

P

PP

E

E

P

P

P

P

P

P

PP

E

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 7/20

VII. Configuration Level

Display Parameter Display

"Process" „Set“

ConF Controller configuration 2P h 2-point- or continuous-controller „heating“ (ex works)

2P c 2point-controller or Continuous-controller „cooling“

2Pnc 2point-controller or Continuous-controller „cooling“

with non-linear cooling*)

3P 3-point controller: "heating - off - cooling"

3Pnc 3-point controller: "heating - off - cooling"

cooling mode with non-linear cooling*)

3PSt 3-point-step-controller „on-neutral-off“

*) Cooling action can be pre-selected with either linear or

non-linear cooling response curve ( e.g. for vapour cooling).

Out1 Configuration Output 1 OFF OUT 1 not active

Controller output rEL. Relay (ex works)

biSt. bistable voltage signal

Out2 Configuration Output 2 OFF OUT 2 not active

Controller output or rEL. Relay (ex works)

alarm (A2) output biSt. bistable voltage signal

Out4 Configuration Output 4 OFF Output OUT4 not active

Only version: R1300-2

and version: R1300-3 if ConF= 2Ph:heating, ConF= 2Pc: cooling, ConF= 2Pnc: cooling

if ConF= 3P :heating, ConF= 3Pnc:heating

Co.h0 Control output: 0...20mA / 0...10V

Co.h4 Control output: 4...20mA / 2...10V

if ConF= 3P :cooling, ConF=3Pnc:cooling

Co.c0 Control output: 0...20mA / 0...10V

Co.c4 Control output: 4...20mA / 2...10V

Only version: R1300-3 Pr. 0 Process value output: 0...20mA / 0...10V DC

Pr. 4 Process value output: 4...20mA / 2...10V DC

SP. 0 Analogue setpoint output: 0...20mA / 0...10V DC

SP. 4 Analogue setpoint output: 4...20mA / 2...10V DC

Out5 Configuration Output 5 OFF Output OUT5 not active

Only version: R1300-3

if ConF= 2Ph:heating, ConF= 2Pc: cooling, ConF= 2Pnc: cooling

if ConF= 3P :heating, ConF= 3Pnc:heating

Co.h0 Control output: 0...20mA / 0...10V

Co.h4 Control output: 4...20mA / 2...10V

if ConF= 3P :cooling, ConF=3Pnc:cooling

Co.c0 Control output: 0...20mA / 0...10V

Co.c4 Control output: 4...20mA / 2...10V

Pr. 0 Process value output: 0...20mA / 0...10V DC

Pr. 4 Process value output: 4...20mA / 2...10V DC

SP. 0 Analogue setpoint output: 0...20mA / 0...10V DC

SP. 4 Analogue setpoint output: 4...20mA / 2...10V DC

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 8/20

Display Parameter Display

"Process" „Set“

SEn Sensor selection P1 °C Pt 100, -50,0...100,0 °C

P1 °F Pt 100, -58,0...212,0 °F

P2 °C Pt 100, -90,0...205,0 °C

P2 °F Pt 100, -130...401 °F

P3 °C Pt 100, 0,0...300,0 °C

P3 °F Pt 100, 32...572 °F

P4 °C Pt 100, 0...400 °C (ex works)

P4 °F Pt 100, 32...752 °F

P8° C Pt 100, 0...800 °C

P8 °F Pt 100, 32...1472 °F

L4 °C T/C Fe-CuNi (L), 0...400 °C

L4 °F T/C Fe-CuNi (L), 32...752 °F

L8 °C T/C Fe-CuNi (L), 0...800 °C

L8 °F T/C Fe-CuNi (L), 32...1472 °F

J8 °C T/C Fe-CuNi (J), 0...800 °C

J8 °F T/C Fe-CuNi (J), 32...1472 °F

n1 °C T/C NiCr-Ni (K), 0...1200 °C

n1 °F T/C NiCr-Ni (K), 32...2192 °F

S1 °C T/C Pt10Rh-Pt (S), 0...1600 °C

S1 °F T/C Pt10Rh-Pt (S), 32...2912 °F

0 - 20 Current 0...20 mA

4 - 20 Current 4...20 mA

10 dc Voltage 0...10 V dc

If the Sensor selection is changed, the following parameters will be reset (setting in brackets)

and need to be re-adjusted:

All Setpoints (OFF); ramps (OFF); alarm value (OFF); control sensivity ( 0);

process offset(OFF); lower setpoint limitation (SP.Lo); higher setpoint limitation (SP.Hi).

The following parameters are only valid for standard signal inputs (0...20mA, 4...20mA, 0...10Vdc). The

difference between the bottom end of the display range and the top end must amount to a minimum of

100 units and a maximum of 2000 units. By adjustment of one of the above parameters, the other

in this case will automatically follow.

rA.SP decimal points 0; 1; 2 (ex works: 1)

rA.Hi display range top end rA.Lo ... 9999 (ex works: 100,0)

rA.Lo display range bottom end -1999 ... rA.Hi (ex works: 0,0)

Only version R1300-3:

Sc.Hi higher indication range limitation valid for the analogue setpoint in- and outputs and

(20mA, 10 VDC) the analogue process value output.

Sc.Lo lower indication range limitation valid for the analogue setpoint in- and outputs and

(0/4mA, 0/2 VDC) the analogue process value output.

The difference between the bottom end of the range and the top end must be an amount to a minimum of

25% percent of the measuring range.

SP.Hi higher setpoint limitation Valid for the analogue input and the keyboard adjustments.

programming range: SP.Lo ... top range (ex works: 400)

SP.Lo lower setpoint limitation Valid for the analogue input and the keyboard adjustments.

programming range: bottom range ... SP.Hi (ex works: 0)

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 9/20

Display Parameter Display

"Process" „Set“

Co.A3 Alarm 3-Configuration OFF alarm OFF, no alarm signalisation (ex works)

(OUT 3) 1 signal contact: off-on

2 limit contact: off-on

3 limit comparator: off-on-off

4 signal contact: on-off

5 limit contact: on-off

6 limit comparator: on-off-on

7 limit comp. with start-up suppression: off-on-off

The signal contact is adjusted and displayed The limit contact is adjusted and displayed

relative to the setpoint. as an absolute value.

Switching behaviour: Configuration: Switching behaviour: Configuration:

off on 1 off on 2

on off 4on off 5

setpoint process process

The limit comparator is adjusted and The alarm relay of the limit comparator with

displayed relative to the setpoint. start-up suppression is activated when the

The selected value is effective below and above controller is first switched on. It is only then de-

the setpoint. activated, when the process value has been

within, and left, the o.k.-zone.

Switching behaviour: Configuration: Switching behaviour: Configuration:

on

off on off 3 off on off 7

on off on 6

setpoint process setpoint process

on: Relay "activated" or bistable voltage output "high".

off: Relay "not active" or bistable voltage output "low".

If a setpoint ramp has been programmed, the alarms that are relative to the setpoint (signal contact,

limit comparator) follow the setpoint up the ramp.

Please note:

In case of sensor error the alarms will react in the same way as range override.

The alarm contacts therefore do not offer protection against all types of plant breakdown.

With this in mind, we recommend the use of a second, independent monitor unit.

Co.A2 Alarm 2-Configuration see Co.A3 (alarm 3 - configuration)

(switches OUT 2)

signal value

vvvalueSignalwe

rt

limit range

limit value

vvvvavvvalue

Grenzwert

limit range

limLimitbereiclh

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 10/20

Display Parameter Display

"Process" „Set“

Only for 2-point- (heat-only) , 3-point-(heating mode) and continuous- (heating) controller

configurations:

Softstart (general function):

Temperature

Setpoint

SP

Softstart setpoint

SoSP

So Y

Soti

t

During the softstart the controllers’ output response is limited to a pre-selected ratio, in order

to achieve a slow baking out of high performance heat cartridges.

Simultaneously the output clock frequency is quadrupled. Once the process value reaches

the softstart setpoint, it remains stable at this value for a pre-selcted hold-duration time.

At the end of this period the process value rises to the valid setpoint.

This results in a slower, more regular heating period.

For this purpose the bistable voltage output must be chosen, that actuates SSR relays.

If the softstart is active, the controllers’ autotune function can’t operated (Er.OP).

If a setpoint-ramp has been programmed, the softstart has priority, and the ramp will only

become active after the softstart has been completed.

The softstart only works, if the parameter „1 P“ (prop. band, xp) is programmed > 0,1%.

So.St Softstart OFF: Softstart not active (ex works)

Next parameter So.Y, So.SP, So.ti are not shown.

On: Softstart in action.

So. Y Softstart output ratio 10 ... 100% (ex works: 10%)

So.SP Softstart setpoint range: SP.Lo .... SP.Hi (ex works: 0)

So.ti Softstart duration time OFF; 0,1 ... 9,9 min. (ex works: OFF)

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 11/20

Display Parameter Display

"Process" „Set“

Hand manual output ratio OFF (ex works)

Auto

Man

Setting: OFF

not active

Setting: Auto

In event of sensor break the controller automatically maintains the

last valid output ratio as the actuating signal.

An „H“ is then displayed as the first digit in the setpoint display,

followed by the valid output ratio. This ratio can be manually altered

in steps of 1% (up/down-keys; enter).

Under the following circumstances, the output ratio willbe 0%:

- if the output ratio at time of the sensor break was 100%.

- if the controller is working along a setpoint-ramp.

- if the control deviation was more than 0,25% of the total

range at the time of sensor break.

- if th prop. band (P; xp) = 0.

- if the soft start was active at the time of the sensor break.

A few seconds after the sensor break has been rectified, the

controller returns to automatic operation and calculates the required

output ratio.

An additional signal can be issued in the event of sensor break, if

the alarm contacts are programmed accordingly.

Setting: MAn

The controller now operates only as an actuator. Within the

operation level, an output ratio can be entered instead of the

setpoint. An „H“ is then displayed as the first digit in the set-

point display, followed by the output ratio.

There is no controlling action.

To generate output signals the controller must be switched on by

setting the setpoint1 (SP1) to a value different from “OFF”

Only > version R-1300-3:

Co.SP Setpoint selection Setpoint setting controlled by the external contact K1

SP2 setpoint 2 valid, if K1 is closed (ex works)

SPA.0 external, analogue setpoint valid, if K1 is closed.

setpoint signal: 0...20mA corresp. to the range.

SPA.4 external, analogue setpoint valid, if K1 is closed.

setpoint signal: 4...20mA corresp. to the range

SPA.U external, analogue setpoint valid, if K1 is closed.

setpoint signal: 0...10 Vdc corresp. to the range

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 12/20

Display Parameter Display

"Process" „Set“

Co.Sb Sensor break This parameter is only available when the controller is configurated as a

3-point-step-controller. Behaviour in event of sensor break:

OFF OUT1: off; OUT2: off (ex works)

OUT2 OUT1: off OUT2: on

OUT1 OUT1: on OUT2: off

LOC Adjustment lock OFF no adjustment lock (ex works)

P C parameter and configuration levels locked

n.SP1 all parameters apart from SP1 locked (not SP1)

ALL all parameters locked

All parameters that have been locked with „LOC“ can be

selected and read, but not altered.

This adjustment cannot be changed if the external contact

K2 is closed.

The following parameters are only valid, if the unit is equipped with a serial interface.

Only > version R-1300-2:

Adr Unit adress 1 .... 255 (ex works: 1)

The computer adresses the unit at this adress.

Each unit has ist own adress.

It is possible to adress 32 units.

For Data format 7E1 7 data, even, 1 stopbit

7o1 7 data, odd, 1 stopbit

7E2 7 data, even, 2 stopbit

7o2 7 data, odd, 2 stopbit

7n2 7 data, none, 2 stopbit

8E1 8 data, even, 1 stopbit

8o1 8 data, odd, 1 stopbit

8n1 8 data, none, 1 stopbit

8n2 8 data, none, 2 stopbit

bAud Baud rate OFF; 0,3 ... 38,4 kBaud (ex works: 9,6)

The baud rate denotes the transmission rate at which one bit

is transmitted.

See interface-description: SST1300E

Download: www.elotech.de

EL.xx Control number end of configuration level

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 13/20

VIII. Parameter Level

Display Parameter Display

"Process" „Set“

Y valid output ratio -100...100 %

The output ratio shows the momentary calculated ratio.

It cannot be altered. The display is in percent of the installed

performance capability for heating or cooling.

Output ratio for cooling is shown as a negative value.

1 LY OUT 1- output ratio limit

OUT 4 0...100 % (ex works: 100)

2 LY OUT 2- output ratio limit

OUT 5 0...100 % (ex works: 100)

Only: heating-off-cooling configuration.

A limitation of the output ratio is only necessary when:

- the heating or cooling energy supply is grossly over-

dimensioned compared to the power required, or

- to turn off a control output (setting = 0%).

Under normal circumstances no limitation is needed (setting = 0%)

The limitation becomes effective, when the controllers’ calculated

output ratio is greater than the maximum permissible (limited) ratio.

Warning!

The output ratio limitation does not work during autotune.

1 P OUT 1 - prop. band (P) OFF; 0,1...100,0 % (ex works: 3,0)

OUT 4 if Xp = OFF,

the next parameter to follow is „1 Sd“ = control sensivity OUT 1

1 d OUT 1- rate (D) OFF; 1...200 secs (ex works: 30)

OUT 4

1 J OUT 1- reset (I) OFF; 1...1000 secs (ex works: 150)

OUT 4 Normally the controller works using PD/I control action.

This means, controlling without deviation and with practically

no overshoot during start-up.

The control action can be altered in its structure by making the

following adjustments to the parameters:

a. no control action, on-off (setting P = OFF)

b. P-action (setting D and I = OFF)

c. PD-action (setting I = OFF)

d. PI-action (setting D = OFF)

e. PD/I modified PID-action

1 CY OUT 1- cycle time heating 0,5...240,0 secs (ex works: 10,0)

OUT 4 The switching frequency of the actuator can be determined

by adjusting the cycle time. This is the total time needed for the

controller to switch on and off once.

a) Relay outputs: cycle time > 10 secs

b) Bistable voltage outputs: cycle time 0,5...10 secs

c) Continuous outputs: cycle time 0,5 secs

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 14/20

Display Parameter Display

"Process" „Set“

Only if 1 P = OFF :

1 Sd control sensivity heating OFF; 0,1... 80,0 units (°C/°F) (ex works: 0,1)

OFF; 0,01... 8,00 units

OFF; 0,001...0,800 units

Sd = 10,0

on

off

-5,0 +5,0

Setpoint Process

The following parameters apply only to the configuration of heat-cool controllers:

Sh switch-point difference OFF; 0,1...80,0 units (ex works: OFF)

OFF; 0,01...8,00 units 1)

OFF; 0,001...0,800 units 2)

This parameter raises the setpoint (switch-point) for cooling output

by the displayed value. It can be help to reduce the switching

frequency between the heating and cooling outputs, if this is to

high.

Simultaneously activation of heat and cool outputs is not possible.

2 P OUT2 / OUT5- cooling OFF; 0,1...100,0 % (ex works: 6,0)

prop.-band (P) if Xp = OFF,

the next parameter to follow is „2 Sd“ = control sensitivity OUT 2

2 d OUT2 / OUT5 - coolingOFF; 1...200 secs (ex works: 150)

rate (D)

2 J OUT2 / OUT5 - coolingOFF; 1...1000 secs (ex works: 15,0)

reset (I)

2 CY OUT2 / OUT5 - cooling

cycle time 0,5...240,0 secs (ex works: 10,0)

Only if 2 P = OFF :

2 Sd control sensivity OFF; 0,1...80,0 units (ex works: OFF)

cooling OFF; 0,01...8,00 units 1)

OFF; 0,001...0,800 units 2)

Opt self tuning see next pages please

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 15/20

Display Parameter Display

"Process" „Set“

The following parameters apply only to the configuration of 3-point-step-controllers:

P xp, prop.-band (P) OFF; 0,1...200,0 % (ex works: 10,0)

tS Motor, actuating time 5 ... 800 secs (ex works: 40)

tn reset time (I) 0,5 ... 80,0 min. (ex works: 3,0)

Sd control sensivity OFF; 0,1...80,0 units (ex works: OFF)

OFF; 0,01...8,00 units 1)

OFF; 0,001...0,800 units 2)

Sh dead band OFF; 0,1...80,0 units (ex works: OFF)

OFF; 0,01...8,00 units 1)

OFF; 0,001...0,800 units 2)

on off

Sh

on

off

Sd

SETPOINT PROCESS

3-point-step-controllers use PI control action in combination with motor actuators.

It is important, that SH should be several times larger than Sd.

Switching frequency is dependant on the pre-selected feedback values.

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 16/20

Display Parameter Display

"Process" „Set“

OPt self tuning OFF self tuning out of action

(autotune) on self tuning on request ( one time)

Auto self tuning automatically if the controller is switched on

and if the difference between process value and

setpoint is > 7 % of the range.

The tuning algorithm determines the characteristic values within the controlled process, and calculates

the valid feedback parameters ( P,D,I ) and the cycle time ( C = 0.3 x D ) of a PD/I-controller for a

wide section of the range.

The determined parameters for heating are also adopted for cooling.

The self tuning activates during start-up shortly before the setpoint (Set) is reached. The setpoint must

amount to the least 5% of the total range.

If activated after the setpoint has already been reached, the temperature will first drop by approx. 5%

of the total range, in order to detect the exact amplification of the process.

The tuning algorithm can be activated at any time by selecting the OPT=on and pressing the „E“-key.

During self tuning „Opt“ is shown in the display, alternating with the setpoint value.

Using the heat-cool controller, the temperature drop will be accelerated by switching on the cooling

for a short duration.

After having calculated the correct feedback parameters, the controller will lead the process value

to the setpoint.

XX

Set Set

OPT on tOPT on t

Self tune Self tune, after the setpoint

during start-up has already been reached

Self-tuning can be stopped by selecting the option OPT = OFF and pressing the „E“ - key.

OFSt process value offset -999 ... OFF ...1000 Units (ex works: OFF)

-99,9 ... OFF ... 100,0 1)

-9,99 ... OFF ... 10,00 2)

This parameter serves to correct the input signal, e.g. for:

- the correction of a gradient between the measuring point and the sensor tip,

- the line resistance balancing of 2-line RTD (Pt100) sensors and

- correction of the control devition when using P- or PD-action.

If for example the offset value is set to +5°C, then the real temperature measured by the

sensor (when process is balanced) is 5°C less than the setpoint and the displayed process value.

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 17/20

IX. Operating Level

Display Parameter Display "Set"

"Process"

Process

(process)

and

Setpoint 1 OFF, SP.Lo...SP.Hi 4) (ex works: 0)

(set)

are displayed simultaneously (basic setting).

If setpoint 1 (SP1) is set to "OFF", the controller switches to stand-by.

The setpoint display then shows "OFF". All main outputs are switched off and the

alarm is de-activated.

All parameters can be displayed and altered during stand-by.

SP2 Setpoint 2 OFF; SP.Lo SP.Hi 4) (ex works: OFF)

The 2. setpoint is active when the external contact K1 is closed.

The corresponding LED „SP2“ lights up on the faceplate,and the second set-point is shown in the

display.“

Please note, that the value of the second setpoint cannot be changed in the oprating level.

In order to change the value the parameter SP2 has to be selected.

SP rising ramp OFF; 0,1...100,0 units/min. (ex works: OFF)

OFF; 0,01 ... 10,00 units/min. 1)

OFF; 0,001 ... 1,000 units/min. 2)

SP falling ramp OFF; 0,1...100,0 units/min. (ex works: OFF)

OFF; 0,01 ... 10,00 units/min. 1)

OFF; 0,001 ... 1,000 units/min. 2)

A programmed ramp is always activated when the setpoint is altered or when the mains

supply is switched on. The ramp constructs itself out of the momentary process value and the

pre-selected setpoint. If the ramp is active, the corresponding LED lights up on the faceplate.

The ramp can be activated for both setpoint1 and setpoint2.

By programming the second setpoint accordingly a setpoint profile can be oblained

(please see example below).

process

SP2

SP1

time

K1, open K1, closed K1, open

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 18/20

Display Parameter Display "Set"

"Process"

The range of adjustment is dependant on the sensor and the alarm configuration.

Both have to be set in the configuration level.

AL 3 Alarm 3, Out3 signal contact, setpoint dependent

OFF; -999...1000 units (ex works)

OFF; -99,9...100,0 1)

OFF; -9,99...10,00 2)

limit comparator, setpoint dependent

OFF; 1...1000 units (ex works)

OFF; 0,1...100,0 1)

OFF; 0,01...10,00 2)

limit contact, process value dependent

OFF; range bottom ... range top

Alarm 2 is only available, if the controller is programmed as a 2-point- or a continuous-controller

in the configuration-level.

AL 2 Alarm 2, Out2 signal contact, setpoint dependent

OFF; -999...1000 units (ex works)

OFF; -99,9...100,0 1)

OFF; -9,99...10,00 2)

limit comparator, setpoint dependent

OFF; 1...1000 units (ex works)

OFF; 0,1...100,0 1)

OFF; 0,01...10,00 2)

limit contact, process value dependent

OFF; range bottom ... range top

The following parameter is only shown, if the controller is configurated as a 3-point-step-controller.

Hand manual mode OFF: The instrument is operating like a controller (ex works)

On : The instrument operates only as an actuator

„On“:

Display „process“ : the actual process value is displayed.

Display „set“ : the word Hand will be displayed, instead of the setpoint.

Press key „ up „: OUT1 (on) is activated

Press key „down“: OUT2 (off) is activated

The next parameter is now the setpoint 1 (SP1).

It has no influence, although it can be preadjusted for later application.

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 19/20

X. Error displays

Display Cause Possible remedy

SP.Lo Lower setpoint limit has been reached Reduce limit, if need be

SP.Hi Upper setpoint limit has been reached Increase limit, if need be

rA.Lo Bottom range end has been reached Reduce limit, if need be

(for standard signal inputs)

rA.Hi Top range end has been reached Increase limit, if need be

(for standard signal inputs)

LOC Parameter has been locked Unlock, if need be

Hand Instrument operates in manual mode Check sensor and cable

Automatically switch over because of

a sensor error (if this is programmed).

Er.Hi Top range end has been exceeded, Check sensor and cable

sensor defect

Er.Lo Bottom range end has been exceeded, Check sensor and cable

sensor defect

Er.SP Analogue setpoint error,

upper or lower value has been reached Check setpoint signal and cable

Er.OP Self tuning error Extinguish error signal by pressing the „E“-key.

Check the self tuning conditions and restart.

Er.SY System error Extinguish error signal by pressing the „E“-key.

Check all parameters.

If the error signal continues please send the controller

back for examination.

Notes: 1) valid for ranges with one decimal point

2) valid for ranges with two decimal points

4) SP.Lo = lower setpoint limitation

SP.Hi = upper setpoint limitation

XI. Installation Instructions

Make certain that the devices described here are used only for the intended purpose.

They are intended for installation in control panels.

The controller must be installed so that it is protected against impermissible humidity and severe contamination.

In addition, make sure that the permitted ambient temperature is not exceeded.

The electrical connections must be made according to the relevant locally applicable regulations.

If using a thermocouple sensor, the compensation cables must be laid directly to the controller terminals.

Transducers must be connected only in compliance with the programmed range.

Transducer cables and signal lines (e.g. logic or linear voltage outputs) must be laid physically

separated from control lines and mains voltage supply cables (power cables). They must be shielded.

Spatial separation between controller and inductive loads is recommneded.

Interference from contactor coils must be suppressed by connecting adapted RC-combinations parallel to the coils.

Control circuits (e.g. for contactors) should not be connected to the mains power supply terminals of the controller.

IMPORTANT:

Before operation, the unit must be configurated for its intended purpose under an experts guidance.

(e.g. controller type, sensor type and range, alarm adjustment etc.). Please see „Configuration Level“.

Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 20/20

Table of contents

Other Elotech Controllers manuals

Popular Controllers manuals by other brands

Fluke Calibration

Fluke Calibration RUSKA 7250 user manual

Siemens

Siemens SINAMICS G Series manual

Honeywell

Honeywell BACnet Specification data

Evco

Evco Vcolor 388 Installer manual

Powder Buy The Pound

Powder Buy The Pound SpectraCoat ES01 Operator's manual

Mitsubishi

Mitsubishi MELSEC-A A1SD71-S2 user manual

Griswold

Griswold FlowCon FNR.0.2 Installation and operation instruction

Sensia

Sensia CLIF MOCK TC2000 ASSEMBLY, INSTALLATION, OPERATION & MAINTENANCE MANUAL

Evco

Evco EV3B94 manual

Tie Down Engineering

Tie Down Engineering 80 Installation, instruction and service manual

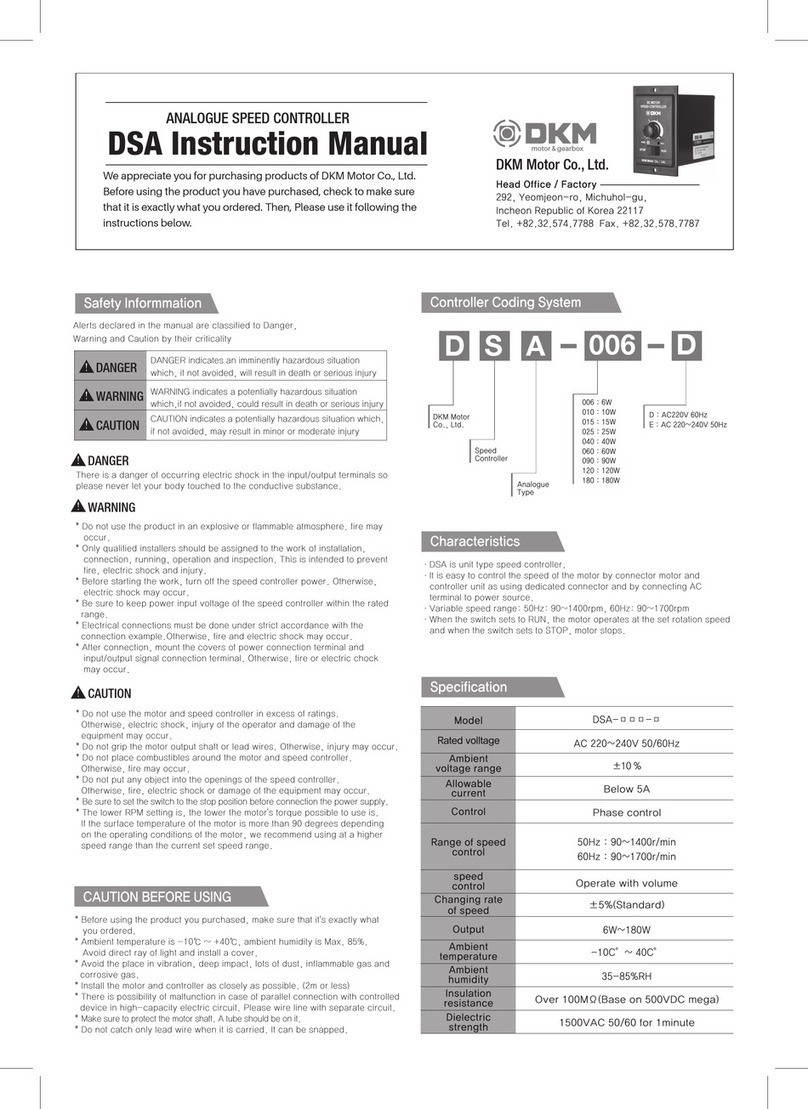

DKM Motor

DKM Motor DSA Series instruction manual

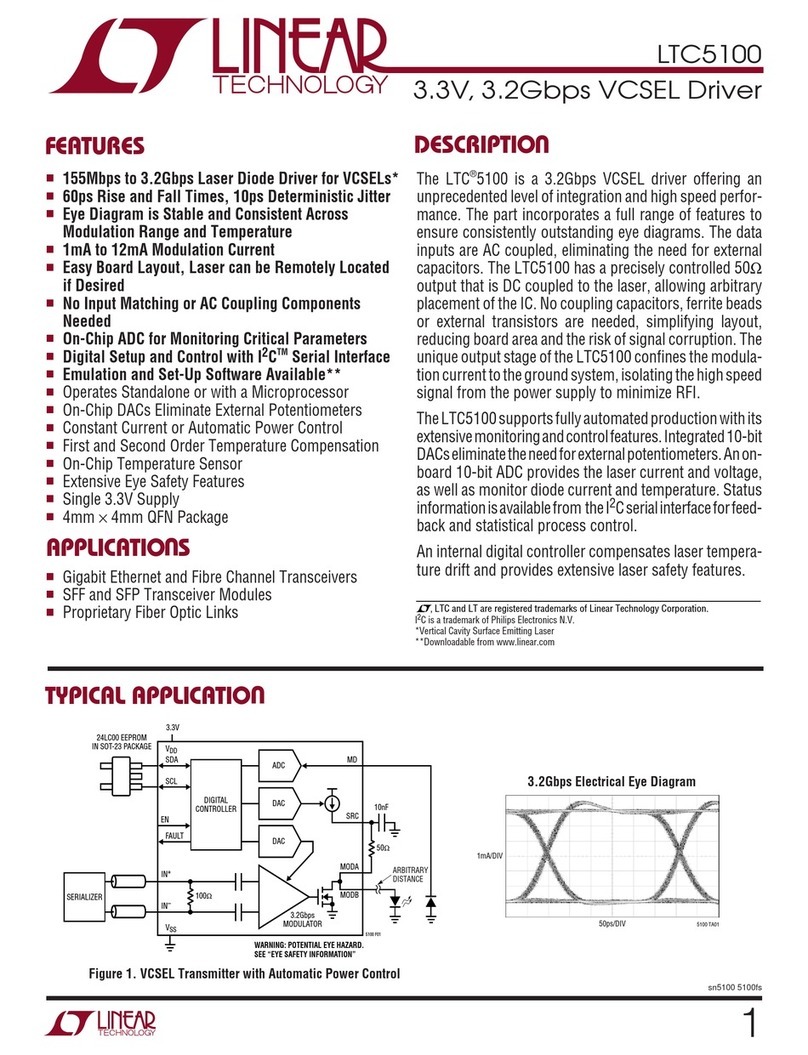

Linear Technology

Linear Technology LTC5100 manual